Intelligent Control And Automation Of Check Valves

NOV 7, 20244 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Check Valve Intelligent Control Background and Goals

The primary objective is to provide a comprehensive overview of the development history and evolution trends in the field of intelligent control and automation of check valves. This includes tracing the key milestones and technological breakthroughs that have shaped the progress of this technology over time. Additionally, it aims to clearly define the expected technological goals and advancements that are anticipated to be achieved through further research and innovation in this domain.

The analysis will delve into the historical context, exploring the driving forces and motivations that have fueled the advancements in intelligent control and automation of check valves. It will also shed light on the potential future directions and trajectories that this technology might take, based on the current state of the art and emerging trends in the field.

The analysis will delve into the historical context, exploring the driving forces and motivations that have fueled the advancements in intelligent control and automation of check valves. It will also shed light on the potential future directions and trajectories that this technology might take, based on the current state of the art and emerging trends in the field.

Check Valve Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from industries like oil and gas, power generation, and water treatment. Key factors fueling this demand include aging infrastructure replacements and new construction projects. - Industry Trends

Trends shaping the check valve market include the adoption of smart valves with remote monitoring capabilities, the need for corrosion-resistant and high-temperature valves, and the growing emphasis on energy efficiency and environmental sustainability. - Regional Dynamics

Asia-Pacific is projected to be the fastest-growing region due to rapid industrialization and infrastructure development. North America and Europe are mature markets, while the Middle East and Africa offer opportunities due to expanding oil and gas exploration activities. - Application Segments

The oil and gas industry is a major consumer of check valves, followed by power generation, water and wastewater treatment, and chemical processing. Emerging applications include pharmaceutical and food and beverage industries.

Check Valve Technology Status and Challenges

- Valve Automation Challenges

Integrating intelligent control systems with mechanical valve components poses significant challenges, including sensor integration, data processing, and real-time decision-making. - Reliability and Robustness

Ensuring reliable and robust operation of automated check valves in harsh industrial environments, such as high temperatures, pressures, and corrosive conditions. - Maintenance and Diagnostics

Developing effective maintenance strategies and diagnostic tools for automated check valves to minimize downtime and ensure optimal performance. - Standardization and Interoperability

Establishing industry standards and protocols for seamless integration of automated check valves with various control systems and plant architectures. - Cybersecurity Concerns

Addressing cybersecurity risks associated with the integration of automated check valves into industrial control systems and networks.

Check Valve Current Technical Solutions

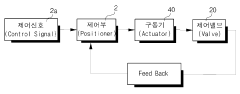

01 Check Valve Control Systems

These patents relate to control systems for check valves used to regulate the flow of fluids or gases in a specific direction. The control systems may involve sensors, actuators, and control algorithms to monitor and adjust the operation of the check valves based on various parameters.- Check Valve Control Systems: These inventions relate to control systems that regulate the flow of fluids or gases through check valves in pipelines or systems. The control systems involve sensors, actuators, and control algorithms to monitor and adjust the check valve operation based on various parameters, ensuring efficient and reliable flow control.

- Intelligent Check Valve Designs: These inventions focus on intelligent or smart check valve designs with advanced features like self-monitoring, self-diagnostics, and self-adjustment capabilities. These intelligent check valves can adapt to changing conditions and optimize their performance, reducing maintenance requirements and improving overall system efficiency.

- Check Valve Automation and Control Methods: These inventions relate to methods and techniques for automating and controlling the operation of check valves using programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, or other automation technologies to monitor and adjust check valve performance based on predefined parameters or algorithms.

- Check Valve Monitoring and Diagnostics: These inventions relate to systems and methods for monitoring and diagnosing the condition and performance of check valves using sensors, data analysis techniques, and predictive maintenance algorithms to detect potential issues, such as leaks, wear, or malfunctions, allowing for timely maintenance or replacement.

- Check Valve Applications and Integration: These inventions cover various applications and integration of check valves in different systems or industries, such as oil and gas, water treatment, chemical processing, or power generation, addressing specific challenges or requirements related to the use of check valves in these applications.

