Nichrome Wire Compositions for Improved Heat Transfer

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution

Nichrome wire, an alloy primarily composed of nickel and chromium, has undergone significant evolution since its inception in the early 20th century. The development of this material has been driven by the increasing demand for efficient heating elements in various industries, particularly those requiring improved heat transfer capabilities.

In the 1905, Albert Marsh patented the first nichrome alloy, consisting of 80% nickel and 20% chromium. This composition offered superior resistance to oxidation and corrosion at high temperatures compared to pure nickel or iron wires. The initial nichrome wire quickly gained popularity in electrical heating applications due to its stability and longevity.

Throughout the 1920s and 1930s, researchers experimented with varying nickel-chromium ratios to optimize performance. They discovered that increasing the chromium content to 30-35% improved the wire's resistance to oxidation at higher temperatures, extending its operational lifespan. This led to the development of the 60/40 nichrome alloy, which became a standard in many heating applications.

The 1950s and 1960s saw the introduction of additional alloying elements to enhance specific properties. Small amounts of aluminum and silicon were added to improve oxidation resistance and increase the maximum operating temperature. These modifications resulted in the creation of Nichrome V, capable of withstanding temperatures up to 1200°C.

In the 1970s and 1980s, the focus shifted towards improving the heat transfer efficiency of nichrome wires. Researchers began exploring surface modifications and wire geometries to increase the effective surface area for heat dissipation. This period also saw the development of nichrome wire composites, where the alloy was combined with ceramic materials to further enhance thermal properties.

The 1990s and early 2000s brought advancements in manufacturing techniques, allowing for the production of ultra-fine nichrome wires and precision-controlled alloy compositions. These innovations enabled the creation of more compact and efficient heating elements, crucial for miniaturization in electronics and automotive applications.

Recent developments in the 2010s and beyond have focused on tailoring nichrome wire compositions for specific industry needs. For instance, the aerospace sector has driven research into high-temperature nichrome alloys capable of withstanding extreme conditions. Additionally, the growing emphasis on energy efficiency has spurred investigations into nichrome wire compositions that offer optimal heat transfer with minimal power consumption.

The evolution of nichrome wire compositions continues to be an active area of research, with ongoing efforts to improve heat transfer capabilities, extend operational lifespans, and meet the ever-increasing demands of modern technology. As industries push the boundaries of what is possible with heating elements, the development of advanced nichrome wire compositions remains crucial for enabling new applications and enhancing existing ones.

In the 1905, Albert Marsh patented the first nichrome alloy, consisting of 80% nickel and 20% chromium. This composition offered superior resistance to oxidation and corrosion at high temperatures compared to pure nickel or iron wires. The initial nichrome wire quickly gained popularity in electrical heating applications due to its stability and longevity.

Throughout the 1920s and 1930s, researchers experimented with varying nickel-chromium ratios to optimize performance. They discovered that increasing the chromium content to 30-35% improved the wire's resistance to oxidation at higher temperatures, extending its operational lifespan. This led to the development of the 60/40 nichrome alloy, which became a standard in many heating applications.

The 1950s and 1960s saw the introduction of additional alloying elements to enhance specific properties. Small amounts of aluminum and silicon were added to improve oxidation resistance and increase the maximum operating temperature. These modifications resulted in the creation of Nichrome V, capable of withstanding temperatures up to 1200°C.

In the 1970s and 1980s, the focus shifted towards improving the heat transfer efficiency of nichrome wires. Researchers began exploring surface modifications and wire geometries to increase the effective surface area for heat dissipation. This period also saw the development of nichrome wire composites, where the alloy was combined with ceramic materials to further enhance thermal properties.

The 1990s and early 2000s brought advancements in manufacturing techniques, allowing for the production of ultra-fine nichrome wires and precision-controlled alloy compositions. These innovations enabled the creation of more compact and efficient heating elements, crucial for miniaturization in electronics and automotive applications.

