Submersible pumps in chemical process industries.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Evolution and Objectives

Submersible pumps have undergone significant evolution in the chemical process industries over the past century. Initially developed for water and sewage applications, these pumps have been adapted to handle corrosive and hazardous chemicals, making them indispensable in various chemical processes. The journey began with simple designs focused on water displacement and has progressed to sophisticated systems capable of operating in extreme conditions.

The early 20th century saw the introduction of basic submersible pump designs, primarily used in mining and construction. As the chemical industry expanded, the need for pumps that could operate while submerged in chemical solutions became apparent. This led to the development of corrosion-resistant materials and improved sealing technologies in the 1950s and 1960s.

The 1970s and 1980s marked a significant leap in submersible pump technology for chemical applications. Engineers focused on enhancing efficiency, reliability, and the ability to handle a wider range of chemicals. This period saw the introduction of advanced impeller designs and the use of new composite materials that could withstand harsh chemical environments.

In recent decades, the evolution of submersible pumps has been driven by the need for greater energy efficiency, reduced maintenance requirements, and improved safety features. The integration of smart technologies and sensors has allowed for real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs in chemical processing plants.

The primary objectives of current research on submersible pumps in chemical process industries are multifaceted. Firstly, there is a strong focus on developing pumps with enhanced chemical resistance to handle an even broader spectrum of corrosive and abrasive substances. This includes the exploration of novel materials and coatings that can withstand extreme pH levels and high temperatures.

Secondly, researchers are working on improving the energy efficiency of submersible pumps, aiming to reduce power consumption without compromising performance. This involves optimizing hydraulic designs and incorporating advanced motor technologies such as permanent magnet motors.

Another key objective is to enhance the reliability and lifespan of submersible pumps in chemical applications. This includes developing better sealing solutions to prevent chemical ingress and improving bearing designs to withstand the challenges of continuous operation in harsh environments.

Lastly, there is a growing emphasis on making submersible pumps more environmentally friendly. This includes research into pumps that can operate with minimal environmental impact, such as those designed for zero-leakage operation and pumps that can handle emerging green chemicals and processes.

The early 20th century saw the introduction of basic submersible pump designs, primarily used in mining and construction. As the chemical industry expanded, the need for pumps that could operate while submerged in chemical solutions became apparent. This led to the development of corrosion-resistant materials and improved sealing technologies in the 1950s and 1960s.

The 1970s and 1980s marked a significant leap in submersible pump technology for chemical applications. Engineers focused on enhancing efficiency, reliability, and the ability to handle a wider range of chemicals. This period saw the introduction of advanced impeller designs and the use of new composite materials that could withstand harsh chemical environments.

In recent decades, the evolution of submersible pumps has been driven by the need for greater energy efficiency, reduced maintenance requirements, and improved safety features. The integration of smart technologies and sensors has allowed for real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs in chemical processing plants.

The primary objectives of current research on submersible pumps in chemical process industries are multifaceted. Firstly, there is a strong focus on developing pumps with enhanced chemical resistance to handle an even broader spectrum of corrosive and abrasive substances. This includes the exploration of novel materials and coatings that can withstand extreme pH levels and high temperatures.

Secondly, researchers are working on improving the energy efficiency of submersible pumps, aiming to reduce power consumption without compromising performance. This involves optimizing hydraulic designs and incorporating advanced motor technologies such as permanent magnet motors.

Another key objective is to enhance the reliability and lifespan of submersible pumps in chemical applications. This includes developing better sealing solutions to prevent chemical ingress and improving bearing designs to withstand the challenges of continuous operation in harsh environments.

Lastly, there is a growing emphasis on making submersible pumps more environmentally friendly. This includes research into pumps that can operate with minimal environmental impact, such as those designed for zero-leakage operation and pumps that can handle emerging green chemicals and processes.

Chemical Industry Demand Analysis

The chemical process industry has witnessed a growing demand for submersible pumps due to their versatility and efficiency in handling various liquid transfer applications. These pumps are particularly valued for their ability to operate in harsh environments, including corrosive and high-temperature conditions often encountered in chemical processing.

