Submersible pumps in agriculture irrigation systems.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Irrigation Pump Evolution and Objectives

Submersible pumps have played a crucial role in the evolution of agricultural irrigation systems, revolutionizing the way farmers manage water resources. The development of these pumps can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially, surface-mounted pumps were the primary means of water extraction for irrigation purposes. However, these systems had limitations in terms of efficiency and depth capabilities.

The introduction of submersible pumps marked a significant turning point in irrigation technology. These pumps, designed to operate while fully submerged in water, offered numerous advantages over their surface-mounted counterparts. They could be installed at greater depths, allowing access to deeper water tables and aquifers. This capability proved particularly valuable in regions facing water scarcity or declining groundwater levels.

As the technology progressed, submersible pumps became more efficient, reliable, and cost-effective. Manufacturers focused on improving motor designs, enhancing pump hydraulics, and developing corrosion-resistant materials. These advancements led to increased pump lifespan, reduced energy consumption, and improved overall performance in agricultural applications.

The integration of electronic controls and variable frequency drives (VFDs) further enhanced the capabilities of submersible pumps. These innovations allowed for precise control over pump operation, enabling farmers to optimize water usage and adapt to varying irrigation needs. The ability to adjust pump speed and output based on real-time conditions contributed to significant water and energy savings.

In recent years, the focus has shifted towards developing smart irrigation systems that incorporate submersible pumps. These systems leverage sensors, data analytics, and automation to provide more efficient and targeted irrigation solutions. The integration of Internet of Things (IoT) technology has enabled remote monitoring and control of pumps, allowing farmers to manage their irrigation systems from anywhere.

Looking ahead, the objectives for submersible pump technology in agricultural irrigation systems are multifaceted. One primary goal is to further improve energy efficiency, reducing operational costs and environmental impact. This includes the development of more efficient motors, advanced materials, and optimized pump designs. Another objective is to enhance the durability and reliability of submersible pumps, particularly in challenging environments with high sediment content or varying water quality.

Additionally, there is a growing emphasis on developing pumps that can operate effectively with renewable energy sources, such as solar power. This aligns with the broader trend towards sustainable agriculture and reduced reliance on fossil fuels. Researchers are also exploring ways to integrate submersible pumps with precision agriculture techniques, aiming to create holistic irrigation solutions that maximize crop yields while minimizing resource usage.

The introduction of submersible pumps marked a significant turning point in irrigation technology. These pumps, designed to operate while fully submerged in water, offered numerous advantages over their surface-mounted counterparts. They could be installed at greater depths, allowing access to deeper water tables and aquifers. This capability proved particularly valuable in regions facing water scarcity or declining groundwater levels.

As the technology progressed, submersible pumps became more efficient, reliable, and cost-effective. Manufacturers focused on improving motor designs, enhancing pump hydraulics, and developing corrosion-resistant materials. These advancements led to increased pump lifespan, reduced energy consumption, and improved overall performance in agricultural applications.

The integration of electronic controls and variable frequency drives (VFDs) further enhanced the capabilities of submersible pumps. These innovations allowed for precise control over pump operation, enabling farmers to optimize water usage and adapt to varying irrigation needs. The ability to adjust pump speed and output based on real-time conditions contributed to significant water and energy savings.

In recent years, the focus has shifted towards developing smart irrigation systems that incorporate submersible pumps. These systems leverage sensors, data analytics, and automation to provide more efficient and targeted irrigation solutions. The integration of Internet of Things (IoT) technology has enabled remote monitoring and control of pumps, allowing farmers to manage their irrigation systems from anywhere.

Looking ahead, the objectives for submersible pump technology in agricultural irrigation systems are multifaceted. One primary goal is to further improve energy efficiency, reducing operational costs and environmental impact. This includes the development of more efficient motors, advanced materials, and optimized pump designs. Another objective is to enhance the durability and reliability of submersible pumps, particularly in challenging environments with high sediment content or varying water quality.

Additionally, there is a growing emphasis on developing pumps that can operate effectively with renewable energy sources, such as solar power. This aligns with the broader trend towards sustainable agriculture and reduced reliance on fossil fuels. Researchers are also exploring ways to integrate submersible pumps with precision agriculture techniques, aiming to create holistic irrigation solutions that maximize crop yields while minimizing resource usage.

