Increasing The Durability Of Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

## Directory:

1. 技术背景与目标:全面审视该技术领域的发展历程,探讨技术演进趋势,并明确预期达成的技术目标。

## Output:

The primary goal is to enhance the durability of turbine engines, a critical component in aviation and power generation industries. Historically, turbine engines have evolved significantly, with advancements in materials science, cooling technologies, and aerodynamic design contributing to improved performance and efficiency. However, the increasing demand for higher operational efficiency and longer service intervals has intensified the need for more durable engines. Key trends include the development of advanced superalloys, ceramic matrix composites, and thermal barrier coatings, which aim to withstand higher temperatures and reduce wear. The objective is to achieve breakthroughs that extend engine life, reduce maintenance costs, and improve overall reliability, ensuring that turbine engines can meet the rigorous demands of modern applications.

Turbine Engine Market Demand Analysis

### Turbine Engine Market Demand Analysis

**Increasing Demand for Fuel Efficiency and Durability**

The aviation industry is increasingly focused on fuel efficiency and durability of turbine engines. Airlines seek engines that offer longer operational life and reduced maintenance costs, driving demand for advanced turbine technologies. **Growth in Air Travel**

The global increase in air travel, particularly in emerging markets, is boosting the demand for more durable and efficient turbine engines. This trend is expected to continue, with significant growth in passenger and cargo air traffic. **Environmental Regulations**

Stricter environmental regulations are pushing the industry towards engines that produce lower emissions and have higher efficiency. This regulatory pressure is a key driver for innovation in turbine engine durability and performance. **Technological Advancements**

Advances in materials science, such as the development of high-temperature alloys and ceramic matrix composites, are critical in enhancing the durability of turbine engines. These innovations are expected to meet the growing market demand for more robust and reliable engines. **Competitive Landscape**

Major players in the turbine engine market are investing heavily in R&D to improve engine durability. Companies like General Electric, Rolls-Royce, and Pratt & Whitney are leading the charge, aiming to capture a larger market share by offering superior engine performance and longevity. **Market Potential**

The potential market for durable turbine engines is vast, encompassing commercial aviation, military applications, and industrial uses. The ongoing need for reliable and efficient engines in these sectors underscores the importance of continued innovation and development in turbine engine technology.

The aviation industry is increasingly focused on fuel efficiency and durability of turbine engines. Airlines seek engines that offer longer operational life and reduced maintenance costs, driving demand for advanced turbine technologies. **Growth in Air Travel**

The global increase in air travel, particularly in emerging markets, is boosting the demand for more durable and efficient turbine engines. This trend is expected to continue, with significant growth in passenger and cargo air traffic. **Environmental Regulations**

Stricter environmental regulations are pushing the industry towards engines that produce lower emissions and have higher efficiency. This regulatory pressure is a key driver for innovation in turbine engine durability and performance. **Technological Advancements**

Advances in materials science, such as the development of high-temperature alloys and ceramic matrix composites, are critical in enhancing the durability of turbine engines. These innovations are expected to meet the growing market demand for more robust and reliable engines. **Competitive Landscape**

Major players in the turbine engine market are investing heavily in R&D to improve engine durability. Companies like General Electric, Rolls-Royce, and Pratt & Whitney are leading the charge, aiming to capture a larger market share by offering superior engine performance and longevity. **Market Potential**

The potential market for durable turbine engines is vast, encompassing commercial aviation, military applications, and industrial uses. The ongoing need for reliable and efficient engines in these sectors underscores the importance of continued innovation and development in turbine engine technology.

Turbine Engine Technology Status and Challenges

Turbine engines are critical in aviation and power generation, but their durability remains a significant challenge. Current advancements focus on materials, cooling techniques, and design improvements to enhance lifespan.

**Material Innovations**:

- Development of high-temperature alloys and ceramic matrix composites to withstand extreme conditions.

- Coatings like thermal barrier coatings (TBCs) to protect against oxidation and corrosion.

**Cooling Techniques**:

- Advanced cooling methods, such as film cooling and transpiration cooling, to manage high temperatures.

- Optimization of cooling channels within turbine blades for efficient heat dissipation.

**Design Improvements**:

- Aerodynamic enhancements to reduce stress and wear on engine components.

- Implementation of real-time monitoring systems for predictive maintenance and early fault detection.

**Challenges**:

- High costs associated with advanced materials and manufacturing processes.

- Balancing performance improvements with environmental regulations and fuel efficiency demands.

**Geographical Distribution**:

- Leading research and development primarily in the US, Europe, and Asia, with significant contributions from major aerospace and energy companies.

Turbine Engine Current Technical Solutions

01 Use of advanced materials for turbine blades

Advanced materials like single-crystal superalloys and ceramic matrix composites enhance turbine blade durability by resisting high temperatures and mechanical stresses.- Use of advanced materials for turbine blades: Advanced materials like single-crystal superalloys and ceramic matrix composites enhance turbine blade durability by resisting high temperatures and mechanical stresses.

