Steering Wheel Innovations: Reducing Production Costs

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Steering Wheel Cost Reduction Background and Objectives

Steering wheel technology has undergone significant evolution since its inception in the automotive industry. From simple wooden designs to complex multi-functional units, steering wheels have become integral components of modern vehicles. The current focus on cost reduction in steering wheel production stems from the increasing pressure on automotive manufacturers to optimize expenses while maintaining quality and safety standards.

The primary objective of this technical research is to explore innovative approaches to reduce the production costs of steering wheels without compromising their functionality, safety, or user experience. This goal aligns with the broader industry trend of streamlining manufacturing processes and adopting cost-effective materials and technologies across the automotive supply chain.

Historical trends in steering wheel development have seen a shift from purely mechanical systems to those incorporating advanced electronics and sensors. This progression has led to increased complexity and, consequently, higher production costs. The challenge now lies in reversing this trend while still meeting the demands of modern automotive design and consumer expectations.

Market dynamics play a crucial role in driving the need for cost reduction. With the global automotive market facing intense competition and evolving consumer preferences, manufacturers are seeking ways to maintain profit margins without raising vehicle prices. Steering wheel cost reduction represents a significant opportunity to achieve this balance, as it is a component present in every vehicle produced.

Technological advancements in materials science, manufacturing processes, and design optimization offer promising avenues for cost reduction. These may include the exploration of alternative materials that are both lightweight and cost-effective, the implementation of advanced manufacturing techniques such as 3D printing for prototyping and small-scale production, and the simplification of design elements without sacrificing functionality.

The scope of this research extends beyond mere cost-cutting measures. It aims to identify innovative solutions that could potentially redefine steering wheel production, considering factors such as sustainability, scalability, and adaptability to future automotive trends. This includes investigating the potential for modular designs that could reduce complexity and allow for more efficient production and customization.

By addressing the challenge of steering wheel cost reduction, this research seeks to contribute to the broader goal of making vehicles more affordable and accessible to a wider consumer base. It also aims to enhance the competitiveness of automotive manufacturers in an increasingly challenging global market.

The primary objective of this technical research is to explore innovative approaches to reduce the production costs of steering wheels without compromising their functionality, safety, or user experience. This goal aligns with the broader industry trend of streamlining manufacturing processes and adopting cost-effective materials and technologies across the automotive supply chain.

Historical trends in steering wheel development have seen a shift from purely mechanical systems to those incorporating advanced electronics and sensors. This progression has led to increased complexity and, consequently, higher production costs. The challenge now lies in reversing this trend while still meeting the demands of modern automotive design and consumer expectations.

Market dynamics play a crucial role in driving the need for cost reduction. With the global automotive market facing intense competition and evolving consumer preferences, manufacturers are seeking ways to maintain profit margins without raising vehicle prices. Steering wheel cost reduction represents a significant opportunity to achieve this balance, as it is a component present in every vehicle produced.

Technological advancements in materials science, manufacturing processes, and design optimization offer promising avenues for cost reduction. These may include the exploration of alternative materials that are both lightweight and cost-effective, the implementation of advanced manufacturing techniques such as 3D printing for prototyping and small-scale production, and the simplification of design elements without sacrificing functionality.

The scope of this research extends beyond mere cost-cutting measures. It aims to identify innovative solutions that could potentially redefine steering wheel production, considering factors such as sustainability, scalability, and adaptability to future automotive trends. This includes investigating the potential for modular designs that could reduce complexity and allow for more efficient production and customization.

By addressing the challenge of steering wheel cost reduction, this research seeks to contribute to the broader goal of making vehicles more affordable and accessible to a wider consumer base. It also aims to enhance the competitiveness of automotive manufacturers in an increasingly challenging global market.

Market Analysis for Cost-Effective Steering Wheels

The steering wheel market has witnessed significant growth in recent years, driven by the increasing global automotive production and the rising demand for advanced steering systems. As automakers strive to reduce production costs while maintaining quality and safety standards, the market for cost-effective steering wheels has become increasingly competitive.

