Check Valves With Advanced Materials And Coatings For Improved Performance

NOV 7, 20243 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Check Valve Technology Background And Goals

The primary objective is to provide a comprehensive overview of the development history and technological evolution trends in the field of check valves with advanced materials and coatings. This section will outline the key milestones and breakthroughs that have shaped the progress of this technology, setting the stage for understanding its current state and future potential. Additionally, it will clearly define the expected technological goals and performance targets that drive research and innovation efforts in this domain.

By establishing a solid foundation of the technology's background and aspirations, this section will provide the necessary context for subsequent analyses and discussions within the broader scope of the technical research report.

By establishing a solid foundation of the technology's background and aspirations, this section will provide the necessary context for subsequent analyses and discussions within the broader scope of the technical research report.

Check Valve Market Demand Analysis

- Growing Demand for Advanced Check Valves Increasing requirements for high-performance, durable, and reliable check valves in critical applications like oil and gas, chemical processing, and power generation are driving the demand for advanced materials and coatings.

- Expanding Market Opportunities The market for advanced check valves is expected to grow significantly due to the need for improved efficiency, safety, and environmental compliance in various industries.

- Replacement and Upgrade Needs Many existing check valve installations are aging and require replacement or upgrades to meet modern standards and regulations, creating a substantial market for advanced solutions.

- Emerging Applications New applications in areas such as renewable energy, desalination, and biotechnology are creating additional demand for specialized check valves with advanced materials and coatings.

Check Valve Technology Status And Challenges

- Material Limitations

Traditional materials like stainless steel and elastomers face challenges in harsh environments, leading to corrosion, erosion, and degradation. - Performance Constraints

Existing valve designs and materials may not meet stringent performance requirements, such as high temperature, pressure, and flow rates. - Maintenance Issues

Frequent maintenance and replacement of valves due to material failures can result in costly downtime and operational disruptions. - Sealing Challenges

Achieving reliable sealing under extreme conditions remains a challenge, leading to potential leakage and safety concerns. - Compatibility Concerns

Compatibility issues may arise when using advanced materials with existing systems, requiring careful integration and testing.

Check Valve Current Technical Solutions

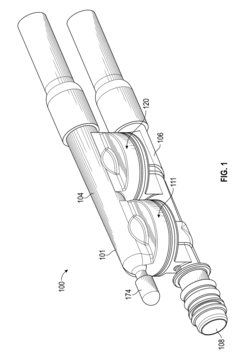

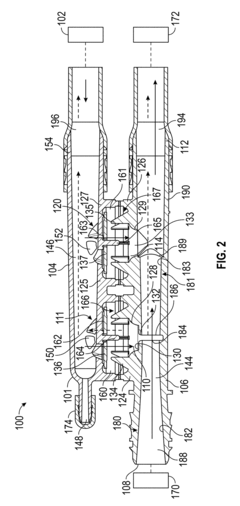

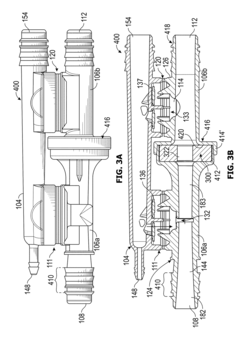

01 Structure and Components

Check valves have specific structures and components like bodies, seats, discs/balls, springs, and sealing elements to control one-way fluid/gas flow, influencing performance and durability.- Check Valve Structure and Components: Check valves are designed with specific structures and components to control fluid/gas flow in one direction while preventing backflow. These components include valve bodies, seats, discs/balls, springs, and sealing elements, influencing performance and durability.

- Applications and Performance Requirements: Check valves are used in various applications like water supply, industrial processes, and fluid handling systems. Their performance requirements vary based on factors like flow rate, pressure, temperature, and fluid/gas nature, necessitating specific designs and materials.

- Materials and Corrosion Resistance: Check valve materials, such as metals (stainless steel, brass, bronze) or non-metallic materials (plastics, composites), are chosen based on corrosion resistance, temperature tolerance, and fluid/gas compatibility, ensuring durability and performance.

- Sealing and Leakage Prevention: Effective sealing mechanisms, like elastomeric seals, metal-to-metal seals, or specialized materials, are employed to prevent leakage and backflow under different operating conditions, considering factors like pressure, temperature, and fluid compatibility.

- Maintenance and Testing: Regular maintenance, including inspections, cleaning, and component replacement, and testing methods like leak testing, pressure testing, or flow testing, are crucial for ensuring proper check valve functioning and identifying potential issues.

02 Applications and Operating Conditions

Check valves are used in various applications like water supply, industrial processes, and fluid handling systems. Their performance depends on factors like fluid properties, temperature, pressure, and flow rates, necessitating design optimization for specific conditions.Expand Specific Solutions03 Materials and Corrosion Resistance

Selecting appropriate materials resistant to corrosion, erosion, and environmental factors is crucial for check valve durability and reliable operation, extending service life.Expand Specific Solutions04 Maintenance and Inspection

Regular maintenance, including cleaning, component replacement, and leak testing, is essential for ensuring proper check valve functioning, preventing failures, and improving overall performance and reliability.Expand Specific Solutions05 Design Improvements and Innovations

Ongoing research and development efforts aim to improve check valve designs, addressing issues like noise reduction, flow efficiency, and ease of maintenance through new materials, geometries, or mechanisms, enhancing performance and addressing specific application challenges.Expand Specific Solutions

Check Valve Main Player Analysis

The market for research on check valves with advanced materials and coatings is growing, driven by demand for enhanced valve performance. Key players like Honeywell, Cameron, and Husky are at the forefront, showcasing high technical maturity with significant advancements. Other notable companies like Toyota, 3M, and Halliburton are also contributing to technological evolution in this sector.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell develops advanced check valves using high-performance materials and specialized coatings to enhance durability, efficiency, and corrosion resistance for various industrial applications.

Strength: High durability and corrosion resistance. Weakness: Higher cost compared to traditional materials.

Cameron International Corp.

Technical Solution: Cameron offers check valves with innovative materials and coatings designed for the oil and gas industry, providing enhanced performance and longevity under extreme conditions.

Strength: Excellent performance in extreme conditions. Weakness: Limited application outside the oil and gas sector.

Check Valve Key Technology Interpretation

Check valves and venturi devices having the same

PatentActiveUS20180156171A1

Innovation

- Reducing stress on the sealing member and extending the life of the check valve.

Check Valve Advanced Materials And Coatings Economic Analysis

Economic analysis is crucial for assessing the viability and potential impact of advanced materials and coatings for check valves. Key factors to consider include the cost of raw materials, manufacturing processes, and implementation compared to traditional solutions. Market demand, potential cost savings from improved performance, and environmental benefits should also be evaluated. A comprehensive cost-benefit analysis considering both short-term and long-term perspectives is essential to determine the economic feasibility and return on investment. Additionally, analyzing the competitive landscape and potential market share can provide insights into the economic opportunities and challenges associated with these advanced technologies.

Check Valve Advanced Materials And Coatings Environmental Impact

The use of advanced materials and coatings in check valves can have a significant environmental impact. These materials often have superior corrosion resistance, durability, and performance compared to traditional materials, leading to longer service life and reduced maintenance requirements. This can result in lower resource consumption and waste generation over the valve's lifetime. Additionally, some advanced coatings can improve energy efficiency by reducing friction and wear, contributing to lower energy usage and emissions. However, the production and disposal of these materials may raise environmental concerns, necessitating responsible manufacturing practices and proper end-of-life management. Overall, a comprehensive life cycle assessment is crucial to evaluate the net environmental impact of using advanced materials and coatings in check valves.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!