Submersible pump efficiency in fracking operations.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fracking Pump Evolution

The evolution of fracking pumps has been closely tied to the advancements in hydraulic fracturing technology and the increasing demands of the oil and gas industry. In the early days of fracking, conventional centrifugal pumps were used, but they quickly proved inadequate for the high-pressure, high-volume requirements of hydraulic fracturing operations.

The 1940s saw the introduction of the first purpose-built fracking pumps, which were essentially modified versions of existing industrial pumps. These early models were capable of generating pressures up to 3,000 psi, a significant improvement over their predecessors. However, they still lacked the power and durability needed for large-scale fracking operations.

The 1960s and 1970s marked a significant leap in fracking pump technology with the development of triplex and quintuplex pumps. These multi-cylinder positive displacement pumps could generate much higher pressures, up to 15,000 psi, and handle larger volumes of fluid. This advancement allowed for more effective fracturing of harder rock formations and deeper wells.

As the fracking industry expanded in the 1980s and 1990s, pump manufacturers focused on improving reliability and efficiency. This period saw the introduction of more durable materials, such as tungsten carbide for valve seats and ceramic plungers, which significantly extended pump life and reduced maintenance requirements.

The turn of the millennium brought about a new era in fracking pump design, driven by the shale gas boom. Pumps became larger and more powerful, with some models capable of generating over 20,000 psi of pressure. Additionally, the industry began to adopt variable frequency drives (VFDs) and advanced control systems, allowing for more precise control of pump output and improved energy efficiency.

In recent years, the focus has shifted towards developing more environmentally friendly and cost-effective pumping solutions. This has led to innovations such as electric-powered fracking pumps, which offer reduced emissions and lower operating costs compared to traditional diesel-powered units. Furthermore, there has been a growing interest in submersible pump technology for fracking operations, as these pumps can potentially offer improved efficiency and reduced surface footprint.

The latest developments in fracking pump technology include the integration of Internet of Things (IoT) sensors and artificial intelligence for predictive maintenance and real-time performance optimization. These advancements aim to further increase pump efficiency, reduce downtime, and lower overall operational costs in hydraulic fracturing operations.

The 1940s saw the introduction of the first purpose-built fracking pumps, which were essentially modified versions of existing industrial pumps. These early models were capable of generating pressures up to 3,000 psi, a significant improvement over their predecessors. However, they still lacked the power and durability needed for large-scale fracking operations.

The 1960s and 1970s marked a significant leap in fracking pump technology with the development of triplex and quintuplex pumps. These multi-cylinder positive displacement pumps could generate much higher pressures, up to 15,000 psi, and handle larger volumes of fluid. This advancement allowed for more effective fracturing of harder rock formations and deeper wells.

As the fracking industry expanded in the 1980s and 1990s, pump manufacturers focused on improving reliability and efficiency. This period saw the introduction of more durable materials, such as tungsten carbide for valve seats and ceramic plungers, which significantly extended pump life and reduced maintenance requirements.

The turn of the millennium brought about a new era in fracking pump design, driven by the shale gas boom. Pumps became larger and more powerful, with some models capable of generating over 20,000 psi of pressure. Additionally, the industry began to adopt variable frequency drives (VFDs) and advanced control systems, allowing for more precise control of pump output and improved energy efficiency.

In recent years, the focus has shifted towards developing more environmentally friendly and cost-effective pumping solutions. This has led to innovations such as electric-powered fracking pumps, which offer reduced emissions and lower operating costs compared to traditional diesel-powered units. Furthermore, there has been a growing interest in submersible pump technology for fracking operations, as these pumps can potentially offer improved efficiency and reduced surface footprint.

The latest developments in fracking pump technology include the integration of Internet of Things (IoT) sensors and artificial intelligence for predictive maintenance and real-time performance optimization. These advancements aim to further increase pump efficiency, reduce downtime, and lower overall operational costs in hydraulic fracturing operations.