The global steering wheel market size was valued at approximately $30 billion in 2020 and is projected to grow at a CAGR of 4.5% from 2021 to 2028. This growth is primarily attributed to the expanding automotive industry, particularly in emerging economies, and the increasing focus on vehicle safety and comfort features.

Cost-effective steering wheels are in high demand across various vehicle segments, including passenger cars, commercial vehicles, and off-highway vehicles. The passenger car segment dominates the market, accounting for over 60% of the total market share. This dominance is expected to continue due to the rising production of passenger vehicles and the increasing adoption of electric and autonomous vehicles.

The market for cost-effective steering wheels is driven by several factors. Firstly, the growing emphasis on lightweight materials to improve fuel efficiency and reduce emissions has led to the development of innovative steering wheel designs using advanced materials such as carbon fiber and high-strength polymers. These materials offer significant weight reduction while maintaining structural integrity, thus contributing to overall cost-effectiveness.

Secondly, the integration of advanced technologies such as haptic feedback, touch-sensitive controls, and gesture recognition in steering wheels has created new opportunities for cost optimization through modular designs and standardized components. This trend is particularly evident in mid-range and entry-level vehicle segments, where manufacturers are seeking to offer premium features at competitive prices.

The market is also influenced by regional factors. In developing countries, the demand for cost-effective steering wheels is primarily driven by the need for affordable vehicles, leading to the adoption of simpler designs and materials. In contrast, developed markets are focusing on advanced features and ergonomic designs while maintaining cost-effectiveness through innovative manufacturing processes and economies of scale.

Key players in the cost-effective steering wheel market include Autoliv Inc., ZF Friedrichshafen AG, Takata Corporation, and Toyoda Gosei Co., Ltd. These companies are investing heavily in research and development to create innovative solutions that balance cost reduction with performance and safety requirements.

Looking ahead, the market for cost-effective steering wheels is expected to evolve with the advent of autonomous vehicles and the increasing electrification of the automotive industry. This shift is likely to drive demand for steering wheels with integrated controls and displays, presenting both challenges and opportunities for cost optimization in production processes.

The global steering wheel market size was valued at approximately $30 billion in 2020 and is projected to grow at a CAGR of 4.5% from 2021 to 2028. This growth is primarily attributed to the expanding automotive industry, particularly in emerging economies, and the increasing focus on vehicle safety and comfort features.

Cost-effective steering wheels are in high demand across various vehicle segments, including passenger cars, commercial vehicles, and off-highway vehicles. The passenger car segment dominates the market, accounting for over 60% of the total market share. This dominance is expected to continue due to the rising production of passenger vehicles and the increasing adoption of electric and autonomous vehicles.

The market for cost-effective steering wheels is driven by several factors. Firstly, the growing emphasis on lightweight materials to improve fuel efficiency and reduce emissions has led to the development of innovative steering wheel designs using advanced materials such as carbon fiber and high-strength polymers. These materials offer significant weight reduction while maintaining structural integrity, thus contributing to overall cost-effectiveness.

Secondly, the integration of advanced technologies such as haptic feedback, touch-sensitive controls, and gesture recognition in steering wheels has created new opportunities for cost optimization through modular designs and standardized components. This trend is particularly evident in mid-range and entry-level vehicle segments, where manufacturers are seeking to offer premium features at competitive prices.

The market is also influenced by regional factors. In developing countries, the demand for cost-effective steering wheels is primarily driven by the need for affordable vehicles, leading to the adoption of simpler designs and materials. In contrast, developed markets are focusing on advanced features and ergonomic designs while maintaining cost-effectiveness through innovative manufacturing processes and economies of scale.

Key players in the cost-effective steering wheel market include Autoliv Inc., ZF Friedrichshafen AG, Takata Corporation, and Toyoda Gosei Co., Ltd. These companies are investing heavily in research and development to create innovative solutions that balance cost reduction with performance and safety requirements.

