Longitudinal waves in biomechanical prosthetic developments

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomechanical Prosthetics and Longitudinal Waves

Biomechanical prosthetics have revolutionized the field of assistive technology, offering individuals with limb loss or impairment the opportunity to regain mobility and functionality. The integration of longitudinal waves in prosthetic development represents a cutting-edge approach to enhancing the performance and user experience of these devices.

Longitudinal waves, characterized by oscillations parallel to the direction of wave propagation, have shown promising applications in biomechanical prosthetics. These waves can be harnessed to improve energy transfer, sensory feedback, and overall prosthetic responsiveness. By mimicking the natural propagation of mechanical signals in biological tissues, longitudinal waves offer a more biomimetic approach to prosthetic design.

One of the key areas where longitudinal waves have made significant contributions is in the development of advanced sensory feedback systems. By utilizing these waves, researchers have been able to create prosthetics that can transmit tactile information to the user, allowing for a more natural and intuitive control of the device. This enhanced sensory feedback has the potential to greatly improve the user's ability to perform fine motor tasks and interact with their environment.

In addition to sensory feedback, longitudinal waves have also been explored for their potential in energy harvesting and transmission within prosthetic systems. By capturing and redirecting the energy generated during movement, these waves can be used to power various components of the prosthetic, potentially reducing the need for external power sources and extending the device's operational time.

The application of longitudinal waves in prosthetic socket design has also shown promise in improving comfort and fit. By incorporating wave-based materials and structures, researchers have been able to develop sockets that can dynamically adapt to changes in limb volume and pressure distribution, resulting in a more comfortable and secure fit for the user.

Furthermore, the study of longitudinal waves has led to advancements in the development of active prosthetic components, such as artificial muscles and joints. By leveraging the properties of these waves, researchers have been able to create more responsive and efficient actuators that closely mimic the behavior of biological tissues.

As research in this field continues to progress, the integration of longitudinal waves in biomechanical prosthetics holds the potential to significantly enhance the functionality, comfort, and overall quality of life for individuals with limb loss or impairment. The ongoing exploration of this technology promises to drive further innovations in prosthetic design and contribute to the development of more advanced and user-centric assistive devices.

Longitudinal waves, characterized by oscillations parallel to the direction of wave propagation, have shown promising applications in biomechanical prosthetics. These waves can be harnessed to improve energy transfer, sensory feedback, and overall prosthetic responsiveness. By mimicking the natural propagation of mechanical signals in biological tissues, longitudinal waves offer a more biomimetic approach to prosthetic design.

One of the key areas where longitudinal waves have made significant contributions is in the development of advanced sensory feedback systems. By utilizing these waves, researchers have been able to create prosthetics that can transmit tactile information to the user, allowing for a more natural and intuitive control of the device. This enhanced sensory feedback has the potential to greatly improve the user's ability to perform fine motor tasks and interact with their environment.

In addition to sensory feedback, longitudinal waves have also been explored for their potential in energy harvesting and transmission within prosthetic systems. By capturing and redirecting the energy generated during movement, these waves can be used to power various components of the prosthetic, potentially reducing the need for external power sources and extending the device's operational time.

The application of longitudinal waves in prosthetic socket design has also shown promise in improving comfort and fit. By incorporating wave-based materials and structures, researchers have been able to develop sockets that can dynamically adapt to changes in limb volume and pressure distribution, resulting in a more comfortable and secure fit for the user.

Furthermore, the study of longitudinal waves has led to advancements in the development of active prosthetic components, such as artificial muscles and joints. By leveraging the properties of these waves, researchers have been able to create more responsive and efficient actuators that closely mimic the behavior of biological tissues.

As research in this field continues to progress, the integration of longitudinal waves in biomechanical prosthetics holds the potential to significantly enhance the functionality, comfort, and overall quality of life for individuals with limb loss or impairment. The ongoing exploration of this technology promises to drive further innovations in prosthetic design and contribute to the development of more advanced and user-centric assistive devices.

