Submersible pump efficiencies: A materials perspective.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Evolution and Efficiency Goals

Submersible pumps have undergone significant evolution since their inception in the early 20th century. Initially designed for dewatering mines and wells, these pumps have transformed into versatile tools used across various industries, including oil and gas, wastewater treatment, and offshore operations. The primary goal driving this evolution has been the continuous improvement of pump efficiency, with a particular focus on materials science as a key enabler.

In the early stages, submersible pumps were predominantly constructed using cast iron and bronze, materials chosen for their durability and corrosion resistance. However, these materials had limitations in terms of weight and efficiency. As technology progressed, the introduction of stainless steel in the 1950s marked a significant milestone, offering superior strength-to-weight ratios and enhanced corrosion resistance, particularly in harsh environments.

The 1970s and 1980s saw a shift towards more specialized materials, with the advent of duplex stainless steels and high-nickel alloys. These materials provided exceptional resistance to corrosion and erosion, crucial for pumps operating in aggressive fluids or high-temperature environments. This period also witnessed the integration of composite materials in non-critical components, reducing overall pump weight and improving energy efficiency.

The turn of the millennium brought about a renewed focus on energy efficiency, driven by increasing environmental concerns and rising energy costs. This led to the development of advanced coatings and surface treatments, such as diamond-like carbon (DLC) coatings and plasma-nitriding processes. These innovations significantly reduced friction and wear, thereby enhancing pump efficiency and longevity.

Current efficiency goals for submersible pumps are ambitious, with industry leaders aiming for overall efficiencies exceeding 80% in certain applications. This push for higher efficiency is not solely focused on materials but encompasses a holistic approach, including improved hydraulic designs, advanced motor technologies, and intelligent control systems. However, materials science remains at the forefront of these advancements, with ongoing research into nanomaterials, advanced ceramics, and smart materials that can adapt to changing operating conditions.

Looking ahead, the future of submersible pump efficiency lies in the development of materials that can withstand even more extreme conditions while maintaining optimal performance. This includes research into self-healing materials that can repair minor damage autonomously, reducing maintenance requirements and extending pump life. Additionally, the integration of sensors and IoT technologies into pump materials is expected to enable real-time monitoring and predictive maintenance, further enhancing overall system efficiency.

In the early stages, submersible pumps were predominantly constructed using cast iron and bronze, materials chosen for their durability and corrosion resistance. However, these materials had limitations in terms of weight and efficiency. As technology progressed, the introduction of stainless steel in the 1950s marked a significant milestone, offering superior strength-to-weight ratios and enhanced corrosion resistance, particularly in harsh environments.

The 1970s and 1980s saw a shift towards more specialized materials, with the advent of duplex stainless steels and high-nickel alloys. These materials provided exceptional resistance to corrosion and erosion, crucial for pumps operating in aggressive fluids or high-temperature environments. This period also witnessed the integration of composite materials in non-critical components, reducing overall pump weight and improving energy efficiency.

The turn of the millennium brought about a renewed focus on energy efficiency, driven by increasing environmental concerns and rising energy costs. This led to the development of advanced coatings and surface treatments, such as diamond-like carbon (DLC) coatings and plasma-nitriding processes. These innovations significantly reduced friction and wear, thereby enhancing pump efficiency and longevity.

Current efficiency goals for submersible pumps are ambitious, with industry leaders aiming for overall efficiencies exceeding 80% in certain applications. This push for higher efficiency is not solely focused on materials but encompasses a holistic approach, including improved hydraulic designs, advanced motor technologies, and intelligent control systems. However, materials science remains at the forefront of these advancements, with ongoing research into nanomaterials, advanced ceramics, and smart materials that can adapt to changing operating conditions.

Looking ahead, the future of submersible pump efficiency lies in the development of materials that can withstand even more extreme conditions while maintaining optimal performance. This includes research into self-healing materials that can repair minor damage autonomously, reducing maintenance requirements and extending pump life. Additionally, the integration of sensors and IoT technologies into pump materials is expected to enable real-time monitoring and predictive maintenance, further enhancing overall system efficiency.

