Enhancing Thermal And Electrochemical Stability Of PVDF Nanocomposites

Technology Background And Goals

Improving the thermal and electrochemical stability of PVDF nanocomposites is crucial for their long-term performance and reliability in various applications. This research aims to explore innovative approaches, such as incorporating advanced nanomaterials, modifying the polymer matrix, or developing novel processing techniques, to address the stability challenges faced by PVDF nanocomposites.

Market Demand Analysis

- Market Size and Growth

The global PVDF nanocomposites market is expected to witness significant growth driven by increasing demand from various end-use industries such as energy, electronics, and automotive. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% during the forecast period. - Key Application Areas

PVDF nanocomposites find extensive applications in lithium-ion batteries, fuel cells, and supercapacitors due to their excellent thermal and electrochemical stability. They are also used in membranes for water treatment, sensors, and protective coatings owing to their chemical resistance and mechanical strength. - Regional Demand Dynamics

Asia Pacific is anticipated to dominate the PVDF nanocomposites market, driven by the rapid growth of the electronics and automotive industries in countries like China, Japan, and South Korea. North America and Europe are also expected to witness significant demand due to the increasing adoption of renewable energy technologies. - Emerging Trends

The demand for PVDF nanocomposites is expected to be fueled by the growing focus on sustainable energy solutions and the development of advanced energy storage systems. Additionally, the increasing use of PVDF nanocomposites in biomedical applications, such as tissue engineering and drug delivery, is likely to create new market opportunities.

Technology Status And Challenges

- Current Status

PVDF nanocomposites have gained significant attention due to their enhanced thermal, mechanical, and electrochemical properties compared to pure PVDF. Various nanofillers like carbon nanotubes, graphene, and metal oxides have been explored to improve the properties of PVDF. - Challenges

- Achieving uniform dispersion of nanofillers in the PVDF matrix is a major challenge, as agglomeration can adversely affect the properties.

- Improving the interfacial adhesion between the nanofillers and PVDF matrix is crucial for effective stress transfer and property enhancement.

- Maintaining the electrochemical stability of PVDF nanocomposites at high temperatures and under harsh conditions is a key challenge for certain applications. - Geographical Distribution

Research on PVDF nanocomposites is being conducted globally, with major contributions from the United States, China, South Korea, Japan, and several European countries like Germany and France.

Current Technical Solutions

01 Improved Thermal Stability

The thermal stability of PVDF nanocomposites can be enhanced by incorporating nanofillers like carbon nanotubes, graphene, or metal oxide nanoparticles, which act as thermal barriers, improving thermal resistance and decomposition temperature.- Improved Thermal Stability: Incorporating nanofillers like carbon nanotubes, graphene, or metal oxide nanoparticles can enhance the thermal stability of PVDF nanocomposites by acting as thermal barriers, improving thermal resistance and degradation temperature.

- Enhanced Electrochemical Stability: Conductive nanofillers such as carbon nanotubes, graphene, or metal nanoparticles can improve the electrochemical stability of PVDF nanocomposites by enhancing charge transfer and electrochemical performance, making them suitable for energy storage devices.

- Improved Mechanical Properties: Nanofillers like carbon nanotubes, graphene, or clay nanoparticles can reinforce the polymer matrix, leading to enhanced mechanical properties such as tensile strength, modulus, and toughness in PVDF nanocomposites.

- Tailored Electrical Properties: Incorporating conductive nanofillers like carbon nanotubes, graphene, or metal nanoparticles can tune the electrical properties of PVDF nanocomposites, such as conductivity, dielectric constant, and energy storage capability, for various applications.

- Improved Barrier Properties: Nanofillers like clay nanoparticles or metal oxide nanoparticles can create a tortuous path for gas or moisture molecules, enhancing the barrier properties of PVDF nanocomposites, such as gas permeability and moisture resistance.

