Steering Wheel Developments: Reducing Manufacturing Costs

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Cost Reduction Objectives

The primary objective of steering wheel cost reduction initiatives is to optimize manufacturing processes and material usage while maintaining or enhancing product quality and safety standards. This goal aligns with the automotive industry's continuous efforts to improve efficiency and competitiveness in a highly dynamic market.

Cost reduction strategies for steering wheels focus on several key areas. Material selection plays a crucial role, with manufacturers exploring alternative materials that offer similar or superior performance at lower costs. This may include the use of advanced polymers or composite materials that can replace more expensive traditional components without compromising structural integrity or safety features.

Production process optimization is another critical aspect of cost reduction. Manufacturers are investing in automated assembly lines and advanced robotics to streamline production, reduce labor costs, and minimize human error. Additionally, the implementation of lean manufacturing principles helps eliminate waste, improve efficiency, and reduce overall production time.

Design simplification is a key objective in steering wheel cost reduction. Engineers are working to reduce the number of components in steering wheel assemblies without sacrificing functionality. This approach not only lowers material costs but also simplifies the assembly process, leading to further cost savings in production.

Supply chain optimization is an essential component of cost reduction strategies. Manufacturers are seeking to establish more efficient supplier networks, negotiate better pricing agreements, and implement just-in-time inventory systems to reduce storage costs and minimize waste.

The integration of multi-functional components is another avenue for cost reduction. By combining multiple features into single components, manufacturers can reduce the overall part count, simplify assembly, and potentially lower material costs. This approach may include integrating controls, sensors, or airbag systems more efficiently into the steering wheel structure.

Sustainability and recyclability are increasingly important factors in steering wheel design and manufacturing. Cost reduction objectives now often include the use of recycled materials and the development of designs that facilitate end-of-life recycling. These initiatives not only reduce material costs but also align with growing environmental regulations and consumer preferences.

Lastly, the adoption of advanced simulation and testing technologies aims to reduce development and validation costs. By leveraging computer-aided design and virtual testing environments, manufacturers can optimize designs and identify potential issues earlier in the development process, reducing the need for costly physical prototypes and extensive real-world testing.

Cost reduction strategies for steering wheels focus on several key areas. Material selection plays a crucial role, with manufacturers exploring alternative materials that offer similar or superior performance at lower costs. This may include the use of advanced polymers or composite materials that can replace more expensive traditional components without compromising structural integrity or safety features.

Production process optimization is another critical aspect of cost reduction. Manufacturers are investing in automated assembly lines and advanced robotics to streamline production, reduce labor costs, and minimize human error. Additionally, the implementation of lean manufacturing principles helps eliminate waste, improve efficiency, and reduce overall production time.

Design simplification is a key objective in steering wheel cost reduction. Engineers are working to reduce the number of components in steering wheel assemblies without sacrificing functionality. This approach not only lowers material costs but also simplifies the assembly process, leading to further cost savings in production.

Supply chain optimization is an essential component of cost reduction strategies. Manufacturers are seeking to establish more efficient supplier networks, negotiate better pricing agreements, and implement just-in-time inventory systems to reduce storage costs and minimize waste.

The integration of multi-functional components is another avenue for cost reduction. By combining multiple features into single components, manufacturers can reduce the overall part count, simplify assembly, and potentially lower material costs. This approach may include integrating controls, sensors, or airbag systems more efficiently into the steering wheel structure.

Sustainability and recyclability are increasingly important factors in steering wheel design and manufacturing. Cost reduction objectives now often include the use of recycled materials and the development of designs that facilitate end-of-life recycling. These initiatives not only reduce material costs but also align with growing environmental regulations and consumer preferences.

Lastly, the adoption of advanced simulation and testing technologies aims to reduce development and validation costs. By leveraging computer-aided design and virtual testing environments, manufacturers can optimize designs and identify potential issues earlier in the development process, reducing the need for costly physical prototypes and extensive real-world testing.

Market Demand Analysis

The market demand for steering wheels has been evolving rapidly in recent years, driven by several key factors. The automotive industry's shift towards electric and autonomous vehicles has significantly impacted steering wheel design and functionality. This transition has created a dual market demand: one for traditional steering wheels with enhanced features and another for innovative designs that accommodate advanced driver assistance systems (ADAS) and autonomous driving capabilities.