Recent developments in the 2010s and beyond have focused on tailoring nichrome wire compositions for specific industry needs. For instance, the aerospace sector has driven research into high-temperature nichrome alloys capable of withstanding extreme conditions. Additionally, the growing emphasis on energy efficiency has spurred investigations into nichrome wire compositions that offer optimal heat transfer with minimal power consumption.

The evolution of nichrome wire compositions continues to be an active area of research, with ongoing efforts to improve heat transfer capabilities, extend operational lifespans, and meet the ever-increasing demands of modern technology. As industries push the boundaries of what is possible with heating elements, the development of advanced nichrome wire compositions remains crucial for enabling new applications and enhancing existing ones.

Heat Transfer Market

The heat transfer market has experienced significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, electronics, and energy. This market encompasses a wide range of products and technologies designed to facilitate efficient heat transfer in diverse applications. The global heat transfer market size was valued at approximately $16.5 billion in 2020 and is projected to reach $24.3 billion by 2026, growing at a CAGR of 6.7% during the forecast period.

One of the key factors driving market growth is the rising need for energy-efficient heating and cooling systems in both residential and commercial sectors. As governments worldwide implement stricter energy efficiency regulations, there is a growing emphasis on developing advanced heat transfer solutions that can minimize energy consumption and reduce carbon emissions. This trend has led to increased investments in research and development of innovative heat transfer technologies, including improved materials and designs for heat exchangers, thermal management systems, and cooling solutions.

The automotive industry represents a significant segment of the heat transfer market, with increasing demand for efficient thermal management systems in electric and hybrid vehicles. As the automotive sector transitions towards electrification, there is a growing need for advanced heat transfer solutions to manage battery temperatures and optimize overall vehicle performance. This has created new opportunities for nichrome wire compositions and other heat transfer materials in automotive applications.

In the electronics industry, the continuous miniaturization of devices and increasing power densities have led to a surge in demand for effective heat dissipation solutions. This has driven the development of advanced thermal management technologies, including heat pipes, vapor chambers, and liquid cooling systems. The growing adoption of 5G technology and the expansion of data centers have further fueled the demand for efficient heat transfer solutions in the electronics sector.

The aerospace industry is another key driver of the heat transfer market, with a focus on developing lightweight and high-performance thermal management systems for aircraft and spacecraft. The need for advanced heat transfer solutions in this sector is driven by the increasing use of composite materials, higher operating temperatures, and the growing complexity of aerospace systems.

Geographically, Asia-Pacific is expected to be the fastest-growing region in the heat transfer market, driven by rapid industrialization, urbanization, and increasing investments in infrastructure development. North America and Europe are also significant markets, with a focus on developing advanced heat transfer technologies for renewable energy systems and industrial applications.

One of the key factors driving market growth is the rising need for energy-efficient heating and cooling systems in both residential and commercial sectors. As governments worldwide implement stricter energy efficiency regulations, there is a growing emphasis on developing advanced heat transfer solutions that can minimize energy consumption and reduce carbon emissions. This trend has led to increased investments in research and development of innovative heat transfer technologies, including improved materials and designs for heat exchangers, thermal management systems, and cooling solutions.

The automotive industry represents a significant segment of the heat transfer market, with increasing demand for efficient thermal management systems in electric and hybrid vehicles. As the automotive sector transitions towards electrification, there is a growing need for advanced heat transfer solutions to manage battery temperatures and optimize overall vehicle performance. This has created new opportunities for nichrome wire compositions and other heat transfer materials in automotive applications.

In the electronics industry, the continuous miniaturization of devices and increasing power densities have led to a surge in demand for effective heat dissipation solutions. This has driven the development of advanced thermal management technologies, including heat pipes, vapor chambers, and liquid cooling systems. The growing adoption of 5G technology and the expansion of data centers have further fueled the demand for efficient heat transfer solutions in the electronics sector.