Looking ahead, the market for cost-effective steering wheels is expected to evolve with the advent of autonomous vehicles and the increasing electrification of the automotive industry. This shift is likely to drive demand for steering wheels with integrated controls and displays, presenting both challenges and opportunities for cost optimization in production processes.

Current Challenges in Steering Wheel Manufacturing

The steering wheel manufacturing industry faces several significant challenges in its pursuit of cost reduction and efficiency improvement. One of the primary issues is the complexity of modern steering wheel designs, which often incorporate multiple electronic components and advanced materials. This complexity increases production time and costs, making it difficult to streamline manufacturing processes.

Material costs represent another major challenge. High-quality materials such as leather, premium plastics, and metals are essential for producing durable and aesthetically pleasing steering wheels. However, these materials are often expensive, and their prices can fluctuate due to market conditions and supply chain disruptions. This volatility in material costs makes it challenging for manufacturers to maintain consistent profit margins.

Labor costs also contribute significantly to the overall production expenses. Skilled workers are required for various stages of steering wheel manufacturing, including molding, assembly, and quality control. In many regions, rising labor costs and a shortage of skilled workers have put additional pressure on manufacturers to find ways to reduce labor-intensive processes without compromising quality.

The integration of advanced technologies, such as haptic feedback systems and touch-sensitive controls, into steering wheels has introduced new manufacturing challenges. These technologies require specialized production techniques and testing procedures, which can increase production time and costs. Additionally, ensuring the reliability and durability of these integrated systems in the harsh automotive environment poses significant technical challenges.

Quality control and safety standards present another hurdle for manufacturers. Steering wheels are critical safety components, and they must meet stringent regulatory requirements and undergo rigorous testing. This necessitates investment in advanced testing equipment and procedures, which adds to the overall production costs.

Customization demands from automakers and consumers have also increased manufacturing complexity. The need to produce a wide range of steering wheel designs, sizes, and features for different vehicle models and trim levels requires flexible manufacturing processes and frequent production line adjustments. This variability can lead to inefficiencies and increased costs.

Lastly, environmental regulations and sustainability concerns are pushing manufacturers to adopt more eco-friendly materials and production processes. While these changes are necessary for long-term sustainability, they often require significant initial investments in new technologies and materials, which can temporarily increase production costs.

Addressing these challenges requires innovative approaches to steering wheel design, material selection, and manufacturing processes. Manufacturers must balance the need for cost reduction with the demands for quality, safety, and advanced features to remain competitive in the evolving automotive industry.

Material costs represent another major challenge. High-quality materials such as leather, premium plastics, and metals are essential for producing durable and aesthetically pleasing steering wheels. However, these materials are often expensive, and their prices can fluctuate due to market conditions and supply chain disruptions. This volatility in material costs makes it challenging for manufacturers to maintain consistent profit margins.

Labor costs also contribute significantly to the overall production expenses. Skilled workers are required for various stages of steering wheel manufacturing, including molding, assembly, and quality control. In many regions, rising labor costs and a shortage of skilled workers have put additional pressure on manufacturers to find ways to reduce labor-intensive processes without compromising quality.

The integration of advanced technologies, such as haptic feedback systems and touch-sensitive controls, into steering wheels has introduced new manufacturing challenges. These technologies require specialized production techniques and testing procedures, which can increase production time and costs. Additionally, ensuring the reliability and durability of these integrated systems in the harsh automotive environment poses significant technical challenges.

Quality control and safety standards present another hurdle for manufacturers. Steering wheels are critical safety components, and they must meet stringent regulatory requirements and undergo rigorous testing. This necessitates investment in advanced testing equipment and procedures, which adds to the overall production costs.

Customization demands from automakers and consumers have also increased manufacturing complexity. The need to produce a wide range of steering wheel designs, sizes, and features for different vehicle models and trim levels requires flexible manufacturing processes and frequent production line adjustments. This variability can lead to inefficiencies and increased costs.

Lastly, environmental regulations and sustainability concerns are pushing manufacturers to adopt more eco-friendly materials and production processes. While these changes are necessary for long-term sustainability, they often require significant initial investments in new technologies and materials, which can temporarily increase production costs.

