Improving The Stability Of Continuously Variable Transmission (CVT) Technology

CVT Technology Background and Objectives

By comprehensively analyzing the background, challenges, and potential solutions in this field, the report aims to provide a solid foundation for strategic planning and decision-making regarding the future development and implementation of improved CVT technology.

Market Demand for Stable CVT Systems

- Growing Demand for Smooth Transmission

Consumers increasingly prefer vehicles with smooth and seamless gear shifting for a comfortable driving experience. CVT systems offer superior smoothness compared to traditional automatic transmissions. - Fuel Efficiency Benefits

CVT technology allows engines to operate at optimal rpm ranges, resulting in improved fuel efficiency. This aligns with stricter emissions regulations and consumer demand for fuel-saving vehicles. - Expanding Adoption in Hybrid and Electric Vehicles

The inherent efficiency advantages of CVTs make them well-suited for hybrid and electric powertrains. Adoption is expected to grow as these vehicle segments gain market share. - Cost-Effectiveness for Automakers

CVTs can potentially reduce manufacturing costs compared to complex multi-gear automatic transmissions, making them an attractive option for automakers seeking cost optimization.

Current State and Challenges of CVT Technology

- Current Technological Limitations

CVT systems face challenges in maintaining stable operation under high torque loads and extreme temperature conditions, leading to potential slippage, vibrations, and premature wear. - Material Constraints

The durability and friction characteristics of materials used in CVT components, such as pulleys and belts, can limit their performance and lifespan. - Control System Complexities

Precise control of the CVT ratio and clamping forces is crucial for optimal performance, but can be challenging due to the dynamic nature of the system. - Lubrication and Cooling Challenges

Maintaining proper lubrication and cooling of the CVT components is essential for reliable operation, but can be difficult under varying load and temperature conditions. - Noise and Vibration Issues

CVT systems can generate undesirable noise and vibrations, particularly during ratio changes or under high loads, which can affect driving comfort and component durability.

Current Solutions for CVT Stability

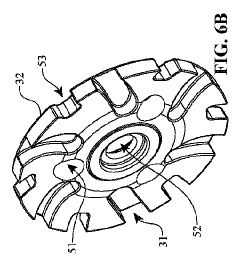

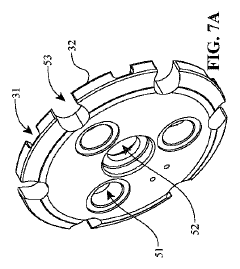

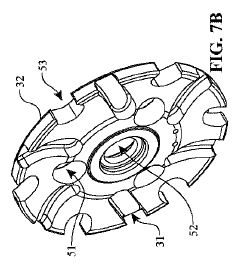

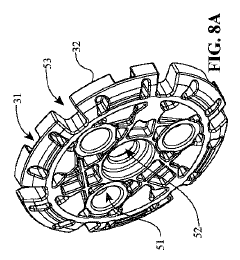

01 CVT Structure and Components

This category covers the structural design and components of continuously variable transmissions (CVTs), including the arrangement of input/output shafts, pulleys, belts or chains, and other mechanical elements that enable continuous gear ratio variation.- CVT Structure and Components: This category covers the structural design and components of CVTs, such as the pulley system, belt or chain mechanism, and planetary gear arrangements, including various configurations and innovations aimed at improving efficiency, durability, and performance.

- CVT Control and Operation: This category focuses on the control systems and operational strategies for CVTs, including ratio control, shift control, and hydraulic or electronic control mechanisms, as well as methods for optimizing transmission performance, efficiency, and responsiveness.

- CVT Applications and Integration: This category encompasses the integration of CVTs into various vehicle types, such as electric vehicles, hybrid vehicles, and motorcycles, as well as the design and optimization of CVT systems for specific applications and vehicle platforms.

- CVT Efficiency and Energy Management: This category focuses on improving the efficiency and energy management of CVTs, including friction reduction, energy recovery, and optimization of power transmission, as well as innovative designs and control strategies to enhance fuel economy and reduce energy losses.

- CVT Simulation and Testing: This category covers simulation techniques, test methods, and evaluation processes for CVTs, including tools and methodologies for analyzing and validating the performance, durability, and reliability of CVT systems under various operating conditions.

02 CVT Control Systems

This category focuses on the control systems and methods used to manage and regulate CVT operation, including electronic, hydraulic, and mechanical control mechanisms for adjusting transmission ratio, clutch engagement, and performance optimization.Expand Specific Solutions03 CVT Applications and Vehicle Integration

This category covers the integration of CVTs into various vehicle types, such as electric, hybrid, and conventional internal combustion engine vehicles, as well as considerations for packaging, mounting, and interfacing with other vehicle systems.Expand Specific Solutions04 CVT Efficiency and Performance Optimization

This category focuses on techniques and designs aimed at improving CVT efficiency, power transmission capabilities, and overall performance, including innovations in friction reduction, torque transfer mechanisms, and ratio range optimization.Expand Specific Solutions05 CVT Simulation and Testing Methods

This category covers methods and systems for simulating, modeling, and testing the behavior and performance of CVTs, including computer simulations, test rigs, and experimental setups for design validation, performance evaluation, and failure analysis.Expand Specific Solutions

Key Players in the CVT Industry

GM Global Technology Operations LLC

Fallbrook Intellectual Property Co LLC

Core Innovations in CVT Technology

- The first stator has a larger outer diameter than the second stator, allowing for larger radial slots that extend further inwardly.

- The stator slots deviate from the radial direction, enabled by the larger outer diameter or extended guide slots, preventing shaft runaway while allowing stator control.

- The timing plate slots are wider than the stator guide slots, facilitating adjustment while preventing shaft runaway.

Regulatory Landscape for Automotive Transmissions

The regulatory landscape for automotive transmissions plays a key role in shaping transmission technologies, with global standards ensuring vehicle safety, efficiency, and environmental compliance. Emission regulations set by agencies like the EPA and EU limit pollutants such as carbon monoxide and nitrogen oxides, where continuously variable transmissions (CVTs) help improve fuel efficiency and reduce emissions.

Safety standards, enforced by bodies like the NHTSA and Euro NCAP, focus on transmission durability, reliability, and fail-safe mechanisms to ensure safe vehicle operation. Additionally, noise regulations, especially in urban areas, have become more stringent, with CVTs contributing to smoother and quieter vehicle performance.

Automotive manufacturers must also adhere to international trade standards from organizations like the WTO and ISO, promoting component compatibility across markets. Staying compliant with these evolving regulations is not only a legal necessity but also a competitive advantage as the demand for safer, greener, and more efficient vehicles grows.

Environmental Impact of CVT Systems

The environmental impact of continuously variable transmission (CVT) systems is a key consideration in automotive development. CVTs enhance fuel efficiency and reduce emissions compared to traditional automatic transmissions, contributing to a more sustainable industry by optimizing engine performance, particularly in urban driving, where frequent acceleration occurs.

However, the production, disposal, and maintenance of CVT systems also carry environmental risks. Manufacturing involves materials like metals and plastics, which need responsible sourcing and disposal to reduce their footprint. Additionally, durable CVTs lower the need for replacements, cutting resource use and waste. Proper handling of lubricants and fluids is crucial to prevent contamination. Research is ongoing to improve CVT sustainability through better materials and efficiency.