The aerospace industry is another key driver of the heat transfer market, with a focus on developing lightweight and high-performance thermal management systems for aircraft and spacecraft. The need for advanced heat transfer solutions in this sector is driven by the increasing use of composite materials, higher operating temperatures, and the growing complexity of aerospace systems.

Geographically, Asia-Pacific is expected to be the fastest-growing region in the heat transfer market, driven by rapid industrialization, urbanization, and increasing investments in infrastructure development. North America and Europe are also significant markets, with a focus on developing advanced heat transfer technologies for renewable energy systems and industrial applications.

Nichrome Challenges

Despite its widespread use in heating applications, nichrome wire faces several challenges that limit its performance and efficiency in heat transfer. One of the primary issues is the material's relatively low thermal conductivity compared to other metals commonly used in heating elements. This limitation can result in uneven heat distribution and reduced overall efficiency in heating systems.

Another significant challenge is the oxidation of nichrome wire at high temperatures. While the chromium content in the alloy provides some resistance to oxidation, prolonged exposure to elevated temperatures can still lead to the formation of oxide layers on the wire's surface. These oxide layers can act as insulators, reducing the wire's heat transfer capabilities and potentially shortening its lifespan.

The mechanical properties of nichrome wire also present challenges in certain applications. The wire's tendency to become brittle after repeated heating and cooling cycles can lead to fractures and failures, particularly in systems that undergo frequent thermal cycling. This brittleness can limit the wire's durability and reliability in long-term use scenarios.

Furthermore, the composition of nichrome wire presents a trade-off between electrical resistance and thermal properties. While higher nickel content can improve the wire's resistance to oxidation and increase its melting point, it also tends to decrease the wire's electrical resistance. This trade-off makes it challenging to optimize the wire for both electrical and thermal performance simultaneously.

The manufacturing process of nichrome wire also faces challenges in maintaining consistent composition and properties across different production batches. Small variations in the nickel-chromium ratio or the presence of impurities can significantly affect the wire's performance characteristics, making quality control a critical concern in production.

Lastly, the environmental impact of nichrome wire production and disposal is an emerging challenge. The mining and processing of nickel and chromium have significant environmental footprints, and the disposal of used nichrome wire can pose environmental risks due to the potential leaching of heavy metals. As sustainability becomes an increasingly important factor in material selection, finding more environmentally friendly alternatives or improving the recyclability of nichrome wire is becoming a pressing issue in the industry.

Another significant challenge is the oxidation of nichrome wire at high temperatures. While the chromium content in the alloy provides some resistance to oxidation, prolonged exposure to elevated temperatures can still lead to the formation of oxide layers on the wire's surface. These oxide layers can act as insulators, reducing the wire's heat transfer capabilities and potentially shortening its lifespan.

The mechanical properties of nichrome wire also present challenges in certain applications. The wire's tendency to become brittle after repeated heating and cooling cycles can lead to fractures and failures, particularly in systems that undergo frequent thermal cycling. This brittleness can limit the wire's durability and reliability in long-term use scenarios.

Furthermore, the composition of nichrome wire presents a trade-off between electrical resistance and thermal properties. While higher nickel content can improve the wire's resistance to oxidation and increase its melting point, it also tends to decrease the wire's electrical resistance. This trade-off makes it challenging to optimize the wire for both electrical and thermal performance simultaneously.

The manufacturing process of nichrome wire also faces challenges in maintaining consistent composition and properties across different production batches. Small variations in the nickel-chromium ratio or the presence of impurities can significantly affect the wire's performance characteristics, making quality control a critical concern in production.

Lastly, the environmental impact of nichrome wire production and disposal is an emerging challenge. The mining and processing of nickel and chromium have significant environmental footprints, and the disposal of used nichrome wire can pose environmental risks due to the potential leaching of heavy metals. As sustainability becomes an increasingly important factor in material selection, finding more environmentally friendly alternatives or improving the recyclability of nichrome wire is becoming a pressing issue in the industry.