Addressing these challenges requires innovative approaches to steering wheel design, material selection, and manufacturing processes. Manufacturers must balance the need for cost reduction with the demands for quality, safety, and advanced features to remain competitive in the evolving automotive industry.

Existing Cost Reduction Strategies for Steering Wheels

01 Cost-effective steering wheel manufacturing processes

Various manufacturing processes are employed to reduce production costs of steering wheels. These include innovative molding techniques, use of lightweight materials, and automated assembly processes. Such methods aim to streamline production, reduce material waste, and minimize labor costs while maintaining quality and safety standards.- Cost-effective materials and manufacturing processes: Utilizing cost-effective materials and optimizing manufacturing processes can significantly reduce steering wheel production costs. This includes using lightweight materials, implementing efficient molding techniques, and streamlining assembly processes to minimize labor and material expenses.

- Integration of electronic components: Integrating electronic components into steering wheels can impact production costs. While it may increase initial expenses, it can lead to long-term cost savings through improved functionality and reduced need for additional controls. Efficient integration methods and component selection are crucial for balancing costs and features.

- Modular design and standardization: Implementing modular design principles and standardizing components across different steering wheel models can reduce production costs. This approach allows for economies of scale, simplified inventory management, and increased flexibility in manufacturing processes.

- Automation and robotics in production: Incorporating automation and robotics in steering wheel production can lead to significant cost reductions. These technologies can improve precision, increase production speed, and reduce labor costs. Implementing smart manufacturing processes and Industry 4.0 principles can further optimize production efficiency.

- Sustainable and recyclable materials: Using sustainable and recyclable materials in steering wheel production can impact costs. While initially more expensive, these materials can lead to long-term cost savings through reduced environmental impact, improved brand image, and potential regulatory compliance. Balancing sustainability with cost-effectiveness is key to optimizing production expenses.

02 Integration of electronic components

Modern steering wheels often incorporate electronic components such as controls and sensors. Efficient integration of these components during production can significantly impact costs. Techniques for embedding electronics, using modular designs, and optimizing wiring layouts are employed to reduce assembly time and material expenses.Expand Specific Solutions03 Material selection for cost optimization

The choice of materials plays a crucial role in steering wheel production costs. Manufacturers explore alternatives to traditional materials, such as high-performance plastics, composite materials, or recycled components. These materials are selected based on their cost-effectiveness, durability, and ability to meet safety requirements.Expand Specific Solutions04 Design optimization for cost reduction

Steering wheel designs are optimized to reduce production costs without compromising functionality or aesthetics. This includes simplifying shapes, reducing the number of components, and designing for ease of assembly. Computer-aided design and simulation tools are used to achieve optimal designs that balance cost, performance, and manufacturability.Expand Specific Solutions05 Supply chain and logistics optimization

Efficient supply chain management and logistics play a significant role in reducing overall production costs. This includes strategies such as just-in-time inventory, strategic supplier partnerships, and optimized transportation routes. Additionally, localization of production and sourcing of components can help reduce costs associated with import duties and transportation.Expand Specific Solutions

Key Players in Automotive Steering Wheel Industry

The steering wheel innovation market is in a mature stage, with established players like Autoliv Development AB, Honda Motor Co., Ltd., and Hyundai Motor Co., Ltd. leading the way. The market size is substantial, driven by the global automotive industry's demand for cost-effective solutions. Technological maturity varies, with companies like Ferrari SpA and LG Chem Ltd. pushing boundaries in high-end applications, while others focus on mass-market innovations. Firms such as ZF Automotive Safety Germany GmbH and JTEKT Corp. are actively developing advanced steering technologies to reduce production costs. The competitive landscape is diverse, with traditional automakers, specialized component manufacturers, and technology companies all vying for market share in this critical automotive segment.