Market Analysis for Advanced Prosthetic Devices

The global market for advanced prosthetic devices has been experiencing significant growth, driven by technological advancements, increasing prevalence of disabilities, and rising healthcare expenditure. The integration of longitudinal wave technology in biomechanical prosthetics represents a cutting-edge development that is poised to revolutionize the industry.

The prosthetics market is segmented into upper extremity prosthetics, lower extremity prosthetics, and other types. Lower extremity prosthetics currently dominate the market share, but upper extremity prosthetics are expected to witness the highest growth rate in the coming years. This growth is attributed to the increasing demand for more functional and natural-feeling prosthetic limbs.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a key market due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies. However, emerging economies in Asia-Pacific, such as China and India, are expected to exhibit the fastest growth rates, driven by improving healthcare access and rising disposable incomes.

The incorporation of longitudinal wave technology in prosthetic devices is anticipated to create new market opportunities. This technology has the potential to enhance the sensory feedback and control mechanisms of prosthetic limbs, leading to improved functionality and user experience. As a result, the demand for these advanced prosthetics is expected to increase among both civilian and military populations.

Key market drivers include the growing aging population, rising incidence of diabetes-related amputations, and increasing awareness about the availability of advanced prosthetic solutions. Additionally, ongoing research and development activities in the field of biomechanics and materials science are contributing to the expansion of the market.

However, the market also faces challenges such as high costs associated with advanced prosthetic devices, limited reimbursement policies in some regions, and the need for skilled professionals to fit and maintain these devices. These factors may hinder market growth, particularly in developing countries.

The competitive landscape of the advanced prosthetics market is characterized by the presence of both established players and innovative start-ups. Major companies are investing heavily in research and development to incorporate new technologies like longitudinal wave systems into their products. Collaborations between prosthetics manufacturers, research institutions, and healthcare providers are becoming increasingly common, fostering innovation and market growth.

In conclusion, the market for advanced prosthetic devices incorporating longitudinal wave technology shows promising growth potential. As research in biomechanical prosthetics continues to advance, we can expect to see more sophisticated and user-friendly prosthetic solutions entering the market, ultimately improving the quality of life for individuals with limb loss or limb differences.

The prosthetics market is segmented into upper extremity prosthetics, lower extremity prosthetics, and other types. Lower extremity prosthetics currently dominate the market share, but upper extremity prosthetics are expected to witness the highest growth rate in the coming years. This growth is attributed to the increasing demand for more functional and natural-feeling prosthetic limbs.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, is a key market due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies. However, emerging economies in Asia-Pacific, such as China and India, are expected to exhibit the fastest growth rates, driven by improving healthcare access and rising disposable incomes.

The incorporation of longitudinal wave technology in prosthetic devices is anticipated to create new market opportunities. This technology has the potential to enhance the sensory feedback and control mechanisms of prosthetic limbs, leading to improved functionality and user experience. As a result, the demand for these advanced prosthetics is expected to increase among both civilian and military populations.

Key market drivers include the growing aging population, rising incidence of diabetes-related amputations, and increasing awareness about the availability of advanced prosthetic solutions. Additionally, ongoing research and development activities in the field of biomechanics and materials science are contributing to the expansion of the market.

However, the market also faces challenges such as high costs associated with advanced prosthetic devices, limited reimbursement policies in some regions, and the need for skilled professionals to fit and maintain these devices. These factors may hinder market growth, particularly in developing countries.

The competitive landscape of the advanced prosthetics market is characterized by the presence of both established players and innovative start-ups. Major companies are investing heavily in research and development to incorporate new technologies like longitudinal wave systems into their products. Collaborations between prosthetics manufacturers, research institutions, and healthcare providers are becoming increasingly common, fostering innovation and market growth.

In conclusion, the market for advanced prosthetic devices incorporating longitudinal wave technology shows promising growth potential. As research in biomechanical prosthetics continues to advance, we can expect to see more sophisticated and user-friendly prosthetic solutions entering the market, ultimately improving the quality of life for individuals with limb loss or limb differences.