Market Demand Analysis for High-Efficiency Submersible Pumps

The market demand for high-efficiency submersible pumps has been steadily increasing across various industries, driven by the need for improved energy efficiency, cost reduction, and environmental sustainability. In the oil and gas sector, submersible pumps are crucial for offshore and onshore operations, with a growing emphasis on pumps that can withstand harsh conditions while maintaining high performance. The water and wastewater treatment industry also shows significant demand, as municipalities and industrial facilities seek to upgrade their infrastructure with more efficient pumping systems.

The agricultural sector represents another major market for high-efficiency submersible pumps, particularly in regions facing water scarcity. Farmers are increasingly adopting advanced irrigation systems that require reliable and energy-efficient pumping solutions. In the mining industry, there is a rising demand for submersible pumps capable of handling abrasive slurries and operating in deep underground environments while minimizing energy consumption.

Market analysis indicates that the global submersible pump market is expected to grow substantially in the coming years. This growth is fueled by rapid industrialization in developing countries, increasing urbanization, and the expansion of water and wastewater treatment facilities worldwide. The Asia-Pacific region, in particular, is projected to witness the highest growth rate due to extensive infrastructure development and agricultural modernization efforts.

The demand for high-efficiency submersible pumps is also being shaped by stringent environmental regulations and energy efficiency standards. Governments and regulatory bodies are implementing policies that encourage the adoption of energy-efficient equipment, creating a favorable market environment for advanced pump technologies. This regulatory push is complemented by a growing awareness among end-users about the long-term cost benefits of investing in high-efficiency pumps.

Material advancements play a crucial role in meeting this market demand. End-users are seeking pumps with improved corrosion resistance, wear resistance, and thermal stability to enhance longevity and reduce maintenance costs. There is a particular interest in materials that can improve the overall efficiency of submersible pumps by reducing friction, enhancing heat dissipation, and optimizing fluid dynamics.

The market is also witnessing a shift towards smart and connected submersible pump systems. Integration of IoT and AI technologies for predictive maintenance and remote monitoring is becoming increasingly important for customers looking to optimize their operations and reduce downtime. This trend is creating new opportunities for pump manufacturers to differentiate their products and offer value-added services.

The agricultural sector represents another major market for high-efficiency submersible pumps, particularly in regions facing water scarcity. Farmers are increasingly adopting advanced irrigation systems that require reliable and energy-efficient pumping solutions. In the mining industry, there is a rising demand for submersible pumps capable of handling abrasive slurries and operating in deep underground environments while minimizing energy consumption.

Market analysis indicates that the global submersible pump market is expected to grow substantially in the coming years. This growth is fueled by rapid industrialization in developing countries, increasing urbanization, and the expansion of water and wastewater treatment facilities worldwide. The Asia-Pacific region, in particular, is projected to witness the highest growth rate due to extensive infrastructure development and agricultural modernization efforts.

The demand for high-efficiency submersible pumps is also being shaped by stringent environmental regulations and energy efficiency standards. Governments and regulatory bodies are implementing policies that encourage the adoption of energy-efficient equipment, creating a favorable market environment for advanced pump technologies. This regulatory push is complemented by a growing awareness among end-users about the long-term cost benefits of investing in high-efficiency pumps.

Material advancements play a crucial role in meeting this market demand. End-users are seeking pumps with improved corrosion resistance, wear resistance, and thermal stability to enhance longevity and reduce maintenance costs. There is a particular interest in materials that can improve the overall efficiency of submersible pumps by reducing friction, enhancing heat dissipation, and optimizing fluid dynamics.

