Check Valves With Integrated Monitoring And Predictive Maintenance Systems

Technology Background And Goals

Check Valves Market Demand Analysis

- Market Size and Growth

Analyze the current and projected market size for check valves with integrated monitoring and predictive maintenance systems. Provide data on market value, unit shipments, and growth rates across different regions and industries. - Key Drivers

Identify the primary factors driving the demand for these advanced check valve solutions, such as regulatory compliance, asset optimization, cost savings, and safety concerns. - Industry Trends

Examine the emerging trends shaping the market, including the adoption of Industry 4.0, the rise of predictive maintenance, and the integration of IoT and data analytics. - Application Analysis

Assess the demand across various applications, such as oil and gas, power generation, chemical processing, and water treatment. Highlight the industries with the highest growth potential. - Regional Outlook

Provide a regional breakdown of the market, analyzing the demand dynamics in key regions like North America, Europe, Asia-Pacific, and the Middle East. Identify regions with the highest adoption rates and growth opportunities.

Technology Status And Challenges

- Valve Monitoring Challenges

Integrating monitoring systems into valves poses challenges in terms of sensor placement, data transmission, and power supply. - Predictive Maintenance Hurdles

Developing accurate predictive models for valve failure and maintenance requirements is complex due to the diverse operating conditions and failure modes. - Technology Integration Issues

Seamlessly integrating monitoring and predictive maintenance technologies into existing valve systems can be technically challenging and may require retrofitting or redesign. - Data Management and Analysis

Effective data management and analysis techniques are needed to extract valuable insights from the large volumes of sensor data generated by valve monitoring systems.

Current Technical Solutions

01 Check valve monitoring systems

Systems and methods for monitoring check valve condition and performance, involving sensors, data acquisition, and analysis techniques to detect issues like leakage, wear, or improper operation.- Check valve monitoring systems: Systems and methods for monitoring check valve condition and performance, involving sensors, data acquisition, and analysis techniques to detect leakage, wear, or improper operation.

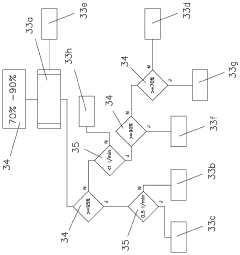

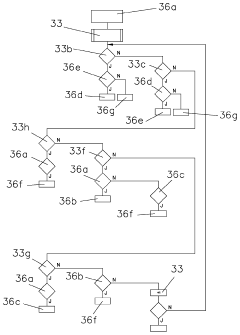

- Predictive maintenance for check valves: Techniques for predicting and scheduling check valve maintenance based on monitored data, using machine learning, statistical models, or rule-based systems to estimate remaining useful life and optimal maintenance intervals.

- Acoustic/vibration analysis for check valve monitoring: Methods and systems utilizing acoustic or vibration signals to assess check valve condition, involving signal processing, pattern recognition, or machine learning to detect anomalies or degradation.

- Wireless sensor networks for check valve monitoring: Implementations of wireless sensor networks for monitoring check valves in remote or hard-to-access locations, using wireless communication protocols, energy-efficient sensor nodes, and reliable data transmission techniques.

- Integrated check valve monitoring and control: Systems combining check valve monitoring with control and automation functions, integrating monitoring data with process control systems for automated responses or adjustments based on valve condition.

02 Predictive maintenance of check valves

Techniques for predicting and scheduling check valve maintenance based on monitored data, using machine learning, statistical models, or rule-based systems to estimate remaining useful life and optimize maintenance schedules.Expand Specific Solutions03 Check valve condition monitoring sensors

Various types of sensors and sensor systems designed specifically for monitoring check valve condition, including pressure, flow, vibration, or other specialized sensors to detect anomalies or degradation.Expand Specific Solutions04 Data analysis for check valve monitoring

Methods and algorithms for analyzing data collected from check valve monitoring systems, involving signal processing, feature extraction, pattern recognition, or other techniques to identify patterns or trends indicative of potential issues or failures.Expand Specific Solutions05 Integrated check valve monitoring systems

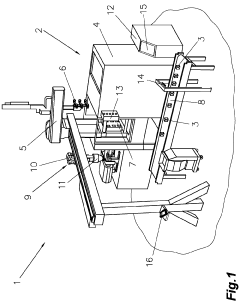

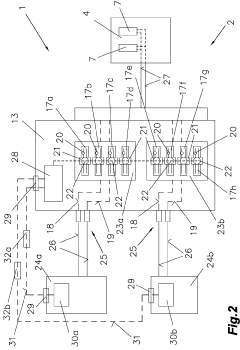

Comprehensive systems combining various components like sensors, data acquisition units, communication networks, and software platforms to provide an integrated solution for monitoring and managing check valves in industrial or critical applications.Expand Specific Solutions

Technology Main Player Analysis

Fisher Controls International LLC

Valmet Automation Oy

Key Technology Interpretation

- The integrated valve allows for data exchange with connected monitoring and predictive maintenance systems, enabling real-time monitoring and predictive maintenance capabilities.

- The integrated valve system is designed for temperature control applications in injection molding, die casting, and extrusion processes, providing precise temperature regulation for shaping tools.

- The integrated valve system combines valve functionality with monitoring and predictive maintenance capabilities, offering a compact and efficient solution for temperature control and maintenance optimization.

Check Valves Monitoring And Maintenance Economic Analysis

Check Valves Monitoring And Maintenance Regulatory Impact

The integration of monitoring and predictive maintenance systems into check valves can have significant regulatory implications. Relevant regulations aim to ensure the safety, reliability, and performance of industrial equipment, particularly in critical applications. Monitoring systems may require compliance with data privacy and cybersecurity regulations, as they often involve collecting and transmitting operational data. Additionally, predictive maintenance algorithms and methodologies might need to adhere to specific standards or undergo validation processes to ensure accuracy and reliability. Regulatory bodies may also impose requirements for documentation, testing, and certification of such integrated systems to mitigate potential risks and maintain industry best practices.