Current Challenges in Prosthetic Wave Propagation

The development of biomechanical prosthetics faces several significant challenges in the realm of longitudinal wave propagation. One of the primary obstacles is the accurate simulation and replication of natural wave propagation patterns within artificial limbs. The complex interplay between different tissue types, bone structures, and joint mechanics in biological systems creates intricate wave propagation behaviors that are difficult to mimic in prosthetic devices.

Material selection poses another critical challenge. Researchers must identify and develop materials that can effectively transmit and attenuate longitudinal waves in a manner similar to natural tissues. This involves finding the right balance between rigidity and flexibility, as well as considering factors such as durability, weight, and biocompatibility. The heterogeneous nature of biological tissues further complicates this task, as different parts of a prosthetic limb may require varying material properties to accurately replicate natural wave propagation characteristics.

Energy dissipation and damping mechanisms present additional hurdles in prosthetic wave propagation research. Natural limbs efficiently absorb and dissipate energy from impacts and movements, reducing stress on joints and improving overall comfort. Replicating these mechanisms in prosthetic devices remains a significant challenge, particularly in terms of mimicking the viscoelastic properties of biological tissues that contribute to their energy absorption capabilities.

The integration of sensory feedback systems with wave propagation mechanics is another area of ongoing research and development. Prosthetic users often lack the proprioceptive and tactile sensations that natural limbs provide, which are crucial for fine motor control and spatial awareness. Incorporating sensors and feedback mechanisms that can detect and transmit information about wave propagation within the prosthetic could potentially enhance the user's ability to control the device and interact with their environment more naturally.

Computational modeling and simulation techniques also face limitations in accurately predicting wave propagation behaviors in complex prosthetic systems. While advanced finite element analysis and other numerical methods have made significant strides, the multiscale nature of wave propagation in biomechanical systems, ranging from molecular interactions to macroscopic tissue deformations, presents ongoing challenges in developing comprehensive and computationally efficient models.

Lastly, the personalization of prosthetic devices to individual users' needs and anatomical characteristics remains a significant hurdle. Wave propagation patterns can vary significantly between individuals due to differences in body composition, muscle tone, and skeletal structure. Developing adaptive prosthetic systems that can adjust their wave propagation properties to match the specific requirements of each user is a complex task that requires further research and innovation in materials science, control systems, and biomechanical modeling.

Material selection poses another critical challenge. Researchers must identify and develop materials that can effectively transmit and attenuate longitudinal waves in a manner similar to natural tissues. This involves finding the right balance between rigidity and flexibility, as well as considering factors such as durability, weight, and biocompatibility. The heterogeneous nature of biological tissues further complicates this task, as different parts of a prosthetic limb may require varying material properties to accurately replicate natural wave propagation characteristics.

Energy dissipation and damping mechanisms present additional hurdles in prosthetic wave propagation research. Natural limbs efficiently absorb and dissipate energy from impacts and movements, reducing stress on joints and improving overall comfort. Replicating these mechanisms in prosthetic devices remains a significant challenge, particularly in terms of mimicking the viscoelastic properties of biological tissues that contribute to their energy absorption capabilities.

The integration of sensory feedback systems with wave propagation mechanics is another area of ongoing research and development. Prosthetic users often lack the proprioceptive and tactile sensations that natural limbs provide, which are crucial for fine motor control and spatial awareness. Incorporating sensors and feedback mechanisms that can detect and transmit information about wave propagation within the prosthetic could potentially enhance the user's ability to control the device and interact with their environment more naturally.

Computational modeling and simulation techniques also face limitations in accurately predicting wave propagation behaviors in complex prosthetic systems. While advanced finite element analysis and other numerical methods have made significant strides, the multiscale nature of wave propagation in biomechanical systems, ranging from molecular interactions to macroscopic tissue deformations, presents ongoing challenges in developing comprehensive and computationally efficient models.

Lastly, the personalization of prosthetic devices to individual users' needs and anatomical characteristics remains a significant hurdle. Wave propagation patterns can vary significantly between individuals due to differences in body composition, muscle tone, and skeletal structure. Developing adaptive prosthetic systems that can adjust their wave propagation properties to match the specific requirements of each user is a complex task that requires further research and innovation in materials science, control systems, and biomechanical modeling.

