Nichrome Wire and Modern Strategies for Heat Management

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution and Objectives

Nichrome wire, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical heating applications for over a century. Its evolution can be traced back to the early 1900s when Albert Marsh patented the first nichrome alloy. This innovation marked a significant leap in heating technology, offering a material with high electrical resistance and excellent heat tolerance.

The development of nichrome wire has been driven by the increasing demand for efficient and reliable heating elements across various industries. From household appliances to industrial furnaces, the versatility of nichrome wire has made it an indispensable component in thermal management systems. Over the years, researchers and engineers have focused on refining the composition and manufacturing processes of nichrome wire to enhance its performance characteristics.

One of the key objectives in nichrome wire research has been to improve its longevity and stability at high temperatures. This has led to the exploration of various nickel-chromium ratios and the addition of trace elements to optimize the alloy's properties. Another significant goal has been to increase the wire's resistance to oxidation, which is crucial for maintaining its efficiency and lifespan in high-temperature applications.

In recent decades, the focus has shifted towards developing nichrome wire variants that can operate at even higher temperatures while maintaining structural integrity. This pursuit aligns with the broader trend in heat management strategies, which aim to push the boundaries of thermal performance in increasingly compact and energy-efficient systems.

The objectives of modern nichrome wire research extend beyond mere material improvements. There is a growing emphasis on integrating nichrome wire-based heating elements with smart control systems. This integration aims to achieve precise temperature regulation, energy optimization, and predictive maintenance capabilities. Such advancements are particularly relevant in the context of Industry 4.0 and the Internet of Things (IoT), where connected devices and data-driven decision-making are becoming the norm.

Another critical objective in the evolution of nichrome wire technology is sustainability. Researchers are exploring ways to reduce the environmental impact of nichrome wire production and usage. This includes investigating alternative manufacturing methods that consume less energy, as well as developing recycling techniques to recover valuable materials from used nichrome wire components.

As we look to the future, the objectives for nichrome wire research are likely to focus on nano-engineered structures and advanced composite materials. These innovations could potentially lead to heating elements with unprecedented efficiency and responsiveness, opening up new possibilities in thermal management across various applications.

The development of nichrome wire has been driven by the increasing demand for efficient and reliable heating elements across various industries. From household appliances to industrial furnaces, the versatility of nichrome wire has made it an indispensable component in thermal management systems. Over the years, researchers and engineers have focused on refining the composition and manufacturing processes of nichrome wire to enhance its performance characteristics.

One of the key objectives in nichrome wire research has been to improve its longevity and stability at high temperatures. This has led to the exploration of various nickel-chromium ratios and the addition of trace elements to optimize the alloy's properties. Another significant goal has been to increase the wire's resistance to oxidation, which is crucial for maintaining its efficiency and lifespan in high-temperature applications.

In recent decades, the focus has shifted towards developing nichrome wire variants that can operate at even higher temperatures while maintaining structural integrity. This pursuit aligns with the broader trend in heat management strategies, which aim to push the boundaries of thermal performance in increasingly compact and energy-efficient systems.

The objectives of modern nichrome wire research extend beyond mere material improvements. There is a growing emphasis on integrating nichrome wire-based heating elements with smart control systems. This integration aims to achieve precise temperature regulation, energy optimization, and predictive maintenance capabilities. Such advancements are particularly relevant in the context of Industry 4.0 and the Internet of Things (IoT), where connected devices and data-driven decision-making are becoming the norm.

Another critical objective in the evolution of nichrome wire technology is sustainability. Researchers are exploring ways to reduce the environmental impact of nichrome wire production and usage. This includes investigating alternative manufacturing methods that consume less energy, as well as developing recycling techniques to recover valuable materials from used nichrome wire components.

As we look to the future, the objectives for nichrome wire research are likely to focus on nano-engineered structures and advanced composite materials. These innovations could potentially lead to heating elements with unprecedented efficiency and responsiveness, opening up new possibilities in thermal management across various applications.

Heat Management Market Analysis

The heat management market has experienced significant growth in recent years, driven by the increasing demand for efficient thermal solutions across various industries. This market encompasses a wide range of products and technologies, including heat sinks, thermal interface materials, and advanced cooling systems. The global heat management market is expected to continue its upward trajectory, with projections indicating substantial expansion in the coming years.

One of the key factors driving market growth is the rapid advancement of electronic devices and components. As these devices become more powerful and compact, the need for effective heat dissipation becomes crucial. This trend is particularly evident in sectors such as consumer electronics, automotive, and telecommunications, where thermal management plays a critical role in ensuring optimal performance and longevity of products.

