Submersible pump failures: causes and preventive measures.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Failure Analysis and Objectives

Submersible pumps have become integral components in various industries, including oil and gas, water supply, and wastewater management. The reliability and efficiency of these pumps are crucial for maintaining operational continuity and cost-effectiveness. However, submersible pump failures remain a significant challenge, necessitating a comprehensive analysis of their causes and the development of effective preventive measures.

The primary objective of this technical research report is to conduct an in-depth examination of submersible pump failures, identifying the root causes and proposing innovative solutions to mitigate these issues. By understanding the historical context and technological evolution of submersible pumps, we can better appreciate the complexities involved in their operation and maintenance.

Over the years, submersible pump technology has advanced significantly, with improvements in materials, design, and control systems. Despite these advancements, failures continue to occur due to various factors, including harsh operating environments, improper installation, and inadequate maintenance practices. This report aims to bridge the gap between current technological capabilities and practical challenges faced in the field.

One of the key goals is to analyze the most common failure modes of submersible pumps, such as bearing failures, seal failures, motor burnouts, and impeller damage. By categorizing these failures and understanding their underlying mechanisms, we can develop targeted strategies for prevention and early detection.

Additionally, this report will explore emerging technologies and methodologies that show promise in enhancing submersible pump reliability. This includes advanced monitoring systems, predictive maintenance algorithms, and novel materials that can withstand extreme conditions.

The findings and recommendations from this research will serve as a valuable resource for engineers, maintenance professionals, and decision-makers in industries reliant on submersible pump technology. By addressing the root causes of failures and implementing proactive measures, organizations can significantly reduce downtime, extend equipment lifespan, and optimize operational efficiency.

Furthermore, this analysis will consider the economic implications of pump failures and the potential cost savings associated with implementing robust preventive measures. This holistic approach will provide a comprehensive understanding of the challenges and opportunities in submersible pump technology, paving the way for future innovations and best practices in the field.

The primary objective of this technical research report is to conduct an in-depth examination of submersible pump failures, identifying the root causes and proposing innovative solutions to mitigate these issues. By understanding the historical context and technological evolution of submersible pumps, we can better appreciate the complexities involved in their operation and maintenance.

Over the years, submersible pump technology has advanced significantly, with improvements in materials, design, and control systems. Despite these advancements, failures continue to occur due to various factors, including harsh operating environments, improper installation, and inadequate maintenance practices. This report aims to bridge the gap between current technological capabilities and practical challenges faced in the field.

One of the key goals is to analyze the most common failure modes of submersible pumps, such as bearing failures, seal failures, motor burnouts, and impeller damage. By categorizing these failures and understanding their underlying mechanisms, we can develop targeted strategies for prevention and early detection.

Additionally, this report will explore emerging technologies and methodologies that show promise in enhancing submersible pump reliability. This includes advanced monitoring systems, predictive maintenance algorithms, and novel materials that can withstand extreme conditions.

The findings and recommendations from this research will serve as a valuable resource for engineers, maintenance professionals, and decision-makers in industries reliant on submersible pump technology. By addressing the root causes of failures and implementing proactive measures, organizations can significantly reduce downtime, extend equipment lifespan, and optimize operational efficiency.

Furthermore, this analysis will consider the economic implications of pump failures and the potential cost savings associated with implementing robust preventive measures. This holistic approach will provide a comprehensive understanding of the challenges and opportunities in submersible pump technology, paving the way for future innovations and best practices in the field.

Market Demand for Reliable Submersible Pumps

The market demand for reliable submersible pumps has been steadily increasing across various industries, driven by the critical need for efficient and durable water management solutions. In the oil and gas sector, submersible pumps play a vital role in extracting fluids from wells, making their reliability crucial for maintaining production levels and minimizing downtime. The mining industry also heavily relies on these pumps for dewatering operations, where pump failures can lead to significant operational disruptions and safety hazards.

In agriculture and irrigation, the demand for reliable submersible pumps continues to grow as farmers seek to optimize water usage and increase crop yields. The ability of these pumps to operate efficiently in deep wells and boreholes makes them indispensable for agricultural operations in regions with limited surface water resources. Similarly, in municipal water supply systems, the reliability of submersible pumps is paramount to ensure consistent water delivery to communities.