- Coating technologies for improved durability: Thermal barrier coatings (TBCs) and oxidation-resistant coatings protect turbine components from high-temperature oxidation and corrosion, maintaining structural integrity.

- Cooling techniques for turbine components: Film cooling and internal cooling channels manage turbine component temperatures, reducing thermal stresses and preventing overheating.

- Design optimization for stress reduction: Advanced computational methods and stress analysis minimize mechanical stresses on turbine components, improving durability.

- Maintenance and monitoring systems: Predictive maintenance and real-time health monitoring detect potential issues early, ensuring timely maintenance and extending turbine engine life.

02 Coating technologies for improved durability

Thermal barrier coatings and oxidation-resistant coatings protect turbine components from high-temperature oxidation and corrosion, maintaining structural integrity.Expand Specific Solutions03 Cooling techniques for turbine components

Film cooling and internal cooling channels manage thermal loads on turbine components, reducing operating temperatures and enhancing durability.Expand Specific Solutions04 Design optimization for stress reduction

Advanced computational methods and finite element analysis minimize mechanical stresses on turbine components, improving durability and service life.Expand Specific Solutions05 Maintenance and monitoring systems

Predictive maintenance and real-time health monitoring detect early signs of wear and damage, enabling timely interventions and extending engine durability.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for increasing the durability of turbine engines includes established leaders and innovative newcomers. The industry is mature with significant market size, driven by demand in aviation and energy sectors. Companies like United Technologies Corp., General Electric Company, Honeywell International Technologies Ltd., and Rolls-Royce Plc lead with high technical maturity and advanced R&D. Emerging players like AVIC Hunan Power Machinery Research Institute and Northwestern Polytechnical University also contribute to technological advancements, creating a dynamic environment.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced materials and coatings for turbine engines, focusing on thermal barrier coatings and high-temperature alloys.

Strength: Advanced material science expertise. Weakness: High development costs.

General Electric Company

Technical Solution: General Electric Company uses ceramic matrix composites (CMCs) in turbine engines for high-temperature resistance and reduced weight.

Strength: Innovative use of CMCs. Weakness: Complex manufacturing process.

Turbine Engine Key Technology Interpretation

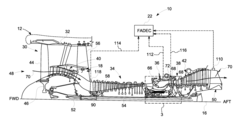

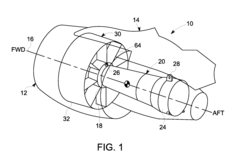

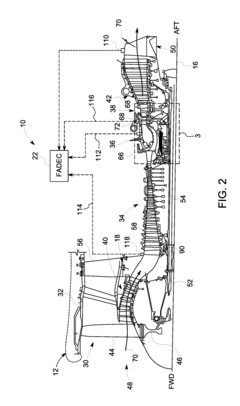

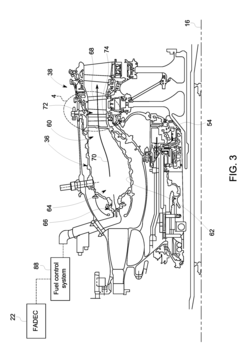

Method and system to increase gas turbine engine durability

PatentActiveUS20160252019A1

Innovation

- Measuring the exhaust gas temperature of the engine, adjusting the position of the first stage turbine nozzle assembly to increase the firing temperature, comparing the firing temperature to a threshold value, and derating the engine power output if the difference value exceeds the threshold value.

Turbine Engine Durability Improvement Economic Analysis

The economic analysis of improving turbine engine durability involves evaluating the cost-benefit ratio of implementing advanced materials, coatings, and design modifications. Enhanced durability can lead to reduced maintenance costs, longer engine life, and improved fuel efficiency, which collectively lower operational expenses. However, the initial investment in research, development, and deployment of these technologies must be justified by the long-term savings and performance gains. Market demand for more durable engines, driven by sectors like aviation and power generation, underscores the economic viability. Balancing upfront costs with potential savings and market competitiveness is crucial for strategic decision-making.

Turbine Engine Durability Improvement Policy and Regulatory Impact

The policy and regulatory impact on increasing the durability of turbine engines involves stringent standards and guidelines set by aviation authorities and environmental agencies. These regulations mandate the use of advanced materials and innovative engineering techniques to enhance engine longevity while ensuring safety and efficiency. Compliance with these policies drives continuous research and development, pushing manufacturers to adopt cutting-edge technologies. Additionally, regulatory frameworks often incentivize the adoption of sustainable practices, promoting the use of eco-friendly materials and reducing emissions. Overall, these policies significantly influence the strategic direction and technological advancements in turbine engine durability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!