Enhancing The Chemical Resistance Of PVDF Copolymers And Blends

Technology Background And Goals

Improving the chemical resistance of PVDF copolymers and blends is crucial for expanding their applications in harsh environments, such as chemical processing, oil and gas exploration, and environmental protection. This can be achieved through various approaches, including modifying the polymer structure, incorporating functional additives, or developing novel blending techniques.

Market Demand Analysis

- Market Size and Growth

The global market for PVDF copolymers and blends is expected to witness significant growth, driven by increasing demand from various end-use industries such as chemical processing, oil and gas, and water treatment. - Key Application Areas

PVDF copolymers and blends find extensive applications in chemical resistant piping, membranes, coatings, and linings due to their exceptional chemical resistance, thermal stability, and mechanical properties. - Regional Demand Dynamics

Asia-Pacific region is anticipated to be the largest consumer of PVDF copolymers and blends, owing to the rapid industrialization and infrastructure development in countries like China and India. - End-Use Industry Analysis

- Chemical Processing: Stringent regulations and the need for corrosion-resistant materials drive the demand for PVDF copolymers and blends in this industry.

- Oil and Gas: The harsh operating conditions in oil and gas exploration and production necessitate the use of chemically resistant materials like PVDF copolymers and blends.

- Water Treatment: PVDF copolymers and blends are widely used in membrane filtration systems due to their excellent chemical resistance and durability.

- Competitive Landscape

The market for PVDF copolymers and blends is highly competitive, with major players investing in research and development to enhance product performance and expand their product portfolios.

Technology Status And Challenges

- Polymer Degradation PVDF copolymers are susceptible to chemical degradation, leading to reduced mechanical properties and shortened lifespan. Common degradation mechanisms include oxidation, hydrolysis, and attack by strong acids or bases.

- Additive Leaching Additives like plasticizers and stabilizers can leach out from PVDF copolymers, compromising their performance and chemical resistance over time.

- Compatibility Issues Achieving good compatibility between PVDF and other polymers in blends can be challenging, potentially leading to phase separation and reduced chemical resistance.

- Processing Difficulties The high melt viscosity and thermal stability requirements of PVDF copolymers can make processing and compounding with other materials difficult.

Current Technical Solutions

01 Chemical Resistance

PVDF copolymers and blends exhibit excellent chemical resistance properties, making them suitable for various applications where exposure to harsh chemicals is expected. The incorporation of different monomers or blending with other polymers can enhance the chemical resistance of PVDF materials.- Chemical Resistance: PVDF copolymers and blends exhibit excellent chemical resistance properties, making them suitable for applications where exposure to harsh chemicals is expected. The incorporation of different monomers or blending with other polymers can enhance the chemical resistance.

- Preparation and Composition: Various methods and compositions are disclosed for preparing PVDF copolymers and blends with improved chemical resistance, including copolymerization techniques, blending processes, and the use of specific additives or fillers.

- Applications: Chemically resistant PVDF copolymers and blends find applications in industries like chemical processing, oil and gas, and semiconductor manufacturing, where exposure to aggressive chemicals is common. These materials are used in components like pipes, linings, and protective coatings.

- Evaluation and Testing: Various methods and techniques are employed to evaluate and test the chemical resistance of PVDF copolymers and blends, including immersion tests, permeation studies, and accelerated aging tests.

- Modification and Improvement: Strategies are disclosed for modifying and improving the chemical resistance of PVDF copolymers and blends, such as incorporating specific functional groups, using compatibilizers or coupling agents, or applying surface treatments.

