Submersible pumps' role within eco-friendly maritime engines.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Tech Evolution and Objectives

Submersible pumps have played a crucial role in the evolution of maritime technology, particularly in the context of eco-friendly engines. The development of these pumps can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially designed for dewatering applications, submersible pumps have since found diverse uses in marine environments, including bilge water management, ballast water treatment, and cooling systems for marine engines.

The technological progression of submersible pumps has been driven by the increasing demand for more efficient and environmentally friendly maritime operations. As global awareness of marine pollution grew, so did the need for pumps that could handle a variety of fluids while minimizing environmental impact. This led to the development of pumps with improved sealing mechanisms, corrosion-resistant materials, and enhanced energy efficiency.

In recent years, the focus has shifted towards integrating submersible pumps into eco-friendly maritime engine systems. This integration aims to optimize fuel consumption, reduce emissions, and improve overall vessel performance. Advanced submersible pumps now incorporate smart technologies, such as variable frequency drives and remote monitoring capabilities, allowing for precise control and real-time adjustments based on engine load and environmental conditions.

The current technological objectives for submersible pumps in eco-friendly maritime engines are multifaceted. Firstly, there is a push towards developing pumps with even higher energy efficiency, reducing the overall power consumption of vessels. Secondly, researchers are exploring new materials and coatings that can withstand harsh marine environments while being environmentally benign. Thirdly, there is a growing emphasis on creating pumps that can handle multiple fluid types, including those used in emission reduction systems like scrubbers.

Another key objective is the development of submersible pumps that can operate effectively in hybrid and fully electric propulsion systems. As the maritime industry moves towards cleaner energy sources, submersible pumps must adapt to new cooling and fluid management requirements. This includes the ability to operate at variable speeds and handle the unique thermal management needs of electric drivetrains.

Looking ahead, the evolution of submersible pumps is expected to continue in parallel with advancements in maritime propulsion technology. Future objectives include the integration of artificial intelligence for predictive maintenance and optimized performance, as well as the development of pumps capable of harvesting energy from waste heat or fluid movement. These advancements will further enhance the role of submersible pumps in creating more sustainable and efficient maritime engines.

The technological progression of submersible pumps has been driven by the increasing demand for more efficient and environmentally friendly maritime operations. As global awareness of marine pollution grew, so did the need for pumps that could handle a variety of fluids while minimizing environmental impact. This led to the development of pumps with improved sealing mechanisms, corrosion-resistant materials, and enhanced energy efficiency.

In recent years, the focus has shifted towards integrating submersible pumps into eco-friendly maritime engine systems. This integration aims to optimize fuel consumption, reduce emissions, and improve overall vessel performance. Advanced submersible pumps now incorporate smart technologies, such as variable frequency drives and remote monitoring capabilities, allowing for precise control and real-time adjustments based on engine load and environmental conditions.

The current technological objectives for submersible pumps in eco-friendly maritime engines are multifaceted. Firstly, there is a push towards developing pumps with even higher energy efficiency, reducing the overall power consumption of vessels. Secondly, researchers are exploring new materials and coatings that can withstand harsh marine environments while being environmentally benign. Thirdly, there is a growing emphasis on creating pumps that can handle multiple fluid types, including those used in emission reduction systems like scrubbers.

Another key objective is the development of submersible pumps that can operate effectively in hybrid and fully electric propulsion systems. As the maritime industry moves towards cleaner energy sources, submersible pumps must adapt to new cooling and fluid management requirements. This includes the ability to operate at variable speeds and handle the unique thermal management needs of electric drivetrains.

Looking ahead, the evolution of submersible pumps is expected to continue in parallel with advancements in maritime propulsion technology. Future objectives include the integration of artificial intelligence for predictive maintenance and optimized performance, as well as the development of pumps capable of harvesting energy from waste heat or fluid movement. These advancements will further enhance the role of submersible pumps in creating more sustainable and efficient maritime engines.

