Additive Manufacturing For Turbine Engine Technology

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive Manufacturing Technology Background And Goals

## Directory: 技术背景与目标

Additive Manufacturing (AM) for Turbine Engine Technology has evolved significantly over the past few decades. Initially, AM was primarily used for prototyping, but advancements in materials and processes have enabled its application in producing complex, high-performance components for turbine engines. The primary goal is to leverage AM to enhance design flexibility, reduce material waste, and improve the performance and efficiency of turbine engines. This technology aims to overcome traditional manufacturing limitations, allowing for the creation of intricate geometries and optimized structures that were previously unattainable. The focus is on achieving higher precision, faster production times, and cost-effective manufacturing solutions, ultimately leading to more efficient and reliable turbine engines.

Additive Manufacturing Market Demand Analysis

Additive manufacturing (AM) for turbine engine technology is experiencing significant market demand due to its potential to revolutionize production processes and enhance performance.

Market Growth Drivers:

Industry Adoption:

Market Potential:

Challenges:

Future Trends:

Market Growth Drivers:

- Increased demand for fuel-efficient and lightweight turbine engines.

- Advancements in AM technologies enabling complex geometries and material properties.

- Cost reduction in production and material waste.

Industry Adoption:

- Leading aerospace companies are integrating AM for prototyping and production.

- Growing investments in R&D for AM applications in turbine engines.

- Regulatory bodies are developing standards for AM-produced components.

Market Potential:

- Significant growth in the aerospace and defense sectors.

- Expansion into other industries such as energy and automotive.

- Potential for aftermarket services and spare parts production.

Challenges:

- High initial investment costs for AM technology adoption.

- Need for skilled workforce and training programs.

- Quality assurance and certification of AM components.

Future Trends:

- Development of new AM materials tailored for turbine engines.

- Integration of AI and machine learning for process optimization.

- Collaborative efforts between industry and academia for innovation.

Additive Manufacturing Technology Status And Challenges

### Additive Manufacturing Technology Status And Challenges

- **Current Status**:

Additive manufacturing (AM) for turbine engines is advancing rapidly, with significant improvements in material properties, precision, and production speed. Key players are developing AM techniques to produce complex geometries and lightweight components, enhancing engine performance and fuel efficiency.

- **Material Challenges**:

The primary challenge is developing materials that can withstand high temperatures and stresses in turbine engines. Current research focuses on high-temperature alloys and ceramic matrix composites to meet these demands.

- **Quality Control**:

Ensuring consistent quality and reliability of AM-produced parts is critical. Advanced non-destructive testing methods and real-time monitoring systems are being developed to address this issue.

- **Cost and Scalability**:

High production costs and scalability remain significant barriers. Efforts are underway to optimize processes and reduce costs through automation and improved material utilization.

- **Regulatory and Certification**:

Meeting stringent aerospace industry standards and obtaining certification for AM parts is a complex and time-consuming process. Collaboration between industry and regulatory bodies is essential to streamline certification procedures.

Additive Manufacturing Current Technical Solutions

01 Use of Additive Manufacturing for Turbine Blades

Additive manufacturing techniques, such as selective laser melting and electron beam melting, produce turbine blades with complex geometries and internal cooling channels. These techniques create lightweight, high-strength components that improve turbine engine efficiency and performance.- Use of additive manufacturing for turbine blade production: Additive manufacturing techniques produce turbine blades with complex geometries and improved performance. These methods create intricate cooling channels and lightweight structures, enhancing turbine engine efficiency and durability.

- Integration of advanced materials in turbine components: Advanced materials, such as high-temperature alloys and ceramic matrix composites, are integrated into turbine components using additive manufacturing. These materials offer superior thermal and mechanical properties, contributing to overall performance and longevity.

- Optimization of turbine engine design through additive manufacturing: Additive manufacturing enables the optimization of turbine engine designs by allowing rapid prototyping and iterative testing. This process refines aerodynamic and structural aspects, leading to enhanced efficiency and reduced fuel consumption.

- Repair and maintenance of turbine engines using additive manufacturing: Additive manufacturing is utilized for the repair and maintenance of turbine engines. This technology allows precise restoration of worn or damaged components, extending service life and reducing downtime.

- Development of hybrid manufacturing processes for turbine engines: Hybrid manufacturing processes, combining additive manufacturing with traditional subtractive methods, are developed for turbine engines. These processes leverage both techniques to produce high-quality components with improved performance and reduced production time.