The market is also witnessing a shift towards smart and connected submersible pump systems. Integration of IoT and AI technologies for predictive maintenance and remote monitoring is becoming increasingly important for customers looking to optimize their operations and reduce downtime. This trend is creating new opportunities for pump manufacturers to differentiate their products and offer value-added services.

Current Materials and Efficiency Challenges

Submersible pumps face significant efficiency challenges due to the harsh environments in which they operate. The current materials used in these pumps, while robust, often struggle to maintain optimal performance under extreme conditions. Traditional materials such as cast iron, stainless steel, and bronze are commonly employed but have limitations in terms of corrosion resistance, wear resistance, and thermal conductivity.

One of the primary challenges is the degradation of pump components due to corrosive fluids and abrasive particles. This leads to reduced efficiency over time and increased maintenance requirements. Stainless steel, while corrosion-resistant, may not provide adequate protection in highly acidic or chloride-rich environments. Additionally, the weight of these conventional materials impacts the overall energy consumption of the pump system.

Thermal management presents another significant challenge. The heat generated during operation can cause premature failure of seals and bearings, reducing pump efficiency and lifespan. Current materials often have limited thermal conductivity, making it difficult to dissipate heat effectively, especially in deep-well applications where ambient temperatures are already elevated.

Cavitation, a phenomenon where vapor bubbles form and collapse rapidly, poses a serious threat to pump efficiency and longevity. The materials currently used may not adequately withstand the repeated impact forces associated with cavitation, leading to surface damage and reduced performance over time.

Energy efficiency is a critical concern in submersible pump design. The materials used in impellers and diffusers play a crucial role in determining the pump's hydraulic efficiency. Current materials may not always provide the optimal surface finish or maintain their geometrical integrity under prolonged use, resulting in decreased pump efficiency.

Scaling and fouling of pump surfaces is another challenge that impacts efficiency. Mineral deposits and biological growth can accumulate on pump components, altering fluid dynamics and reducing overall performance. The materials presently used often lack inherent anti-fouling properties, necessitating frequent cleaning and maintenance.

Weight reduction while maintaining structural integrity remains a significant challenge. Lighter pumps require less energy to operate, but achieving this without compromising strength and durability is difficult with conventional materials. This balance is particularly crucial for deep-well applications where the weight of the pump assembly is a major consideration.

Addressing these material-related challenges is essential for improving submersible pump efficiencies. Research into advanced materials such as ceramic composites, high-performance polymers, and novel metal alloys shows promise in overcoming some of these limitations. However, the integration of these materials into practical, cost-effective pump designs remains an ongoing challenge for the industry.

One of the primary challenges is the degradation of pump components due to corrosive fluids and abrasive particles. This leads to reduced efficiency over time and increased maintenance requirements. Stainless steel, while corrosion-resistant, may not provide adequate protection in highly acidic or chloride-rich environments. Additionally, the weight of these conventional materials impacts the overall energy consumption of the pump system.

Thermal management presents another significant challenge. The heat generated during operation can cause premature failure of seals and bearings, reducing pump efficiency and lifespan. Current materials often have limited thermal conductivity, making it difficult to dissipate heat effectively, especially in deep-well applications where ambient temperatures are already elevated.

Cavitation, a phenomenon where vapor bubbles form and collapse rapidly, poses a serious threat to pump efficiency and longevity. The materials currently used may not adequately withstand the repeated impact forces associated with cavitation, leading to surface damage and reduced performance over time.

Energy efficiency is a critical concern in submersible pump design. The materials used in impellers and diffusers play a crucial role in determining the pump's hydraulic efficiency. Current materials may not always provide the optimal surface finish or maintain their geometrical integrity under prolonged use, resulting in decreased pump efficiency.

Scaling and fouling of pump surfaces is another challenge that impacts efficiency. Mineral deposits and biological growth can accumulate on pump components, altering fluid dynamics and reducing overall performance. The materials presently used often lack inherent anti-fouling properties, necessitating frequent cleaning and maintenance.