The automotive industry has emerged as a major contributor to the heat management market. With the rise of electric vehicles and the integration of advanced electronics in conventional vehicles, the demand for sophisticated thermal management solutions has surged. This includes cooling systems for batteries, power electronics, and electric motors, as well as thermal management for in-vehicle infotainment systems.

In the industrial sector, heat management solutions are gaining traction due to the increasing focus on energy efficiency and sustainability. Industries such as manufacturing, power generation, and aerospace are adopting advanced thermal management technologies to optimize processes, reduce energy consumption, and enhance overall operational efficiency.

The data center industry represents another significant market for heat management solutions. As the demand for cloud computing and data storage continues to grow, data centers face increasing challenges in managing heat generated by servers and other equipment. This has led to the development of innovative cooling technologies, including liquid cooling systems and advanced air management solutions.

Geographically, North America and Asia-Pacific are the leading regions in the heat management market. North America's dominance can be attributed to the presence of major technology companies and the early adoption of advanced thermal management solutions. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is experiencing rapid growth due to the expanding electronics manufacturing sector and increasing investments in infrastructure development.

The competitive landscape of the heat management market is characterized by the presence of both established players and innovative startups. Key market players are focusing on research and development to introduce novel materials and technologies that offer superior thermal performance. Additionally, strategic partnerships and collaborations are becoming increasingly common as companies seek to expand their product portfolios and market reach.

One of the key factors driving market growth is the rapid advancement of electronic devices and components. As these devices become more powerful and compact, the need for effective heat dissipation becomes crucial. This trend is particularly evident in sectors such as consumer electronics, automotive, and telecommunications, where thermal management plays a critical role in ensuring optimal performance and longevity of products.

The automotive industry has emerged as a major contributor to the heat management market. With the rise of electric vehicles and the integration of advanced electronics in conventional vehicles, the demand for sophisticated thermal management solutions has surged. This includes cooling systems for batteries, power electronics, and electric motors, as well as thermal management for in-vehicle infotainment systems.

In the industrial sector, heat management solutions are gaining traction due to the increasing focus on energy efficiency and sustainability. Industries such as manufacturing, power generation, and aerospace are adopting advanced thermal management technologies to optimize processes, reduce energy consumption, and enhance overall operational efficiency.

The data center industry represents another significant market for heat management solutions. As the demand for cloud computing and data storage continues to grow, data centers face increasing challenges in managing heat generated by servers and other equipment. This has led to the development of innovative cooling technologies, including liquid cooling systems and advanced air management solutions.

Geographically, North America and Asia-Pacific are the leading regions in the heat management market. North America's dominance can be attributed to the presence of major technology companies and the early adoption of advanced thermal management solutions. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is experiencing rapid growth due to the expanding electronics manufacturing sector and increasing investments in infrastructure development.

The competitive landscape of the heat management market is characterized by the presence of both established players and innovative startups. Key market players are focusing on research and development to introduce novel materials and technologies that offer superior thermal performance. Additionally, strategic partnerships and collaborations are becoming increasingly common as companies seek to expand their product portfolios and market reach.

Nichrome Wire Challenges

Nichrome wire, a widely used resistance alloy in heating applications, faces several challenges in modern heat management strategies. One of the primary issues is the wire's tendency to oxidize at high temperatures, which can lead to reduced performance and shortened lifespan. This oxidation process accelerates as temperatures increase, making it particularly problematic in high-heat applications.

Another significant challenge is the wire's limited maximum operating temperature. While nichrome can withstand temperatures up to 1200°C, many industrial and technological applications require even higher heat resistance. This limitation restricts its use in extreme temperature environments and necessitates the exploration of alternative materials or protective coatings.

The thermal expansion of nichrome wire also presents difficulties in precise heat control applications. As the wire heats up, it expands, potentially causing deformation or misalignment in tightly designed systems. This expansion can lead to inconsistent heating patterns and reduced efficiency in heat distribution.

Durability under repeated thermal cycling is another concern. Nichrome wire can become brittle over time when subjected to frequent heating and cooling cycles, increasing the risk of wire breakage and system failure. This issue is particularly relevant in applications that require rapid temperature changes or frequent on-off cycles.

The relatively high electrical resistance of nichrome wire, while beneficial for heat generation, can be a drawback in terms of energy efficiency. In large-scale heating systems or applications requiring precise temperature control, the power consumption of nichrome-based heating elements can be substantial, leading to increased operational costs.