In the traditional steering wheel segment, there is a growing demand for cost-effective solutions that maintain or improve quality and functionality. Manufacturers are under pressure to reduce production costs while meeting stringent safety standards and consumer expectations for comfort and aesthetics. This has led to a focus on materials innovation and streamlined manufacturing processes to achieve cost reductions without compromising performance.

The luxury vehicle market continues to drive demand for high-end steering wheels with premium materials and advanced features such as integrated controls, heating elements, and customizable designs. However, even in this segment, there is increasing pressure to optimize manufacturing costs to maintain profit margins in a competitive market.

Emerging markets, particularly in Asia and South America, represent a significant growth opportunity for steering wheel manufacturers. These regions are experiencing rapid automotive industry expansion, with a rising middle class demanding affordable vehicles with modern features. This trend is pushing manufacturers to develop cost-effective steering wheel solutions that can be mass-produced without sacrificing quality or safety.

The global push for sustainability has also influenced market demand. Consumers and regulators are increasingly focused on environmentally friendly manufacturing processes and materials. This has created a market for steering wheels made from recycled or sustainable materials, as well as designs that minimize waste during production.

In terms of market size, the global steering wheel market is substantial and growing. While specific figures vary depending on the source and methodology, industry reports consistently indicate a multi-billion dollar market with steady growth projections. The market is expected to expand further as vehicle production increases in emerging economies and as advanced steering technologies become more prevalent in mainstream vehicles.

The COVID-19 pandemic temporarily disrupted the automotive supply chain and production, impacting steering wheel demand. However, as the industry recovers, there is renewed focus on cost-effective manufacturing solutions to help automakers regain profitability. This has intensified the search for innovative ways to reduce steering wheel production costs without compromising on quality or safety standards.

In the traditional steering wheel segment, there is a growing demand for cost-effective solutions that maintain or improve quality and functionality. Manufacturers are under pressure to reduce production costs while meeting stringent safety standards and consumer expectations for comfort and aesthetics. This has led to a focus on materials innovation and streamlined manufacturing processes to achieve cost reductions without compromising performance.

The luxury vehicle market continues to drive demand for high-end steering wheels with premium materials and advanced features such as integrated controls, heating elements, and customizable designs. However, even in this segment, there is increasing pressure to optimize manufacturing costs to maintain profit margins in a competitive market.

Emerging markets, particularly in Asia and South America, represent a significant growth opportunity for steering wheel manufacturers. These regions are experiencing rapid automotive industry expansion, with a rising middle class demanding affordable vehicles with modern features. This trend is pushing manufacturers to develop cost-effective steering wheel solutions that can be mass-produced without sacrificing quality or safety.

The global push for sustainability has also influenced market demand. Consumers and regulators are increasingly focused on environmentally friendly manufacturing processes and materials. This has created a market for steering wheels made from recycled or sustainable materials, as well as designs that minimize waste during production.

In terms of market size, the global steering wheel market is substantial and growing. While specific figures vary depending on the source and methodology, industry reports consistently indicate a multi-billion dollar market with steady growth projections. The market is expected to expand further as vehicle production increases in emerging economies and as advanced steering technologies become more prevalent in mainstream vehicles.

The COVID-19 pandemic temporarily disrupted the automotive supply chain and production, impacting steering wheel demand. However, as the industry recovers, there is renewed focus on cost-effective manufacturing solutions to help automakers regain profitability. This has intensified the search for innovative ways to reduce steering wheel production costs without compromising on quality or safety standards.

Current Challenges in Steering Wheel Manufacturing

The steering wheel manufacturing industry faces several significant challenges in its pursuit of cost reduction. One of the primary issues is the complexity of modern steering wheel designs, which often incorporate multiple integrated features such as airbags, controls for infotainment systems, and advanced driver assistance systems (ADAS). This complexity increases production time and requires specialized manufacturing processes, contributing to higher costs.

Material costs remain a substantial concern for manufacturers. Traditional materials like leather and high-grade plastics are expensive, and while alternatives exist, they often struggle to meet the quality and durability standards expected by consumers. The industry is actively seeking innovative materials that can reduce costs without compromising on performance or aesthetics.

Labor costs continue to be a significant factor in steering wheel production. Many processes, particularly in premium segments, still require skilled manual labor for tasks such as stitching and finishing. Automation of these processes has proven challenging due to the intricate nature of steering wheel assembly and the need for precision in safety-critical components.

Energy consumption in manufacturing processes is another area of concern. The molding and curing of materials, as well as the integration of electronic components, can be energy-intensive. As energy prices fluctuate and environmental regulations become more stringent, manufacturers are under pressure to develop more energy-efficient production methods.