Market analysis indicates a steady increase in the adoption of submersible pumps across different segments of the chemical industry. The global submersible pump market for chemical applications is projected to experience significant growth over the next five years, driven by the expansion of chemical manufacturing facilities and the need for more efficient fluid handling solutions.

One of the key factors fueling the demand for submersible pumps in the chemical industry is the increasing focus on process optimization and energy efficiency. These pumps offer advantages such as reduced energy consumption, lower maintenance requirements, and improved reliability compared to traditional pump designs. As chemical companies strive to enhance their operational efficiency and reduce costs, the adoption of submersible pumps is expected to accelerate.

The chemical industry's shift towards more sustainable practices has also contributed to the rising demand for submersible pumps. These pumps are well-suited for handling environmentally sensitive fluids and can be designed to meet stringent environmental regulations. Their ability to operate in closed systems with minimal leakage risk makes them an attractive option for chemical manufacturers looking to improve their environmental performance.

Another significant driver of demand is the growing complexity of chemical processes, which often require pumps capable of handling a wide range of fluid viscosities, temperatures, and chemical compositions. Submersible pumps can be customized to meet specific application requirements, making them ideal for diverse chemical processing operations.

The pharmaceutical and fine chemicals sectors have emerged as particularly strong markets for submersible pumps. These industries require high-purity fluid handling and precise flow control, which submersible pumps can provide effectively. The increasing investment in pharmaceutical manufacturing facilities, especially in emerging markets, is expected to further boost the demand for specialized submersible pump solutions.

In terms of regional demand, Asia-Pacific is anticipated to be the fastest-growing market for submersible pumps in the chemical industry. This growth is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in chemical manufacturing infrastructure. North America and Europe are also expected to maintain steady demand, driven by the need to replace aging equipment and upgrade existing facilities with more efficient pump technologies.

Market analysis indicates a steady increase in the adoption of submersible pumps across different segments of the chemical industry. The global submersible pump market for chemical applications is projected to experience significant growth over the next five years, driven by the expansion of chemical manufacturing facilities and the need for more efficient fluid handling solutions.

One of the key factors fueling the demand for submersible pumps in the chemical industry is the increasing focus on process optimization and energy efficiency. These pumps offer advantages such as reduced energy consumption, lower maintenance requirements, and improved reliability compared to traditional pump designs. As chemical companies strive to enhance their operational efficiency and reduce costs, the adoption of submersible pumps is expected to accelerate.

The chemical industry's shift towards more sustainable practices has also contributed to the rising demand for submersible pumps. These pumps are well-suited for handling environmentally sensitive fluids and can be designed to meet stringent environmental regulations. Their ability to operate in closed systems with minimal leakage risk makes them an attractive option for chemical manufacturers looking to improve their environmental performance.

Another significant driver of demand is the growing complexity of chemical processes, which often require pumps capable of handling a wide range of fluid viscosities, temperatures, and chemical compositions. Submersible pumps can be customized to meet specific application requirements, making them ideal for diverse chemical processing operations.

The pharmaceutical and fine chemicals sectors have emerged as particularly strong markets for submersible pumps. These industries require high-purity fluid handling and precise flow control, which submersible pumps can provide effectively. The increasing investment in pharmaceutical manufacturing facilities, especially in emerging markets, is expected to further boost the demand for specialized submersible pump solutions.

In terms of regional demand, Asia-Pacific is anticipated to be the fastest-growing market for submersible pumps in the chemical industry. This growth is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in chemical manufacturing infrastructure. North America and Europe are also expected to maintain steady demand, driven by the need to replace aging equipment and upgrade existing facilities with more efficient pump technologies.

Challenges in Corrosive Environments

Submersible pumps in chemical process industries face significant challenges when operating in corrosive environments. The aggressive nature of many chemicals and the harsh conditions present in these industries can severely impact the performance and longevity of pump components. One of the primary concerns is material degradation due to chemical attack, which can lead to premature failure of critical pump parts.