Agricultural Demand for Submersible Pumps

The agricultural sector has witnessed a significant increase in demand for submersible pumps in irrigation systems. This surge is driven by several factors, including the need for efficient water management, increased crop yields, and the expansion of irrigated land. Submersible pumps have become essential components in modern agricultural practices, offering numerous advantages over traditional surface pumps.

One of the primary drivers of demand is the growing awareness of water scarcity and the need for sustainable irrigation practices. Submersible pumps allow for more precise control of water distribution, reducing waste and improving overall water use efficiency. This is particularly crucial in regions facing water shortages or experiencing irregular rainfall patterns due to climate change.

The adoption of advanced farming techniques, such as precision agriculture and drip irrigation, has further fueled the demand for submersible pumps. These systems require reliable and consistent water supply, which submersible pumps can provide with greater efficiency than surface alternatives. The ability to maintain constant pressure and flow rates makes submersible pumps ideal for these modern irrigation methods.

Expanding agricultural land, especially in arid and semi-arid regions, has also contributed to the increased demand. As farmers seek to cultivate previously unproductive areas, submersible pumps offer a viable solution for accessing groundwater resources. Their ability to operate at greater depths compared to surface pumps makes them indispensable in areas with low water tables.

The trend towards mechanization and automation in agriculture has positively impacted the submersible pump market. These pumps can be easily integrated with smart irrigation systems, allowing for remote monitoring and control. This integration enhances operational efficiency and reduces labor costs, making them attractive to both small-scale and large commercial farmers.

Energy efficiency is another factor driving demand. Modern submersible pumps are designed to consume less power while delivering higher performance, aligning with the agricultural sector's push towards sustainability and cost reduction. The long-term economic benefits of reduced energy consumption make submersible pumps an attractive investment for farmers.

Government initiatives and subsidies aimed at promoting efficient irrigation practices have also played a role in boosting demand. Many countries offer incentives for farmers to adopt water-saving technologies, including submersible pumps, as part of broader water conservation strategies.

The versatility of submersible pumps in handling various types of water, including slightly contaminated or sandy water, adds to their appeal in agricultural applications. This capability is particularly valuable in areas where water quality may be compromised or variable.

As the global population continues to grow and the pressure on food production intensifies, the demand for submersible pumps in agriculture is expected to maintain its upward trajectory. Manufacturers are responding by developing more advanced, durable, and efficient models tailored to the specific needs of the agricultural sector.

One of the primary drivers of demand is the growing awareness of water scarcity and the need for sustainable irrigation practices. Submersible pumps allow for more precise control of water distribution, reducing waste and improving overall water use efficiency. This is particularly crucial in regions facing water shortages or experiencing irregular rainfall patterns due to climate change.

The adoption of advanced farming techniques, such as precision agriculture and drip irrigation, has further fueled the demand for submersible pumps. These systems require reliable and consistent water supply, which submersible pumps can provide with greater efficiency than surface alternatives. The ability to maintain constant pressure and flow rates makes submersible pumps ideal for these modern irrigation methods.

Expanding agricultural land, especially in arid and semi-arid regions, has also contributed to the increased demand. As farmers seek to cultivate previously unproductive areas, submersible pumps offer a viable solution for accessing groundwater resources. Their ability to operate at greater depths compared to surface pumps makes them indispensable in areas with low water tables.

The trend towards mechanization and automation in agriculture has positively impacted the submersible pump market. These pumps can be easily integrated with smart irrigation systems, allowing for remote monitoring and control. This integration enhances operational efficiency and reduces labor costs, making them attractive to both small-scale and large commercial farmers.

Energy efficiency is another factor driving demand. Modern submersible pumps are designed to consume less power while delivering higher performance, aligning with the agricultural sector's push towards sustainability and cost reduction. The long-term economic benefits of reduced energy consumption make submersible pumps an attractive investment for farmers.

Government initiatives and subsidies aimed at promoting efficient irrigation practices have also played a role in boosting demand. Many countries offer incentives for farmers to adopt water-saving technologies, including submersible pumps, as part of broader water conservation strategies.