The construction industry represents another significant market for reliable submersible pumps, particularly in dewatering applications for large-scale projects. As urbanization accelerates globally, the need for robust pumping solutions in construction sites, tunnels, and foundations has intensified. Pump failures in these contexts can lead to costly delays and compromised structural integrity.

Environmental concerns and stringent regulations have also contributed to the increased demand for reliable submersible pumps in wastewater treatment facilities. These pumps are essential for maintaining proper sewage management and preventing environmental contamination. The reliability of these pumps directly impacts the efficiency of treatment processes and compliance with environmental standards.

The industrial sector, including chemical processing, food and beverage production, and manufacturing, requires dependable submersible pumps for various applications such as coolant circulation, waste removal, and process fluid handling. In these settings, pump failures can result in production halts, product quality issues, and potential safety risks.

As global water scarcity concerns grow, there is an emerging market for reliable submersible pumps in desalination plants and water reclamation projects. These applications demand pumps that can withstand corrosive environments and operate continuously under high-pressure conditions. The reliability of these pumps is crucial for ensuring a stable supply of potable water in water-stressed regions.

The increasing focus on energy efficiency and sustainability has also shaped the market demand for reliable submersible pumps. End-users across industries are seeking pumps that not only offer dependable performance but also contribute to reduced energy consumption and lower operational costs. This trend has driven manufacturers to innovate and develop more efficient and durable pump designs to meet these evolving market requirements.

In agriculture and irrigation, the demand for reliable submersible pumps continues to grow as farmers seek to optimize water usage and increase crop yields. The ability of these pumps to operate efficiently in deep wells and boreholes makes them indispensable for agricultural operations in regions with limited surface water resources. Similarly, in municipal water supply systems, the reliability of submersible pumps is paramount to ensure consistent water delivery to communities.

The construction industry represents another significant market for reliable submersible pumps, particularly in dewatering applications for large-scale projects. As urbanization accelerates globally, the need for robust pumping solutions in construction sites, tunnels, and foundations has intensified. Pump failures in these contexts can lead to costly delays and compromised structural integrity.

Environmental concerns and stringent regulations have also contributed to the increased demand for reliable submersible pumps in wastewater treatment facilities. These pumps are essential for maintaining proper sewage management and preventing environmental contamination. The reliability of these pumps directly impacts the efficiency of treatment processes and compliance with environmental standards.

The industrial sector, including chemical processing, food and beverage production, and manufacturing, requires dependable submersible pumps for various applications such as coolant circulation, waste removal, and process fluid handling. In these settings, pump failures can result in production halts, product quality issues, and potential safety risks.

As global water scarcity concerns grow, there is an emerging market for reliable submersible pumps in desalination plants and water reclamation projects. These applications demand pumps that can withstand corrosive environments and operate continuously under high-pressure conditions. The reliability of these pumps is crucial for ensuring a stable supply of potable water in water-stressed regions.

The increasing focus on energy efficiency and sustainability has also shaped the market demand for reliable submersible pumps. End-users across industries are seeking pumps that not only offer dependable performance but also contribute to reduced energy consumption and lower operational costs. This trend has driven manufacturers to innovate and develop more efficient and durable pump designs to meet these evolving market requirements.

Current Challenges in Submersible Pump Technology

Submersible pump technology, while advanced, still faces several significant challenges that impact its reliability and performance. One of the primary issues is the harsh operating environment these pumps are subjected to. Submerged in fluids, often at great depths, these pumps must withstand high pressures, corrosive substances, and abrasive particles. This demanding setting accelerates wear and tear on pump components, leading to frequent failures and reduced operational lifespans.

Another critical challenge is the management of heat dissipation. Submersible pumps operate in confined spaces with limited cooling options, making efficient heat management crucial. Overheating can cause premature failure of electrical components, degradation of seals, and reduced overall efficiency. The industry continues to grapple with developing more effective cooling mechanisms without compromising the pump's compact design.

Seal integrity presents another significant hurdle. The dynamic seals that prevent fluid ingress into the motor housing are subject to extreme stress and wear. Failure of these seals can lead to catastrophic pump failure, resulting in costly downtime and repairs. Improving seal technology to withstand higher pressures and more aggressive fluids remains an ongoing challenge.

