Submersible pump applications in mineral slurry transportation.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Slurry Pump Evolution

The evolution of slurry pumps in mineral slurry transportation has been marked by significant technological advancements over the past century. Initially, centrifugal pumps were adapted for handling abrasive slurries, but their performance and durability were limited. The introduction of rubber linings in the 1920s marked a crucial milestone, significantly improving wear resistance and pump longevity.

In the 1950s and 1960s, the development of high-chrome alloys revolutionized slurry pump design. These materials offered superior abrasion resistance, enabling pumps to handle more aggressive slurries and operate for extended periods. This period also saw the introduction of variable speed drives, allowing for more precise control of pump performance and energy efficiency.

The 1970s and 1980s witnessed the emergence of computer-aided design (CAD) and computational fluid dynamics (CFD) in pump engineering. These tools enabled engineers to optimize impeller and volute designs, resulting in improved hydraulic efficiency and reduced wear. Concurrently, advancements in seal technology, such as expeller seals and mechanical seals with hard-face materials, enhanced pump reliability in demanding slurry applications.

The late 1990s and early 2000s saw a focus on modular pump designs, facilitating easier maintenance and parts replacement. This period also marked the introduction of smart pumping systems, incorporating sensors and monitoring equipment to provide real-time performance data and predictive maintenance capabilities.

In recent years, the development of submersible slurry pumps has gained momentum, addressing the challenges of pumping mineral slurries from greater depths and in more confined spaces. These pumps feature innovative cooling systems, robust sealing arrangements, and advanced materials to withstand harsh underwater environments and abrasive slurries.

The latest trends in slurry pump evolution include the integration of Internet of Things (IoT) technologies for remote monitoring and control, the use of advanced composite materials for improved wear resistance, and the development of high-efficiency pump designs that reduce energy consumption while maintaining performance in challenging slurry applications.

As the mining industry continues to explore deeper deposits and more complex ore bodies, the evolution of slurry pumps is expected to focus on enhancing submersible capabilities, improving energy efficiency, and developing more durable materials to handle increasingly abrasive and corrosive slurries. The integration of artificial intelligence and machine learning algorithms for pump optimization and predictive maintenance is also anticipated to play a significant role in future slurry pump designs.

In the 1950s and 1960s, the development of high-chrome alloys revolutionized slurry pump design. These materials offered superior abrasion resistance, enabling pumps to handle more aggressive slurries and operate for extended periods. This period also saw the introduction of variable speed drives, allowing for more precise control of pump performance and energy efficiency.

The 1970s and 1980s witnessed the emergence of computer-aided design (CAD) and computational fluid dynamics (CFD) in pump engineering. These tools enabled engineers to optimize impeller and volute designs, resulting in improved hydraulic efficiency and reduced wear. Concurrently, advancements in seal technology, such as expeller seals and mechanical seals with hard-face materials, enhanced pump reliability in demanding slurry applications.

The late 1990s and early 2000s saw a focus on modular pump designs, facilitating easier maintenance and parts replacement. This period also marked the introduction of smart pumping systems, incorporating sensors and monitoring equipment to provide real-time performance data and predictive maintenance capabilities.

In recent years, the development of submersible slurry pumps has gained momentum, addressing the challenges of pumping mineral slurries from greater depths and in more confined spaces. These pumps feature innovative cooling systems, robust sealing arrangements, and advanced materials to withstand harsh underwater environments and abrasive slurries.

The latest trends in slurry pump evolution include the integration of Internet of Things (IoT) technologies for remote monitoring and control, the use of advanced composite materials for improved wear resistance, and the development of high-efficiency pump designs that reduce energy consumption while maintaining performance in challenging slurry applications.

As the mining industry continues to explore deeper deposits and more complex ore bodies, the evolution of slurry pumps is expected to focus on enhancing submersible capabilities, improving energy efficiency, and developing more durable materials to handle increasingly abrasive and corrosive slurries. The integration of artificial intelligence and machine learning algorithms for pump optimization and predictive maintenance is also anticipated to play a significant role in future slurry pump designs.

Market Demand Analysis

The market demand for submersible pumps in mineral slurry transportation has been experiencing significant growth in recent years, driven by the expanding mining and mineral processing industries worldwide. As global demand for minerals continues to rise, efficient and reliable slurry transportation systems have become crucial for optimizing production processes and reducing operational costs.