Weight reduction while maintaining structural integrity remains a significant challenge. Lighter pumps require less energy to operate, but achieving this without compromising strength and durability is difficult with conventional materials. This balance is particularly crucial for deep-well applications where the weight of the pump assembly is a major consideration.

Addressing these material-related challenges is essential for improving submersible pump efficiencies. Research into advanced materials such as ceramic composites, high-performance polymers, and novel metal alloys shows promise in overcoming some of these limitations. However, the integration of these materials into practical, cost-effective pump designs remains an ongoing challenge for the industry.

Existing Material Solutions for Efficiency Improvement

01 Improved impeller design

Enhancing the efficiency of submersible pumps through advanced impeller designs. This includes optimizing blade geometry, reducing turbulence, and improving fluid flow patterns to maximize energy transfer from the impeller to the fluid.- Improved impeller design: Enhancing the efficiency of submersible pumps through advanced impeller designs. This includes optimizing blade geometry, reducing turbulence, and improving fluid flow patterns to maximize energy transfer from the impeller to the fluid.

- Motor efficiency optimization: Focusing on the electric motor's efficiency to improve overall submersible pump performance. This involves using high-efficiency motors, advanced control systems, and optimizing motor cooling to reduce energy losses and increase operational efficiency.

- Hydraulic design improvements: Enhancing the hydraulic components of submersible pumps to reduce friction losses and improve flow characteristics. This includes optimizing the pump casing, diffuser, and discharge designs to minimize energy loss and increase overall pump efficiency.

- Advanced materials and coatings: Utilizing innovative materials and surface treatments to reduce friction, improve wear resistance, and enhance the overall efficiency of submersible pumps. This includes the use of composite materials, ceramic coatings, and other advanced surface technologies.

- Intelligent pump control and monitoring: Implementing smart control systems and real-time monitoring technologies to optimize pump operation based on changing conditions. This includes variable frequency drives, adaptive control algorithms, and IoT-enabled monitoring to ensure pumps operate at peak efficiency across various scenarios.

02 Motor efficiency optimization

Focusing on the electric motor's efficiency to improve overall submersible pump performance. This involves using high-efficiency motors, advanced control systems, and optimizing motor cooling to reduce energy losses and increase operational efficiency.Expand Specific Solutions03 Hydraulic design improvements

Enhancing the hydraulic components of submersible pumps to reduce friction losses and improve flow characteristics. This includes optimizing the pump casing, diffuser, and discharge designs to minimize energy loss and increase overall pump efficiency.Expand Specific Solutions04 Advanced materials and coatings

Utilizing innovative materials and surface treatments to reduce friction, improve wear resistance, and enhance overall pump efficiency. This includes the use of composite materials, ceramic coatings, and other advanced surface technologies to optimize pump performance.Expand Specific Solutions05 Intelligent control and monitoring systems

Implementing smart control systems and real-time monitoring technologies to optimize pump operation based on changing conditions. This includes variable frequency drives, adaptive control algorithms, and sensor-based systems to maintain peak efficiency across various operating conditions.Expand Specific Solutions

Key Players in Submersible Pump Manufacturing

The submersible pump efficiency market is in a mature stage, with a global market size estimated to exceed $10 billion by 2025. The industry is characterized by intense competition among established players like Schlumberger, Grundfos, and Baker Hughes, who are focusing on materials innovation to improve pump performance and energy efficiency. Emerging companies such as Guangdong Ruirong Pump Industry and Zhongshan AL Yahya Home Appliance are also making strides in the market. The technology maturity is high, with ongoing research in advanced materials and designs to enhance pump durability and efficiency in challenging environments, particularly in oil and gas applications.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced materials and coatings for submersible pump components to enhance efficiency and durability in harsh downhole environments. Their REDA Maximus ESP system utilizes high-performance polymer bearings and abrasion-resistant coatings to reduce friction and wear[1]. The company has also implemented computational fluid dynamics (CFD) modeling to optimize impeller and diffuser designs, resulting in improved hydraulic efficiency and reduced power consumption[2]. Additionally, Schlumberger's ToughMet alloy for pump shafts offers superior corrosion resistance and mechanical strength, extending pump life in high-temperature and corrosive wells[3].