02 Enhanced Electrochemical Stability

Conductive nanofillers such as carbon nanotubes, graphene, or metal nanoparticles can improve the electrochemical stability of PVDF nanocomposites by enhancing charge transfer and electrochemical performance, making them suitable for energy storage devices.Expand Specific Solutions03 Improved Mechanical Properties

Nanofillers like carbon nanotubes, graphene, or clay nanoparticles can reinforce the polymer matrix, leading to improved mechanical properties such as tensile strength, modulus, and toughness in PVDF nanocomposites.Expand Specific Solutions04 Tailored Electrical Properties

Incorporating conductive nanofillers like carbon nanotubes, graphene, or metal nanoparticles can tune the electrical properties of PVDF nanocomposites, such as conductivity, permittivity, and dielectric strength, for applications in electronics, energy storage, and electromagnetic shielding.Expand Specific Solutions05 Improved Barrier Properties

Nanofillers like clay nanoparticles or metal oxide nanoparticles can enhance the barrier properties of PVDF nanocomposites, such as gas and moisture resistance, making them suitable for applications in packaging, membranes, and protective coatings.Expand Specific Solutions

Main Player Analysis

Arkema France SA

Solvay SA

Key Technology Interpretation

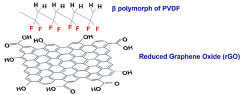

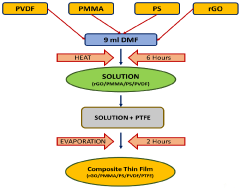

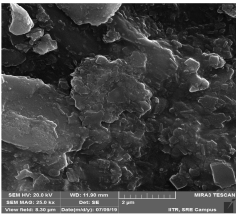

- The present application addresses the shortcomings of existing polymer composites by using reduced graphene oxide (rGO) with multiple polymers (PVDF, PMMA, and PTFE) to create a nanocomposite thin film.

- The nanocomposite thin film exhibits improved electrical and mechanical properties, such as enhanced tensile strength, elasticity, and capacitance, while maintaining hydrophilicity and thermal stability.

- The nanocomposite thin film is prepared using a cost-effective and easy-to-operate solvent casting technique.

PVDF Nanocomposites Thermal Stability Enhancement Techniques

The economic impact of using PVDF nanocomposites to enhance thermal and electrochemical stability is multifaceted, with potential to significantly influence several industries. These advanced materials can lead to cost efficiencies within the manufacturing sector by improving product durability and lifespan, thereby reducing replacement and maintenance expenses. In the energy storage industry, enhanced stability in batteries and supercapacitors could lower the overall cost-per-cycle, thus making these technologies more economically viable and competitive compared to traditional solutions. This shift could attract investments and lead to the creation of new markets, driving economic growth.

Moreover, by integrating PVDF nanocomposites, consumer electronics and electric vehicles can offer superior performance, potentially stimulating market demand. This could result in increased production outputs and job creation within these sectors. Additionally, in markets that prioritize sustainability, such materials can provide a competitive advantage by contributing to eco-friendly product lines, satisfying regulatory requirements and consumer preferences for greener technologies. Collectively, the broad adoption of PVDF nanocomposites could transform economic landscapes by fostering innovation, heightening competitiveness, and enhancing the sustainability of industries worldwide.

PVDF Nanocomposites Electrochemical Stability Improvement Strategies

In exploring the potential of PVDF nanocomposites for enhanced thermal and electrochemical stability, it is crucial to identify innovative strategies that could address existing limitations and open new avenues of application. The development of these nanocomposites could benefit significantly from an interdisciplinary approach, blending insights from materials science, chemistry, and engineering. This cross-disciplinary collaboration can spur the development of novel synthesis techniques that optimize the dispersion and interfacial bonding of nanoparticles within the PVDF matrix, thereby improving the composite’s overall stability and performance.

Advanced computational models and simulations may offer predictive insights into how varying types and concentrations of nanoparticles influence the thermal and electrochemical properties of the composites. This approach can fine-tune the design process, reducing the time and resources needed for experimental trials. Concurrently, leveraging machine learning algorithms may facilitate the identification of patterns and correlations in large datasets, further guiding the development of more efficient and effective materials.

Furthermore, exploring eco-friendly and sustainable sources for nanomaterials could align the development of PVDF nanocomposites with broader environmental goals, ensuring that the push for technological advancement does not come at the expense of ecological responsibility. Collaborations with industrial partners can also spur the commercialization of these advanced materials, promoting their integration into existing supply chains and expanding their application potential across various sectors, from electronics to energy storage systems.