The mining sector, particularly in regions such as Australia, South America, and Africa, has been a major contributor to the increasing demand for submersible pumps in slurry applications. These pumps are essential for handling abrasive and high-density mineral slurries, which are common in various mining operations, including copper, gold, iron ore, and coal extraction.

One of the key factors driving market growth is the need for improved efficiency and reduced downtime in mineral processing operations. Submersible pumps offer several advantages over traditional pump designs, including better handling of solids, reduced maintenance requirements, and the ability to operate in challenging environments. These benefits have led to increased adoption across the industry, particularly in applications such as dewatering, tailings management, and process water circulation.

The market for submersible pumps in mineral slurry transportation is also being influenced by environmental regulations and sustainability concerns. As mining companies face stricter environmental standards, there is a growing emphasis on water management and recycling. Submersible pumps play a crucial role in these efforts by enabling efficient water recirculation and reducing the overall water footprint of mining operations.

Technological advancements in pump design and materials have further fueled market growth. Manufacturers are developing more durable and efficient submersible pumps capable of handling increasingly challenging slurry compositions. Features such as advanced wear-resistant materials, improved hydraulic designs, and intelligent monitoring systems are becoming standard in high-performance submersible pumps for mineral slurry applications.

The market is also seeing increased demand for larger capacity pumps to handle higher throughput rates in modern mining operations. This trend is particularly evident in large-scale open-pit mines and mineral processing facilities, where the ability to move large volumes of slurry efficiently is critical to maintaining productivity and profitability.

Geographically, emerging markets in Asia-Pacific and Latin America are expected to drive significant growth in the submersible pump market for mineral slurry transportation. Rapid industrialization and increasing mining activities in these regions are creating new opportunities for pump manufacturers and suppliers. Additionally, the ongoing modernization of existing mining infrastructure in developed markets is contributing to steady demand for advanced submersible pump solutions.

The mining sector, particularly in regions such as Australia, South America, and Africa, has been a major contributor to the increasing demand for submersible pumps in slurry applications. These pumps are essential for handling abrasive and high-density mineral slurries, which are common in various mining operations, including copper, gold, iron ore, and coal extraction.

One of the key factors driving market growth is the need for improved efficiency and reduced downtime in mineral processing operations. Submersible pumps offer several advantages over traditional pump designs, including better handling of solids, reduced maintenance requirements, and the ability to operate in challenging environments. These benefits have led to increased adoption across the industry, particularly in applications such as dewatering, tailings management, and process water circulation.

The market for submersible pumps in mineral slurry transportation is also being influenced by environmental regulations and sustainability concerns. As mining companies face stricter environmental standards, there is a growing emphasis on water management and recycling. Submersible pumps play a crucial role in these efforts by enabling efficient water recirculation and reducing the overall water footprint of mining operations.

Technological advancements in pump design and materials have further fueled market growth. Manufacturers are developing more durable and efficient submersible pumps capable of handling increasingly challenging slurry compositions. Features such as advanced wear-resistant materials, improved hydraulic designs, and intelligent monitoring systems are becoming standard in high-performance submersible pumps for mineral slurry applications.

The market is also seeing increased demand for larger capacity pumps to handle higher throughput rates in modern mining operations. This trend is particularly evident in large-scale open-pit mines and mineral processing facilities, where the ability to move large volumes of slurry efficiently is critical to maintaining productivity and profitability.

Geographically, emerging markets in Asia-Pacific and Latin America are expected to drive significant growth in the submersible pump market for mineral slurry transportation. Rapid industrialization and increasing mining activities in these regions are creating new opportunities for pump manufacturers and suppliers. Additionally, the ongoing modernization of existing mining infrastructure in developed markets is contributing to steady demand for advanced submersible pump solutions.

Technical Challenges

The application of submersible pumps in mineral slurry transportation faces several significant technical challenges that require innovative solutions. One of the primary issues is the highly abrasive nature of mineral slurries, which can cause rapid wear and tear on pump components. The presence of solid particles in the slurry leads to erosion of impellers, casings, and seals, significantly reducing the pump's operational lifespan and efficiency.

Another major challenge is the varying viscosity and density of mineral slurries, which can fluctuate depending on the mineral composition and concentration. This variability makes it difficult to maintain consistent pump performance across different operating conditions. Pumps must be designed to handle a wide range of slurry consistencies without compromising on efficiency or reliability.