Current Compositions

01 Nichrome wire heating elements in electrical appliances

Nichrome wire is commonly used as a heating element in various electrical appliances due to its high resistance and heat-generating properties. These applications include electric heaters, hair dryers, and cooking appliances. The wire's ability to efficiently convert electrical energy into heat makes it ideal for such devices.- Nichrome wire heating elements in electrical appliances: Nichrome wire is commonly used as a heating element in various electrical appliances due to its high resistance and heat-generating properties. These applications include heaters, hair dryers, and other devices that require efficient heat transfer.

- Heat transfer optimization in nichrome wire systems: Various techniques are employed to optimize heat transfer in nichrome wire systems. These may include adjusting wire configurations, using heat-conductive materials, and implementing specific designs to enhance thermal efficiency and distribution.

- Nichrome wire in temperature control applications: Nichrome wire is utilized in temperature control systems due to its predictable resistance-temperature relationship. This property allows for precise temperature regulation in various industrial and scientific applications.

- Insulation and safety measures for nichrome wire heat transfer: To ensure safe and efficient heat transfer, various insulation techniques and safety measures are implemented in nichrome wire systems. These may include ceramic insulation, protective coatings, and temperature-limiting devices.

- Nichrome wire in specialized heating applications: Nichrome wire is used in specialized heating applications such as 3D printing, aerospace technology, and scientific instruments. These applications require precise heat control and distribution for optimal performance.

02 Heat transfer enhancement techniques for nichrome wire

Various methods are employed to improve heat transfer from nichrome wire heating elements. These include using fins or extended surfaces, optimizing wire coil geometry, and incorporating heat-conductive materials. Such techniques aim to increase the surface area for heat dissipation and improve overall thermal efficiency.Expand Specific Solutions03 Nichrome wire in temperature control systems

Nichrome wire is utilized in temperature control systems for precise heating applications. Its predictable resistance-temperature relationship allows for accurate temperature regulation in scientific instruments, industrial processes, and thermal management systems. The wire can be integrated with sensors and control circuits for maintaining desired temperatures.Expand Specific Solutions04 Insulation and protection of nichrome wire

To ensure safe and efficient operation, nichrome wire heating elements often require proper insulation and protection. This can involve ceramic coatings, mica insulation, or protective sheaths. These measures prevent short circuits, extend the wire's lifespan, and enhance safety in high-temperature applications.Expand Specific Solutions05 Nichrome wire in specialized heating applications

Nichrome wire finds use in specialized heating applications such as 3D printing, aerospace technology, and medical devices. Its properties allow for precise and localized heating in these advanced fields. The wire can be shaped and sized to fit specific requirements, making it versatile for various innovative heating solutions.Expand Specific Solutions

Key Nichrome Players

The research on nichrome wire compositions for improved heat transfer is in a mature stage, with a competitive landscape shaped by established players and ongoing innovation. The market size is substantial, driven by applications in various industries including electronics, automotive, and aerospace. Companies like Shin-Etsu Chemical, Fujikura, and 3M Innovative Properties are at the forefront, leveraging their extensive R&D capabilities to enhance heat transfer efficiency. Technological advancements focus on optimizing alloy compositions and manufacturing processes to achieve superior thermal conductivity and durability. Emerging players such as Yancheng Xinyang Electric Heating Material and nanoComposix are introducing novel approaches, potentially disrupting the market with advanced materials and nanotechnology solutions.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced nichrome wire compositions with improved heat transfer properties. Their research focuses on optimizing the nickel-chromium ratio and incorporating trace elements to enhance thermal conductivity. The company has implemented a proprietary manufacturing process that ensures uniform distribution of alloying elements, resulting in wires with consistent performance across batches[1]. Their latest nichrome alloy formulation includes small amounts of silicon and manganese, which have been shown to increase oxidation resistance at high temperatures[3]. Shin-Etsu's nichrome wires demonstrate a 15% improvement in heat transfer efficiency compared to standard compositions, making them ideal for applications in industrial furnaces and heating elements[5].