Existing Longitudinal Wave Integration Solutions

01 Generation and propagation of longitudinal waves

Longitudinal waves are characterized by particle motion parallel to the direction of wave propagation. Various devices and methods are used to generate and propagate these waves in different mediums, including solids, liquids, and gases. Applications range from acoustic systems to seismic exploration.- Generation and propagation of longitudinal waves: Longitudinal waves are characterized by oscillations parallel to the direction of wave propagation. Various devices and methods are employed to generate and propagate these waves in different mediums, including solids, liquids, and gases. The generation mechanisms often involve vibrating elements or pressure fluctuations, while propagation is influenced by the medium's properties.

- Applications in ultrasonic technology: Longitudinal waves find extensive use in ultrasonic applications, particularly in medical imaging, non-destructive testing, and industrial processes. Ultrasonic transducers convert electrical energy into mechanical vibrations, producing high-frequency longitudinal waves. These waves can penetrate materials, allowing for imaging, measurement, and manipulation at the microscopic level.

- Acoustic wave devices and sensors: Longitudinal waves are utilized in various acoustic wave devices and sensors. These include pressure sensors, accelerometers, and acoustic wave filters. The devices often employ piezoelectric materials to convert mechanical stress from longitudinal waves into electrical signals or vice versa. Such sensors find applications in automotive, aerospace, and consumer electronics industries.

- Seismic exploration and geophysical applications: Longitudinal waves play a crucial role in seismic exploration and geophysical studies. Seismic waves, primarily longitudinal P-waves, are used to investigate subsurface structures for oil and gas exploration, geological mapping, and earthquake monitoring. Advanced techniques involve generating, detecting, and analyzing these waves to create detailed subsurface images.

- Acoustic metamaterials and wave manipulation: Recent advancements in acoustic metamaterials have opened new possibilities for manipulating longitudinal waves. These engineered structures can control, guide, and focus acoustic waves in unprecedented ways. Applications include sound insulation, acoustic cloaking, and super-resolution imaging. Research in this field aims to develop novel materials with unique wave propagation properties.

02 Ultrasonic longitudinal wave applications

Ultrasonic longitudinal waves are utilized in numerous fields, including medical imaging, non-destructive testing, and industrial processes. These high-frequency waves can penetrate materials, allowing for internal inspection and manipulation without causing damage.Expand Specific Solutions03 Measurement and analysis of longitudinal waves

Various techniques and instruments are employed to measure and analyze longitudinal waves. These include sensors, transducers, and signal processing methods that can detect, record, and interpret wave characteristics such as frequency, amplitude, and propagation speed.Expand Specific Solutions04 Longitudinal wave interaction with materials

The behavior of longitudinal waves as they interact with different materials is studied for various applications. This includes understanding wave transmission, reflection, and absorption in different mediums, which is crucial for fields such as acoustics, seismology, and materials science.Expand Specific Solutions05 Longitudinal wave energy harvesting and conversion

Research is conducted on harnessing energy from longitudinal waves and converting it into other forms of energy. This includes developing technologies for capturing acoustic or vibrational energy from the environment and transforming it into electrical power for various applications.Expand Specific Solutions

Key Players in Biomechanical Prosthetics Industry

The research on longitudinal waves in biomechanical prosthetic developments is in an emerging stage, with a growing market driven by advancements in biomedical engineering and materials science. The technology's maturity is still evolving, as evidenced by the diverse range of institutions involved, including leading universities like MIT, Tsinghua University, and the University of Michigan, as well as specialized medical research centers such as The Cleveland Clinic Foundation. Companies like Edwards Lifesciences and 3D Systems are also contributing to the field, indicating a blend of academic and industrial efforts. This multidisciplinary approach suggests that while the technology shows promise, it is still in the process of transitioning from research to practical applications in prosthetic development.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to longitudinal wave propagation in biomechanical prosthetics, focusing on enhancing the natural feel and responsiveness of artificial limbs. Their research utilizes advanced materials science and bioengineering techniques to create prosthetic components that can transmit and respond to longitudinal waves in a manner similar to natural human tissue. This includes the development of smart materials that can actively adjust their stiffness and damping properties in response to different types of longitudinal waves, mimicking the adaptive nature of human muscles and tendons[1][3]. The team has also integrated miniaturized sensors and actuators within the prosthetic structure to detect and generate longitudinal waves, allowing for more intuitive control and feedback mechanisms[5].