Oilfield Demand Analysis

The demand for submersible pumps in fracking operations has been steadily increasing due to the growing complexity and scale of hydraulic fracturing activities in the oil and gas industry. As unconventional oil and gas extraction methods become more prevalent, the need for efficient and reliable submersible pumps has become paramount.

Fracking operations require high-pressure pumping systems to inject large volumes of fluid into wells, creating fractures in rock formations to release trapped oil and gas. Submersible pumps play a crucial role in this process by efficiently moving fluids and maintaining pressure throughout the operation. The market for these pumps is driven by the continuous expansion of shale gas and tight oil production, particularly in regions such as North America, China, and Argentina.

The global hydraulic fracturing market, which directly impacts the demand for submersible pumps, is projected to grow significantly in the coming years. This growth is fueled by increasing energy demand, technological advancements in fracking techniques, and the discovery of new shale reserves. As a result, oilfield service companies and equipment manufacturers are investing heavily in research and development to improve pump efficiency and durability.

One of the key factors driving the demand for more efficient submersible pumps is the need to reduce operational costs in fracking. As oil prices fluctuate, operators are constantly seeking ways to optimize their processes and maximize returns. Improved pump efficiency translates to lower energy consumption, reduced maintenance requirements, and increased production rates, all of which contribute to better economic outcomes for oil and gas companies.

Environmental concerns and regulatory pressures are also shaping the demand for advanced submersible pump technologies in fracking operations. There is a growing emphasis on reducing water usage, minimizing chemical additives, and preventing groundwater contamination. This has led to a surge in demand for pumps that can handle a wider range of fluid compositions, including those with higher solid content and corrosive properties.

The trend towards deeper wells and more challenging geological formations has further intensified the need for high-performance submersible pumps. These pumps must withstand extreme pressures, temperatures, and abrasive conditions while maintaining optimal efficiency. As a result, there is a strong market pull for pumps with enhanced materials, improved designs, and advanced control systems that can adapt to varying downhole conditions.

In conclusion, the oilfield demand analysis for submersible pump efficiency in fracking operations reveals a robust and growing market driven by technological advancements, cost optimization needs, and environmental considerations. The industry's focus on improving pump performance aligns with the broader goals of increasing productivity, reducing operational expenses, and enhancing sustainability in hydraulic fracturing activities.

Fracking operations require high-pressure pumping systems to inject large volumes of fluid into wells, creating fractures in rock formations to release trapped oil and gas. Submersible pumps play a crucial role in this process by efficiently moving fluids and maintaining pressure throughout the operation. The market for these pumps is driven by the continuous expansion of shale gas and tight oil production, particularly in regions such as North America, China, and Argentina.

The global hydraulic fracturing market, which directly impacts the demand for submersible pumps, is projected to grow significantly in the coming years. This growth is fueled by increasing energy demand, technological advancements in fracking techniques, and the discovery of new shale reserves. As a result, oilfield service companies and equipment manufacturers are investing heavily in research and development to improve pump efficiency and durability.

One of the key factors driving the demand for more efficient submersible pumps is the need to reduce operational costs in fracking. As oil prices fluctuate, operators are constantly seeking ways to optimize their processes and maximize returns. Improved pump efficiency translates to lower energy consumption, reduced maintenance requirements, and increased production rates, all of which contribute to better economic outcomes for oil and gas companies.

Environmental concerns and regulatory pressures are also shaping the demand for advanced submersible pump technologies in fracking operations. There is a growing emphasis on reducing water usage, minimizing chemical additives, and preventing groundwater contamination. This has led to a surge in demand for pumps that can handle a wider range of fluid compositions, including those with higher solid content and corrosive properties.

The trend towards deeper wells and more challenging geological formations has further intensified the need for high-performance submersible pumps. These pumps must withstand extreme pressures, temperatures, and abrasive conditions while maintaining optimal efficiency. As a result, there is a strong market pull for pumps with enhanced materials, improved designs, and advanced control systems that can adapt to varying downhole conditions.