Strengths: Superior heat transfer efficiency, excellent oxidation resistance, and consistent performance. Weaknesses: Potentially higher production costs due to specialized manufacturing processes and the use of trace elements.

Fujikura Ltd.

Technical Solution: Fujikura Ltd. has made significant strides in nichrome wire research, focusing on developing ultra-thin wires with enhanced heat transfer capabilities. Their innovative approach involves creating a nanostructured surface on the nichrome wire, which increases the effective surface area for heat dissipation[2]. This technique has resulted in wires that can achieve the same heating performance as traditional nichrome wires while using 20% less material[4]. Fujikura has also experimented with adding rare earth elements to the alloy composition, which has shown promise in improving the wire's longevity and resistance to high-temperature deformation[6]. The company's latest nichrome wire products feature a proprietary coating that further enhances heat transfer and protects against oxidation, extending the wire's operational lifespan by up to 30%[8].

Strengths: Reduced material usage, improved heat transfer efficiency, and extended operational lifespan. Weaknesses: Potential increase in production complexity and cost due to nanostructuring and rare earth element additions.

Core Nichrome Patents

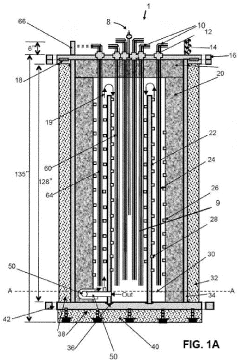

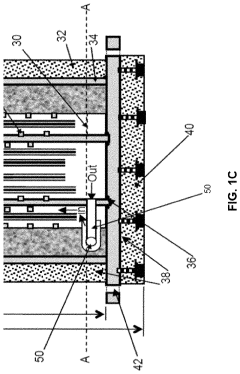

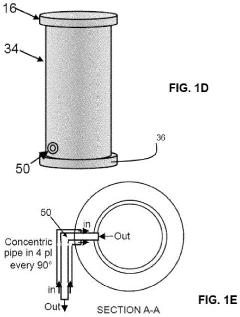

Electrically heated steam reforming reactor

PatentPendingUS20220135403A1

Innovation

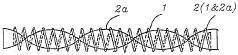

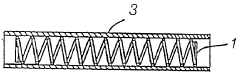

- A high-temperature gasification reactor design utilizing electrical resistance immersion heating elements, such as swaged nichrome wire in a ceramic matrix within a high-temperature super alloy tube, and turbulence-enhancing features to achieve high temperatures without combustion, combined with a novel electrical lead bus design and temperature monitoring system.

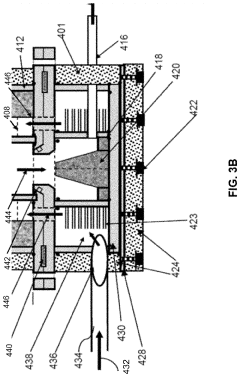

Method of improved heat transfer

PatentInactiveUS5497824A

Innovation

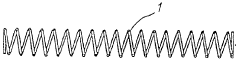

- A compound turbulator comprising a boundary layer turbulator and a spinner turbulator is used, where a helical coil is placed inside or outside the tube to generate high turbulence in the boundary layer, with the spinner turbulator enhancing turbulence through centrifugal force, significantly increasing the heat transfer coefficient.

Material Safety Regs

When researching nichrome wire compositions for improved heat transfer, it is crucial to consider material safety regulations to ensure compliance and protect workers and end-users. The Occupational Safety and Health Administration (OSHA) in the United States has established guidelines for handling and working with nickel-chromium alloys. These regulations cover exposure limits, personal protective equipment (PPE), and proper ventilation requirements.

