Improving The Stability Of Check Valves

NOV 7, 20243 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Check Valve Technology Background And Goals

The primary objective is to investigate and analyze the current state, challenges, and future development trends of check valve stability improvement technologies. This involves comprehensively evaluating the existing technical solutions, identifying key issues and constraints, and exploring potential innovative approaches to enhance check valve stability.

The analysis will cover the evolution of relevant technologies, geographical distribution patterns, and the competitive landscape among major industry players. By examining core patents, technical literature, and mainstream solutions, the report aims to provide insights into the technological advancements, implementation details, and potential breakthroughs that could address the stability challenges faced by check valves.

The analysis will cover the evolution of relevant technologies, geographical distribution patterns, and the competitive landscape among major industry players. By examining core patents, technical literature, and mainstream solutions, the report aims to provide insights into the technological advancements, implementation details, and potential breakthroughs that could address the stability challenges faced by check valves.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current market size for check valves and related products, highlighting key application areas. Provide projections for market growth over the next 5-10 years, considering factors like industrial expansion and infrastructure development. - Regional Demand Patterns

Examine regional variations in demand for check valves, identifying regions with high growth potential. Discuss factors influencing regional demand, such as regulatory requirements, industry concentrations, and economic conditions. - Industry Trends and Drivers

Identify major trends shaping the check valve market, such as the adoption of new materials, design innovations, or changing industry standards. Discuss key drivers fueling market demand, like energy efficiency, safety concerns, or maintenance requirements. - Customer Segments and Needs

Analyze the diverse customer segments for check valves, including industries like oil and gas, power generation, and water treatment. Highlight specific needs and requirements for each segment, such as durability, flow capacity, or compatibility with certain fluids.

Check Valve Technology Status And Challenges

- Valve Stability Issues

Check valves face stability challenges like vibration, water hammer, and premature failure. - Material Degradation

Corrosion, erosion, and fatigue can degrade valve materials, compromising structural integrity. - Flow Dynamics

Complex flow patterns, turbulence, and cavitation can induce instability and damage. - Installation Factors

Improper installation, misalignment, and piping stress can lead to valve instability. - Environmental Conditions

Extreme temperatures, pressures, and fluid properties can affect valve performance.

Check Valve Current Technical Solutions

01 Check Valve Structure and Components

The check valve structure and its components, such as the valve body, valve seat, valve disc or ball, and other components that control flow direction and prevent backflow, play a crucial role in ensuring stability and proper functioning, with the design and materials impacting durability and resistance to wear and corrosion.- Check Valve Structure and Components: The search results cover various aspects related to the structure and components of check valves, such as valve bodies, valve seats, valve discs, and sealing mechanisms, which play a crucial role in ensuring stability and proper functioning.

- Check Valve Materials and Coatings: The search results discuss the use of different materials and coatings for check valve components to enhance their stability and durability, including metals, plastics, composites, ceramics, and polymers, to improve resistance to wear, corrosion, and environmental factors.

- Check Valve Design and Configurations: The search results cover various design and configuration aspects of check valves, such as valve types (e.g., swing, ball, lift), flow patterns, and valve orientations, aimed at optimizing stability and performance in different applications.

- Check Valve Applications and Operating Conditions: The search results explore the use of check valves in various applications and operating conditions, such as fluid handling, pressure systems, and extreme environments, where understanding the requirements and conditions is crucial for ensuring stability and reliable performance.

- Check Valve Testing and Performance Evaluation: The search results discuss methods and techniques for testing and evaluating the performance and stability of check valves, including testing procedures, performance metrics, and failure analysis, to ensure reliable operation under various conditions.

02 Check Valve Sealing Mechanisms

The sealing mechanisms employed in check valves, including various sealing materials and geometries, are essential for maintaining stability and preventing leakage, ensuring reliable operation and preventing backflow under varying pressure conditions.Expand Specific Solutions03 Check Valve Flow Characteristics

The flow characteristics of check valves, such as pressure drop, flow coefficients, and flow patterns, can influence their stability and performance, and optimizing these characteristics through design modifications can enhance the valve's ability to handle varying flow conditions while maintaining stability.Expand Specific Solutions04 Check Valve Materials and Coatings

The materials used in check valve construction, as well as any protective coatings or surface treatments applied, can contribute to their stability by providing resistance to corrosion, erosion, and other environmental factors, extending the valve's service life and maintaining performance over time.Expand Specific Solutions05 Check Valve Installation and Maintenance

Proper installation and maintenance practices, such as valve orientation, support and anchoring, regular inspection, and addressing issues like debris buildup or wear, can significantly impact the stability of check valves by ensuring their performance and preventing issues that can affect their stability.Expand Specific Solutions

Check Valve Main Player Analysis

The check valve market is substantial, driven by demand across various sectors. Key players like Halkey-Roberts Corp., Neway Valve (Suzhou) Co., Ltd., and Delphi Technology, Inc. contribute to the technological maturity of check valves. These companies focus on innovative materials, design improvements, and addressing stability issues to enhance reliability and extend the lifespan of check valves.

Neway Valve (Suzhou) Co., Ltd.

Technical Solution: Neway Valve specializes in high-performance check valves with advanced sealing technologies and durable materials for improved stability and reduced leakage.

Strength: Advanced sealing technology. Weakness: Higher cost due to premium materials.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell offers check valves with smart sensors and real-time monitoring for predictive maintenance and early fault detection, improving overall system reliability.

Strength: Real-time monitoring. Weakness: Complexity in integration with existing systems.

Check Valve Key Technology Interpretation

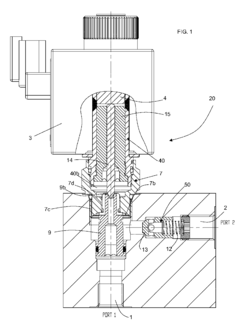

Pressure regulating valve

PatentActiveEP2821683A3

Innovation

- The integration of a check valve constituted by a movable ring shutter and a thrust spring, which generates a counter-pressure downstream of the cone-like shutter within the chamber. this integrated check valve also prevents oil leakage and air entry, ensuring stability of the valve.

Check Valve Stability Improvement Economic Analysis

Check valve stability is crucial for ensuring reliable and efficient fluid flow control in various industrial applications. An economic analysis of improving check valve stability involves evaluating the potential costs and benefits associated with implementing solutions to enhance valve performance and longevity. Key considerations include the initial investment required for research, development, and implementation of stability enhancement measures, as well as the long-term operational and maintenance cost savings resulting from improved valve reliability. Additionally, the analysis should factor in potential productivity gains, reduced downtime, and extended equipment lifespan facilitated by stable check valve operation. By quantifying these economic factors, organizations can make informed decisions about the feasibility and return on investment of pursuing check valve stability improvements within their specific operational contexts.

Check Valve Stability Improvement Policy And Regulatory Impact

Check valves are crucial components in various industrial applications, ensuring the safe and efficient flow of fluids or gases. However, their stability can be compromised by factors such as wear, corrosion, and improper installation, leading to potential leakages or malfunctions. Regulatory bodies have implemented guidelines and standards to enhance check valve stability, addressing design specifications, material selection, and installation procedures. These regulations aim to minimize risks, improve operational safety, and promote environmental compliance. Manufacturers and operators must adhere to these regulations to maintain optimal performance and mitigate potential hazards associated with unstable check valves.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!