02 Integration of Advanced Materials in Turbine Components

Advanced materials, including superalloys and ceramic matrix composites, are integrated into turbine components using additive manufacturing. These materials offer superior thermal and mechanical properties, enabling parts to withstand high temperatures and stresses.Expand Specific Solutions03 Optimization of Turbine Engine Design through Additive Manufacturing

Additive manufacturing allows for the optimization of turbine engine designs by enabling the production of parts with complex shapes and reduced weight. This leads to improved fuel efficiency and reduced emissions.Expand Specific Solutions04 Repair and Maintenance of Turbine Components

Additive manufacturing is used for the repair and maintenance of turbine components. Techniques such as laser cladding and direct energy deposition restore worn or damaged parts, extending engine lifespan and reducing maintenance costs.Expand Specific Solutions05 Development of Customized Turbine Parts

Additive manufacturing facilitates the development of customized turbine parts tailored to specific engine requirements. This customization enhances performance and reliability by allowing precise control of part dimensions and material properties.Expand Specific Solutions

Additive Manufacturing Main Player Analysis

The competitive landscape for Additive Manufacturing in Turbine Engine Technology features industry giants and specialized players. The market is growing, driven by demand for efficient, lightweight turbine components. Leading companies like United Technologies Corp., General Electric Company, and Siemens AG showcase advanced technology and significant R&D investments. Other key players such as Rolls-Royce Plc, Safran Aircraft Engines SAS, and Honeywell International Technologies Ltd. also contribute to the sector's advancement.

United Technologies Corp.

Technical Solution: UTC uses additive manufacturing to enhance turbine engine components. Pratt & Whitney division creates complex, lightweight parts with 3D printing, resulting in more efficient engines.

Strengths: Complex geometries, lighter engines. Weaknesses: Limited scalability.

General Electric Company

Technical Solution: GE's Additive division pioneers 3D printing for turbine components, improving performance and reducing weight. The LEAP engine with 3D-printed fuel nozzles exemplifies their success.

Strengths: Advanced technology, proven success with LEAP engine. Weaknesses: High initial investment costs.

Additive Manufacturing Key Technology Interpretation

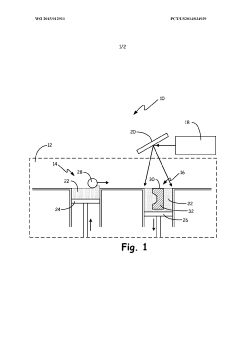

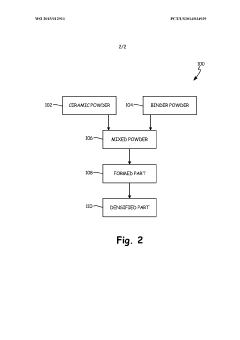

Additive manufacturing of ceramic turbine components by transient liquid phase bonding using metal or ceramic binders

PatentWO2015012911A2

Innovation

- Utilization of transient liquid phase bonding for densification of ceramic turbine components.

- Integration of metal or ceramic binders in the additive manufacturing process to improve the structural integrity of the turbine components.

- Layer-wise construction method to create precise and complex shapes of ceramic turbine components.

Additive Manufacturing For Turbine Engine Material Analysis

Additive Manufacturing (AM) for turbine engine technology offers significant advantages in material efficiency, design flexibility, and production speed. This technology enables the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. AM can reduce material waste and lead times, and improve performance by optimizing component designs for weight and strength. However, challenges include ensuring material consistency, achieving the required mechanical properties, and scaling up production. Future innovations may focus on advanced materials, improved process controls, and integration with other manufacturing techniques to enhance the overall performance and reliability of turbine engines.

Additive Manufacturing For Turbine Engine Regulatory Impact

Additive Manufacturing (AM) for turbine engine technology has significant regulatory implications. Regulatory bodies must ensure that AM-produced components meet stringent safety and performance standards. This involves developing new certification processes and standards specific to AM, addressing material properties, manufacturing consistency, and inspection methods. The regulatory landscape is evolving to accommodate the unique aspects of AM, such as layer-by-layer construction and complex geometries. Collaboration between industry stakeholders and regulatory agencies is crucial to establish robust guidelines that ensure the reliability and safety of AM components in turbine engines, ultimately fostering innovation while maintaining high safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!