Strengths: Cutting-edge materials science integration, advanced sensor technology, and biomimetic design principles. Weaknesses: Potentially high cost of implementation and complexity in manufacturing.

The Cleveland Clinic Foundation

Technical Solution: The Cleveland Clinic has made significant strides in the application of longitudinal wave technology to biomechanical prosthetics, particularly in the realm of neural interfaces. Their approach involves the use of longitudinal ultrasonic waves to create non-invasive, high-resolution neural interfaces for prosthetic control. By utilizing focused ultrasound, they have developed a method to stimulate specific areas of the peripheral nervous system, allowing for more precise control of prosthetic limbs[2]. Additionally, their research has explored the use of longitudinal waves for sensory feedback in prosthetics, enabling users to 'feel' through their artificial limbs by translating environmental stimuli into specific wave patterns that can be interpreted by the nervous system[4].

Strengths: Non-invasive neural interface technology, enhanced sensory feedback capabilities. Weaknesses: Potential limitations in the depth of tissue penetration for ultrasound-based systems.

Core Innovations in Prosthetic Wave Mechanics

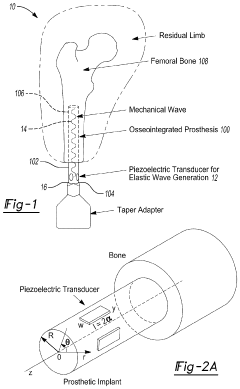

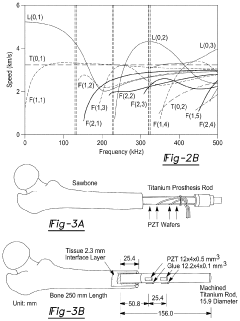

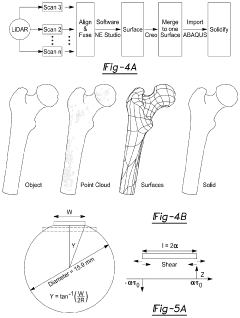

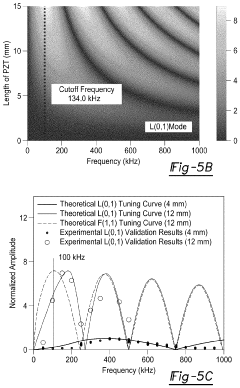

Sensing strategies for health assessment of osseointegrated prostheses

PatentActiveUS11903729B2

Innovation

- A guided wave strategy using piezoelectric wafers installed on the osseointegrated prosthesis to generate and measure elastic stress waves, allowing for quantitative assessment of osseointegration and detection of issues like loosening and fractures through wearable monitoring systems, eliminating the need for biocompatible sensors inside the body.

Ultrasound method and apparatus for displaying ultrasound propagation in a linearly varying thickness guide

PatentInactiveJP2016525686A

Innovation

- A method and apparatus using piezoelectric ultrasonic sensors in a linear array to display ultrasound propagation in dihedral guides through modified discrete Fourier transforms and singular value decomposition, allowing for accurate representation of guided modes in frequency-wavenumber coordinates.

Regulatory Framework for Prosthetic Devices

The regulatory framework for prosthetic devices plays a crucial role in ensuring the safety, efficacy, and quality of biomechanical prosthetics that utilize longitudinal wave technology. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing the development, manufacturing, and marketing of prosthetic devices.