Corrosion resistance is a key factor in the design and selection of submersible pumps for chemical applications. The choice of materials for pump construction must be carefully considered to withstand the specific corrosive agents present in the process fluids. Stainless steel alloys, such as 316L or duplex grades, are commonly used for their excellent corrosion resistance. However, even these materials may be susceptible to certain types of corrosion, such as pitting or stress corrosion cracking, under extreme conditions.

The presence of abrasive particles in corrosive fluids presents an additional challenge. These particles can cause erosion-corrosion, a synergistic effect that accelerates material loss and component damage. This phenomenon is particularly problematic in areas of high fluid velocity, such as impeller surfaces and discharge nozzles.

Temperature fluctuations in chemical processes can exacerbate corrosion issues. Elevated temperatures often accelerate chemical reactions and corrosion rates, while thermal cycling can lead to material fatigue and stress-induced corrosion. Proper thermal management and material selection are crucial to mitigate these effects.

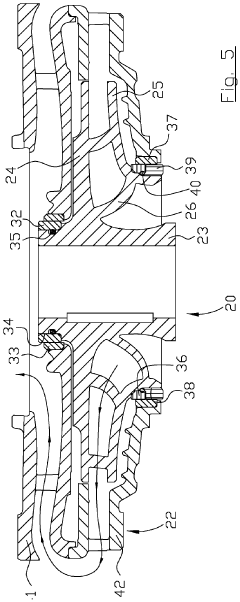

Sealing systems in submersible pumps are particularly vulnerable to corrosive attack. Mechanical seals and O-rings must maintain their integrity in harsh chemical environments to prevent leakage and ensure pump reliability. The development of advanced sealing materials and designs is an ongoing challenge in the industry.

Electrical components of submersible pumps, including motors and sensors, are also at risk in corrosive environments. Ingress of corrosive fluids can lead to short circuits, insulation breakdown, and sensor malfunction. Effective encapsulation and protective coatings are essential to safeguard these critical elements.

Maintenance and monitoring of submersible pumps in corrosive environments present unique challenges. Regular inspection and preventive maintenance are crucial, but access to submerged pumps can be difficult and hazardous. Advanced monitoring techniques, such as corrosion sensors and predictive maintenance algorithms, are being developed to address these issues and extend pump service life.

Corrosion resistance is a key factor in the design and selection of submersible pumps for chemical applications. The choice of materials for pump construction must be carefully considered to withstand the specific corrosive agents present in the process fluids. Stainless steel alloys, such as 316L or duplex grades, are commonly used for their excellent corrosion resistance. However, even these materials may be susceptible to certain types of corrosion, such as pitting or stress corrosion cracking, under extreme conditions.

The presence of abrasive particles in corrosive fluids presents an additional challenge. These particles can cause erosion-corrosion, a synergistic effect that accelerates material loss and component damage. This phenomenon is particularly problematic in areas of high fluid velocity, such as impeller surfaces and discharge nozzles.

Temperature fluctuations in chemical processes can exacerbate corrosion issues. Elevated temperatures often accelerate chemical reactions and corrosion rates, while thermal cycling can lead to material fatigue and stress-induced corrosion. Proper thermal management and material selection are crucial to mitigate these effects.

Sealing systems in submersible pumps are particularly vulnerable to corrosive attack. Mechanical seals and O-rings must maintain their integrity in harsh chemical environments to prevent leakage and ensure pump reliability. The development of advanced sealing materials and designs is an ongoing challenge in the industry.

Electrical components of submersible pumps, including motors and sensors, are also at risk in corrosive environments. Ingress of corrosive fluids can lead to short circuits, insulation breakdown, and sensor malfunction. Effective encapsulation and protective coatings are essential to safeguard these critical elements.

Maintenance and monitoring of submersible pumps in corrosive environments present unique challenges. Regular inspection and preventive maintenance are crucial, but access to submerged pumps can be difficult and hazardous. Advanced monitoring techniques, such as corrosion sensors and predictive maintenance algorithms, are being developed to address these issues and extend pump service life.