The potential for clogging and blockages presents another significant hurdle in submersible pump applications for mineral slurry transport. Large or irregularly shaped particles can accumulate within the pump, leading to reduced flow rates, increased power consumption, and potential pump failure. Developing effective mechanisms to prevent or mitigate clogging is crucial for maintaining continuous operation.

Seal integrity is a critical concern in submersible pump applications, particularly when dealing with abrasive mineral slurries. Conventional sealing systems may struggle to withstand the harsh operating environment, leading to premature failure and potential contamination of the pumped medium. Innovative sealing technologies that can withstand high pressures and abrasive particles are essential for improving pump reliability.

The high power requirements of submersible pumps in mineral slurry applications pose challenges in terms of energy efficiency and heat management. The dense and viscous nature of mineral slurries often necessitates higher power inputs, which can lead to increased operational costs and potential overheating issues. Balancing power consumption with pump performance is a key consideration in pump design and selection.

Monitoring and maintenance of submersible pumps in mineral slurry applications present unique challenges due to their submerged operation. Traditional inspection and maintenance techniques may be inadequate, necessitating the development of advanced monitoring systems and predictive maintenance strategies to ensure optimal pump performance and minimize downtime.

The corrosive nature of some mineral slurries adds another layer of complexity to pump design and material selection. Pumps must be constructed from materials that can withstand both abrasion and chemical attack, often requiring specialized alloys or coatings. Balancing corrosion resistance with cost-effectiveness remains an ongoing challenge in the industry.

Another major challenge is the varying viscosity and density of mineral slurries, which can fluctuate depending on the mineral composition and concentration. This variability makes it difficult to maintain consistent pump performance across different operating conditions. Pumps must be designed to handle a wide range of slurry consistencies without compromising on efficiency or reliability.

The potential for clogging and blockages presents another significant hurdle in submersible pump applications for mineral slurry transport. Large or irregularly shaped particles can accumulate within the pump, leading to reduced flow rates, increased power consumption, and potential pump failure. Developing effective mechanisms to prevent or mitigate clogging is crucial for maintaining continuous operation.

Seal integrity is a critical concern in submersible pump applications, particularly when dealing with abrasive mineral slurries. Conventional sealing systems may struggle to withstand the harsh operating environment, leading to premature failure and potential contamination of the pumped medium. Innovative sealing technologies that can withstand high pressures and abrasive particles are essential for improving pump reliability.

The high power requirements of submersible pumps in mineral slurry applications pose challenges in terms of energy efficiency and heat management. The dense and viscous nature of mineral slurries often necessitates higher power inputs, which can lead to increased operational costs and potential overheating issues. Balancing power consumption with pump performance is a key consideration in pump design and selection.

Monitoring and maintenance of submersible pumps in mineral slurry applications present unique challenges due to their submerged operation. Traditional inspection and maintenance techniques may be inadequate, necessitating the development of advanced monitoring systems and predictive maintenance strategies to ensure optimal pump performance and minimize downtime.

The corrosive nature of some mineral slurries adds another layer of complexity to pump design and material selection. Pumps must be constructed from materials that can withstand both abrasion and chemical attack, often requiring specialized alloys or coatings. Balancing corrosion resistance with cost-effectiveness remains an ongoing challenge in the industry.

Current Pump Solutions

01 Design and construction of submersible pumps

Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor directly coupled to the pump body. The design focuses on efficient operation underwater, including features for heat dissipation, pressure equalization, and protection against liquid ingress.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. They typically feature a sealed motor closely coupled to the pump body, ensuring efficient operation in underwater environments. The construction often includes corrosion-resistant materials and specialized sealing techniques to prevent liquid ingress into sensitive components.

- Control systems for submersible pumps: Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring various parameters such as pressure, flow rate, and temperature. They can also incorporate remote monitoring and control capabilities, allowing for efficient operation and maintenance of pumps in challenging underwater environments.

- Energy efficiency improvements in submersible pumps: Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, improved impeller designs, and the use of variable frequency drives. These advancements aim to reduce power consumption while maintaining or improving pump performance, particularly important in deep-well and offshore applications.

- Specialized submersible pumps for specific applications: Various specialized submersible pumps are designed for specific industries or applications. These may include pumps for handling abrasive slurries in mining, high-temperature pumps for geothermal wells, or pumps designed for handling corrosive fluids in chemical processing. The designs are tailored to meet the unique challenges of each application, incorporating specialized materials and features.

