PVDF Surface Modifications For Improved Biocompatibility And Fouling Resistance

Background And Goals

Key challenges to be addressed include improving cell adhesion and proliferation on PVDF surfaces for biomedical applications, as well as enhancing antifouling properties to prevent the accumulation of proteins, microorganisms, and other contaminants on PVDF membranes used in water treatment and separation processes. The analysis will identify the most promising surface modification strategies, their underlying mechanisms, and their potential for practical implementation in various application domains.

Market Demand Analysis

- Market Size and Growth

Provide an overview of the current market size for PVDF membranes and products, highlighting key application areas. Analyze the projected growth rate and market potential, considering factors like increasing demand for water treatment, healthcare, and industrial applications. - Regional Market Analysis

Examine the regional distribution of PVDF membrane demand, identifying major markets and growth hotspots. Discuss factors influencing regional variations, such as regulatory environments, infrastructure development, and industry clusters. - Application Segmentation

Segment the PVDF market based on major application areas, such as water treatment, biopharmaceuticals, food and beverage, and chemical processing. Analyze the specific requirements and growth drivers for each segment, highlighting emerging applications with high potential. - Competitive Landscape

Provide an overview of the competitive landscape, identifying key players in the PVDF membrane market. Analyze their market shares, strengths, and strategies, as well as potential disruptors or new entrants that could impact the market dynamics. - Trends and Drivers

Discuss the major trends and drivers shaping the PVDF membrane market, such as sustainability concerns, regulatory changes, technological advancements, and shifting consumer preferences. Highlight how these factors influence market demand and potential growth opportunities.

Technology Status And Challenges

- Polymer Properties

PVDF is a semi-crystalline fluoropolymer with excellent chemical resistance, thermal stability, and mechanical strength. - Biocompatibility Challenges

Despite its desirable properties, PVDF surfaces are hydrophobic and prone to protein adsorption and bacterial adhesion, limiting their biomedical applications. - Surface Modification Techniques

Various surface modification techniques, such as plasma treatment, grafting, and coating, have been explored to improve PVDF's biocompatibility and fouling resistance. - Plasma Treatment

Plasma treatment introduces polar functional groups on the PVDF surface, enhancing its hydrophilicity and reducing protein adsorption. - Grafting Techniques

Grafting techniques, like UV-induced graft polymerization, covalently attach biocompatible polymers or biomolecules to the PVDF surface, improving its biocompatibility. - Coating Approaches

Coating PVDF with biocompatible materials, such as hydrogels or zwitterionic polymers, can create a non-fouling surface and improve its biocompatibility.

Current Technical Solutions

01 PVDF Membrane Preparation and Modification

Methods for preparing and modifying PVDF membranes to enhance biocompatibility and fouling resistance, including blending, surface grafting, and incorporating additives.- Biocompatible and Antifouling PVDF Membranes: PVDF membranes are modified with various materials or techniques to enhance biocompatibility and resistance to fouling, such as surface grafting, blending with hydrophilic polymers, or incorporating nanoparticles or functional groups.

- Hydrophilic and Fouling-Resistant PVDF Membranes: The hydrophilicity of PVDF membranes is improved by blending with hydrophilic polymers or incorporating hydrophilic nanoparticles, reducing fouling and enhancing antifouling properties.

- Antimicrobial and Antifouling PVDF Membranes: PVDF membranes are modified with antimicrobial agents or materials to impart antimicrobial properties, preventing biofouling and improving overall antifouling performance.

- Mechanically and Thermally Enhanced PVDF Membranes: The mechanical and thermal properties of PVDF membranes are improved by blending with reinforcing materials or incorporating nanofillers, leading to better durability and stability, indirectly contributing to antifouling performance.

- High-Performance PVDF Membranes: The permeability and selectivity of PVDF membranes are optimized through techniques like controlling pore size and distribution or incorporating functional materials, enhancing performance and potentially reducing fouling.