Supply chain management presents its own set of challenges. The global nature of automotive production means that steering wheel manufacturers often rely on a complex network of suppliers. Disruptions in this network, as seen during recent global events, can lead to production delays and increased costs. Streamlining the supply chain while maintaining quality and reliability is a delicate balance that manufacturers must strike.

Quality control and safety testing requirements add another layer of complexity and cost to the manufacturing process. Steering wheels are critical safety components, subject to rigorous standards and regulations. Ensuring compliance while maintaining cost-effectiveness is an ongoing challenge for manufacturers.

Lastly, the industry faces pressure to innovate and adapt to changing market demands. The shift towards electric and autonomous vehicles is driving changes in steering wheel design and functionality. Manufacturers must invest in research and development to stay competitive, which can strain resources and impact short-term cost reduction efforts.

Addressing these challenges requires a multifaceted approach, combining technological innovation, process optimization, and strategic planning. As the industry evolves, finding solutions to these manufacturing challenges will be crucial for companies looking to maintain competitiveness in the automotive market.

Material costs remain a substantial concern for manufacturers. Traditional materials like leather and high-grade plastics are expensive, and while alternatives exist, they often struggle to meet the quality and durability standards expected by consumers. The industry is actively seeking innovative materials that can reduce costs without compromising on performance or aesthetics.

Labor costs continue to be a significant factor in steering wheel production. Many processes, particularly in premium segments, still require skilled manual labor for tasks such as stitching and finishing. Automation of these processes has proven challenging due to the intricate nature of steering wheel assembly and the need for precision in safety-critical components.

Energy consumption in manufacturing processes is another area of concern. The molding and curing of materials, as well as the integration of electronic components, can be energy-intensive. As energy prices fluctuate and environmental regulations become more stringent, manufacturers are under pressure to develop more energy-efficient production methods.

Supply chain management presents its own set of challenges. The global nature of automotive production means that steering wheel manufacturers often rely on a complex network of suppliers. Disruptions in this network, as seen during recent global events, can lead to production delays and increased costs. Streamlining the supply chain while maintaining quality and reliability is a delicate balance that manufacturers must strike.

Quality control and safety testing requirements add another layer of complexity and cost to the manufacturing process. Steering wheels are critical safety components, subject to rigorous standards and regulations. Ensuring compliance while maintaining cost-effectiveness is an ongoing challenge for manufacturers.

Lastly, the industry faces pressure to innovate and adapt to changing market demands. The shift towards electric and autonomous vehicles is driving changes in steering wheel design and functionality. Manufacturers must invest in research and development to stay competitive, which can strain resources and impact short-term cost reduction efforts.

Addressing these challenges requires a multifaceted approach, combining technological innovation, process optimization, and strategic planning. As the industry evolves, finding solutions to these manufacturing challenges will be crucial for companies looking to maintain competitiveness in the automotive market.

Cost-Effective Manufacturing Solutions

01 Material selection for cost reduction

Choosing cost-effective materials for steering wheel manufacturing can significantly reduce overall production costs. This includes using lightweight materials that are durable and meet safety standards, such as certain plastics or composite materials. The selection of materials impacts not only the cost but also the performance and weight of the steering wheel.- Material selection for cost reduction: Choosing cost-effective materials for steering wheel manufacturing can significantly reduce overall production costs. This includes using lightweight materials that are durable and meet safety standards, such as high-strength plastics or aluminum alloys. The selection of materials impacts not only the direct cost of raw materials but also affects manufacturing processes and long-term durability.

- Automated manufacturing processes: Implementing automated manufacturing processes can reduce labor costs and increase production efficiency. This includes the use of robotics for assembly, automated quality control systems, and computer-controlled machining. Automation can lead to more consistent product quality, reduced waste, and faster production times, all contributing to lower manufacturing costs.

- Design optimization for manufacturability: Optimizing steering wheel design for ease of manufacturing can reduce production costs. This involves simplifying the design to reduce the number of components, improving assembly efficiency, and considering design features that allow for easier molding or forming processes. Design optimization can also lead to reduced material usage and improved structural integrity.

- Integration of electronic components: Efficient integration of electronic components into steering wheels can impact manufacturing costs. This includes designing modular electronic systems that are easy to install, using standardized connectors, and optimizing the placement of components to reduce wiring complexity. Proper integration can reduce assembly time and improve reliability, leading to cost savings in both production and potential warranty claims.