The FDA classifies prosthetic devices into three categories based on their level of risk and intended use. Class I devices are considered low-risk and are subject to general controls. Class II devices, which include most prosthetic limbs, require special controls and premarket notification (510(k)) submission. Class III devices, typically those with the highest risk or novel technologies, require premarket approval (PMA).

For prosthetic devices incorporating longitudinal wave technology, manufacturers must demonstrate compliance with FDA regulations throughout the product lifecycle. This includes adhering to Good Manufacturing Practices (GMP), conducting appropriate clinical trials, and submitting comprehensive documentation on device safety and effectiveness.

In the European Union, prosthetic devices are regulated under the Medical Device Regulation (MDR), which came into effect in May 2021. The MDR introduces stricter requirements for clinical evidence, post-market surveillance, and traceability of medical devices, including prosthetics.

International standards, such as ISO 13485 for quality management systems and ISO 14971 for risk management, provide additional guidance for manufacturers developing prosthetic devices with longitudinal wave technology. These standards help ensure consistency in design, manufacturing, and risk assessment processes across different regulatory jurisdictions.

Regulatory bodies also focus on the cybersecurity aspects of advanced prosthetic devices, particularly those with embedded software or connectivity features. Manufacturers must implement robust security measures to protect against potential vulnerabilities and ensure patient safety.

As research on longitudinal waves in biomechanical prosthetic developments progresses, regulatory frameworks may need to evolve to address new challenges and opportunities. This could include the development of specific guidelines for evaluating the long-term effects of longitudinal wave technology on biological tissues and the establishment of performance standards for prosthetic devices utilizing this technology.

Manufacturers and researchers must maintain open communication channels with regulatory authorities to navigate the complex landscape of prosthetic device regulation. Early engagement with regulators can help identify potential hurdles and streamline the approval process for innovative prosthetic solutions incorporating longitudinal wave technology.

The FDA classifies prosthetic devices into three categories based on their level of risk and intended use. Class I devices are considered low-risk and are subject to general controls. Class II devices, which include most prosthetic limbs, require special controls and premarket notification (510(k)) submission. Class III devices, typically those with the highest risk or novel technologies, require premarket approval (PMA).

For prosthetic devices incorporating longitudinal wave technology, manufacturers must demonstrate compliance with FDA regulations throughout the product lifecycle. This includes adhering to Good Manufacturing Practices (GMP), conducting appropriate clinical trials, and submitting comprehensive documentation on device safety and effectiveness.

In the European Union, prosthetic devices are regulated under the Medical Device Regulation (MDR), which came into effect in May 2021. The MDR introduces stricter requirements for clinical evidence, post-market surveillance, and traceability of medical devices, including prosthetics.

International standards, such as ISO 13485 for quality management systems and ISO 14971 for risk management, provide additional guidance for manufacturers developing prosthetic devices with longitudinal wave technology. These standards help ensure consistency in design, manufacturing, and risk assessment processes across different regulatory jurisdictions.

Regulatory bodies also focus on the cybersecurity aspects of advanced prosthetic devices, particularly those with embedded software or connectivity features. Manufacturers must implement robust security measures to protect against potential vulnerabilities and ensure patient safety.

As research on longitudinal waves in biomechanical prosthetic developments progresses, regulatory frameworks may need to evolve to address new challenges and opportunities. This could include the development of specific guidelines for evaluating the long-term effects of longitudinal wave technology on biological tissues and the establishment of performance standards for prosthetic devices utilizing this technology.

Manufacturers and researchers must maintain open communication channels with regulatory authorities to navigate the complex landscape of prosthetic device regulation. Early engagement with regulators can help identify potential hurdles and streamline the approval process for innovative prosthetic solutions incorporating longitudinal wave technology.

Biomechanical Testing and Validation Methods

Biomechanical testing and validation methods play a crucial role in the development of prosthetic devices that utilize longitudinal waves. These methods ensure the safety, efficacy, and reliability of prosthetic components and systems before they are implemented in clinical settings.