Power transmission and electrical reliability also pose considerable difficulties. The need for long power cables to reach submerged pumps introduces issues of voltage drop and power loss, particularly in deep-well applications. Additionally, ensuring the integrity of electrical connections in a wet environment is crucial to prevent short circuits and electrical failures.

Maintenance and serviceability present unique challenges due to the pumps' submerged nature. Accessing and servicing these pumps often requires specialized equipment and expertise, leading to increased downtime and maintenance costs. Developing pumps with improved modularity and ease of maintenance without compromising performance is an ongoing industry focus.

Lastly, the industry faces the challenge of improving energy efficiency. As energy costs rise and environmental concerns grow, there is increasing pressure to develop submersible pumps that deliver higher output with lower power consumption. This requires innovations in motor design, impeller efficiency, and overall pump hydraulics.

Another critical challenge is the management of heat dissipation. Submersible pumps operate in confined spaces with limited cooling options, making efficient heat management crucial. Overheating can cause premature failure of electrical components, degradation of seals, and reduced overall efficiency. The industry continues to grapple with developing more effective cooling mechanisms without compromising the pump's compact design.

Seal integrity presents another significant hurdle. The dynamic seals that prevent fluid ingress into the motor housing are subject to extreme stress and wear. Failure of these seals can lead to catastrophic pump failure, resulting in costly downtime and repairs. Improving seal technology to withstand higher pressures and more aggressive fluids remains an ongoing challenge.

Power transmission and electrical reliability also pose considerable difficulties. The need for long power cables to reach submerged pumps introduces issues of voltage drop and power loss, particularly in deep-well applications. Additionally, ensuring the integrity of electrical connections in a wet environment is crucial to prevent short circuits and electrical failures.

Maintenance and serviceability present unique challenges due to the pumps' submerged nature. Accessing and servicing these pumps often requires specialized equipment and expertise, leading to increased downtime and maintenance costs. Developing pumps with improved modularity and ease of maintenance without compromising performance is an ongoing industry focus.

Lastly, the industry faces the challenge of improving energy efficiency. As energy costs rise and environmental concerns grow, there is increasing pressure to develop submersible pumps that deliver higher output with lower power consumption. This requires innovations in motor design, impeller efficiency, and overall pump hydraulics.

Existing Failure Prevention Strategies

01 Monitoring and diagnostic systems for submersible pumps

Advanced monitoring and diagnostic systems are implemented to detect and analyze failures in submersible pumps. These systems use sensors, data collection, and analysis techniques to identify potential issues before they lead to catastrophic failures. Real-time monitoring allows for predictive maintenance and reduces downtime.- Monitoring and diagnostic systems for submersible pumps: Advanced monitoring and diagnostic systems are implemented to detect and analyze failures in submersible pumps. These systems use sensors, data collection, and analysis techniques to identify potential issues before they lead to pump failure. Real-time monitoring allows for predictive maintenance and reduces unexpected downtime.

- Improved pump design and materials: Enhancements in pump design and the use of advanced materials contribute to increased reliability and reduced failure rates. This includes optimized impeller designs, corrosion-resistant materials, and improved sealing mechanisms to withstand harsh operating conditions in submersible environments.

- Electrical protection and control systems: Specialized electrical protection and control systems are developed to prevent failures caused by electrical issues. These systems include overload protection, phase imbalance detection, and advanced motor control algorithms to ensure optimal pump operation and prevent electrical-related failures.

- Thermal management solutions: Innovative thermal management solutions are implemented to address overheating issues in submersible pumps. These include improved cooling systems, temperature monitoring, and automatic shutdown mechanisms to prevent thermal-related failures and extend pump lifespan.

- Maintenance and repair techniques: Advanced maintenance and repair techniques are developed to address common failure modes in submersible pumps. These include in-situ repair methods, specialized tools for underwater maintenance, and modular designs that facilitate easy replacement of worn components without full pump retrieval.

