Improving The Stability Of Hydraulic Cylinders

Hydraulic Cylinder Stability Challenges and Goals

The primary objective is to investigate and analyze the current state, challenges, and potential solutions for improving the stability of hydraulic cylinders. This involves a comprehensive assessment of the existing technologies, key players, and market trends in this field. Hydraulic cylinders are critical components in various industrial applications, and their stability is crucial for ensuring reliable and efficient operation. However, factors such as wear, contamination, and external forces can compromise their stability, leading to performance issues and potential safety hazards.

This section will delve into the current technological landscape, identifying the main challenges and bottlenecks hindering the stability of hydraulic cylinders. It will also explore the geographical distribution of relevant research and development activities, shedding light on the regions driving innovation in this domain. By thoroughly examining the present status and obstacles, this section aims to lay the foundation for proposing effective solutions and future research directions.

Market Demand for Stable Hydraulic Systems

- Hydraulic System Stability Importance Stable hydraulic systems are crucial for various industries like construction, manufacturing, and mining. Unstable systems can lead to equipment failure, safety hazards, and productivity losses.

- Market Drivers

- Stringent safety regulations demanding reliable hydraulic systems

- Increasing demand for high-precision and heavy-duty machinery

- Need for efficient and low-maintenance hydraulic systems

- Market Segments

Key market segments include:

- Construction equipment (excavators, cranes, etc.)

- Industrial machinery (presses, injection molding machines)

- Aerospace and defense (aircraft actuators, missile systems)

- Oil and gas (drilling rigs, subsea equipment)

- Market Trends

- Shift towards electro-hydraulic systems for improved control

- Integration of sensors and IoT for predictive maintenance

- Demand for compact and lightweight hydraulic systems

- Market Potential The global hydraulic cylinder market is projected to reach $XX billion by 20XX, driven by the increasing adoption of stable hydraulic systems across various end-use industries.

Current State and Limitations of Hydraulic Cylinders

- Cylinder Stability Issues

Hydraulic cylinders face stability challenges due to factors like pressure fluctuations, seal wear, and external forces. - Performance Limitations

Instability can lead to reduced efficiency, increased maintenance needs, and premature failure of hydraulic systems. - Design Constraints

Cylinder design is constrained by factors like size, weight, and operating conditions, making stability optimization difficult. - Material Degradation

Materials used in cylinders can degrade over time, affecting sealing and causing leaks that impact stability. - Environmental Factors

External factors like temperature, contamination, and vibrations can contribute to cylinder instability and reduced lifespan.

Existing Solutions for Hydraulic Cylinder Stability

01 Structural Design for Stability

Reinforced cylinder walls, optimized piston and rod configurations, and robust end cap designs help withstand high pressures and prevent deformation or failure, improving hydraulic cylinder stability.- Structural Design for Stability: Reinforced cylinder walls, optimized piston and rod configurations, and robust end cap designs help withstand high pressures and prevent deformation or failure, improving hydraulic cylinder stability.

- Material Selection for Stability: High-strength alloys, composite materials, or specialized coatings enhance resistance to wear, corrosion, and fatigue, contributing to improved stability and durability of hydraulic cylinders.

- Sealing Mechanisms for Stability: Advanced sealing technologies like specialized gaskets, piston seals, or rod seals prevent leakage and ensure proper fluid containment, maintaining hydraulic cylinder stability and performance.

- Damping and Vibration Control for Stability: Incorporating shock absorbers, dampers, or specialized mounting systems mitigates external forces and vibrations, enhancing hydraulic cylinder stability in dynamic load or vibration-prone applications.

- Monitoring and Control Systems for Stability: Sensors, feedback loops, and control algorithms detect and compensate for factors affecting cylinder stability, such as pressure fluctuations, temperature changes, or misalignment, maintaining hydraulic cylinder stability.

02 Material Selection for Stability

High-strength alloys, composite materials, or specialized coatings enhance resistance to wear, corrosion, and fatigue, contributing to improved stability and durability of hydraulic cylinders.Expand Specific Solutions03 Sealing Mechanisms for Stability

Advanced sealing technologies like specialized gaskets, piston seals, or rod seals prevent leakage and ensure proper fluid containment, maintaining hydraulic cylinder stability and performance.Expand Specific Solutions04 Damping Systems for Stability

Specialized damping mechanisms, shock absorbers, or vibration isolation components mitigate vibrations, shocks, and oscillations, enhancing hydraulic cylinder stability.Expand Specific Solutions05 Control Systems for Stability

Sensors, feedback loops, and intelligent control algorithms monitor and adjust hydraulic cylinder operation, ensuring stability under varying load conditions and operating environments.Expand Specific Solutions

Key Players in Hydraulic Cylinder Industry

Caterpillar, Inc.

Hitachi Astemo Ltd.

Core Innovations in Hydraulic Cylinder Design

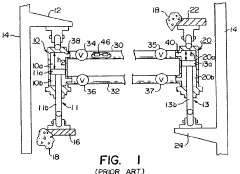

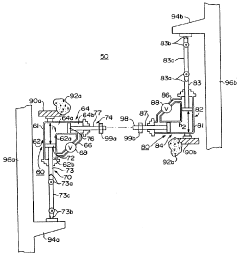

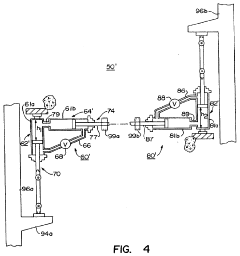

- Providing an improved damping system employing hydraulic dampers that minimizes or eliminates the problem of hydraulic fluid compressibility or leakage.

- Providing an improved damping system capable of selective and more reliable damping control than conventional damping systems.

- Minimizing the number of fluid paths and interconnections to avoid frictional problems and leakage issues.