In conclusion, the oilfield demand analysis for submersible pump efficiency in fracking operations reveals a robust and growing market driven by technological advancements, cost optimization needs, and environmental considerations. The industry's focus on improving pump performance aligns with the broader goals of increasing productivity, reducing operational expenses, and enhancing sustainability in hydraulic fracturing activities.

Submersible Pump Challenges

Submersible pumps in fracking operations face numerous challenges that impact their efficiency and overall performance. One of the primary issues is the harsh downhole environment, characterized by high temperatures, extreme pressures, and corrosive fluids. These conditions can lead to accelerated wear and tear on pump components, reducing their lifespan and operational efficiency.

The presence of abrasive materials, such as sand and other proppants used in hydraulic fracturing, poses a significant threat to pump integrity. These particles can cause erosion of pump internals, including impellers, diffusers, and bearings, leading to decreased pump efficiency and potential failure. Additionally, the high solid content in fracking fluids can result in clogging and reduced flow rates, further compromising pump performance.

Gas entrainment is another critical challenge for submersible pumps in fracking operations. The presence of free gas in the fluid can cause gas locking, where gas bubbles accumulate in the pump, preventing proper fluid flow and potentially leading to pump shutdown. This phenomenon not only reduces efficiency but also increases the risk of equipment damage.

The variable flow rates and pressures encountered in fracking operations present difficulties in maintaining optimal pump performance. Pumps must be capable of handling fluctuating conditions without sacrificing efficiency or reliability. This requirement often necessitates sophisticated control systems and robust pump designs, which can increase complexity and cost.

Scaling and mineral deposition on pump surfaces is a persistent issue in many fracking environments. These deposits can restrict fluid flow, increase power consumption, and reduce overall pump efficiency. Regular maintenance and chemical treatments are often required to mitigate this problem, adding to operational costs and downtime.

The limited space in wellbores constrains the size and design of submersible pumps, making it challenging to achieve high flow rates and efficiencies within these physical limitations. Engineers must balance the need for compact designs with the requirement for robust, high-performance pumping systems.

Power supply and transmission to submersible pumps in deep wells present additional challenges. Voltage drop along long power cables can reduce motor efficiency, while the risk of cable damage during installation or operation can lead to pump failure and costly interventions.

Lastly, the unpredictable nature of reservoir conditions and fluid properties in fracking operations complicates pump selection and optimization. Pumps must be versatile enough to handle a wide range of fluid viscosities, densities, and compositions, which can vary significantly over the life of a well. This variability makes it difficult to maintain peak efficiency across all operating conditions, requiring ongoing monitoring and adjustment of pump parameters.

The presence of abrasive materials, such as sand and other proppants used in hydraulic fracturing, poses a significant threat to pump integrity. These particles can cause erosion of pump internals, including impellers, diffusers, and bearings, leading to decreased pump efficiency and potential failure. Additionally, the high solid content in fracking fluids can result in clogging and reduced flow rates, further compromising pump performance.

Gas entrainment is another critical challenge for submersible pumps in fracking operations. The presence of free gas in the fluid can cause gas locking, where gas bubbles accumulate in the pump, preventing proper fluid flow and potentially leading to pump shutdown. This phenomenon not only reduces efficiency but also increases the risk of equipment damage.

The variable flow rates and pressures encountered in fracking operations present difficulties in maintaining optimal pump performance. Pumps must be capable of handling fluctuating conditions without sacrificing efficiency or reliability. This requirement often necessitates sophisticated control systems and robust pump designs, which can increase complexity and cost.

Scaling and mineral deposition on pump surfaces is a persistent issue in many fracking environments. These deposits can restrict fluid flow, increase power consumption, and reduce overall pump efficiency. Regular maintenance and chemical treatments are often required to mitigate this problem, adding to operational costs and downtime.