Current Submersible Pump Solutions

01 Design and construction of submersible pumps

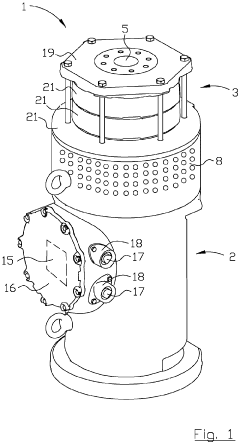

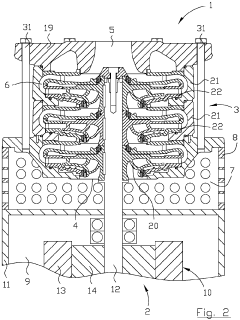

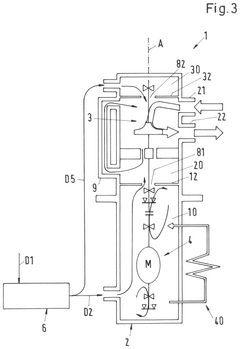

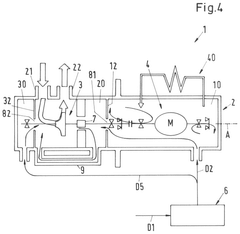

Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor coupled to a pump body, allowing for efficient operation in underwater environments. The construction often includes features to protect against water ingress and ensure reliable performance in various submersed conditions.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. They typically feature a sealed motor closely coupled to the pump body, ensuring efficient operation in underwater environments. The construction often includes corrosion-resistant materials and specialized sealing techniques to prevent liquid ingress into sensitive components.

- Control systems for submersible pumps: Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring various parameters such as pressure, flow rate, and temperature. They can also incorporate remote monitoring and control capabilities, allowing for efficient operation and maintenance of pumps in challenging environments.

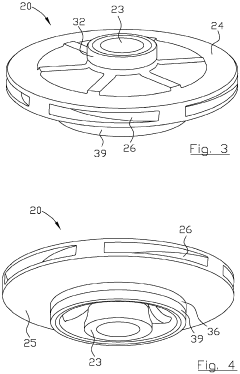

- Energy efficiency improvements in submersible pumps: Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, improved impeller designs, and the use of variable frequency drives. These advancements aim to reduce power consumption while maintaining or improving pump performance, particularly important in applications where energy costs are a significant factor.

- Specialized submersible pumps for specific applications: Submersible pumps are designed for various specialized applications, such as oil and gas extraction, wastewater treatment, and deep-sea exploration. These pumps may incorporate features like high-pressure capabilities, abrasion-resistant materials, or the ability to handle multiphase fluids. The designs are tailored to meet the unique challenges of each application environment.

- Maintenance and reliability enhancements for submersible pumps: Improving the reliability and ease of maintenance of submersible pumps is a key focus area. This includes the development of self-diagnostic systems, modular designs for easy component replacement, and the use of advanced materials to extend pump life. Additionally, innovations in sealing technology and bearing designs aim to reduce the frequency of maintenance interventions in challenging underwater environments.

02 Control systems for submersible pumps

Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors, monitoring devices, and intelligent algorithms to regulate pump operation, detect faults, and adjust performance based on changing conditions. Such control systems enhance efficiency and extend the lifespan of submersible pumps.Expand Specific Solutions03 Energy efficiency improvements in submersible pumps

Innovations in submersible pump technology focus on improving energy efficiency. This includes the development of high-efficiency motors, optimized impeller designs, and the use of advanced materials to reduce friction and power consumption. These improvements result in reduced operating costs and environmental impact.Expand Specific Solutions04 Specialized submersible pumps for specific applications

Submersible pumps are designed for various specialized applications, such as oil and gas extraction, wastewater treatment, and deep-sea exploration. These pumps are engineered to withstand harsh environments, handle specific types of fluids, and operate at extreme depths or pressures. The designs incorporate features tailored to the unique requirements of each application.Expand Specific Solutions05 Maintenance and reliability enhancements for submersible pumps

Advancements in submersible pump technology focus on improving reliability and ease of maintenance. This includes the development of self-diagnostic systems, modular designs for easy component replacement, and materials resistant to corrosion and wear. These enhancements reduce downtime, extend service intervals, and improve overall pump longevity.Expand Specific Solutions