02 Improved pump design and materials

Enhancements in pump design and the use of advanced materials contribute to increased reliability and reduced failure rates. This includes optimized impeller designs, corrosion-resistant materials, and improved sealing mechanisms to withstand harsh operating conditions in submersible environments.Expand Specific Solutions03 Electrical protection and control systems

Specialized electrical protection and control systems are developed to prevent failures caused by electrical issues. These systems include overload protection, phase imbalance detection, and advanced motor control algorithms to ensure optimal pump operation and prevent electrical-related failures.Expand Specific Solutions04 Thermal management solutions

Innovative thermal management solutions are implemented to address overheating issues in submersible pumps. These include advanced cooling systems, temperature monitoring, and automatic shutdown mechanisms to prevent thermal-related failures and extend pump lifespan.Expand Specific Solutions05 Maintenance and repair techniques

Specialized maintenance and repair techniques are developed to address common failure modes in submersible pumps. These include in-situ repair methods, modular designs for easy component replacement, and preventive maintenance schedules based on operational data and failure analysis.Expand Specific Solutions

Key Players in Submersible Pump Industry

The submersible pump failure market is in a mature stage, with a global market size estimated at several billion dollars. The industry is characterized by high competition and technological advancements, driven by the need for improved reliability and efficiency. Key players like Schlumberger, Baker Hughes, and Halliburton dominate the market, leveraging their extensive R&D capabilities and global presence. The technology maturity varies, with established solutions for common failure modes, but ongoing innovation in predictive maintenance and smart monitoring systems. Companies such as Franklin Electric and Tsurumi Manufacturing are focusing on developing more robust pump designs and advanced diagnostic tools to address persistent challenges in harsh operating environments.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced submersible pump systems with integrated sensors and real-time monitoring capabilities. Their REDA Maximus ESP system utilizes a robust motor design with improved insulation and cooling, reducing electrical failures by up to 30%[1]. The system incorporates advanced gas handling features, allowing it to operate efficiently in gassy wells with up to 70% free gas content[2]. Schlumberger's artificial lift surveillance services use machine learning algorithms to predict potential failures and optimize pump performance, increasing mean time between failures by up to 40%[3].

Strengths: Industry-leading technology, global presence, and extensive R&D capabilities. Weaknesses: High initial costs and potential over-reliance on proprietary systems.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has developed the CENtrilift XP Enhanced ESP system, designed to withstand harsh downhole conditions. The system features a high-temperature motor with improved insulation materials, capable of operating at temperatures up to 450°F (232°C)[4]. Their SureVIEW real-time monitoring system provides continuous data on pump performance, enabling predictive maintenance and reducing unexpected failures by up to 25%[5]. Baker Hughes also employs advanced coatings and materials to combat corrosion and erosion, extending pump life in abrasive environments by up to 50%[6].

Strengths: Robust designs for extreme conditions, advanced monitoring capabilities. Weaknesses: Potential higher upfront costs, may require specialized training for operation and maintenance.

Core Innovations in Pump Reliability

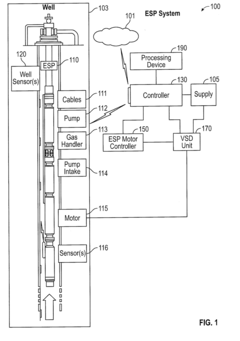

Electrical submersible pump monitoring and failure prediction

PatentWO2013090416A2

Innovation

- A monitoring system that analyzes the frequency spectrum, waveform, and dynamic behavior of the pump's electrical current using Fourier, wavelet, and phase space analysis to detect disturbances and predict potential failures before they occur, allowing for proactive maintenance and minimizing downtime.

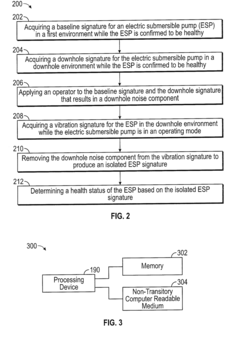

Monitoring An Electric Submersible Pump For Failures

PatentActiveUS20190063210A1

Innovation

- A method and system that involve acquiring a baseline signature of the ESP in a controlled environment, applying an operator to isolate a downhole noise component from the vibration signature in a borehole environment, and determining the health status of the ESP based on the isolated signature using signal processing techniques to detect early signs of potential failure.