The versatility of submersible pumps in handling various types of water, including slightly contaminated or sandy water, adds to their appeal in agricultural applications. This capability is particularly valuable in areas where water quality may be compromised or variable.

As the global population continues to grow and the pressure on food production intensifies, the demand for submersible pumps in agriculture is expected to maintain its upward trajectory. Manufacturers are responding by developing more advanced, durable, and efficient models tailored to the specific needs of the agricultural sector.

Submersible Pump Technology Status and Challenges

Submersible pumps have become an integral part of modern agricultural irrigation systems, offering numerous advantages over traditional surface pumps. However, the current state of submersible pump technology in agriculture faces several challenges that need to be addressed for optimal performance and sustainability.

One of the primary challenges is energy efficiency. While submersible pumps have improved in this aspect over the years, there is still significant room for enhancement. Many existing models consume substantial amounts of electricity, leading to high operational costs for farmers. This issue is particularly pronounced in regions with limited access to reliable power grids or where electricity costs are high.

Durability and maintenance present another set of challenges. Submersible pumps operate in harsh underground environments, exposed to various contaminants, abrasive particles, and potentially corrosive elements. This can lead to wear and tear, reducing the pump's lifespan and efficiency. Regular maintenance is crucial but can be difficult and costly due to the pump's submerged location.

Water quality issues also pose significant challenges for submersible pumps in agricultural applications. Sediment, minerals, and other impurities in groundwater can cause clogging, scaling, and damage to pump components. This not only affects the pump's performance but can also lead to frequent breakdowns and increased maintenance requirements.

The depth of water tables is another factor influencing submersible pump technology. As groundwater levels continue to deplete in many agricultural regions, pumps need to be designed to operate efficiently at greater depths. This requires advancements in motor technology, materials, and overall pump design to withstand increased pressure and maintain performance.

Automation and smart control systems represent both a challenge and an opportunity in submersible pump technology. While there is a growing trend towards intelligent irrigation systems, integrating these technologies with submersible pumps presents technical hurdles. Developing robust, waterproof sensors and control mechanisms that can operate reliably underground is an ongoing challenge.

Environmental concerns also play a role in shaping the future of submersible pump technology. There is an increasing need for pumps that can operate with minimal environmental impact, including reduced energy consumption, lower noise levels, and the ability to work with renewable energy sources such as solar power.

In terms of geographical distribution, the challenges and technological advancements in submersible pumps vary across regions. Developed countries are focusing on high-efficiency, smart pumps integrated with precision agriculture systems. In contrast, developing nations are grappling with issues of affordability, reliability, and adapting the technology to work in areas with limited infrastructure.

One of the primary challenges is energy efficiency. While submersible pumps have improved in this aspect over the years, there is still significant room for enhancement. Many existing models consume substantial amounts of electricity, leading to high operational costs for farmers. This issue is particularly pronounced in regions with limited access to reliable power grids or where electricity costs are high.

Durability and maintenance present another set of challenges. Submersible pumps operate in harsh underground environments, exposed to various contaminants, abrasive particles, and potentially corrosive elements. This can lead to wear and tear, reducing the pump's lifespan and efficiency. Regular maintenance is crucial but can be difficult and costly due to the pump's submerged location.

Water quality issues also pose significant challenges for submersible pumps in agricultural applications. Sediment, minerals, and other impurities in groundwater can cause clogging, scaling, and damage to pump components. This not only affects the pump's performance but can also lead to frequent breakdowns and increased maintenance requirements.

The depth of water tables is another factor influencing submersible pump technology. As groundwater levels continue to deplete in many agricultural regions, pumps need to be designed to operate efficiently at greater depths. This requires advancements in motor technology, materials, and overall pump design to withstand increased pressure and maintain performance.

Automation and smart control systems represent both a challenge and an opportunity in submersible pump technology. While there is a growing trend towards intelligent irrigation systems, integrating these technologies with submersible pumps presents technical hurdles. Developing robust, waterproof sensors and control mechanisms that can operate reliably underground is an ongoing challenge.

Environmental concerns also play a role in shaping the future of submersible pump technology. There is an increasing need for pumps that can operate with minimal environmental impact, including reduced energy consumption, lower noise levels, and the ability to work with renewable energy sources such as solar power.