Autoliv Development AB

Technical Solution: Autoliv has developed an innovative steering wheel design that incorporates advanced materials and manufacturing processes to reduce production costs. Their approach involves using a hybrid construction method that combines injection-molded thermoplastics with structural reinforcements. This allows for a significant reduction in the number of components, streamlining the assembly process. The company has also implemented a modular design strategy, enabling customization without increasing complexity. Autoliv's steering wheels feature integrated airbag systems and electronic controls, which are designed for efficient mass production. The use of advanced simulation tools has allowed Autoliv to optimize the design for both safety and cost-effectiveness, reducing the need for extensive physical prototyping[1][3].

Strengths: Reduced component count, streamlined assembly, and modular design for customization. Weaknesses: May require significant upfront investment in tooling and manufacturing processes.

Honda Motor Co., Ltd.

Technical Solution: Honda has focused on reducing steering wheel production costs through a combination of material innovation and process optimization. They have developed a new lightweight composite material that maintains the necessary strength and durability while reducing raw material costs. Honda's manufacturing process incorporates advanced robotics and automation, significantly reducing labor costs and improving consistency. The company has also implemented a just-in-time production system for steering wheel components, minimizing inventory costs. Honda's design emphasizes simplicity without compromising functionality, reducing the number of parts and assembly steps. Additionally, they have invested in 3D printing technology for rapid prototyping, accelerating the development cycle and reducing associated costs[2][5].

Strengths: Lightweight materials, highly automated production, and efficient supply chain management. Weaknesses: Initial high investment in automation and potential challenges in scaling up new material production.

Innovative Materials and Manufacturing Processes

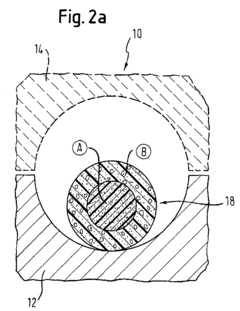

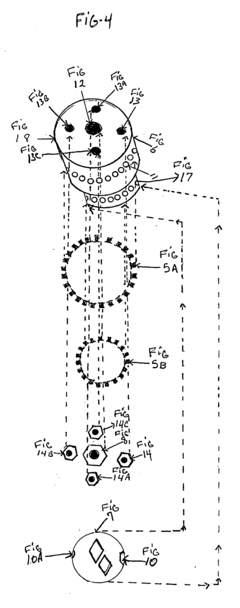

Process of fabrication of a steering wheel

PatentInactiveEP1302384A3

Innovation

- A method using a two-part foam mold to inject two different foam components - a central support component and a soft component - into an open mold, which is then closed and heated to shape the steering wheel, eliminating the need for post-processing and providing a comfortable grip.

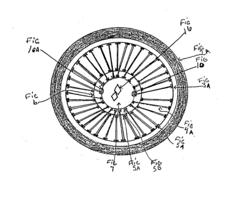

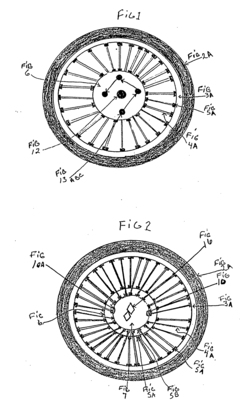

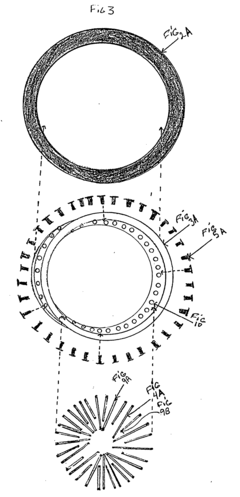

Custom steering wheels

PatentInactiveUS20070227292A1

Innovation

- A custom steering wheel design featuring a hub, rim, and 72-100 spokes made from a metal alloy, where the hub core and base body are molded together with the spokes, eliminating the need for a separate skeleton, and allowing for integration of a reinforcing insert for gas bag module support, using a pressureless injection method with an aluminum alloy material.

Supply Chain Optimization for Steering Wheel Production

Supply chain optimization plays a crucial role in reducing production costs for steering wheels. By streamlining the entire process from raw material procurement to final product delivery, manufacturers can significantly improve efficiency and minimize expenses.