The National Institute for Occupational Safety and Health (NIOSH) has set recommended exposure limits (RELs) for nickel and chromium compounds. For nickel, the REL is 0.015 mg/m³ as a time-weighted average (TWA) for up to 10 hours per day during a 40-hour workweek. Chromium compounds have varying RELs depending on their oxidation state, with hexavalent chromium having the strictest limit of 0.0002 mg/m³ as a TWA.

Proper PPE is essential when working with nichrome wire. This includes respiratory protection, such as NIOSH-approved respirators with appropriate filters for metal fumes. Skin protection is also crucial, as both nickel and chromium can cause dermatitis and allergic reactions. Workers should wear chemical-resistant gloves, protective clothing, and safety goggles to prevent skin contact and eye irritation.

Ventilation systems play a critical role in maintaining safe working conditions. Local exhaust ventilation should be used to capture and remove metal fumes generated during the manufacturing and handling of nichrome wire. The American Conference of Governmental Industrial Hygienists (ACGIH) provides guidelines for designing and implementing effective ventilation systems in industrial settings.

The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation also impacts the use of nichrome wire compositions. REACH requires manufacturers and importers to register substances and provide safety information. Nickel compounds are subject to specific restrictions under REACH, particularly concerning their use in articles that come into direct and prolonged contact with the skin.

In the context of heat transfer applications, it is essential to consider the potential release of nickel and chromium ions at elevated temperatures. The European Food Safety Authority (EFSA) has established specific migration limits for nickel in food contact materials, which may be relevant for certain heat transfer applications in the food industry.

Manufacturers and researchers working on nichrome wire compositions must also adhere to waste disposal regulations. The Resource Conservation and Recovery Act (RCRA) in the United States classifies certain nickel and chromium compounds as hazardous waste, requiring specific handling and disposal procedures.

The National Institute for Occupational Safety and Health (NIOSH) has set recommended exposure limits (RELs) for nickel and chromium compounds. For nickel, the REL is 0.015 mg/m³ as a time-weighted average (TWA) for up to 10 hours per day during a 40-hour workweek. Chromium compounds have varying RELs depending on their oxidation state, with hexavalent chromium having the strictest limit of 0.0002 mg/m³ as a TWA.

Proper PPE is essential when working with nichrome wire. This includes respiratory protection, such as NIOSH-approved respirators with appropriate filters for metal fumes. Skin protection is also crucial, as both nickel and chromium can cause dermatitis and allergic reactions. Workers should wear chemical-resistant gloves, protective clothing, and safety goggles to prevent skin contact and eye irritation.

Ventilation systems play a critical role in maintaining safe working conditions. Local exhaust ventilation should be used to capture and remove metal fumes generated during the manufacturing and handling of nichrome wire. The American Conference of Governmental Industrial Hygienists (ACGIH) provides guidelines for designing and implementing effective ventilation systems in industrial settings.

The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation also impacts the use of nichrome wire compositions. REACH requires manufacturers and importers to register substances and provide safety information. Nickel compounds are subject to specific restrictions under REACH, particularly concerning their use in articles that come into direct and prolonged contact with the skin.

In the context of heat transfer applications, it is essential to consider the potential release of nickel and chromium ions at elevated temperatures. The European Food Safety Authority (EFSA) has established specific migration limits for nickel in food contact materials, which may be relevant for certain heat transfer applications in the food industry.

Manufacturers and researchers working on nichrome wire compositions must also adhere to waste disposal regulations. The Resource Conservation and Recovery Act (RCRA) in the United States classifies certain nickel and chromium compounds as hazardous waste, requiring specific handling and disposal procedures.

Sustainability Aspects

Sustainability is a critical aspect to consider in the research on nichrome wire compositions for improved heat transfer. The development of more efficient and environmentally friendly heating elements has become increasingly important in the face of global climate change and resource scarcity.