- Maintenance and reliability enhancements for submersible pumps: Improving the reliability and ease of maintenance of submersible pumps is a key focus area. This includes the development of self-diagnostic systems, easy-to-service designs, and the use of wear-resistant materials. Some innovations also focus on reducing the need for frequent maintenance, particularly in hard-to-access underwater installations.

02 Control systems for submersible pumps

Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors for monitoring various parameters such as pressure, flow rate, and temperature. They can adjust pump operation based on real-time data, improving efficiency and preventing damage.Expand Specific Solutions03 Energy efficiency improvements in submersible pumps

Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, improved impeller designs, and the use of variable frequency drives. These advancements aim to reduce power consumption while maintaining or improving pump performance.Expand Specific Solutions04 Materials and coatings for submersible pumps

The selection of materials and coatings plays a crucial role in the durability and performance of submersible pumps. Corrosion-resistant alloys, wear-resistant coatings, and advanced polymers are used to extend pump life and maintain efficiency in harsh underwater environments.Expand Specific Solutions05 Application-specific submersible pump designs

Submersible pumps are tailored for specific applications such as wastewater treatment, oil and gas extraction, and deep-sea exploration. These specialized designs incorporate features to handle particular fluid properties, operating depths, and environmental conditions unique to each application.Expand Specific Solutions

Industry Leaders

The submersible pump market for mineral slurry transportation is in a mature growth stage, with a global market size estimated to be in the billions of dollars. The technology has reached a high level of maturity, with ongoing innovations focused on improving efficiency and durability. Key players like Weir Minerals Australia Ltd., ITT Manufacturing Enterprises LLC, and Baker Hughes Co. are leading the market with advanced pump designs. Companies such as Schlumberger Technologies, Inc. and Caterpillar, Inc. are also significant contributors, leveraging their expertise in oilfield services and heavy machinery. The competitive landscape is characterized by a mix of established industrial giants and specialized pump manufacturers, with ongoing research and development efforts aimed at addressing the challenges of handling abrasive mineral slurries in demanding mining environments.

Weir Minerals Australia Ltd.

Technical Solution: Weir Minerals has developed advanced submersible pump technologies specifically for mineral slurry transportation. Their WARMAN® MCR® pump series utilizes innovative hydraulic designs and wear-resistant materials to handle high-density slurries efficiently. The pumps feature a modular design with interchangeable wet-end components, allowing for easy maintenance and adaptability to various slurry conditions[1]. Weir's pumps incorporate advanced sealing systems and bearing arrangements to withstand the abrasive nature of mineral slurries, ensuring longer operational life and reduced downtime[2]. The company has also implemented smart monitoring systems that provide real-time performance data, enabling predictive maintenance and optimized pump operation in challenging mining environments[3].

Strengths: Specialized design for mineral slurries, modular construction for easy maintenance, advanced wear-resistant materials, and smart monitoring capabilities. Weaknesses: Potentially higher initial cost compared to standard pumps, may require specialized training for maintenance personnel.

ITT Manufacturing Enterprises LLC

Technical Solution: ITT's Goulds Pumps division has developed the XHD Extra Heavy Duty Slurry Pump series for mineral slurry transportation applications. These pumps feature a robust design with extra-thick wet end components to withstand the abrasive nature of mineral slurries[1]. The XHD series incorporates an innovative suction seal ring that reduces recirculation and improves hydraulic efficiency[2]. ITT has also implemented advanced computational fluid dynamics (CFD) in the design process to optimize flow paths and minimize wear. The pumps use high-chrome alloy materials for critical components, providing excellent resistance to both abrasion and corrosion[3]. Additionally, ITT offers a range of impeller designs to match specific slurry characteristics, ensuring optimal performance across various mining applications.

Strengths: Robust construction for harsh environments, hydraulically efficient design, customizable impeller options. Weaknesses: May have higher power consumption compared to some competitors, potentially limited to certain slurry density ranges.

