Digital Twin Technology For Turbine Engine Technology

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Technology Background And Goals

## Directory: 技术背景与目标

Digital twin technology for turbine engines has evolved significantly over the past decade, driven by advancements in computational power, data analytics, and sensor technology. The primary goal is to create a virtual replica of a physical turbine engine that can simulate its performance, predict failures, and optimize maintenance schedules. This technology aims to enhance operational efficiency, reduce downtime, and extend the lifespan of turbine engines. By integrating real-time data from sensors with advanced modeling techniques, digital twins provide a comprehensive understanding of engine behavior under various conditions. This enables proactive maintenance and informed decision-making, ultimately leading to cost savings and improved reliability in turbine engine operations.

Digital Twin Technology Market Demand Analysis

Digital twin technology for turbine engines has significant market demand due to its potential to enhance performance, reduce maintenance costs, and improve operational efficiency.

**Market Drivers**:

**Industry Adoption**:

**Market Potential**:

**Challenges**:

**Market Drivers**:

- **Performance Optimization**: Digital twins enable real-time monitoring and predictive maintenance, leading to improved engine performance and reduced downtime.

- **Cost Reduction**: By predicting failures and optimizing maintenance schedules, digital twins help in reducing operational and maintenance costs.

- **Regulatory Compliance**: Enhanced monitoring and data analytics assist in meeting stringent regulatory requirements for safety and emissions.

**Industry Adoption**:

- **Aerospace**: Major aerospace companies are adopting digital twin technology to enhance the reliability and efficiency of turbine engines.

- **Energy Sector**: Power generation companies use digital twins to optimize the performance of gas turbines, leading to better energy efficiency.

**Market Potential**:

- **Growth Projections**: The market for digital twin technology in turbine engines is expected to grow significantly, driven by advancements in IoT, AI, and data analytics.

- **Investment Trends**: Increasing investments in R&D and technology integration by key industry players indicate a strong market potential.

**Challenges**:

- **Data Integration**: Integrating vast amounts of data from various sources remains a challenge.

- **Cybersecurity**: Ensuring the security of digital twin systems against cyber threats is critical.

Digital Twin Technology Status And Challenges

### Digital Twin Technology Status And Challenges

**Current Status:**

- **Adoption and Integration:** Digital twin technology is increasingly adopted in turbine engine development, enabling real-time monitoring and predictive maintenance.

- **Technological Maturity:** The technology is maturing, with advancements in data analytics, IoT, and AI enhancing its capabilities.

**Challenges:**

- **Data Management:** Handling vast amounts of data generated by turbine engines remains a significant challenge.

- **Interoperability:** Ensuring seamless integration with existing systems and standards is complex.

- **Accuracy and Reliability:** Maintaining high accuracy and reliability of digital twins to reflect real-world conditions is critical.

- **Cost and Resources:** High implementation costs and resource requirements can be barriers for widespread adoption.

Digital Twin Technology Current Technical Solutions

01 Integration of Digital Twin for Predictive Maintenance

Digital twin technology can be integrated into turbine engine systems to enable predictive maintenance. By creating a virtual model of the engine, real-time data can be monitored and analyzed to predict potential failures and optimize maintenance schedules, thereby improving engine reliability and reducing downtime.- Integration of Digital Twin for Predictive Maintenance: Digital twin technology can be used to create a virtual model of a turbine engine, allowing for real-time monitoring and predictive maintenance. This helps in identifying potential issues before they occur, reducing downtime and maintenance costs.

- Optimization of Turbine Engine Performance: Digital twins can be utilized to simulate and optimize the performance of turbine engines. By analyzing data from the digital twin, engineers can make adjustments to improve efficiency, reduce fuel consumption, and enhance overall performance.

- Enhancing Design and Development Processes: The use of digital twin technology in the design and development of turbine engines allows for virtual testing and validation. This accelerates the development process, reduces the need for physical prototypes, and helps in identifying design flaws early.

- Real-time Monitoring and Control: Digital twins enable real-time monitoring and control of turbine engines. By continuously collecting and analyzing data, operators can make informed decisions to ensure optimal operation and prevent failures.

- Lifecycle Management and Sustainability: Digital twin technology supports the entire lifecycle management of turbine engines, from design to decommissioning. It helps in tracking the performance, maintenance history, and remaining useful life, contributing to sustainability and efficient resource utilization.