In terms of geographical distribution, the challenges and technological advancements in submersible pumps vary across regions. Developed countries are focusing on high-efficiency, smart pumps integrated with precision agriculture systems. In contrast, developing nations are grappling with issues of affordability, reliability, and adapting the technology to work in areas with limited infrastructure.

Current Submersible Pump Solutions

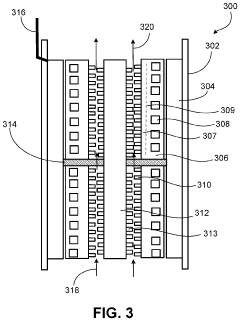

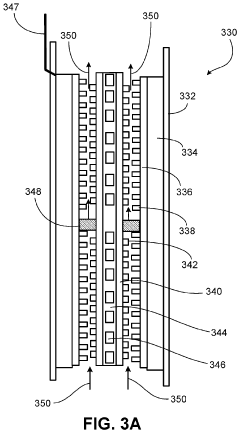

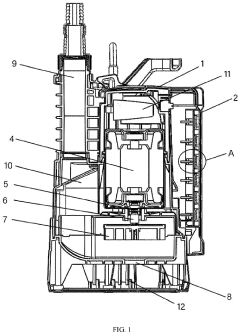

01 Design and construction of submersible pumps

Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor coupled to a pump body. The design focuses on efficient operation underwater, including features for cooling, pressure equalization, and protection against liquid ingress.- Design and construction of submersible pumps: This category focuses on the structural aspects and design innovations of submersible pumps. It includes improvements in pump housing, impeller design, and overall construction to enhance efficiency and durability in submerged environments. These advancements aim to optimize pump performance, increase lifespan, and improve reliability in various applications.

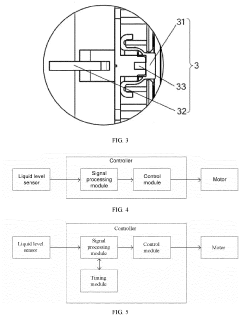

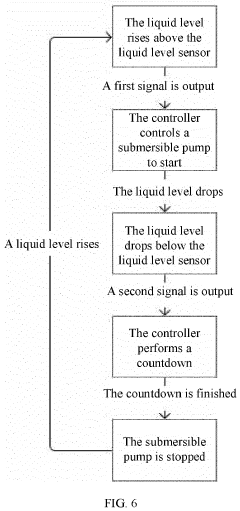

- Control systems for submersible pumps: This point covers the development of advanced control systems for submersible pumps. It includes innovations in pump monitoring, automation, and remote operation. These control systems aim to improve pump efficiency, prevent failures, and enable real-time adjustments based on operating conditions.

- Energy efficiency in submersible pumps: This category focuses on improving the energy efficiency of submersible pumps. It includes innovations in motor design, power management, and hydraulic optimization. These advancements aim to reduce power consumption, improve overall pump efficiency, and minimize operational costs in various applications.

- Specialized submersible pumps for specific applications: This point covers the development of submersible pumps tailored for specific industries or applications. It includes pumps designed for oil and gas extraction, wastewater treatment, mining, and other specialized uses. These pumps are engineered to meet unique requirements and overcome challenges in their respective fields.

- Materials and coatings for submersible pumps: This category focuses on the use of advanced materials and coatings in submersible pump construction. It includes innovations in corrosion-resistant alloys, wear-resistant coatings, and materials that can withstand harsh underwater environments. These advancements aim to extend pump lifespan, improve reliability, and reduce maintenance requirements.

02 Control systems for submersible pumps

Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring pump conditions, variable frequency drives for adjusting motor speed, and intelligent algorithms for efficient operation and fault detection.Expand Specific Solutions03 Materials and coatings for submersible pumps

Specialized materials and coatings are used in submersible pump construction to enhance durability and performance in harsh underwater environments. These may include corrosion-resistant alloys, wear-resistant coatings, and materials designed to withstand high pressures and temperatures.Expand Specific Solutions04 Energy efficiency improvements in submersible pumps

Innovations in submersible pump design focus on improving energy efficiency. This includes optimizing impeller designs, reducing friction losses, and implementing energy-saving control strategies. Such improvements lead to reduced power consumption and operational costs.Expand Specific Solutions05 Maintenance and monitoring of submersible pumps