Strengths: Industry-leading materials research, extensive field testing capabilities, and integrated system approach. Weaknesses: Higher initial costs compared to conventional pumps, and potential over-engineering for less demanding applications.

Grundfos Management A/S

Technical Solution: Grundfos has focused on developing innovative materials and manufacturing processes to improve submersible pump efficiencies. Their SuperMan (Super Manufacturing) initiative utilizes advanced 3D printing techniques to create complex impeller geometries that were previously impossible to manufacture[4]. This allows for optimized fluid dynamics and reduced energy consumption. Grundfos has also pioneered the use of composite materials in pump construction, such as carbon fiber reinforced polymers (CFRP) for impellers and diffusers, which offer weight reduction and improved corrosion resistance[5]. The company's E-pump technology incorporates high-efficiency permanent magnet motors with advanced materials to achieve energy savings of up to 60% compared to conventional pumps[6].

Strengths: Strong focus on sustainability and energy efficiency, innovative manufacturing techniques, and broad product range. Weaknesses: Higher upfront costs for advanced materials and potential limitations in extreme temperature applications.

Innovative Materials for Submersible Pump Components

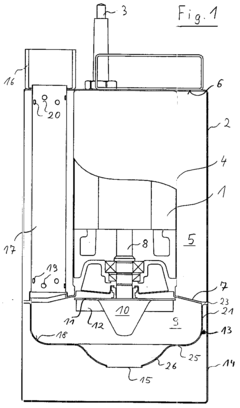

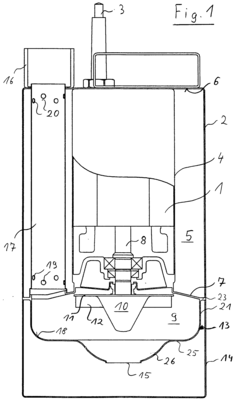

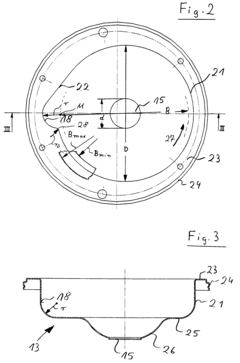

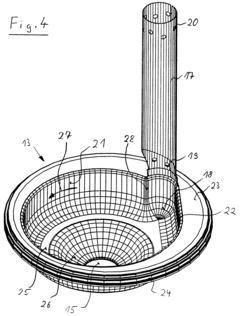

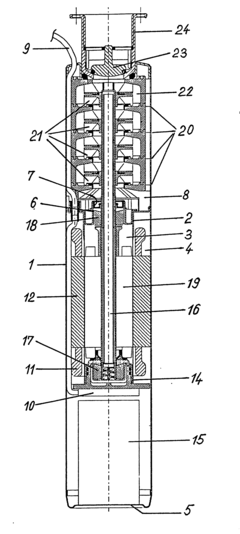

Submersible pump assembly

PatentInactiveEP0599204A1

Innovation

- A submersible pump unit with a concentric housing featuring a bulge forming a stagnation zone for parallel flow deflection, reducing energy losses and allowing for a slimmer design, equipped with a single-blade or vortex impeller and a shell-shaped housing part for improved efficiency and free passage.

Submersible pump

PatentInactiveEP0346731A2

Innovation

- A submersible pump unit design where the motor, pump body, and frequency converter are arranged in series within a tubular jacket, with a thermally conductive base and heat-dissipating materials, and an internal cable routing to simplify production and reduce thermal resistance, along with a self-adjusting axial bearing for easier installation.