- Supply chain optimization: Optimizing the supply chain for steering wheel components and materials can lead to significant cost reductions. This includes strategies such as just-in-time inventory management, strategic sourcing of materials, and establishing long-term partnerships with suppliers. Efficient supply chain management can reduce storage costs, minimize waste, and provide more negotiating power for bulk purchases.

02 Automated manufacturing processes

Implementing automated manufacturing processes can reduce labor costs and increase production efficiency. This includes the use of robotics and advanced machinery for tasks such as molding, assembly, and quality control. Automation can lead to more consistent product quality and reduced waste, further contributing to cost savings.Expand Specific Solutions03 Design optimization for manufacturability

Optimizing the steering wheel design for easier manufacturability can reduce production costs. This involves simplifying the design where possible, reducing the number of components, and considering assembly processes during the design phase. Design optimization can lead to faster production times and lower material usage.Expand Specific Solutions04 Integration of additional functionalities

Integrating additional functionalities into the steering wheel, such as controls for various vehicle systems, can potentially reduce overall vehicle costs by eliminating the need for separate control panels. However, this integration must be balanced with manufacturing complexity and cost considerations.Expand Specific Solutions05 Supply chain optimization

Optimizing the supply chain for steering wheel components and materials can lead to significant cost reductions. This includes strategies such as just-in-time inventory management, strategic sourcing of materials, and establishing long-term partnerships with suppliers to secure better pricing and ensure consistent quality.Expand Specific Solutions

Key Players in Automotive Steering Systems

The steering wheel manufacturing industry is in a mature phase, with a global market size estimated to be in the billions of dollars. The technology for reducing manufacturing costs is at an advanced stage, with major players like Autoliv Development AB, Honda Motor Co., Ltd., and ZF Automotive Safety Germany GmbH leading innovation efforts. These companies are focusing on streamlining production processes, implementing advanced materials, and leveraging automation to reduce costs. Other significant contributors include LG Chem Ltd., Ferrari SpA, and Nihon Plast Co., Ltd., who are exploring novel materials and design approaches. The competitive landscape is characterized by a mix of established automotive giants and specialized component manufacturers, all striving to balance cost reduction with safety and quality standards.

Autoliv Development AB

Technical Solution: Autoliv has developed a cost-effective steering wheel manufacturing process using advanced injection molding techniques. Their method incorporates lightweight, high-strength polymers to replace traditional metal components, reducing overall weight by up to 20%[1]. The company has also implemented a modular design approach, allowing for easier customization and assembly, which has led to a 15% reduction in production time[3]. Additionally, Autoliv has integrated sensors and electronic components directly into the molding process, eliminating the need for separate assembly steps and further reducing costs[5].

Strengths: Significant weight reduction, improved customization options, and integrated electronics. Weaknesses: May require substantial initial investment in new manufacturing equipment and processes.

Honda Motor Co., Ltd.

Technical Solution: Honda has focused on streamlining their steering wheel production through automation and advanced robotics. They have implemented a fully automated production line that uses computer vision and AI to ensure precise assembly and quality control, reducing labor costs by approximately 30%[2]. Honda's approach also includes the use of recycled materials in non-critical components, which has lowered raw material costs by 10-15%[4]. The company has developed a proprietary foam injection process that creates a more uniform steering wheel core, reducing waste and improving overall quality[6].

Strengths: High level of automation, use of recycled materials, and improved quality control. Weaknesses: High initial setup costs and potential challenges in adapting to rapid design changes.