02 Copolymerization for Improved Resistance

The chemical resistance of PVDF can be improved by copolymerizing it with other monomers, such as hexafluoropropylene (HFP) or tetrafluoroethylene (TFE). The resulting copolymers exhibit enhanced resistance to various chemicals, including acids, bases, and organic solvents.Expand Specific Solutions03 Polymer Blending for Chemical Resistance

The chemical resistance of PVDF can be tailored by blending it with other polymers, such as polyamides, polyesters, or fluoropolymers. These blends can exhibit improved resistance to specific chemicals or a broader range of chemical resistance compared to pure PVDF.Expand Specific Solutions04 PVDF Membranes and Coatings

PVDF and its copolymers are widely used in the production of membranes and coatings due to their excellent chemical resistance. These materials can withstand exposure to various chemicals, making them suitable for applications such as water treatment, chemical processing, and protective coatings.Expand Specific Solutions05 Evaluation and Testing

Various techniques are employed to evaluate and test the chemical resistance of PVDF copolymers and blends, including immersion tests, permeation studies, and accelerated aging tests to assess the material's performance under different chemical environments and exposure conditions.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Solvay SA

Key Technology Interpretation

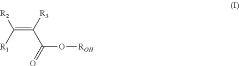

- Use of a vdf copolymer: the use of a vdf copolymer with recurring units derived from hydrophilic (meth)acrylic monomers (ma) and other monomers (fm) is a key innovation in this scheme. this combination allows the polymer to have good flexibility, adhesion to metal substrates, and chemical resistance.

- Specific copolymer composition: the copolymer described in this scheme has a certain composition of recurring units, including vinylidene fluoride (vdf), hydrophilic (meth)acrylic monomers (ma), and other monomers (fm). this specific composition contributes to the excellent flexibility and adhesion properties of the polymer.

- High molecular weight: the polymer (f) has an intrinsic viscosity measured in dimethylformamide that is higher than 0.35l/g. this high molecular weight is a factor that contributes to the good mechanical properties of the polymer.

PVDF Copolymers Chemical Resistance Enhancement Economic Impact

The economic impact of utilizing PVDF copolymers and blends for enhanced chemical resistance is significant across various industries. These materials offer superior durability and longevity, which can translate into reduced maintenance costs and extended life cycles for products in sectors like automotive, aerospace, and chemical processing. By improving the chemical resistance of components, companies can achieve cost savings by minimizing the frequency of repairs and replacements.

Furthermore, the demand for these advanced materials is expected to rise as industries increasingly prioritize sustainability, driving innovation and business opportunities. This focus on durability and performance aligns well with broader economic trends towards resource efficiency and cost-effective production processes. Additionally, as regulations become more stringent regarding the use of traditional materials, PVDF copolymers and blends may see heightened market adoption, thus opening up new revenue streams.

The economic implications are not only confined to cost savings but also involve the potential for generating higher revenues by offering premium products that meet specific industry needs. This can create competitive advantages for firms that invest early in these technologies. In summary, harnessing the capabilities of PVDF copolymers and blends presents a promising avenue for economic growth and sustainability across multiple market sectors.

PVDF Copolymers Chemical Resistance Enhancement Policy And Regulatory Impact

Policy and regulatory impacts surrounding PVDF copolymers and blends for enhanced chemical resistance are pivotal in shaping their development and utilization. Globally, environmental regulations increasingly emphasize reducing harmful emissions and prioritizing sustainable materials, influencing the production processes and applications of PVDF copolymers. Regulations such as the European Union's REACH and the U.S. Environmental Protection Agency's guidelines impact the permissible use of specific solvents and additives in PVDF manufacturing, driving the industry towards greener alternatives.

Additionally, patents and intellectual property rights play a significant role in fostering innovation while also creating competitive barriers. Companies are encouraged to develop proprietary formulations and manufacturing techniques that comply with existing regulatory standards. Compliance with industry standards, like ASTM and ISO, ensures the safe and effective application of these materials in various industries, including automotive and aerospace, which require high chemical resistance.

As regulatory landscapes evolve, ongoing monitoring and adaptation will be crucial for companies to remain compliant and capitalize on emerging opportunities. This dynamic regulatory environment not only poses challenges but also presents opportunities for industries to innovate and lead in the development of advanced materials with improved chemical resistance.