The limited space in wellbores constrains the size and design of submersible pumps, making it challenging to achieve high flow rates and efficiencies within these physical limitations. Engineers must balance the need for compact designs with the requirement for robust, high-performance pumping systems.

Power supply and transmission to submersible pumps in deep wells present additional challenges. Voltage drop along long power cables can reduce motor efficiency, while the risk of cable damage during installation or operation can lead to pump failure and costly interventions.

Lastly, the unpredictable nature of reservoir conditions and fluid properties in fracking operations complicates pump selection and optimization. Pumps must be versatile enough to handle a wide range of fluid viscosities, densities, and compositions, which can vary significantly over the life of a well. This variability makes it difficult to maintain peak efficiency across all operating conditions, requiring ongoing monitoring and adjustment of pump parameters.

Current Submersible Pump Solutions

01 Impeller design optimization

Improving the design of the impeller can significantly enhance the efficiency of submersible pumps. This includes optimizing the shape, size, and number of blades to reduce turbulence and increase fluid flow. Advanced computational fluid dynamics (CFD) simulations are often used to refine impeller designs for maximum performance.- Impeller design optimization: Improving the design of the impeller is crucial for enhancing submersible pump efficiency. This includes optimizing the shape, size, and number of blades to reduce hydraulic losses and improve flow characteristics. Advanced computational fluid dynamics (CFD) analysis can be used to refine impeller geometry for maximum performance.

- Motor efficiency enhancements: Increasing the efficiency of the submersible pump's motor contributes significantly to overall pump efficiency. This can be achieved through the use of high-efficiency electric motors, improved cooling systems, and advanced motor control technologies such as variable frequency drives (VFDs) to optimize power consumption across different operating conditions.

- Hydraulic passage optimization: Enhancing the efficiency of hydraulic passages within the pump, including the suction inlet, diffuser, and discharge outlet, can reduce friction losses and improve overall pump performance. This involves streamlining flow paths, minimizing turbulence, and optimizing the geometry of internal components to ensure smooth fluid flow through the pump.

- Advanced materials and coatings: Utilizing advanced materials and surface coatings can improve pump efficiency by reducing friction, enhancing wear resistance, and preventing corrosion. This includes the use of composite materials, ceramic coatings, and specialized alloys that can withstand harsh operating environments while maintaining optimal performance.

- Intelligent monitoring and control systems: Implementing smart monitoring and control systems can optimize pump operation in real-time, leading to improved efficiency. These systems can include sensors for performance monitoring, predictive maintenance algorithms, and adaptive control strategies that adjust pump operation based on changing conditions to maintain peak efficiency.

02 Motor efficiency enhancements

Increasing the efficiency of the electric motor driving the submersible pump can lead to overall improved pump performance. This may involve using high-efficiency materials, advanced winding techniques, or implementing variable frequency drives (VFDs) to optimize motor operation across different load conditions.Expand Specific Solutions03 Hydraulic passage optimization

Refining the hydraulic passages within the pump, including the inlet, diffuser, and outlet, can reduce friction losses and improve overall pump efficiency. This may involve using computational modeling to identify and eliminate areas of flow separation or recirculation.Expand Specific Solutions04 Sealing and bearing improvements

Enhancing the sealing mechanisms and bearing systems in submersible pumps can reduce mechanical losses and improve overall efficiency. This may include using advanced materials for seals, implementing labyrinth-style sealing systems, or utilizing hydrodynamic bearings to minimize friction.Expand Specific Solutions05 Smart control and monitoring systems

Implementing intelligent control systems and real-time monitoring can optimize pump operation for maximum efficiency. This may involve using sensors to adjust pump performance based on changing conditions, predictive maintenance algorithms to prevent efficiency losses, or adaptive control strategies to maintain optimal performance over time.Expand Specific Solutions