Advanced techniques for maintenance and monitoring of submersible pumps are developed to ensure reliable operation and extend service life. These may include remote monitoring systems, predictive maintenance algorithms, and innovative methods for in-situ repair and servicing of submerged pumps.Expand Specific Solutions

Key Submersible Pump Manufacturers

The research on submersible pumps in agriculture irrigation systems is in a mature stage, with a growing market driven by increasing agricultural demands and water scarcity concerns. The global market size for these pumps is expected to expand significantly in the coming years. Key players like Schlumberger Technologies, Baker Hughes, and ABB Group are leveraging their expertise in fluid dynamics and electrical systems to develop advanced submersible pump technologies. Companies such as Valmont Industries and Capillary Concrete are focusing on integrating these pumps into comprehensive irrigation solutions. Academic institutions like China Agricultural University and research centers such as the Institute of Farmland Irrigation are contributing to technological advancements, emphasizing efficiency and sustainability in agricultural water management.

Institute of Farmland Irrigation, Chinese Academy of Agricultural Sciences

Technical Solution: The Institute of Farmland Irrigation has developed advanced submersible pump systems specifically designed for agricultural irrigation. Their research focuses on improving pump efficiency and durability in harsh agricultural environments. They have implemented variable frequency drive (VFD) technology to optimize pump performance based on varying water demands[1]. The institute has also developed corrosion-resistant materials for pump components to extend operational life in chemically treated irrigation water[3]. Their latest innovation includes smart monitoring systems that use IoT sensors to provide real-time data on pump performance, water flow rates, and energy consumption[5].

Strengths: Specialized knowledge in agricultural applications, innovative materials research, and integration of smart technologies. Weaknesses: Potentially limited global market presence compared to larger multinational corporations.

Valmont Industries, Inc.

Technical Solution: Valmont Industries has developed a range of submersible pumps tailored for agricultural irrigation systems. Their pumps feature high-efficiency motors and advanced impeller designs that maximize water flow while minimizing energy consumption[2]. Valmont has integrated their pumps with precision irrigation systems, allowing for variable rate irrigation based on field conditions and crop needs[4]. They have also developed a proprietary anti-clogging mechanism that reduces maintenance requirements in silty or debris-laden water sources common in agricultural settings[6]. Valmont's pumps are designed to be compatible with solar power systems, enabling off-grid irrigation solutions for remote agricultural areas[8].

Strengths: Comprehensive irrigation solutions, integration with precision agriculture technologies, and adaptability to various power sources. Weaknesses: May face competition from specialized pump manufacturers in certain markets.

Innovative Submersible Pump Designs

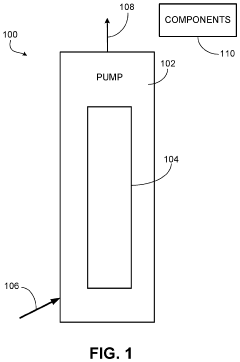

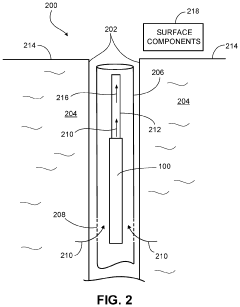

Motorized pump

PatentActiveUS20220243570A1

Innovation

- The integration of a motor and pump as a single unit without a shaft or protector section, utilizing magnetic coupling and an external-rotor motor design to enhance reliability and facilitate rigless deployment, allowing for higher motor torque and larger pump head generation capabilities.

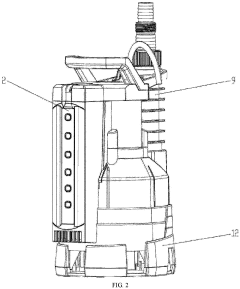

Submersible pump and automatic liquid level control method

PatentActiveEP4328452A1

Innovation

- A submersible pump with adjustable liquid level sensors, indicator lights, and a controller module that includes a signal processing and timing module, allowing for manual switching and automatic control of the pump based on detected liquid levels, preventing idling and adapting to different environments.