One key aspect of supply chain optimization is strategic sourcing. This involves identifying and partnering with reliable suppliers who can provide high-quality materials at competitive prices. Establishing long-term relationships with suppliers can lead to better pricing, improved quality control, and more reliable delivery schedules. Additionally, implementing a just-in-time inventory system can help reduce storage costs and minimize waste.

Another important factor is the optimization of production processes. This may include implementing lean manufacturing principles, such as reducing unnecessary steps, minimizing waste, and improving overall workflow. Automation and robotics can also play a significant role in increasing production efficiency and reducing labor costs. For example, automated assembly lines can perform repetitive tasks with greater speed and precision than human workers.

Logistics optimization is another critical component of supply chain management for steering wheel production. This involves carefully planning transportation routes, consolidating shipments, and selecting the most cost-effective shipping methods. Implementing advanced tracking systems can help monitor shipments in real-time, allowing for better coordination and reducing the risk of delays or lost inventory.

Data analytics and artificial intelligence can be leveraged to improve forecasting accuracy and demand planning. By analyzing historical data and market trends, manufacturers can better predict future demand and adjust production accordingly. This helps prevent overproduction and reduces the costs associated with excess inventory or stockouts.

Collaboration and communication across the supply chain are essential for successful optimization. Implementing integrated software systems that connect suppliers, manufacturers, and distributors can improve information flow and decision-making. This enhanced visibility allows for quicker response times to changes in demand or supply disruptions.

Sustainability initiatives can also contribute to cost reduction in the long term. Implementing eco-friendly practices, such as using recycled materials or optimizing energy consumption in production facilities, can lead to cost savings while also improving the company's environmental footprint.

By focusing on these key areas of supply chain optimization, steering wheel manufacturers can achieve significant reductions in production costs, ultimately leading to improved profitability and competitiveness in the market.

One key aspect of supply chain optimization is strategic sourcing. This involves identifying and partnering with reliable suppliers who can provide high-quality materials at competitive prices. Establishing long-term relationships with suppliers can lead to better pricing, improved quality control, and more reliable delivery schedules. Additionally, implementing a just-in-time inventory system can help reduce storage costs and minimize waste.

Another important factor is the optimization of production processes. This may include implementing lean manufacturing principles, such as reducing unnecessary steps, minimizing waste, and improving overall workflow. Automation and robotics can also play a significant role in increasing production efficiency and reducing labor costs. For example, automated assembly lines can perform repetitive tasks with greater speed and precision than human workers.

Logistics optimization is another critical component of supply chain management for steering wheel production. This involves carefully planning transportation routes, consolidating shipments, and selecting the most cost-effective shipping methods. Implementing advanced tracking systems can help monitor shipments in real-time, allowing for better coordination and reducing the risk of delays or lost inventory.

Data analytics and artificial intelligence can be leveraged to improve forecasting accuracy and demand planning. By analyzing historical data and market trends, manufacturers can better predict future demand and adjust production accordingly. This helps prevent overproduction and reduces the costs associated with excess inventory or stockouts.

Collaboration and communication across the supply chain are essential for successful optimization. Implementing integrated software systems that connect suppliers, manufacturers, and distributors can improve information flow and decision-making. This enhanced visibility allows for quicker response times to changes in demand or supply disruptions.

Sustainability initiatives can also contribute to cost reduction in the long term. Implementing eco-friendly practices, such as using recycled materials or optimizing energy consumption in production facilities, can lead to cost savings while also improving the company's environmental footprint.

By focusing on these key areas of supply chain optimization, steering wheel manufacturers can achieve significant reductions in production costs, ultimately leading to improved profitability and competitiveness in the market.

Environmental Impact of Steering Wheel Manufacturing

The environmental impact of steering wheel manufacturing is a critical consideration in the automotive industry's efforts to reduce production costs while maintaining sustainability. The production process involves various materials and techniques that can have significant ecological consequences.