Key Fracking Equipment Manufacturers

The research on submersible pump efficiency in fracking operations is in a mature stage, with significant market growth driven by increasing shale oil and gas production. The global fracking market size is projected to reach billions of dollars by 2025. Major players like Halliburton, Schlumberger, and Baker Hughes dominate the field, leveraging their extensive experience and technological capabilities. Chinese companies such as Sinopec and CNPC are also making strides in this area. The technology is well-established, with ongoing innovations focused on improving pump efficiency, reducing environmental impact, and optimizing overall fracking operations.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed advanced submersible pump systems specifically designed for fracking operations. Their technology incorporates innovative impeller designs and advanced materials to enhance efficiency in harsh downhole environments. The company's submersible pumps utilize variable speed drives and intelligent control systems to optimize performance based on real-time well conditions[1]. Halliburton's pumps also feature advanced seal technology to prevent contamination and extend operational life in abrasive fracking fluids[2]. The company has implemented machine learning algorithms to predict pump performance and schedule preventive maintenance, further improving overall efficiency[3].

Strengths: Extensive experience in oilfield services, strong R&D capabilities, and global presence. Weaknesses: High operational costs and potential environmental concerns associated with fracking operations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in submersible pump technology for fracking operations. The company has developed high-efficiency electric submersible pumps that incorporate advanced materials resistant to corrosion and wear in harsh fracking environments[10]. Sinopec's pumps feature optimized impeller designs and advanced sealing technologies to maintain efficiency under high-pressure conditions. The company has also implemented intelligent control systems that adjust pump parameters in real-time based on well conditions and production data[11]. Sinopec's research efforts have focused on improving energy efficiency and reducing the environmental impact of fracking operations through innovative pump designs and operational strategies[12].

Strengths: Strong government support, extensive domestic market, and integrated operations across the oil and gas value chain. Weaknesses: Limited international presence compared to Western competitors and potential geopolitical challenges.

Innovative Pump Designs

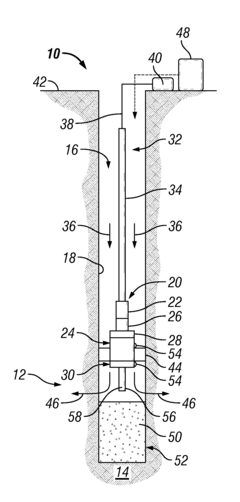

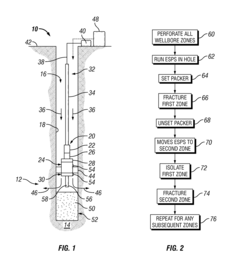

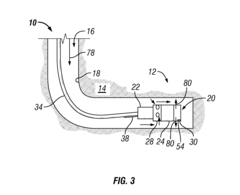

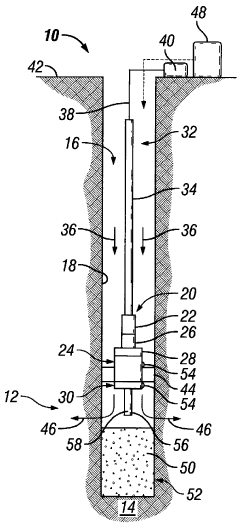

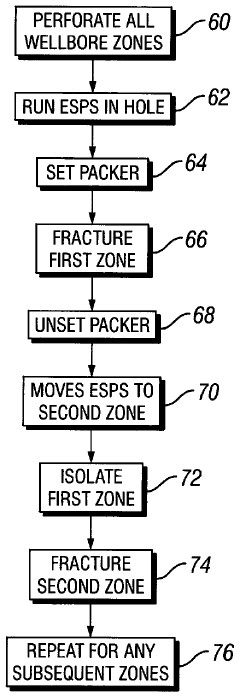

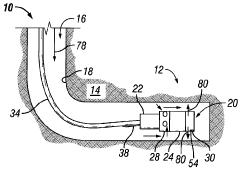

Well Treatment Using Electric Submersible Pumping System

PatentInactiveUS20120312531A1

Innovation

- An electric submersible pumping system is deployed downhole to increase the pressure of the fracturing fluid, reducing the pressure required at the surface and enabling efficient fracturing by boosting pressure at the wellbore, allowing for cyclic pressure waves and zone-by-zone fracturing.