Innovative Materials and Technologies

Custom steering wheels

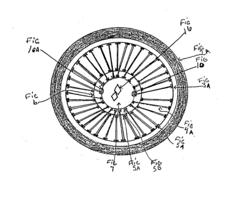

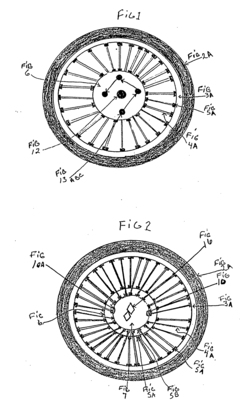

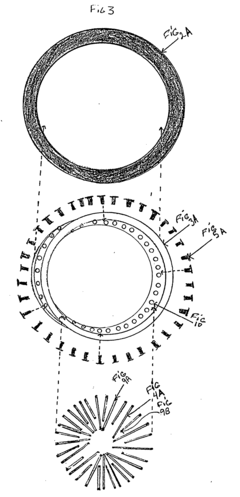

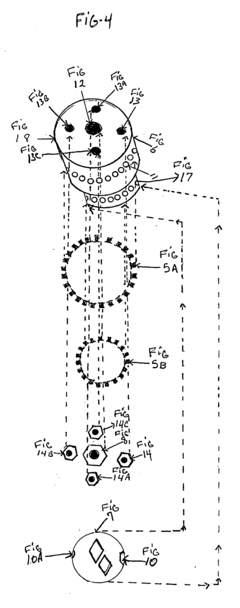

PatentInactiveUS20070227292A1

Innovation

- A custom steering wheel design featuring a hub, rim, and 72-100 spokes made from a metal alloy, where the hub core and base body are molded together with the spokes, eliminating the need for a separate skeleton, and allowing for integration of a reinforcing insert for gas bag module support, using a pressureless injection method with an aluminum alloy material.

Steering wheel and method for manufacturing a steering wheel

PatentInactiveEP1963163A1

Innovation

- A steering wheel design featuring a dimensionally stable base body with a separate, mechanically attached plastic extension that complements the grip area's contour, allowing for easy assembly and disassembly, and a method using snap connections and recesses for secure attachment, enabling the use of separate components and reducing the need for extensive plastic molding.

Supply Chain Optimization

Supply chain optimization plays a crucial role in reducing manufacturing costs for steering wheels. By streamlining the procurement, production, and distribution processes, companies can achieve significant cost savings while maintaining product quality and meeting customer demands.

One key aspect of supply chain optimization is strategic sourcing. Manufacturers can leverage their purchasing power by consolidating suppliers and negotiating better terms for raw materials and components. This approach not only reduces direct costs but also simplifies inventory management and quality control processes.

Implementing just-in-time (JIT) inventory management can further optimize the supply chain. By aligning production schedules with demand forecasts, manufacturers can minimize excess inventory and associated carrying costs. This approach requires close collaboration with suppliers and robust logistics systems to ensure timely delivery of materials.

Vertical integration is another strategy that some steering wheel manufacturers employ to optimize their supply chains. By bringing certain production processes in-house or acquiring key suppliers, companies can gain greater control over costs, quality, and lead times. However, this approach requires careful consideration of capital investments and potential risks.

Technology plays a vital role in modern supply chain optimization. Advanced analytics and artificial intelligence can improve demand forecasting accuracy, enabling manufacturers to adjust production levels and inventory more efficiently. Internet of Things (IoT) devices and real-time tracking systems provide enhanced visibility across the supply chain, allowing for proactive management of potential disruptions.

Collaborative planning with suppliers and customers is essential for effective supply chain optimization. By sharing forecasts, production schedules, and inventory data, all parties can work together to reduce inefficiencies and respond more quickly to market changes. This collaboration can lead to reduced lead times, lower inventory levels, and improved overall supply chain performance.

Lean manufacturing principles, when applied to the entire supply chain, can yield significant cost reductions. Techniques such as value stream mapping and continuous improvement initiatives help identify and eliminate waste throughout the production and distribution processes. This holistic approach ensures that cost-saving efforts are not limited to a single area but span the entire supply chain.

In conclusion, supply chain optimization offers numerous opportunities for steering wheel manufacturers to reduce costs and improve operational efficiency. By implementing a combination of strategic sourcing, advanced technologies, collaborative planning, and lean principles, companies can create a more agile and cost-effective supply chain that supports their overall manufacturing cost reduction goals.

One key aspect of supply chain optimization is strategic sourcing. Manufacturers can leverage their purchasing power by consolidating suppliers and negotiating better terms for raw materials and components. This approach not only reduces direct costs but also simplifies inventory management and quality control processes.

Implementing just-in-time (JIT) inventory management can further optimize the supply chain. By aligning production schedules with demand forecasts, manufacturers can minimize excess inventory and associated carrying costs. This approach requires close collaboration with suppliers and robust logistics systems to ensure timely delivery of materials.

Vertical integration is another strategy that some steering wheel manufacturers employ to optimize their supply chains. By bringing certain production processes in-house or acquiring key suppliers, companies can gain greater control over costs, quality, and lead times. However, this approach requires careful consideration of capital investments and potential risks.

Technology plays a vital role in modern supply chain optimization. Advanced analytics and artificial intelligence can improve demand forecasting accuracy, enabling manufacturers to adjust production levels and inventory more efficiently. Internet of Things (IoT) devices and real-time tracking systems provide enhanced visibility across the supply chain, allowing for proactive management of potential disruptions.