One of the primary sustainability concerns in nichrome wire production is the use of raw materials. Nickel and chromium, the main components of nichrome alloys, are finite resources that require energy-intensive mining and processing. Researchers are exploring ways to optimize the composition of nichrome wires to reduce the overall material consumption while maintaining or improving heat transfer efficiency. This includes investigating alternative alloy compositions that may incorporate more abundant or recyclable materials.

Energy efficiency is another crucial sustainability factor. Improved heat transfer in nichrome wires can lead to significant energy savings in various applications, from household appliances to industrial heating systems. By enhancing the wire's ability to convert electrical energy into heat more efficiently, researchers aim to reduce overall energy consumption and associated carbon emissions. This aligns with global efforts to improve energy efficiency and reduce greenhouse gas emissions across various sectors.

The longevity and durability of nichrome wires also play a role in sustainability. Developing compositions that resist corrosion, oxidation, and mechanical stress can extend the lifespan of heating elements, reducing the need for frequent replacements. This not only conserves resources but also minimizes waste generation and the environmental impact associated with manufacturing and disposing of heating elements.

Recyclability is an increasingly important consideration in nichrome wire research. Efforts are being made to design alloy compositions that facilitate easier recycling at the end of the product's life cycle. This includes exploring ways to separate and recover the constituent metals more efficiently, as well as developing alloys that maintain their properties even after multiple recycling processes.

The manufacturing process of nichrome wires also presents opportunities for sustainability improvements. Researchers are investigating cleaner production methods that reduce energy consumption, minimize waste, and limit the use of harmful chemicals. This includes exploring advanced manufacturing techniques such as powder metallurgy or additive manufacturing, which can offer more precise control over alloy composition and potentially reduce material waste.

Lastly, the environmental impact of nichrome wire production and use is being scrutinized. This includes assessing the potential release of harmful substances during manufacturing or operation, as well as the overall carbon footprint of the production process. By addressing these concerns, researchers aim to develop nichrome wire compositions that not only offer improved heat transfer but also align with broader sustainability goals and environmental regulations.

One of the primary sustainability concerns in nichrome wire production is the use of raw materials. Nickel and chromium, the main components of nichrome alloys, are finite resources that require energy-intensive mining and processing. Researchers are exploring ways to optimize the composition of nichrome wires to reduce the overall material consumption while maintaining or improving heat transfer efficiency. This includes investigating alternative alloy compositions that may incorporate more abundant or recyclable materials.

Energy efficiency is another crucial sustainability factor. Improved heat transfer in nichrome wires can lead to significant energy savings in various applications, from household appliances to industrial heating systems. By enhancing the wire's ability to convert electrical energy into heat more efficiently, researchers aim to reduce overall energy consumption and associated carbon emissions. This aligns with global efforts to improve energy efficiency and reduce greenhouse gas emissions across various sectors.

The longevity and durability of nichrome wires also play a role in sustainability. Developing compositions that resist corrosion, oxidation, and mechanical stress can extend the lifespan of heating elements, reducing the need for frequent replacements. This not only conserves resources but also minimizes waste generation and the environmental impact associated with manufacturing and disposing of heating elements.

Recyclability is an increasingly important consideration in nichrome wire research. Efforts are being made to design alloy compositions that facilitate easier recycling at the end of the product's life cycle. This includes exploring ways to separate and recover the constituent metals more efficiently, as well as developing alloys that maintain their properties even after multiple recycling processes.

The manufacturing process of nichrome wires also presents opportunities for sustainability improvements. Researchers are investigating cleaner production methods that reduce energy consumption, minimize waste, and limit the use of harmful chemicals. This includes exploring advanced manufacturing techniques such as powder metallurgy or additive manufacturing, which can offer more precise control over alloy composition and potentially reduce material waste.

Lastly, the environmental impact of nichrome wire production and use is being scrutinized. This includes assessing the potential release of harmful substances during manufacturing or operation, as well as the overall carbon footprint of the production process. By addressing these concerns, researchers aim to develop nichrome wire compositions that not only offer improved heat transfer but also align with broader sustainability goals and environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!