Well treatment using electric submersible pumping system

PatentWO2008132641A2

Innovation

- An electric submersible pumping system is positioned downhole to intake and pressurize the fracturing fluid, reducing the surface pressure requirements by boosting the fluid pressure at the wellbore, allowing for efficient hydraulic fracturing and other well treatments with reduced tubular friction losses.

Environmental Impact Assessment

The environmental impact of submersible pump usage in fracking operations is a critical consideration for the oil and gas industry. These pumps play a crucial role in the extraction process, but their efficiency and environmental footprint require careful assessment.

Water usage is a primary concern in fracking operations. Submersible pumps are responsible for extracting large volumes of water, which can strain local water resources. Improved pump efficiency can lead to reduced water consumption, mitigating the impact on aquifers and surface water bodies. Additionally, more efficient pumps can decrease the energy required for water extraction, indirectly reducing greenhouse gas emissions associated with power generation.

The potential for groundwater contamination is another significant environmental issue. Submersible pumps must maintain integrity to prevent leakage of fracking fluids into surrounding soil and groundwater. Enhanced pump efficiency can reduce the risk of mechanical failures and subsequent environmental contamination. Moreover, efficient pumps can help in the proper management of flowback and produced water, minimizing the risk of spills and contamination of surface water bodies.

Noise pollution is an often-overlooked environmental impact of fracking operations. Submersible pumps contribute to the overall noise levels at fracking sites. Research into pump efficiency can lead to quieter operations, reducing disturbance to local wildlife and nearby communities. This is particularly important in areas where fracking operations occur close to residential or ecologically sensitive zones.

The disposal of worn-out pump components presents another environmental challenge. More efficient pumps typically have longer operational lifespans, reducing the frequency of replacements and the associated waste. Research into materials and design can lead to pumps that are not only more efficient but also more recyclable or biodegradable, further reducing their environmental footprint.

Lastly, the impact on local ecosystems must be considered. Efficient submersible pumps can help minimize surface disturbance by reducing the need for extensive infrastructure. This can help preserve habitats and maintain biodiversity in areas surrounding fracking operations. Furthermore, improved efficiency in water extraction and management can help maintain the delicate balance of local ecosystems that depend on consistent water availability.

Water usage is a primary concern in fracking operations. Submersible pumps are responsible for extracting large volumes of water, which can strain local water resources. Improved pump efficiency can lead to reduced water consumption, mitigating the impact on aquifers and surface water bodies. Additionally, more efficient pumps can decrease the energy required for water extraction, indirectly reducing greenhouse gas emissions associated with power generation.

The potential for groundwater contamination is another significant environmental issue. Submersible pumps must maintain integrity to prevent leakage of fracking fluids into surrounding soil and groundwater. Enhanced pump efficiency can reduce the risk of mechanical failures and subsequent environmental contamination. Moreover, efficient pumps can help in the proper management of flowback and produced water, minimizing the risk of spills and contamination of surface water bodies.

Noise pollution is an often-overlooked environmental impact of fracking operations. Submersible pumps contribute to the overall noise levels at fracking sites. Research into pump efficiency can lead to quieter operations, reducing disturbance to local wildlife and nearby communities. This is particularly important in areas where fracking operations occur close to residential or ecologically sensitive zones.

The disposal of worn-out pump components presents another environmental challenge. More efficient pumps typically have longer operational lifespans, reducing the frequency of replacements and the associated waste. Research into materials and design can lead to pumps that are not only more efficient but also more recyclable or biodegradable, further reducing their environmental footprint.

Lastly, the impact on local ecosystems must be considered. Efficient submersible pumps can help minimize surface disturbance by reducing the need for extensive infrastructure. This can help preserve habitats and maintain biodiversity in areas surrounding fracking operations. Furthermore, improved efficiency in water extraction and management can help maintain the delicate balance of local ecosystems that depend on consistent water availability.