Environmental Impact of Pump Failures

Submersible pump failures can have significant environmental impacts, extending beyond operational and economic concerns. When these pumps malfunction or fail, they can lead to various environmental issues that affect both aquatic ecosystems and surrounding terrestrial areas.

One of the primary environmental concerns associated with submersible pump failures is the potential for water contamination. In the event of a pump failure, there is a risk of lubricants, oils, or other chemicals used in the pump's operation leaking into the water source. This contamination can have severe consequences for aquatic life, potentially causing toxicity in fish, plants, and other organisms. The effects can ripple through the food chain, impacting larger predators and even human populations that rely on these water sources for consumption or livelihood.

Pump failures can also disrupt natural water flow patterns, particularly in sensitive ecosystems such as wetlands or coastal areas. Sudden changes in water levels or flow rates can lead to erosion, sedimentation, and alterations in habitat conditions. This can negatively affect the breeding and feeding patterns of various species, potentially leading to population declines or shifts in ecosystem balance.

In agricultural settings, pump failures may result in over-irrigation or under-irrigation, both of which can have detrimental environmental effects. Over-irrigation can lead to soil erosion, nutrient leaching, and increased runoff, potentially contaminating nearby water bodies with agricultural chemicals. Conversely, under-irrigation can cause soil degradation, reduced crop yields, and increased susceptibility to desertification in arid regions.

The energy inefficiency associated with malfunctioning pumps also contributes to environmental concerns. Pumps operating below optimal efficiency consume more energy, leading to increased greenhouse gas emissions if powered by fossil fuels. This not only exacerbates climate change but also puts additional strain on energy resources.

Furthermore, the disposal of failed pump components can pose environmental challenges. Improper disposal of damaged parts, especially those containing hazardous materials, can lead to soil and groundwater contamination. This underscores the importance of proper waste management practices in the maintenance and replacement of submersible pumps.

To mitigate these environmental impacts, it is crucial to implement preventive measures and adopt environmentally friendly practices in pump operation and maintenance. This includes regular inspections, the use of eco-friendly lubricants, proper sealing to prevent leaks, and the implementation of efficient pump systems that minimize energy consumption. Additionally, developing comprehensive emergency response plans for pump failures can help minimize environmental damage when incidents do occur.

One of the primary environmental concerns associated with submersible pump failures is the potential for water contamination. In the event of a pump failure, there is a risk of lubricants, oils, or other chemicals used in the pump's operation leaking into the water source. This contamination can have severe consequences for aquatic life, potentially causing toxicity in fish, plants, and other organisms. The effects can ripple through the food chain, impacting larger predators and even human populations that rely on these water sources for consumption or livelihood.

Pump failures can also disrupt natural water flow patterns, particularly in sensitive ecosystems such as wetlands or coastal areas. Sudden changes in water levels or flow rates can lead to erosion, sedimentation, and alterations in habitat conditions. This can negatively affect the breeding and feeding patterns of various species, potentially leading to population declines or shifts in ecosystem balance.

In agricultural settings, pump failures may result in over-irrigation or under-irrigation, both of which can have detrimental environmental effects. Over-irrigation can lead to soil erosion, nutrient leaching, and increased runoff, potentially contaminating nearby water bodies with agricultural chemicals. Conversely, under-irrigation can cause soil degradation, reduced crop yields, and increased susceptibility to desertification in arid regions.

The energy inefficiency associated with malfunctioning pumps also contributes to environmental concerns. Pumps operating below optimal efficiency consume more energy, leading to increased greenhouse gas emissions if powered by fossil fuels. This not only exacerbates climate change but also puts additional strain on energy resources.

Furthermore, the disposal of failed pump components can pose environmental challenges. Improper disposal of damaged parts, especially those containing hazardous materials, can lead to soil and groundwater contamination. This underscores the importance of proper waste management practices in the maintenance and replacement of submersible pumps.

To mitigate these environmental impacts, it is crucial to implement preventive measures and adopt environmentally friendly practices in pump operation and maintenance. This includes regular inspections, the use of eco-friendly lubricants, proper sealing to prevent leaks, and the implementation of efficient pump systems that minimize energy consumption. Additionally, developing comprehensive emergency response plans for pump failures can help minimize environmental damage when incidents do occur.