One of the primary testing methods involves the use of mechanical loading systems to simulate the forces and stresses experienced by prosthetic devices during normal use. These systems can apply cyclic loads to mimic the repetitive nature of human movement, allowing researchers to assess the durability and fatigue resistance of prosthetic materials and components.

Finite element analysis (FEA) is another valuable tool in biomechanical testing. This computational method enables researchers to model the behavior of prosthetic devices under various loading conditions, helping to identify potential weak points or areas of high stress concentration. FEA can be particularly useful in optimizing the design of prosthetic components that utilize longitudinal waves for improved functionality.

In vitro testing using tissue phantoms or cadaveric specimens provides valuable insights into the interaction between prosthetic devices and biological tissues. These tests can help evaluate the transmission of longitudinal waves through different tissue types and assess the potential for tissue damage or discomfort.

Motion capture systems and force plates are often employed to analyze the gait and movement patterns of individuals using prosthetic devices. This data can be used to validate the effectiveness of longitudinal wave-based prosthetics in improving mobility and reducing energy expenditure during locomotion.

Electromyography (EMG) is another important tool in biomechanical testing, particularly for assessing the integration of prosthetic devices with the user's neuromuscular system. EMG can provide valuable information on muscle activation patterns and the efficiency of control systems that utilize longitudinal waves for prosthetic movement.

Validation of biomechanical testing results often involves comparison with established standards and benchmarks. This may include adherence to ISO standards for prosthetic devices or comparison with the performance of natural limbs in terms of range of motion, force generation, and energy efficiency.

Clinical trials and user feedback are essential components of the validation process. These studies provide real-world data on the performance, comfort, and user satisfaction of prosthetic devices incorporating longitudinal wave technology. Long-term follow-up studies can help assess the durability and reliability of these devices over extended periods of use.

As research in longitudinal waves for biomechanical prosthetic developments continues to advance, it is likely that new testing and validation methods will emerge. These may include more sophisticated simulation techniques, advanced imaging technologies for real-time assessment of prosthetic performance, and novel sensor systems for continuous monitoring of device function and user interaction.

One of the primary testing methods involves the use of mechanical loading systems to simulate the forces and stresses experienced by prosthetic devices during normal use. These systems can apply cyclic loads to mimic the repetitive nature of human movement, allowing researchers to assess the durability and fatigue resistance of prosthetic materials and components.

Finite element analysis (FEA) is another valuable tool in biomechanical testing. This computational method enables researchers to model the behavior of prosthetic devices under various loading conditions, helping to identify potential weak points or areas of high stress concentration. FEA can be particularly useful in optimizing the design of prosthetic components that utilize longitudinal waves for improved functionality.

In vitro testing using tissue phantoms or cadaveric specimens provides valuable insights into the interaction between prosthetic devices and biological tissues. These tests can help evaluate the transmission of longitudinal waves through different tissue types and assess the potential for tissue damage or discomfort.

Motion capture systems and force plates are often employed to analyze the gait and movement patterns of individuals using prosthetic devices. This data can be used to validate the effectiveness of longitudinal wave-based prosthetics in improving mobility and reducing energy expenditure during locomotion.

Electromyography (EMG) is another important tool in biomechanical testing, particularly for assessing the integration of prosthetic devices with the user's neuromuscular system. EMG can provide valuable information on muscle activation patterns and the efficiency of control systems that utilize longitudinal waves for prosthetic movement.

Validation of biomechanical testing results often involves comparison with established standards and benchmarks. This may include adherence to ISO standards for prosthetic devices or comparison with the performance of natural limbs in terms of range of motion, force generation, and energy efficiency.

Clinical trials and user feedback are essential components of the validation process. These studies provide real-world data on the performance, comfort, and user satisfaction of prosthetic devices incorporating longitudinal wave technology. Long-term follow-up studies can help assess the durability and reliability of these devices over extended periods of use.

As research in longitudinal waves for biomechanical prosthetic developments continues to advance, it is likely that new testing and validation methods will emerge. These may include more sophisticated simulation techniques, advanced imaging technologies for real-time assessment of prosthetic performance, and novel sensor systems for continuous monitoring of device function and user interaction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!