Regulatory Compliance in Fracking

Regulatory compliance in fracking operations is a critical aspect that significantly impacts the efficiency and sustainability of submersible pump usage. The regulatory landscape for hydraulic fracturing is complex and varies across different regions, with federal, state, and local regulations often overlapping. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing fracking activities, particularly concerning water quality and waste management.

State-level regulations often provide more specific guidelines for fracking operations, including requirements for well construction, water usage, and chemical disclosure. For instance, some states mandate the use of FracFocus, a national hydraulic fracturing chemical registry, to report the chemicals used in fracking fluids. These regulations directly influence the design and operation of submersible pumps, as they must comply with stringent environmental and safety standards.

The Safe Drinking Water Act (SDWA) is a key piece of legislation that affects fracking operations, particularly in areas where underground sources of drinking water may be at risk. While hydraulic fracturing is generally exempt from SDWA regulations under the "Halliburton Loophole," the use of diesel fuels in fracking fluids still requires a permit under the Underground Injection Control program.

Compliance with air quality regulations is another important consideration for submersible pump efficiency in fracking. The Clean Air Act regulates emissions from fracking sites, including volatile organic compounds (VOCs) and methane. This has led to the development of more efficient pump technologies that minimize fugitive emissions and reduce the overall environmental impact of fracking operations.

Water management regulations also play a significant role in shaping submersible pump usage. Many states have implemented strict rules regarding water sourcing, usage, and disposal in fracking operations. These regulations often require operators to implement water recycling and treatment technologies, which in turn affects the design and operation of submersible pumps used in the process.

The Occupational Safety and Health Administration (OSHA) sets standards for worker safety in fracking operations, including those related to the operation and maintenance of submersible pumps. These regulations cover aspects such as proper equipment handling, hazard communication, and personal protective equipment requirements.

As the regulatory landscape continues to evolve, submersible pump manufacturers and fracking operators must stay abreast of new requirements and adapt their technologies accordingly. This ongoing process of regulatory compliance drives innovation in pump design, leading to more efficient and environmentally friendly solutions for fracking operations.

State-level regulations often provide more specific guidelines for fracking operations, including requirements for well construction, water usage, and chemical disclosure. For instance, some states mandate the use of FracFocus, a national hydraulic fracturing chemical registry, to report the chemicals used in fracking fluids. These regulations directly influence the design and operation of submersible pumps, as they must comply with stringent environmental and safety standards.

The Safe Drinking Water Act (SDWA) is a key piece of legislation that affects fracking operations, particularly in areas where underground sources of drinking water may be at risk. While hydraulic fracturing is generally exempt from SDWA regulations under the "Halliburton Loophole," the use of diesel fuels in fracking fluids still requires a permit under the Underground Injection Control program.

Compliance with air quality regulations is another important consideration for submersible pump efficiency in fracking. The Clean Air Act regulates emissions from fracking sites, including volatile organic compounds (VOCs) and methane. This has led to the development of more efficient pump technologies that minimize fugitive emissions and reduce the overall environmental impact of fracking operations.

Water management regulations also play a significant role in shaping submersible pump usage. Many states have implemented strict rules regarding water sourcing, usage, and disposal in fracking operations. These regulations often require operators to implement water recycling and treatment technologies, which in turn affects the design and operation of submersible pumps used in the process.

The Occupational Safety and Health Administration (OSHA) sets standards for worker safety in fracking operations, including those related to the operation and maintenance of submersible pumps. These regulations cover aspects such as proper equipment handling, hazard communication, and personal protective equipment requirements.

As the regulatory landscape continues to evolve, submersible pump manufacturers and fracking operators must stay abreast of new requirements and adapt their technologies accordingly. This ongoing process of regulatory compliance drives innovation in pump design, leading to more efficient and environmentally friendly solutions for fracking operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!