Furthermore, the uniform heat distribution along the length of nichrome wire can be challenging to achieve, especially in complex geometries or when specific heating patterns are required. This limitation can result in hotspots or uneven heating, which is problematic in applications demanding precise temperature control across surfaces or volumes.

Lastly, the environmental impact of nichrome wire production and disposal is becoming an increasing concern. The mining and processing of nickel and chromium, the primary components of nichrome, have significant environmental footprints. Additionally, the disposal of used nichrome wire can pose challenges due to the potential leaching of heavy metals into the environment.

Another significant challenge is the wire's limited maximum operating temperature. While nichrome can withstand temperatures up to 1200°C, many industrial and technological applications require even higher heat resistance. This limitation restricts its use in extreme temperature environments and necessitates the exploration of alternative materials or protective coatings.

The thermal expansion of nichrome wire also presents difficulties in precise heat control applications. As the wire heats up, it expands, potentially causing deformation or misalignment in tightly designed systems. This expansion can lead to inconsistent heating patterns and reduced efficiency in heat distribution.

Durability under repeated thermal cycling is another concern. Nichrome wire can become brittle over time when subjected to frequent heating and cooling cycles, increasing the risk of wire breakage and system failure. This issue is particularly relevant in applications that require rapid temperature changes or frequent on-off cycles.

The relatively high electrical resistance of nichrome wire, while beneficial for heat generation, can be a drawback in terms of energy efficiency. In large-scale heating systems or applications requiring precise temperature control, the power consumption of nichrome-based heating elements can be substantial, leading to increased operational costs.

Furthermore, the uniform heat distribution along the length of nichrome wire can be challenging to achieve, especially in complex geometries or when specific heating patterns are required. This limitation can result in hotspots or uneven heating, which is problematic in applications demanding precise temperature control across surfaces or volumes.

Lastly, the environmental impact of nichrome wire production and disposal is becoming an increasing concern. The mining and processing of nickel and chromium, the primary components of nichrome, have significant environmental footprints. Additionally, the disposal of used nichrome wire can pose challenges due to the potential leaching of heavy metals into the environment.

Current Nichrome Solutions

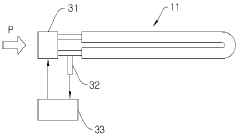

01 Temperature control in nichrome wire heating systems

Nichrome wire heating systems often incorporate temperature control mechanisms to manage heat output effectively. These systems may include sensors, thermostats, or microcontrollers to monitor and adjust the temperature, ensuring precise and efficient heating. Advanced control systems can provide variable heat settings and maintain consistent temperatures for various applications.- Nichrome wire heating element design: Nichrome wire is commonly used as a heating element in various applications due to its high resistance and heat-generating properties. The design of nichrome wire heating elements involves considerations such as wire gauge, coil shape, and spacing to achieve optimal heat distribution and efficiency.

- Temperature control systems for nichrome wire: Effective heat management of nichrome wire involves implementing temperature control systems. These systems may include thermocouples, temperature sensors, and feedback mechanisms to regulate the current flow and maintain desired temperatures, ensuring safe and efficient operation of the heating element.

- Insulation and heat dissipation techniques: Proper insulation and heat dissipation are crucial for managing nichrome wire heat. This includes using heat-resistant materials for insulation, implementing cooling mechanisms, and designing structures that facilitate efficient heat transfer or containment, depending on the application requirements.

- Nichrome wire configuration for specific applications: The configuration of nichrome wire can be optimized for specific applications such as household appliances, industrial equipment, or specialized heating systems. This involves adjusting factors like wire length, diameter, and arrangement to achieve the desired heating characteristics and power output.

- Power supply and current regulation for nichrome wire: Effective heat management of nichrome wire requires careful consideration of power supply and current regulation. This includes implementing voltage controllers, current limiters, and power management systems to ensure consistent and controlled heating while preventing overheating or burnout of the wire.