Traditional steering wheel manufacturing often relies on petroleum-based materials, such as polyurethane foam and synthetic leather, which contribute to carbon emissions and non-biodegradable waste. The use of these materials not only impacts the environment during production but also at the end of the product's life cycle when disposal becomes an issue.

Energy consumption in steering wheel production is another major environmental concern. The molding, shaping, and finishing processes require substantial amounts of electricity, often sourced from non-renewable energy sources. This contributes to the overall carbon footprint of the automotive industry and presents an opportunity for cost reduction through energy efficiency improvements.

Water usage and pollution are also significant factors in the environmental impact of steering wheel manufacturing. The cleaning and coating processes can involve chemicals that, if not properly managed, may contaminate local water sources. Implementing water recycling systems and using eco-friendly cleaning agents can mitigate these effects while potentially reducing production costs.

The transportation of raw materials and finished products adds to the environmental burden through fuel consumption and emissions. Localizing production and optimizing supply chains can help reduce this impact while simultaneously cutting transportation costs.

Innovations in materials science offer promising solutions to reduce both environmental impact and production costs. Bio-based materials, such as plant-derived polymers and natural fibers, are being explored as alternatives to traditional petroleum-based components. These materials not only have a lower environmental impact but can also lead to weight reduction, improving fuel efficiency in vehicles.

Advancements in manufacturing techniques, such as 3D printing and precision molding, can significantly reduce material waste and energy consumption. These technologies allow for more efficient use of resources and can decrease the overall environmental footprint of steering wheel production.

Recycling and circular economy principles are increasingly being applied to steering wheel manufacturing. Designing for disassembly and using recyclable materials can reduce waste and create opportunities for material recovery at the end of the product's life cycle. This approach not only benefits the environment but can also lead to cost savings through reduced raw material requirements.

As regulations on environmental impact become more stringent, steering wheel manufacturers must adapt their processes to comply with new standards. This regulatory pressure, while challenging, also drives innovation in cleaner production methods and materials, potentially leading to long-term cost reductions and improved environmental performance.

Traditional steering wheel manufacturing often relies on petroleum-based materials, such as polyurethane foam and synthetic leather, which contribute to carbon emissions and non-biodegradable waste. The use of these materials not only impacts the environment during production but also at the end of the product's life cycle when disposal becomes an issue.

Energy consumption in steering wheel production is another major environmental concern. The molding, shaping, and finishing processes require substantial amounts of electricity, often sourced from non-renewable energy sources. This contributes to the overall carbon footprint of the automotive industry and presents an opportunity for cost reduction through energy efficiency improvements.

Water usage and pollution are also significant factors in the environmental impact of steering wheel manufacturing. The cleaning and coating processes can involve chemicals that, if not properly managed, may contaminate local water sources. Implementing water recycling systems and using eco-friendly cleaning agents can mitigate these effects while potentially reducing production costs.

The transportation of raw materials and finished products adds to the environmental burden through fuel consumption and emissions. Localizing production and optimizing supply chains can help reduce this impact while simultaneously cutting transportation costs.

Innovations in materials science offer promising solutions to reduce both environmental impact and production costs. Bio-based materials, such as plant-derived polymers and natural fibers, are being explored as alternatives to traditional petroleum-based components. These materials not only have a lower environmental impact but can also lead to weight reduction, improving fuel efficiency in vehicles.

Advancements in manufacturing techniques, such as 3D printing and precision molding, can significantly reduce material waste and energy consumption. These technologies allow for more efficient use of resources and can decrease the overall environmental footprint of steering wheel production.

Recycling and circular economy principles are increasingly being applied to steering wheel manufacturing. Designing for disassembly and using recyclable materials can reduce waste and create opportunities for material recovery at the end of the product's life cycle. This approach not only benefits the environment but can also lead to cost savings through reduced raw material requirements.

As regulations on environmental impact become more stringent, steering wheel manufacturers must adapt their processes to comply with new standards. This regulatory pressure, while challenging, also drives innovation in cleaner production methods and materials, potentially leading to long-term cost reductions and improved environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!