02 Biomedical and Filtration Applications of PVDF Membranes

Use of PVDF membranes in biomedical applications like hemodialysis and tissue engineering, as well as in filtration processes, where biocompatibility and fouling resistance are crucial.Expand Specific Solutions03 Surface Modification of PVDF Membranes

Various surface modification techniques applied to PVDF membranes to improve biocompatibility, fouling resistance, and other properties, such as plasma treatment, coating, and grafting.Expand Specific Solutions04 PVDF Membrane Composites and Blends

Development of PVDF membrane composites and blends with materials like nanoparticles, polymers, or additives to enhance biocompatibility, fouling resistance, and overall performance.Expand Specific Solutions05 Characterization and Evaluation of PVDF Membranes

Techniques and methods for characterizing and evaluating biocompatibility, fouling resistance, and other relevant properties of PVDF membranes, including analytical techniques and performance testing.Expand Specific Solutions

Main Player Analysis

Evoqua Water Technologies LLC

Arkema, Inc.

Key Technology Interpretation

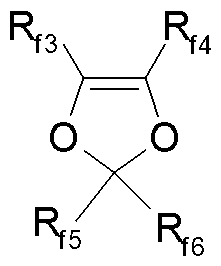

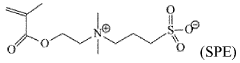

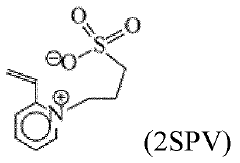

- A polymer additive comprising zwitterionic moieties is proposed to enhance the hydrophilicity, water permeability, and anti-fouling behavior of PVDF membranes without impairing their inherent properties.

- The polymer additive is designed to be highly efficient in hydrophilizing PVDF membranes, allowing for a low amount to be used, thus minimizing potential detrimental effects on the mechanical, thermal, and chemical resistance of the porous PVDF membrane.

- The polymer additive is suitable for use with various solvents commonly employed in membrane preparation processes, such as N,N-dimethylacetamide (DMAc), N,N-diethylacetamide, dimethylformamide (DMF), diethylformamide, or N-methyl-2-pyrrolidone (NMP).

Economic Impact

Assessing the economic impact of PVDF surface modifications for improved biocompatibility and fouling resistance demonstrates considerable potential across multiple sectors. Enhanced PVDF surfaces can significantly benefit the healthcare industry, particularly in medical devices like implants and biodegradable sensors, where biocompatibility is crucial. By reducing fouling, these modifications decrease maintenance costs and extend the lifespan of filtration systems used in water treatment and industrial applications. This improvement can ultimately lead to reduced operational costs and a decrease in resource consumption, positively affecting the bottom line.

Moreover, PVDF enhancements can drive innovation in industries reliant on membrane technologies, such as energy and chemical processing, by increasing efficiency and productivity. This advancement could generate new market opportunities, stimulating further research investment and commercial interest. The ripple effect of such adoption may lead to the creation of new jobs and partnerships, promoting economic growth in regions actively involved in manufacturing or utilizing PVDF materials. Thus, from a strategic perspective, leveraging PVDF surface modifications aligns well with long-term economic objectives, encompassing both cost optimization and market expansion.

Policy And Regulatory Impact

When examining the policy and regulatory impact on PVDF surface modifications aimed at enhancing biocompatibility and fouling resistance, it is essential to consider existing and emerging regulatory frameworks that influence material usage in biomedical applications. Regulatory bodies such as the FDA in the United States and the European Medicines Agency in the EU provide guidelines and standards for implantable materials and devices. These guidelines emphasize the need for biocompatibility, ensuring that PVDF modifications do not introduce cytotoxicity or adverse reactions in medical environments.

Furthermore, environmental regulations concerning surface treatments and chemical modifications are crucial. The use of certain chemicals in surface modifications may be restricted due to environmental and safety concerns, necessitating the exploration of environmentally friendly alternatives. Additionally, intellectual property rights and patent landscapes can affect the adoption and development of new modification techniques, influencing competitive strategies within the industry.

In conclusion, navigating the complex web of regulatory requirements, safety standards, and environmental considerations is vital for developing PVDF modifications that are not only effective but also compliant with global regulations, thereby ensuring successful market entry and acceptance.