Key Manufacturers and Competitors

The research on submersible pumps in chemical process industries is in a mature stage, with a significant market size and established technological solutions. The competitive landscape is characterized by a mix of large multinational corporations and specialized pump manufacturers. Companies like Schlumberger, Baker Hughes, and Halliburton dominate the market with their extensive resources and global presence. Sulzer and Xylem are key players focusing on innovative pump technologies for chemical applications. Chinese manufacturers such as Jiangxi Zhongchao Pump and Zhejiang Doyin Technology are emerging as strong competitors, particularly in the Asian market. The industry is seeing a trend towards more efficient, durable, and environmentally friendly pump designs, driven by the need for improved performance in harsh chemical environments.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced submersible pump systems for chemical process industries, focusing on reliability and efficiency. Their REDA Maximus ESP system incorporates a high-efficiency motor and advanced pump stages designed to handle corrosive and abrasive fluids common in chemical processes[1]. The system utilizes a variable speed drive for optimal performance across different operating conditions. Schlumberger's pumps feature specialized coatings and materials to resist chemical degradation, extending operational life in harsh environments[2]. They have also implemented smart monitoring systems that use real-time data analytics to predict maintenance needs and optimize pump performance, reducing downtime and improving overall efficiency[3].

Strengths: Industry-leading technology, global presence, and extensive R&D capabilities. Weaknesses: High initial costs and potential over-reliance on oil and gas sector expertise.

Sulzer Management AG

Technical Solution: Sulzer has developed a range of submersible pumps specifically designed for chemical process industries. Their AHLSTAR NPT submersible pump series is engineered to handle corrosive, abrasive, and high-temperature fluids commonly found in chemical processes[4]. These pumps feature a patented hydraulic balancing system that reduces axial thrust, extending bearing life and improving overall reliability. Sulzer's pumps incorporate advanced materials such as duplex stainless steel and specialized elastomers to resist chemical attack[5]. They have also implemented a modular design approach, allowing for easy maintenance and customization to specific process requirements. Sulzer's latest innovations include the integration of IoT sensors for predictive maintenance and performance optimization, enabling real-time monitoring and analysis of pump operations[6].

Strengths: Extensive experience in pump technology, strong focus on efficiency and reliability. Weaknesses: May face challenges in rapidly adapting to emerging digital technologies.

Innovative Materials and Coatings

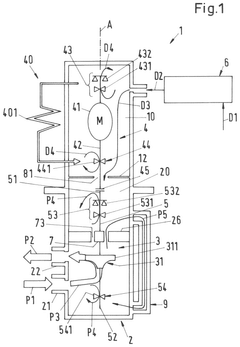

Submergible multistage pump

PatentPendingEP4390134A1

Innovation

- The pump design incorporates radial play between the housing and diffuser, allowing the diffuser to float during assembly and be aligned with the impeller, enabling smaller gaps without extensive machining, and features face seals to enhance wear resistance without altering the impeller or diffuser materials.

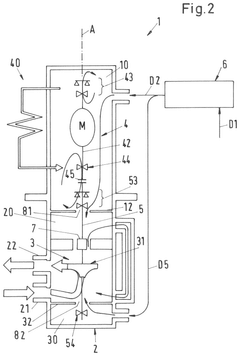

Submersible pump

PatentPendingUS20240410371A1

Innovation

- A seal-less submersible pump design with a common housing having two compartments, one filled with dosing fluid and the other with process fluid, where the dosing fluid is used to prevent process fluid from entering the drive unit, allowing for the use of polymer bearings and reducing the need for additional fluid supply systems.

Environmental Impact Assessment

The environmental impact of submersible pumps in chemical process industries is a critical consideration for sustainable operations. These pumps, while essential for various chemical processes, can have significant effects on the surrounding ecosystem if not properly managed. One of the primary concerns is the potential for chemical leaks or spills during pump operation. Even small leaks can lead to soil and groundwater contamination, affecting local flora and fauna. The materials used in pump construction must be carefully selected to withstand corrosive chemicals and prevent environmental release.