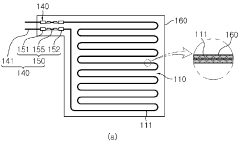

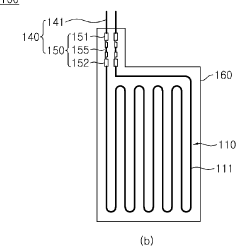

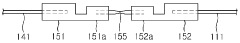

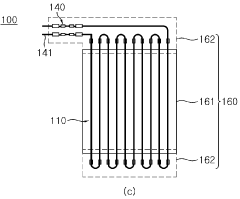

02 Nichrome wire configuration for optimal heat distribution

The arrangement and configuration of nichrome wire in heating devices play a crucial role in heat management. Various designs, such as coiled or serpentine patterns, are used to maximize heat distribution and efficiency. The spacing, thickness, and length of the wire are carefully calculated to achieve the desired heating characteristics and ensure even heat distribution across the target area.Expand Specific Solutions03 Insulation and safety features in nichrome wire heaters

Proper insulation and safety features are essential in nichrome wire heat management. This includes the use of heat-resistant materials to prevent overheating and electrical insulation to ensure safe operation. Safety mechanisms such as thermal fuses, circuit breakers, or automatic shut-off systems are often incorporated to prevent accidents and protect the device from damage due to overheating or electrical faults.Expand Specific Solutions04 Power supply and current regulation for nichrome wire

Effective heat management in nichrome wire systems involves careful control of power supply and current regulation. This may include the use of voltage regulators, current limiters, or pulse-width modulation (PWM) techniques to adjust the power input and consequently the heat output. Proper power management ensures efficient operation, prevents overheating, and extends the lifespan of the heating element.Expand Specific Solutions05 Application-specific nichrome wire heat management

Nichrome wire heat management techniques are often tailored to specific applications. This may involve customized wire gauges, alloy compositions, or heating element designs to meet the requirements of different industries or products. For instance, automotive applications might require rapid heating and cooling cycles, while industrial processes may need sustained high temperatures. The heat management approach is adapted to suit the specific needs of each application.Expand Specific Solutions

Key Heat Management Players

The research on Nichrome Wire and Modern Strategies for Heat Management is in a mature stage, with a growing market driven by increasing demand for efficient heating solutions across various industries. The global market size for nichrome wire and related heat management technologies is estimated to be substantial, with steady growth projected in the coming years. Technologically, the field is well-established, with ongoing innovations focused on improving efficiency and durability. Key players like Xi'an Thermal Power Research Institute Co., Ltd., China Huaneng Group Co., Ltd., and Vishay Electronic GmbH are at the forefront, continuously developing advanced materials and heat management strategies. Universities such as Kyoto University and the University of Science & Technology Beijing are contributing significantly to research and development in this area, pushing the boundaries of heat management technologies.

Vishay Electronic GmbH

Technical Solution: Vishay Electronic GmbH has developed advanced nichrome wire solutions for precision resistors and heating elements. Their technology focuses on improving the stability and reliability of nichrome wire under high-temperature conditions. They have implemented a proprietary coating process that enhances the wire's oxidation resistance, extending its lifespan in extreme environments[1]. Additionally, Vishay has introduced a micro-alloy technology that fine-tunes the nichrome composition, optimizing its electrical and thermal properties for specific applications[2]. Their heat management strategy includes the development of multi-layer insulation techniques that allow for better heat distribution and reduced thermal gradients across the wire surface[3].

Strengths: High precision and stability in extreme conditions, extended lifespan due to oxidation resistance, customizable properties for specific applications. Weaknesses: Potentially higher cost due to specialized manufacturing processes, may require specific handling and installation procedures.

Kyoto University

Technical Solution: Kyoto University has conducted extensive research on nichrome wire and modern heat management strategies, focusing on fundamental material science and advanced applications. Their team has developed a novel nanocomposite nichrome material that exhibits enhanced thermal stability and electrical conductivity[1]. This breakthrough allows for higher operating temperatures and improved energy efficiency in various heating applications. The university has also pioneered a unique surface modification technique that significantly reduces oxidation and extends the lifespan of nichrome wires in harsh environments[2]. In terms of heat management, Kyoto University researchers have designed an innovative microfluidic cooling system that can be integrated with nichrome heating elements, allowing for precise temperature control and rapid heat dissipation[3]. This technology has potential applications in microelectronics and advanced manufacturing processes. Additionally, they have explored the use of machine learning algorithms to optimize heat distribution and power consumption in complex nichrome wire-based systems[4].

Strengths: Cutting-edge material science research, innovative cooling technologies, potential for cross-industry applications. Weaknesses: Some technologies may still be in experimental stages, potential challenges in scaling up for industrial production.

Nichrome Innovations

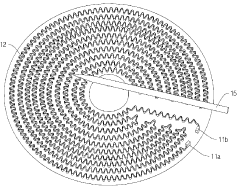

Heating apparatus having structure of nichrome strip

PatentInactiveKR1020150058831A

Innovation

- A heater device with a nichrome strip structure that extends in a screw or zigzag form, varying in thickness and length to optimize resistance and heat generation, incorporating a detection sensor and control unit for voltage regulation to enhance efficiency.