02 Optimization of Engine Performance Using Digital Twin

Digital twin technology can be used to optimize the performance of turbine engines. By simulating different operating conditions and scenarios, the digital twin can provide insights into performance improvements, fuel efficiency, and emissions reduction, leading to better overall engine performance.Expand Specific Solutions03 Real-time Monitoring and Diagnostics

Digital twin technology enables real-time monitoring and diagnostics of turbine engines. By continuously collecting and analyzing data from sensors, the digital twin can detect anomalies, diagnose issues, and provide actionable insights to ensure the engine operates within optimal parameters.Expand Specific Solutions04 Lifecycle Management and Simulation

Digital twin technology supports lifecycle management and simulation of turbine engines. It allows for the simulation of the entire lifecycle of the engine, from design and manufacturing to operation and decommissioning, helping to improve design processes, predict wear and tear, and plan for end-of-life scenarios.Expand Specific Solutions05 Enhanced Design and Testing

Digital twin technology enhances the design and testing of turbine engines. By creating a virtual prototype, engineers can test and validate new designs, identify potential issues, and make necessary adjustments before physical production, leading to more efficient and cost-effective development processes.Expand Specific Solutions

Digital Twin Technology Main Player Analysis

The competitive landscape for digital twin technology in turbine engine technology is characterized by a mix of academic institutions and industry leaders. The industry is in a growth phase with increasing market size driven by advancements in IoT and AI. Companies like Siemens AG, Siemens Industry Software NV, and Cummins, Inc. are at the forefront, showcasing high technical maturity. Academic institutions such as Xi'an Jiaotong University and Northwestern Polytechnical University contribute significantly to research and innovation. The technology is maturing rapidly, with significant contributions from both industry and academia, indicating a robust and dynamic competitive environment.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive digital twin technology for turbine engines. Their solution integrates real-time data analytics, predictive maintenance, and simulation models to optimize engine performance and reduce downtime.

Strength: Advanced integration of real-time data and predictive analytics. Weakness: High implementation cost.

Cummins, Inc.

Technical Solution: Cummins, Inc. offers a digital twin solution for turbine engines, focusing on enhancing engine efficiency and reliability. Their technology includes detailed simulation models and real-time data integration to predict engine behavior.

Strength: Strong focus on engine efficiency and reliability. Weakness: Limited scalability for different engine types.

Digital Twin Technology Key Technology Interpretation

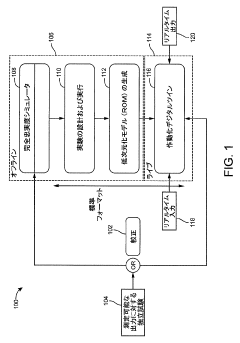

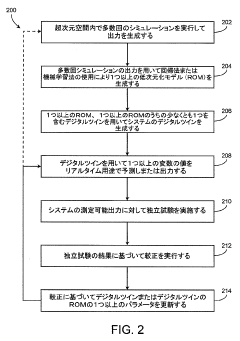

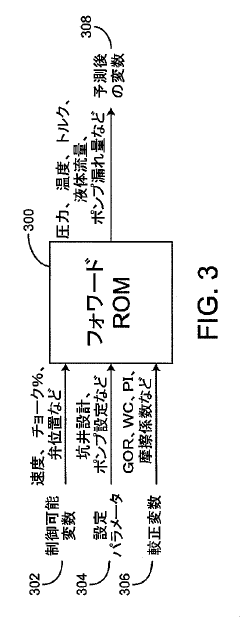

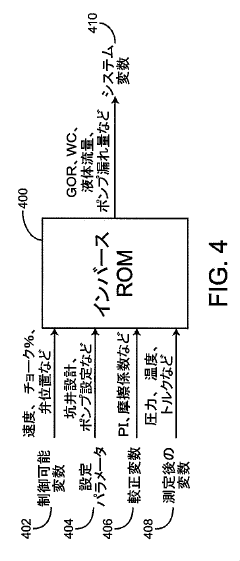

Digital twinning system and method for hydrocarbon systems

PatentPendingJP2024500323A

Innovation

- Performing multiple simulations in a hyperdimensional space to enhance the accuracy and reliability of the digital twin.

- Using regression or machine learning methods to process the output of multiple simulations for better predictive capabilities.

- Generating a digital twin by instantiating one or more Reduced Order Models (ROMs) for real-time estimation of hydrocarbon system variables.

Digital Twin Technology For Turbine Engine Economic Analysis

The economic analysis of Digital Twin Technology for turbine engines involves evaluating the cost-benefit aspects, including initial investment, operational savings, and potential revenue enhancements. Digital twins can significantly reduce maintenance costs by predicting failures and optimizing performance, leading to extended engine life and reduced downtime. Additionally, they enable more efficient fuel usage and lower emissions, contributing to cost savings and compliance with environmental regulations. The technology also opens new revenue streams through enhanced service offerings and data monetization. Overall, the economic benefits of implementing digital twins in turbine engines can outweigh the initial costs, providing a strong return on investment.

Digital Twin Technology For Turbine Engine Policy And Regulatory Impact

Digital twin technology for turbine engines has significant policy and regulatory implications. It enhances predictive maintenance, operational efficiency, and safety, aligning with regulatory standards for emissions and performance. Policymakers must address data security, interoperability, and standardization to ensure widespread adoption. Regulatory frameworks should evolve to support innovation while ensuring compliance with safety and environmental norms. Collaboration between industry stakeholders and regulatory bodies is crucial to harmonize standards and foster technological advancements. This synergy will drive the successful integration of digital twin technology in turbine engines, promoting sustainable and efficient aviation practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!