Energy Efficiency in Irrigation Systems

Energy efficiency in irrigation systems has become a critical focus in agricultural practices, particularly with the increasing adoption of submersible pumps. These pumps, when properly integrated into irrigation systems, can significantly reduce energy consumption while maintaining or even improving water distribution efficiency. The primary advantage of submersible pumps lies in their ability to operate directly within the water source, eliminating the need for long suction pipes and reducing friction losses.

Recent advancements in submersible pump technology have led to the development of variable frequency drives (VFDs) and smart control systems. These innovations allow for precise adjustment of pump speed and output based on real-time irrigation needs, resulting in substantial energy savings. Studies have shown that VFD-equipped submersible pumps can reduce energy consumption by up to 30-50% compared to traditional fixed-speed pumps.

The integration of renewable energy sources, particularly solar power, with submersible pumps has further enhanced energy efficiency in irrigation systems. Solar-powered submersible pumps have gained popularity in remote agricultural areas, offering a sustainable and cost-effective solution for irrigation needs. These systems eliminate the reliance on grid electricity or diesel generators, significantly reducing both operational costs and carbon emissions.

Improved pump design and materials have also contributed to increased energy efficiency. High-efficiency motors, optimized impeller designs, and the use of corrosion-resistant materials have extended pump lifespan and maintained performance over time. Additionally, the implementation of advanced hydraulic designs has minimized internal friction and improved overall pump efficiency.

Water management techniques play a crucial role in maximizing the energy efficiency of submersible pump-based irrigation systems. Precision irrigation methods, such as drip irrigation and micro-sprinklers, when combined with submersible pumps, can dramatically reduce water waste and, consequently, energy consumption. These systems deliver water directly to the plant roots, minimizing evaporation and runoff.

The adoption of smart irrigation scheduling and soil moisture sensors further enhances the energy efficiency of submersible pump systems. By accurately determining when and how much water is needed, these technologies prevent over-irrigation and unnecessary pump operation. This not only conserves water but also significantly reduces energy expenditure.

As agriculture continues to face challenges related to water scarcity and increasing energy costs, the focus on energy-efficient irrigation systems will intensify. Future developments in submersible pump technology are likely to include more advanced AI-driven control systems, further integration with IoT devices for real-time monitoring and adjustment, and the development of even more efficient pump designs and materials.

Recent advancements in submersible pump technology have led to the development of variable frequency drives (VFDs) and smart control systems. These innovations allow for precise adjustment of pump speed and output based on real-time irrigation needs, resulting in substantial energy savings. Studies have shown that VFD-equipped submersible pumps can reduce energy consumption by up to 30-50% compared to traditional fixed-speed pumps.

The integration of renewable energy sources, particularly solar power, with submersible pumps has further enhanced energy efficiency in irrigation systems. Solar-powered submersible pumps have gained popularity in remote agricultural areas, offering a sustainable and cost-effective solution for irrigation needs. These systems eliminate the reliance on grid electricity or diesel generators, significantly reducing both operational costs and carbon emissions.

Improved pump design and materials have also contributed to increased energy efficiency. High-efficiency motors, optimized impeller designs, and the use of corrosion-resistant materials have extended pump lifespan and maintained performance over time. Additionally, the implementation of advanced hydraulic designs has minimized internal friction and improved overall pump efficiency.

Water management techniques play a crucial role in maximizing the energy efficiency of submersible pump-based irrigation systems. Precision irrigation methods, such as drip irrigation and micro-sprinklers, when combined with submersible pumps, can dramatically reduce water waste and, consequently, energy consumption. These systems deliver water directly to the plant roots, minimizing evaporation and runoff.

The adoption of smart irrigation scheduling and soil moisture sensors further enhances the energy efficiency of submersible pump systems. By accurately determining when and how much water is needed, these technologies prevent over-irrigation and unnecessary pump operation. This not only conserves water but also significantly reduces energy expenditure.

As agriculture continues to face challenges related to water scarcity and increasing energy costs, the focus on energy-efficient irrigation systems will intensify. Future developments in submersible pump technology are likely to include more advanced AI-driven control systems, further integration with IoT devices for real-time monitoring and adjustment, and the development of even more efficient pump designs and materials.