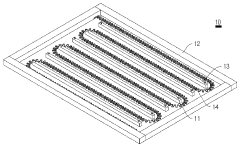

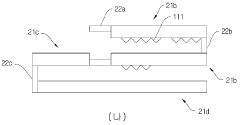

Heating device and liquid heating device comprising same

PatentWO2012134242A2

Innovation

- A heating device featuring a carbon fiber heating element shaped in columns or rows, covered with fluororesin (Teflon) for insulation, which prevents oxidation and volatilization, and includes a terminal unit connected via a bare copper wire with a fuse or bimetal cut-off mechanism for safe power connection, ensuring stable insulation even in contact with liquids.

Thermal Efficiency Standards

Thermal efficiency standards play a crucial role in the development and implementation of heat management strategies, particularly in the context of nichrome wire applications. These standards serve as benchmarks for evaluating the performance of heating systems and guide manufacturers in designing more energy-efficient products.

In recent years, there has been a significant push towards stricter thermal efficiency standards across various industries. This trend is driven by the growing awareness of energy conservation and the need to reduce carbon emissions. For nichrome wire applications, these standards typically focus on factors such as heat output, power consumption, and overall system efficiency.

One of the key aspects of thermal efficiency standards for nichrome wire-based heating systems is the measurement of heat transfer efficiency. This involves assessing the ratio of useful heat output to the total energy input. Advanced testing methodologies have been developed to accurately measure and quantify this efficiency, taking into account factors such as heat distribution, thermal losses, and response time.

The implementation of these standards has led to innovations in nichrome wire design and manufacturing processes. Manufacturers are now focusing on developing alloys with improved electrical resistivity and thermal conductivity properties. These advancements allow for more precise control over heat generation and distribution, resulting in higher overall system efficiency.

Furthermore, thermal efficiency standards have prompted the integration of smart control systems in nichrome wire applications. These systems utilize advanced sensors and algorithms to optimize heat output based on real-time environmental conditions and user requirements. This dynamic approach to heat management significantly reduces energy waste and improves overall system performance.

Another important aspect of thermal efficiency standards is the consideration of insulation and heat retention. Modern standards emphasize the importance of minimizing heat loss through proper insulation techniques and materials. This has led to the development of advanced insulation solutions specifically designed for high-temperature applications involving nichrome wire.

The impact of these standards extends beyond individual product performance. They also influence the broader energy consumption patterns in industries relying on nichrome wire heating systems. By promoting more efficient technologies, these standards contribute to reducing overall energy demand and associated environmental impacts.

As thermal efficiency standards continue to evolve, they are expected to drive further innovations in nichrome wire technology and heat management strategies. Future standards may incorporate more comprehensive lifecycle assessments, considering factors such as material sourcing, manufacturing processes, and end-of-life recycling. This holistic approach will ensure that thermal efficiency is optimized not just during operation, but throughout the entire product lifecycle.

In recent years, there has been a significant push towards stricter thermal efficiency standards across various industries. This trend is driven by the growing awareness of energy conservation and the need to reduce carbon emissions. For nichrome wire applications, these standards typically focus on factors such as heat output, power consumption, and overall system efficiency.

One of the key aspects of thermal efficiency standards for nichrome wire-based heating systems is the measurement of heat transfer efficiency. This involves assessing the ratio of useful heat output to the total energy input. Advanced testing methodologies have been developed to accurately measure and quantify this efficiency, taking into account factors such as heat distribution, thermal losses, and response time.

The implementation of these standards has led to innovations in nichrome wire design and manufacturing processes. Manufacturers are now focusing on developing alloys with improved electrical resistivity and thermal conductivity properties. These advancements allow for more precise control over heat generation and distribution, resulting in higher overall system efficiency.

Furthermore, thermal efficiency standards have prompted the integration of smart control systems in nichrome wire applications. These systems utilize advanced sensors and algorithms to optimize heat output based on real-time environmental conditions and user requirements. This dynamic approach to heat management significantly reduces energy waste and improves overall system performance.

Another important aspect of thermal efficiency standards is the consideration of insulation and heat retention. Modern standards emphasize the importance of minimizing heat loss through proper insulation techniques and materials. This has led to the development of advanced insulation solutions specifically designed for high-temperature applications involving nichrome wire.