Key Innovations

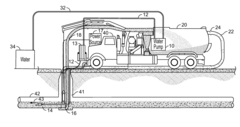

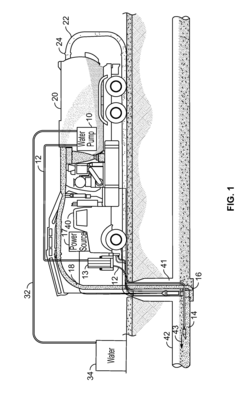

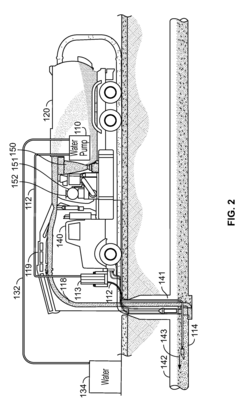

Dripless expanding tubes for combination truck

PatentActiveUS20150360259A1

Innovation

- A system combining a high-pressure water source, submersible pump, vacuum system, and pressurized container that allows for continuous cleaning and efficient separation of solids and liquids, enabling the use of either pumping or vacuuming technology based on site conditions without prior assessment, and reusing decanted water for further cleaning.

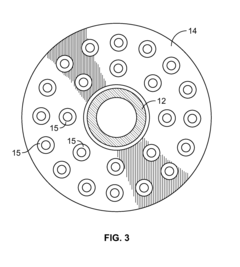

Submersible centrifugal pump with normal and ejector modes of operation

PatentInactiveEP2145111A1

Innovation

- The pump assembly features an impeller seat that is journalled for limited rotational and axial movements, allowing for ejection of oversized solids by creating a gap between the impeller and seat, with guide means and bias mechanisms ensuring smooth operation and return to normal position.

Environmental Impact

The application of submersible pumps in mineral slurry transportation has significant environmental implications that must be carefully considered. These pumps, while efficient in their primary function, can potentially impact various aspects of the surrounding ecosystem. One of the primary concerns is the disturbance of aquatic habitats during installation and operation. The physical presence of the pump and associated infrastructure may alter local hydrodynamics, potentially affecting the distribution of sediments and aquatic organisms.

Water quality is another critical environmental factor influenced by submersible pump operations in mineral slurry transport. The process can lead to increased turbidity and suspended solids in the water column, which may have detrimental effects on aquatic life. Additionally, the potential for accidental releases of mineral slurry or pump lubricants poses a risk of contamination to water bodies and surrounding soil. This necessitates stringent monitoring and containment measures to prevent and mitigate such incidents.

Energy consumption is a significant environmental consideration in submersible pump applications. The high power requirements of these pumps contribute to increased energy demand and associated greenhouse gas emissions, particularly if the energy source is not renewable. This aspect underscores the importance of optimizing pump efficiency and exploring alternative energy sources to minimize the carbon footprint of slurry transportation operations.

Noise pollution is another environmental concern, especially in sensitive ecological areas. The continuous operation of submersible pumps can generate underwater noise that may disrupt marine life communication and behavior patterns. This impact can be particularly pronounced in areas with endangered or protected species, requiring careful assessment and potential mitigation strategies.

The disposal of waste generated during the mineral slurry transportation process also presents environmental challenges. Proper management of tailings and other byproducts is crucial to prevent soil and water contamination. Sustainable practices in waste handling and disposal are essential to minimize long-term environmental impacts and ensure compliance with regulatory standards.

Lastly, the potential for habitat fragmentation and disruption of wildlife corridors must be considered when implementing submersible pump systems for mineral slurry transport. The installation of pipelines and associated infrastructure can create barriers to animal movement and alter natural ecosystems. Careful planning and environmental impact assessments are necessary to minimize these effects and preserve biodiversity in affected areas.

Water quality is another critical environmental factor influenced by submersible pump operations in mineral slurry transport. The process can lead to increased turbidity and suspended solids in the water column, which may have detrimental effects on aquatic life. Additionally, the potential for accidental releases of mineral slurry or pump lubricants poses a risk of contamination to water bodies and surrounding soil. This necessitates stringent monitoring and containment measures to prevent and mitigate such incidents.

Energy consumption is a significant environmental consideration in submersible pump applications. The high power requirements of these pumps contribute to increased energy demand and associated greenhouse gas emissions, particularly if the energy source is not renewable. This aspect underscores the importance of optimizing pump efficiency and exploring alternative energy sources to minimize the carbon footprint of slurry transportation operations.

Noise pollution is another environmental concern, especially in sensitive ecological areas. The continuous operation of submersible pumps can generate underwater noise that may disrupt marine life communication and behavior patterns. This impact can be particularly pronounced in areas with endangered or protected species, requiring careful assessment and potential mitigation strategies.

The disposal of waste generated during the mineral slurry transportation process also presents environmental challenges. Proper management of tailings and other byproducts is crucial to prevent soil and water contamination. Sustainable practices in waste handling and disposal are essential to minimize long-term environmental impacts and ensure compliance with regulatory standards.