Energy consumption is another key environmental factor. Submersible pumps often operate continuously, consuming substantial amounts of electricity. This contributes to the overall carbon footprint of chemical facilities. Implementing energy-efficient pump designs and optimizing operational schedules can help mitigate this impact. Additionally, the use of renewable energy sources to power these pumps can further reduce their environmental footprint.

Noise pollution is a less obvious but still important environmental concern. Submersible pumps, especially when operating at high capacities, can generate significant noise levels. This can disturb local wildlife and affect the quality of life for nearby communities. Proper insulation and noise-reduction technologies should be incorporated into pump installations to minimize this impact.

The disposal of worn-out pump components and maintenance waste presents another environmental challenge. Many parts of submersible pumps used in chemical industries are exposed to hazardous substances and require special handling and disposal procedures. Implementing effective recycling and waste management programs is crucial to prevent these materials from harming the environment.

Water usage and discharge are also significant environmental considerations. Some submersible pump applications in chemical industries involve the extraction or movement of large volumes of water. This can affect local water tables and aquatic ecosystems. Moreover, the discharge of process water, even after treatment, may contain trace chemicals that can impact receiving water bodies. Stringent water management practices and advanced treatment technologies are essential to minimize these effects.

The manufacturing process of submersible pumps itself has environmental implications. The production of specialized materials and components often involves energy-intensive processes and the use of potentially harmful substances. Adopting cleaner production methods and sourcing materials from environmentally responsible suppliers can help reduce the overall environmental impact of pump manufacturing.

In conclusion, while submersible pumps are indispensable in chemical process industries, their environmental impact must be carefully managed. This requires a holistic approach, considering all aspects from design and manufacturing to operation and disposal. By implementing best practices and leveraging innovative technologies, the chemical industry can significantly reduce the environmental footprint of submersible pump applications.

Energy consumption is another key environmental factor. Submersible pumps often operate continuously, consuming substantial amounts of electricity. This contributes to the overall carbon footprint of chemical facilities. Implementing energy-efficient pump designs and optimizing operational schedules can help mitigate this impact. Additionally, the use of renewable energy sources to power these pumps can further reduce their environmental footprint.

Noise pollution is a less obvious but still important environmental concern. Submersible pumps, especially when operating at high capacities, can generate significant noise levels. This can disturb local wildlife and affect the quality of life for nearby communities. Proper insulation and noise-reduction technologies should be incorporated into pump installations to minimize this impact.

The disposal of worn-out pump components and maintenance waste presents another environmental challenge. Many parts of submersible pumps used in chemical industries are exposed to hazardous substances and require special handling and disposal procedures. Implementing effective recycling and waste management programs is crucial to prevent these materials from harming the environment.

Water usage and discharge are also significant environmental considerations. Some submersible pump applications in chemical industries involve the extraction or movement of large volumes of water. This can affect local water tables and aquatic ecosystems. Moreover, the discharge of process water, even after treatment, may contain trace chemicals that can impact receiving water bodies. Stringent water management practices and advanced treatment technologies are essential to minimize these effects.

The manufacturing process of submersible pumps itself has environmental implications. The production of specialized materials and components often involves energy-intensive processes and the use of potentially harmful substances. Adopting cleaner production methods and sourcing materials from environmentally responsible suppliers can help reduce the overall environmental impact of pump manufacturing.

In conclusion, while submersible pumps are indispensable in chemical process industries, their environmental impact must be carefully managed. This requires a holistic approach, considering all aspects from design and manufacturing to operation and disposal. By implementing best practices and leveraging innovative technologies, the chemical industry can significantly reduce the environmental footprint of submersible pump applications.

Safety Standards and Regulations

Safety standards and regulations play a crucial role in the application of submersible pumps in chemical process industries. These standards are designed to protect workers, equipment, and the environment from potential hazards associated with the use of submersible pumps in corrosive and potentially dangerous chemical environments.

The International Electrotechnical Commission (IEC) has established several standards specifically for submersible pumps used in hazardous locations. IEC 60079-14 provides guidelines for the design, selection, and installation of electrical equipment in explosive atmospheres, which is particularly relevant for submersible pumps in chemical processing facilities. Additionally, IEC 60529 defines the degrees of protection provided by enclosures, ensuring that submersible pumps are adequately protected against ingress of solid objects and liquids.