Environmental Impact of Pump Usage

The environmental impact of submersible pumps in agricultural irrigation systems is a critical consideration for sustainable farming practices. These pumps, while essential for efficient water distribution, can have both positive and negative effects on the surrounding ecosystem.

One of the primary environmental benefits of submersible pumps is their potential to reduce water waste. By delivering water directly to the root zone of crops, these systems minimize evaporation and runoff, leading to more efficient water use. This is particularly important in regions facing water scarcity, as it helps conserve precious water resources and reduces the strain on local aquifers.

However, the energy consumption of submersible pumps can contribute to increased greenhouse gas emissions, especially if powered by non-renewable energy sources. The carbon footprint associated with pump operation is a growing concern in the context of climate change mitigation efforts. To address this issue, there is a rising trend towards integrating renewable energy sources, such as solar panels, to power these pumps, thereby reducing their environmental impact.

Submersible pumps can also affect local ecosystems, particularly when drawing water from natural water bodies. Excessive water extraction may lead to reduced water levels in rivers, lakes, or groundwater aquifers, potentially impacting aquatic habitats and biodiversity. This highlights the importance of responsible water management practices and adherence to sustainable extraction limits.

Soil salinization is another environmental concern associated with improper use of submersible pumps in irrigation. Over-extraction of groundwater can lead to saltwater intrusion in coastal areas, compromising soil quality and reducing agricultural productivity. Implementing proper drainage systems and monitoring soil salinity levels are crucial measures to mitigate this risk.

The disposal of old or damaged submersible pumps presents another environmental challenge. These devices often contain materials that can be harmful if not properly recycled or disposed of, such as lubricants, plastics, and metals. Developing efficient recycling programs and promoting the use of environmentally friendly materials in pump construction are important steps towards reducing the environmental footprint of these systems.

Noise pollution from submersible pumps, while generally less significant than surface pumps, can still impact local wildlife, particularly in sensitive ecosystems. Manufacturers are increasingly focusing on developing quieter pump models to minimize this disturbance.

In conclusion, while submersible pumps offer significant benefits for agricultural irrigation, their environmental impact must be carefully managed. Balancing the need for efficient water distribution with environmental conservation requires ongoing research, technological innovation, and the implementation of sustainable farming practices.

One of the primary environmental benefits of submersible pumps is their potential to reduce water waste. By delivering water directly to the root zone of crops, these systems minimize evaporation and runoff, leading to more efficient water use. This is particularly important in regions facing water scarcity, as it helps conserve precious water resources and reduces the strain on local aquifers.

However, the energy consumption of submersible pumps can contribute to increased greenhouse gas emissions, especially if powered by non-renewable energy sources. The carbon footprint associated with pump operation is a growing concern in the context of climate change mitigation efforts. To address this issue, there is a rising trend towards integrating renewable energy sources, such as solar panels, to power these pumps, thereby reducing their environmental impact.

Submersible pumps can also affect local ecosystems, particularly when drawing water from natural water bodies. Excessive water extraction may lead to reduced water levels in rivers, lakes, or groundwater aquifers, potentially impacting aquatic habitats and biodiversity. This highlights the importance of responsible water management practices and adherence to sustainable extraction limits.

Soil salinization is another environmental concern associated with improper use of submersible pumps in irrigation. Over-extraction of groundwater can lead to saltwater intrusion in coastal areas, compromising soil quality and reducing agricultural productivity. Implementing proper drainage systems and monitoring soil salinity levels are crucial measures to mitigate this risk.

The disposal of old or damaged submersible pumps presents another environmental challenge. These devices often contain materials that can be harmful if not properly recycled or disposed of, such as lubricants, plastics, and metals. Developing efficient recycling programs and promoting the use of environmentally friendly materials in pump construction are important steps towards reducing the environmental footprint of these systems.

Noise pollution from submersible pumps, while generally less significant than surface pumps, can still impact local wildlife, particularly in sensitive ecosystems. Manufacturers are increasingly focusing on developing quieter pump models to minimize this disturbance.

In conclusion, while submersible pumps offer significant benefits for agricultural irrigation, their environmental impact must be carefully managed. Balancing the need for efficient water distribution with environmental conservation requires ongoing research, technological innovation, and the implementation of sustainable farming practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!