Environmental Impact of Pump Materials

The environmental impact of materials used in submersible pumps is a critical consideration in the pursuit of improved pump efficiencies. Traditional pump materials, such as cast iron and stainless steel, have long been favored for their durability and corrosion resistance. However, these materials often come with significant environmental costs associated with their extraction, processing, and disposal.

The mining and refining of metals for pump components contribute to habitat destruction, water pollution, and greenhouse gas emissions. Furthermore, the energy-intensive manufacturing processes required to produce these materials result in substantial carbon footprints. As the demand for submersible pumps continues to grow, particularly in sectors like water management and oil extraction, the cumulative environmental impact of these materials becomes increasingly concerning.

In recent years, there has been a shift towards more sustainable material choices for submersible pumps. Advanced composites and polymer materials are emerging as promising alternatives, offering reduced weight and improved chemical resistance while potentially lowering the overall environmental impact. These materials often require less energy to produce and can be more easily recycled at the end of their lifecycle.

Nanotechnology is also playing a role in developing more environmentally friendly pump materials. Nanocoatings can enhance the performance and longevity of pump components, reducing the need for frequent replacements and minimizing waste. Additionally, nanomaterials can improve the efficiency of pumps by reducing friction and wear, thereby decreasing energy consumption during operation.

The use of bio-based materials in pump construction is another area of growing interest. These materials, derived from renewable sources, have the potential to significantly reduce the carbon footprint of pump manufacturing. While still in the early stages of development, bio-based composites could offer a sustainable alternative to traditional petroleum-based polymers.

Lifecycle assessment (LCA) studies are increasingly being employed to evaluate the environmental impact of different pump materials. These assessments consider factors such as resource depletion, energy consumption, and emissions throughout the entire lifecycle of the pump, from raw material extraction to disposal. LCA results are guiding manufacturers towards more sustainable material choices and design practices.

As environmental regulations become more stringent, pump manufacturers are also focusing on the recyclability and end-of-life management of their products. Design for disassembly and the use of easily separable materials are becoming important considerations in pump development. This approach not only reduces the environmental impact of pump disposal but also supports the circular economy by enabling the recovery and reuse of valuable materials.

The mining and refining of metals for pump components contribute to habitat destruction, water pollution, and greenhouse gas emissions. Furthermore, the energy-intensive manufacturing processes required to produce these materials result in substantial carbon footprints. As the demand for submersible pumps continues to grow, particularly in sectors like water management and oil extraction, the cumulative environmental impact of these materials becomes increasingly concerning.

In recent years, there has been a shift towards more sustainable material choices for submersible pumps. Advanced composites and polymer materials are emerging as promising alternatives, offering reduced weight and improved chemical resistance while potentially lowering the overall environmental impact. These materials often require less energy to produce and can be more easily recycled at the end of their lifecycle.

Nanotechnology is also playing a role in developing more environmentally friendly pump materials. Nanocoatings can enhance the performance and longevity of pump components, reducing the need for frequent replacements and minimizing waste. Additionally, nanomaterials can improve the efficiency of pumps by reducing friction and wear, thereby decreasing energy consumption during operation.

The use of bio-based materials in pump construction is another area of growing interest. These materials, derived from renewable sources, have the potential to significantly reduce the carbon footprint of pump manufacturing. While still in the early stages of development, bio-based composites could offer a sustainable alternative to traditional petroleum-based polymers.

Lifecycle assessment (LCA) studies are increasingly being employed to evaluate the environmental impact of different pump materials. These assessments consider factors such as resource depletion, energy consumption, and emissions throughout the entire lifecycle of the pump, from raw material extraction to disposal. LCA results are guiding manufacturers towards more sustainable material choices and design practices.

As environmental regulations become more stringent, pump manufacturers are also focusing on the recyclability and end-of-life management of their products. Design for disassembly and the use of easily separable materials are becoming important considerations in pump development. This approach not only reduces the environmental impact of pump disposal but also supports the circular economy by enabling the recovery and reuse of valuable materials.