02 Intelligent Check Valve Designs

These patents cover intelligent or smart check valve designs that incorporate advanced features or functionalities, such as self-monitoring capabilities, adaptive control mechanisms, or integration with other system components for improved performance, efficiency, or safety.Expand Specific Solutions03 Check Valve Automation and Control Methods

These patents describe methods and techniques for automating and controlling the operation of check valves, involving algorithms, software, or hardware solutions to optimize valve performance, reduce maintenance requirements, or enhance system reliability.Expand Specific Solutions04 Check Valve Monitoring and Diagnostics

These patents relate to systems and methods for monitoring and diagnosing the condition or performance of check valves, involving sensors, data analysis techniques, or predictive maintenance strategies to detect issues, predict failures, or optimize maintenance schedules.Expand Specific Solutions05 Check Valve Applications and Integration

These patents cover specific applications or integration of check valves in various systems or industries, including fluid handling systems, process control systems, or other industrial or commercial applications.Expand Specific Solutions

Check Valve Main Player Analysis

The intelligent control and automation of check valves market is growing, driven by increasing demand for efficient and reliable valve control solutions across industries like automotive, manufacturing, and energy. Established players like Robert Bosch GmbH, DENSO Corp., and Honeywell International Technologies Ltd. lead in advanced R&D, while emerging innovators like Sense Eletrônica Ltda and Neway Valve (Suzhou) Co., Ltd. are integrating intelligent control systems, indicating a competitive and dynamic market.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an intelligent control system for check valves integrating IoT sensors and AI algorithms for real-time monitoring and automated adjustments to optimize performance and reduce maintenance costs.

Strength: High integration with IoT and AI. Weakness: High initial implementation cost.

DENSO Corp.

Technical Solution: DENSO Corp. offers a smart valve control solution using machine learning to predict and prevent potential failures, enhancing reliability and efficiency in various industrial applications.

Strength: Predictive maintenance capabilities. Weakness: Limited customization options.

Check Valve Key Technology Interpretation

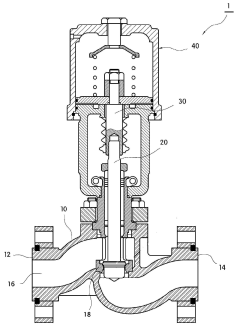

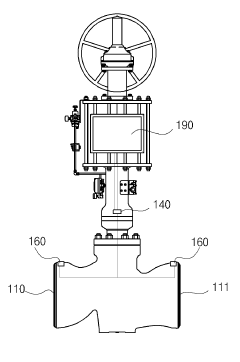

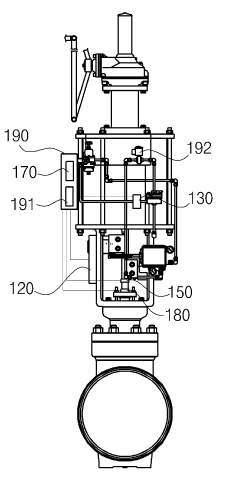

Intelligent control valve with safety function based on self-diagnosis function and control valve management system using it

PatentInactiveKR1020190012325A

Innovation

- The control valve incorporates multiple sensors to measure various parameters like valve opening, actuator pressure, vibration, noise, and temperature in real-time.

- The control valve utilizes a control unit to analyze the real-time sensor data, determine the current state of the valve, and self-control the valve opening in case of an emergency situation.

- The control valve combines self-diagnosis functionality with safety features, enabling it to take necessary actions in case of exceeding set thresholds or alarm conditions.

Check Valve Automation Economic Analysis

Check valve automation offers significant economic benefits by reducing maintenance costs, improving operational efficiency, and enhancing safety. Automated check valves can monitor and control valve positions, detect leaks or malfunctions, and provide real-time data for predictive maintenance. This minimizes unplanned downtime, extends equipment lifespan, and optimizes resource utilization. Additionally, automated systems can enhance worker safety by reducing manual interventions in hazardous environments. While initial investment costs may be higher, the long-term savings from increased productivity, reduced energy consumption, and minimized failures often outweigh the upfront expenses, resulting in a favorable return on investment for industries adopting check valve automation solutions.

Check Valve Intelligent Control Policy and Regulatory Impact

Check valves are critical components in various industrial systems, ensuring unidirectional flow and preventing backflow. Intelligent control and automation of these valves can significantly enhance operational efficiency, safety, and reliability. This report explores the regulatory landscape and potential policies surrounding the intelligent control of check valves.

Regulatory bodies and industry standards play a crucial role in governing the implementation of intelligent control systems for check valves. Compliance with safety regulations, cybersecurity protocols, and data privacy laws is essential. Additionally, policies may be introduced to promote the adoption of intelligent control technologies, fostering innovation and addressing potential challenges.

Furthermore, the impact of intelligent control on maintenance practices, operational costs, and environmental considerations should be evaluated. Policies may be developed to incentivize the adoption of intelligent control systems that reduce downtime, optimize resource utilization, and minimize environmental footprint. Overall, a comprehensive regulatory framework is necessary to ensure the safe and effective implementation of intelligent control and automation for check valves.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!