In the United States, the Occupational Safety and Health Administration (OSHA) has set forth regulations under 29 CFR 1910.119, which addresses process safety management of highly hazardous chemicals. This regulation requires employers to develop and implement safe work practices to prevent or mitigate the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals, which directly impacts the use of submersible pumps in chemical processes.

The National Fire Protection Association (NFPA) has also developed standards relevant to submersible pumps in chemical industries. NFPA 820 provides standard guidelines for fire protection in wastewater treatment and collection facilities, which often involve the use of submersible pumps. This standard addresses the classification of hazardous areas and the appropriate selection of equipment for these environments.

European standards, such as the ATEX Directive (2014/34/EU), set requirements for equipment and protective systems intended for use in potentially explosive atmospheres. Submersible pumps used in chemical process industries must comply with these standards to ensure safe operation in potentially explosive environments.

The American Petroleum Institute (API) has developed standards specific to centrifugal pumps for petroleum, petrochemical, and natural gas industries. API 610 provides guidelines for the design, materials, fabrication, inspection, testing, and preparation for shipment of centrifugal pumps, including submersible types, used in petroleum, petrochemical, and gas industry services.

Manufacturers of submersible pumps for chemical process industries must adhere to these standards and regulations during the design, production, and testing phases. End-users are responsible for ensuring that the selected pumps meet the required safety standards for their specific applications and operating environments. Regular inspections, maintenance, and testing are essential to maintain compliance with these safety standards throughout the operational life of the submersible pumps.

As chemical processes evolve and new hazards are identified, safety standards and regulations continue to be updated. It is crucial for both manufacturers and users of submersible pumps in chemical process industries to stay informed about the latest developments in safety standards and implement necessary changes to ensure ongoing compliance and safety in their operations.

The International Electrotechnical Commission (IEC) has established several standards specifically for submersible pumps used in hazardous locations. IEC 60079-14 provides guidelines for the design, selection, and installation of electrical equipment in explosive atmospheres, which is particularly relevant for submersible pumps in chemical processing facilities. Additionally, IEC 60529 defines the degrees of protection provided by enclosures, ensuring that submersible pumps are adequately protected against ingress of solid objects and liquids.

In the United States, the Occupational Safety and Health Administration (OSHA) has set forth regulations under 29 CFR 1910.119, which addresses process safety management of highly hazardous chemicals. This regulation requires employers to develop and implement safe work practices to prevent or mitigate the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals, which directly impacts the use of submersible pumps in chemical processes.

The National Fire Protection Association (NFPA) has also developed standards relevant to submersible pumps in chemical industries. NFPA 820 provides standard guidelines for fire protection in wastewater treatment and collection facilities, which often involve the use of submersible pumps. This standard addresses the classification of hazardous areas and the appropriate selection of equipment for these environments.

European standards, such as the ATEX Directive (2014/34/EU), set requirements for equipment and protective systems intended for use in potentially explosive atmospheres. Submersible pumps used in chemical process industries must comply with these standards to ensure safe operation in potentially explosive environments.

The American Petroleum Institute (API) has developed standards specific to centrifugal pumps for petroleum, petrochemical, and natural gas industries. API 610 provides guidelines for the design, materials, fabrication, inspection, testing, and preparation for shipment of centrifugal pumps, including submersible types, used in petroleum, petrochemical, and gas industry services.

Manufacturers of submersible pumps for chemical process industries must adhere to these standards and regulations during the design, production, and testing phases. End-users are responsible for ensuring that the selected pumps meet the required safety standards for their specific applications and operating environments. Regular inspections, maintenance, and testing are essential to maintain compliance with these safety standards throughout the operational life of the submersible pumps.

As chemical processes evolve and new hazards are identified, safety standards and regulations continue to be updated. It is crucial for both manufacturers and users of submersible pumps in chemical process industries to stay informed about the latest developments in safety standards and implement necessary changes to ensure ongoing compliance and safety in their operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!