Collaborative planning with suppliers and customers is essential for effective supply chain optimization. By sharing forecasts, production schedules, and inventory data, all parties can work together to reduce inefficiencies and respond more quickly to market changes. This collaboration can lead to reduced lead times, lower inventory levels, and improved overall supply chain performance.

Lean manufacturing principles, when applied to the entire supply chain, can yield significant cost reductions. Techniques such as value stream mapping and continuous improvement initiatives help identify and eliminate waste throughout the production and distribution processes. This holistic approach ensures that cost-saving efforts are not limited to a single area but span the entire supply chain.

In conclusion, supply chain optimization offers numerous opportunities for steering wheel manufacturers to reduce costs and improve operational efficiency. By implementing a combination of strategic sourcing, advanced technologies, collaborative planning, and lean principles, companies can create a more agile and cost-effective supply chain that supports their overall manufacturing cost reduction goals.

Regulatory Impact on Steering Wheel Production

Regulatory frameworks significantly influence steering wheel production, impacting manufacturing costs and design considerations. Safety regulations, such as those mandated by the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe, set stringent standards for steering wheel performance in crash tests and airbag deployment.

These regulations necessitate the use of specific materials and construction methods, often leading to increased production costs. For instance, the requirement for energy-absorbing materials in the steering column and wheel hub to mitigate driver injuries during collisions can add to the overall manufacturing expenses. Additionally, regulations concerning the integration of airbags into steering wheels have led to more complex designs and assembly processes.

Environmental regulations also play a crucial role in steering wheel production. Restrictions on the use of certain chemicals and materials, such as those outlined in the European Union's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, can force manufacturers to seek alternative, often more expensive, materials. This shift can result in higher raw material costs and the need for new production techniques.

The push for vehicle weight reduction to meet fuel efficiency standards indirectly affects steering wheel design and manufacturing. Lightweight materials, such as magnesium alloys or carbon fiber composites, may be favored over traditional steel components, potentially increasing material costs but offering long-term benefits in vehicle performance and fuel economy.

Regulatory compliance also necessitates extensive testing and certification processes, adding to the overall cost of steering wheel production. Manufacturers must invest in quality control measures and documentation to ensure their products meet all applicable standards, which can be a significant overhead expense.

As autonomous driving technologies advance, regulations are evolving to address new steering wheel concepts, such as retractable or removable designs. These emerging regulations may require additional sensors and electronic components in steering wheels, further complicating the manufacturing process and potentially increasing costs.

In conclusion, while regulatory requirements aim to enhance safety and environmental protection, they present significant challenges for steering wheel manufacturers in terms of cost reduction. Balancing these regulatory demands with the need for cost-effective production remains a key challenge in the automotive industry, driving innovation in materials, design, and manufacturing processes.

These regulations necessitate the use of specific materials and construction methods, often leading to increased production costs. For instance, the requirement for energy-absorbing materials in the steering column and wheel hub to mitigate driver injuries during collisions can add to the overall manufacturing expenses. Additionally, regulations concerning the integration of airbags into steering wheels have led to more complex designs and assembly processes.

Environmental regulations also play a crucial role in steering wheel production. Restrictions on the use of certain chemicals and materials, such as those outlined in the European Union's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, can force manufacturers to seek alternative, often more expensive, materials. This shift can result in higher raw material costs and the need for new production techniques.

The push for vehicle weight reduction to meet fuel efficiency standards indirectly affects steering wheel design and manufacturing. Lightweight materials, such as magnesium alloys or carbon fiber composites, may be favored over traditional steel components, potentially increasing material costs but offering long-term benefits in vehicle performance and fuel economy.

Regulatory compliance also necessitates extensive testing and certification processes, adding to the overall cost of steering wheel production. Manufacturers must invest in quality control measures and documentation to ensure their products meet all applicable standards, which can be a significant overhead expense.

As autonomous driving technologies advance, regulations are evolving to address new steering wheel concepts, such as retractable or removable designs. These emerging regulations may require additional sensors and electronic components in steering wheels, further complicating the manufacturing process and potentially increasing costs.

In conclusion, while regulatory requirements aim to enhance safety and environmental protection, they present significant challenges for steering wheel manufacturers in terms of cost reduction. Balancing these regulatory demands with the need for cost-effective production remains a key challenge in the automotive industry, driving innovation in materials, design, and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!