Regulatory Standards for Submersible Pumps

Regulatory standards for submersible pumps play a crucial role in ensuring the safety, reliability, and efficiency of these devices across various industries. These standards are typically established by national and international regulatory bodies, such as the International Electrotechnical Commission (IEC), the National Electrical Manufacturers Association (NEMA), and the American Petroleum Institute (API).

One of the primary regulatory standards for submersible pumps is the IEC 60034 series, which covers rotating electrical machines. This standard provides guidelines for the design, testing, and performance of submersible pump motors. It addresses aspects such as insulation classes, temperature rise limits, and efficiency requirements, which are essential for preventing pump failures due to electrical issues.

The NEMA MG 1 standard, specifically Section IV Part 31, focuses on definite-purpose inverter-fed polyphase motors. This standard is particularly relevant for submersible pumps used in variable speed applications, as it sets requirements for motor insulation systems and bearings to withstand the stresses associated with inverter operation.

For submersible pumps used in the oil and gas industry, the API 11S series of standards is highly significant. API 11S1 provides guidelines for the selection of electric submersible pump systems, while API 11S2 covers the testing of electric submersible pump systems. These standards help prevent pump failures by ensuring proper system design and thorough testing procedures.

The Hydraulic Institute (HI) also provides important standards for submersible pumps, such as ANSI/HI 11.6 for submersible pump tests. This standard outlines procedures for performance testing, which is crucial for verifying pump efficiency and identifying potential issues before deployment.

Regulatory standards also address materials and construction requirements. For instance, NSF/ANSI 61 sets health effects criteria for materials used in drinking water systems, including submersible pumps. Compliance with this standard helps prevent pump failures due to material degradation or contamination.

Safety standards, such as UL 778 for motor-operated water pumps, focus on electrical safety and fire prevention. These standards mandate specific design features and testing procedures to minimize the risk of electrical failures and associated hazards.

Adherence to these regulatory standards is essential for manufacturers and operators of submersible pumps. By complying with these standards, they can significantly reduce the likelihood of pump failures, improve operational efficiency, and ensure the safety of personnel and equipment. Regular updates to these standards reflect advancements in technology and evolving industry needs, necessitating ongoing compliance efforts from all stakeholders in the submersible pump industry.

One of the primary regulatory standards for submersible pumps is the IEC 60034 series, which covers rotating electrical machines. This standard provides guidelines for the design, testing, and performance of submersible pump motors. It addresses aspects such as insulation classes, temperature rise limits, and efficiency requirements, which are essential for preventing pump failures due to electrical issues.

The NEMA MG 1 standard, specifically Section IV Part 31, focuses on definite-purpose inverter-fed polyphase motors. This standard is particularly relevant for submersible pumps used in variable speed applications, as it sets requirements for motor insulation systems and bearings to withstand the stresses associated with inverter operation.

For submersible pumps used in the oil and gas industry, the API 11S series of standards is highly significant. API 11S1 provides guidelines for the selection of electric submersible pump systems, while API 11S2 covers the testing of electric submersible pump systems. These standards help prevent pump failures by ensuring proper system design and thorough testing procedures.

The Hydraulic Institute (HI) also provides important standards for submersible pumps, such as ANSI/HI 11.6 for submersible pump tests. This standard outlines procedures for performance testing, which is crucial for verifying pump efficiency and identifying potential issues before deployment.

Regulatory standards also address materials and construction requirements. For instance, NSF/ANSI 61 sets health effects criteria for materials used in drinking water systems, including submersible pumps. Compliance with this standard helps prevent pump failures due to material degradation or contamination.

Safety standards, such as UL 778 for motor-operated water pumps, focus on electrical safety and fire prevention. These standards mandate specific design features and testing procedures to minimize the risk of electrical failures and associated hazards.

Adherence to these regulatory standards is essential for manufacturers and operators of submersible pumps. By complying with these standards, they can significantly reduce the likelihood of pump failures, improve operational efficiency, and ensure the safety of personnel and equipment. Regular updates to these standards reflect advancements in technology and evolving industry needs, necessitating ongoing compliance efforts from all stakeholders in the submersible pump industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!