The impact of these standards extends beyond individual product performance. They also influence the broader energy consumption patterns in industries relying on nichrome wire heating systems. By promoting more efficient technologies, these standards contribute to reducing overall energy demand and associated environmental impacts.

As thermal efficiency standards continue to evolve, they are expected to drive further innovations in nichrome wire technology and heat management strategies. Future standards may incorporate more comprehensive lifecycle assessments, considering factors such as material sourcing, manufacturing processes, and end-of-life recycling. This holistic approach will ensure that thermal efficiency is optimized not just during operation, but throughout the entire product lifecycle.

Environmental Impact Assessment

The environmental impact of nichrome wire and modern heat management strategies is a critical consideration in the context of sustainable technology development. Nichrome wire, primarily composed of nickel and chromium, has been widely used in heating elements due to its high electrical resistance and durability. However, its production and disposal pose significant environmental challenges.

The mining and refining processes for nickel and chromium contribute to air and water pollution, as well as habitat destruction. These activities release greenhouse gases and toxic substances, impacting local ecosystems and contributing to global climate change. Furthermore, the energy-intensive manufacturing of nichrome wire results in a substantial carbon footprint, raising concerns about its long-term sustainability.

In terms of usage, nichrome wire-based heating systems often consume significant amounts of electricity, leading to increased energy demand and associated environmental impacts. This has prompted research into more energy-efficient alternatives and improved heat management strategies. Modern approaches focus on minimizing heat loss, optimizing thermal distribution, and incorporating smart control systems to reduce overall energy consumption.

The disposal of nichrome wire presents another environmental challenge. While the material is recyclable, the process is complex and energy-intensive. Improper disposal can lead to soil and water contamination, as nickel and chromium compounds can leach into the environment, potentially harming ecosystems and human health.

Recent advancements in heat management strategies have aimed to address these environmental concerns. The development of more efficient heating elements, such as ceramic-based alternatives, offers reduced energy consumption and lower environmental impact. Additionally, the integration of renewable energy sources with heating systems helps mitigate the carbon footprint associated with their operation.

Innovations in thermal insulation and heat recovery systems have also contributed to reducing the environmental impact of heat management. These technologies minimize heat loss and maximize energy utilization, thereby decreasing the overall energy demand and associated emissions. Furthermore, the adoption of smart heating systems and IoT-enabled devices allows for precise control and optimization of heat distribution, further enhancing energy efficiency.

The shift towards circular economy principles in heat management technology is gaining momentum. This approach emphasizes the design of products for easy disassembly, repair, and recycling, reducing waste and resource consumption. Manufacturers are increasingly focusing on developing heating solutions with longer lifespans and using materials that are more readily recyclable or biodegradable.

The mining and refining processes for nickel and chromium contribute to air and water pollution, as well as habitat destruction. These activities release greenhouse gases and toxic substances, impacting local ecosystems and contributing to global climate change. Furthermore, the energy-intensive manufacturing of nichrome wire results in a substantial carbon footprint, raising concerns about its long-term sustainability.

In terms of usage, nichrome wire-based heating systems often consume significant amounts of electricity, leading to increased energy demand and associated environmental impacts. This has prompted research into more energy-efficient alternatives and improved heat management strategies. Modern approaches focus on minimizing heat loss, optimizing thermal distribution, and incorporating smart control systems to reduce overall energy consumption.

The disposal of nichrome wire presents another environmental challenge. While the material is recyclable, the process is complex and energy-intensive. Improper disposal can lead to soil and water contamination, as nickel and chromium compounds can leach into the environment, potentially harming ecosystems and human health.

Recent advancements in heat management strategies have aimed to address these environmental concerns. The development of more efficient heating elements, such as ceramic-based alternatives, offers reduced energy consumption and lower environmental impact. Additionally, the integration of renewable energy sources with heating systems helps mitigate the carbon footprint associated with their operation.

Innovations in thermal insulation and heat recovery systems have also contributed to reducing the environmental impact of heat management. These technologies minimize heat loss and maximize energy utilization, thereby decreasing the overall energy demand and associated emissions. Furthermore, the adoption of smart heating systems and IoT-enabled devices allows for precise control and optimization of heat distribution, further enhancing energy efficiency.

The shift towards circular economy principles in heat management technology is gaining momentum. This approach emphasizes the design of products for easy disassembly, repair, and recycling, reducing waste and resource consumption. Manufacturers are increasingly focusing on developing heating solutions with longer lifespans and using materials that are more readily recyclable or biodegradable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!