Corrosion Resistance in Submersible Pump Design

Corrosion resistance is a critical factor in the design and performance of submersible pumps, particularly when considering the materials perspective for improving pump efficiencies. The harsh operating environments of submersible pumps, often involving exposure to corrosive fluids, high temperatures, and abrasive particles, necessitate careful material selection to ensure longevity and maintain optimal performance.

Traditional materials used in submersible pump construction, such as cast iron and carbon steel, are susceptible to various forms of corrosion, including general corrosion, pitting, and galvanic corrosion. These corrosion mechanisms can lead to premature pump failure, reduced efficiency, and increased maintenance costs. To address these challenges, manufacturers have turned to advanced materials and surface treatments to enhance corrosion resistance.

Stainless steel alloys, particularly grades such as 316L and duplex stainless steels, have become popular choices for submersible pump components due to their excellent corrosion resistance in a wide range of environments. These alloys form a protective passive layer that significantly reduces corrosion rates, even in the presence of chlorides and other aggressive ions. Additionally, the use of super duplex stainless steels has gained traction in extremely corrosive applications, offering superior resistance to pitting and crevice corrosion.

For applications requiring even greater corrosion resistance, nickel-based alloys like Inconel and Hastelloy have proven effective. These materials exhibit exceptional resistance to both reducing and oxidizing environments, making them suitable for use in highly corrosive fluids encountered in oil and gas production, chemical processing, and geothermal applications.

Surface treatments and coatings have also played a crucial role in enhancing the corrosion resistance of submersible pumps. Techniques such as nitriding, carburizing, and the application of ceramic coatings can significantly improve the surface properties of pump components, providing an additional barrier against corrosive attack. Advanced coating technologies, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), have enabled the development of ultra-thin, highly adherent coatings that offer superior corrosion protection without compromising the dimensional tolerances of critical pump components.

The selection of appropriate materials and surface treatments for corrosion resistance must be balanced with other performance requirements, such as wear resistance, thermal stability, and cost-effectiveness. This necessitates a holistic approach to material selection, considering the specific operating conditions, fluid properties, and expected service life of the submersible pump.

Traditional materials used in submersible pump construction, such as cast iron and carbon steel, are susceptible to various forms of corrosion, including general corrosion, pitting, and galvanic corrosion. These corrosion mechanisms can lead to premature pump failure, reduced efficiency, and increased maintenance costs. To address these challenges, manufacturers have turned to advanced materials and surface treatments to enhance corrosion resistance.

Stainless steel alloys, particularly grades such as 316L and duplex stainless steels, have become popular choices for submersible pump components due to their excellent corrosion resistance in a wide range of environments. These alloys form a protective passive layer that significantly reduces corrosion rates, even in the presence of chlorides and other aggressive ions. Additionally, the use of super duplex stainless steels has gained traction in extremely corrosive applications, offering superior resistance to pitting and crevice corrosion.

For applications requiring even greater corrosion resistance, nickel-based alloys like Inconel and Hastelloy have proven effective. These materials exhibit exceptional resistance to both reducing and oxidizing environments, making them suitable for use in highly corrosive fluids encountered in oil and gas production, chemical processing, and geothermal applications.

Surface treatments and coatings have also played a crucial role in enhancing the corrosion resistance of submersible pumps. Techniques such as nitriding, carburizing, and the application of ceramic coatings can significantly improve the surface properties of pump components, providing an additional barrier against corrosive attack. Advanced coating technologies, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), have enabled the development of ultra-thin, highly adherent coatings that offer superior corrosion protection without compromising the dimensional tolerances of critical pump components.

The selection of appropriate materials and surface treatments for corrosion resistance must be balanced with other performance requirements, such as wear resistance, thermal stability, and cost-effectiveness. This necessitates a holistic approach to material selection, considering the specific operating conditions, fluid properties, and expected service life of the submersible pump.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!