Lastly, the potential for habitat fragmentation and disruption of wildlife corridors must be considered when implementing submersible pump systems for mineral slurry transport. The installation of pipelines and associated infrastructure can create barriers to animal movement and alter natural ecosystems. Careful planning and environmental impact assessments are necessary to minimize these effects and preserve biodiversity in affected areas.

Maintenance Strategies

Maintenance strategies for submersible pumps in mineral slurry transportation are critical for ensuring operational efficiency, minimizing downtime, and extending equipment lifespan. A comprehensive maintenance approach typically involves a combination of preventive, predictive, and corrective measures tailored to the specific challenges posed by abrasive slurries and harsh operating conditions.

Preventive maintenance forms the foundation of an effective strategy, involving regular inspections, cleaning, and component replacement based on predetermined schedules. This proactive approach helps identify potential issues before they escalate into major failures. Key preventive measures include routine checks of impeller wear, seal integrity, and motor performance.

Predictive maintenance leverages advanced monitoring technologies to assess equipment condition in real-time. Vibration analysis, thermal imaging, and oil analysis are commonly employed techniques that provide valuable insights into pump health. By detecting subtle changes in performance parameters, operators can anticipate and address emerging problems, optimizing maintenance timing and resource allocation.

Corrective maintenance, while reactive in nature, remains an essential component of the overall strategy. Rapid response protocols and well-stocked spare parts inventories are crucial for minimizing downtime when unexpected failures occur. Implementing a robust failure analysis process helps identify root causes and informs future preventive measures.

Condition-based maintenance represents a more advanced approach, utilizing sensor data and machine learning algorithms to dynamically adjust maintenance schedules based on actual equipment condition. This strategy can significantly reduce unnecessary interventions while ensuring timely attention to degrading components.

Reliability-centered maintenance (RCM) principles are increasingly applied to submersible pump maintenance, focusing on identifying and mitigating failure modes that have the greatest impact on system reliability. This systematic approach helps prioritize maintenance activities and optimize resource allocation.

Training and skill development for maintenance personnel are crucial elements of an effective strategy. Technicians must be well-versed in pump technology, slurry characteristics, and advanced diagnostic techniques to effectively execute maintenance tasks and interpret equipment data.

Implementing a computerized maintenance management system (CMMS) enhances overall strategy execution by streamlining work order management, tracking maintenance history, and facilitating data-driven decision-making. Integration with enterprise asset management systems further optimizes maintenance planning and resource allocation across the entire operation.

Preventive maintenance forms the foundation of an effective strategy, involving regular inspections, cleaning, and component replacement based on predetermined schedules. This proactive approach helps identify potential issues before they escalate into major failures. Key preventive measures include routine checks of impeller wear, seal integrity, and motor performance.

Predictive maintenance leverages advanced monitoring technologies to assess equipment condition in real-time. Vibration analysis, thermal imaging, and oil analysis are commonly employed techniques that provide valuable insights into pump health. By detecting subtle changes in performance parameters, operators can anticipate and address emerging problems, optimizing maintenance timing and resource allocation.

Corrective maintenance, while reactive in nature, remains an essential component of the overall strategy. Rapid response protocols and well-stocked spare parts inventories are crucial for minimizing downtime when unexpected failures occur. Implementing a robust failure analysis process helps identify root causes and informs future preventive measures.

Condition-based maintenance represents a more advanced approach, utilizing sensor data and machine learning algorithms to dynamically adjust maintenance schedules based on actual equipment condition. This strategy can significantly reduce unnecessary interventions while ensuring timely attention to degrading components.

Reliability-centered maintenance (RCM) principles are increasingly applied to submersible pump maintenance, focusing on identifying and mitigating failure modes that have the greatest impact on system reliability. This systematic approach helps prioritize maintenance activities and optimize resource allocation.

Training and skill development for maintenance personnel are crucial elements of an effective strategy. Technicians must be well-versed in pump technology, slurry characteristics, and advanced diagnostic techniques to effectively execute maintenance tasks and interpret equipment data.

Implementing a computerized maintenance management system (CMMS) enhances overall strategy execution by streamlining work order management, tracking maintenance history, and facilitating data-driven decision-making. Integration with enterprise asset management systems further optimizes maintenance planning and resource allocation across the entire operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!