Maritime Engine Market Demand Analysis

The maritime engine market has witnessed significant growth in recent years, driven by increasing global trade, expansion of shipping fleets, and the rising demand for eco-friendly propulsion systems. This market segment is characterized by a complex interplay of economic, environmental, and technological factors that shape its trajectory.

The demand for maritime engines is closely tied to the overall health of the shipping industry, which has shown resilience despite global economic fluctuations. As international trade continues to expand, there is a corresponding increase in the need for efficient and reliable marine propulsion systems. This trend is particularly evident in the container shipping sector, where larger vessels require more powerful and sophisticated engines.

Environmental regulations have emerged as a key driver in the maritime engine market. Stringent emission norms, such as the International Maritime Organization's (IMO) sulfur cap and upcoming regulations on greenhouse gas emissions, have spurred demand for cleaner engine technologies. This shift has led to a growing interest in alternative fuels, hybrid systems, and more efficient conventional engines.

The cruise industry, despite recent challenges, remains a significant contributor to the maritime engine market demand. Cruise lines are increasingly focusing on passenger comfort and environmental sustainability, driving the adoption of advanced propulsion systems that offer reduced vibration, noise, and emissions.

In the offshore sector, the demand for specialized vessels for oil and gas exploration, as well as offshore wind farm installation and maintenance, continues to influence the maritime engine market. These applications often require high-power engines capable of operating in challenging marine environments.

The fishing industry, while a smaller segment, also contributes to the market demand, particularly for medium-sized engines. As fishing fleets modernize and adopt more sustainable practices, there is a growing need for fuel-efficient and environmentally friendly propulsion systems.

Geographically, Asia-Pacific dominates the maritime engine market, with China, South Korea, and Japan being major shipbuilding nations. Europe follows closely, with a strong focus on advanced technologies and eco-friendly solutions. North America and the Middle East are also significant markets, driven by naval shipbuilding and offshore activities respectively.

The role of submersible pumps within eco-friendly maritime engines is gaining prominence as part of the broader trend towards more efficient and environmentally conscious propulsion systems. These pumps play a crucial role in various engine subsystems, including cooling, lubrication, and fuel management, contributing to overall engine efficiency and reduced environmental impact.

The demand for maritime engines is closely tied to the overall health of the shipping industry, which has shown resilience despite global economic fluctuations. As international trade continues to expand, there is a corresponding increase in the need for efficient and reliable marine propulsion systems. This trend is particularly evident in the container shipping sector, where larger vessels require more powerful and sophisticated engines.

Environmental regulations have emerged as a key driver in the maritime engine market. Stringent emission norms, such as the International Maritime Organization's (IMO) sulfur cap and upcoming regulations on greenhouse gas emissions, have spurred demand for cleaner engine technologies. This shift has led to a growing interest in alternative fuels, hybrid systems, and more efficient conventional engines.

The cruise industry, despite recent challenges, remains a significant contributor to the maritime engine market demand. Cruise lines are increasingly focusing on passenger comfort and environmental sustainability, driving the adoption of advanced propulsion systems that offer reduced vibration, noise, and emissions.

In the offshore sector, the demand for specialized vessels for oil and gas exploration, as well as offshore wind farm installation and maintenance, continues to influence the maritime engine market. These applications often require high-power engines capable of operating in challenging marine environments.

The fishing industry, while a smaller segment, also contributes to the market demand, particularly for medium-sized engines. As fishing fleets modernize and adopt more sustainable practices, there is a growing need for fuel-efficient and environmentally friendly propulsion systems.

Geographically, Asia-Pacific dominates the maritime engine market, with China, South Korea, and Japan being major shipbuilding nations. Europe follows closely, with a strong focus on advanced technologies and eco-friendly solutions. North America and the Middle East are also significant markets, driven by naval shipbuilding and offshore activities respectively.

The role of submersible pumps within eco-friendly maritime engines is gaining prominence as part of the broader trend towards more efficient and environmentally conscious propulsion systems. These pumps play a crucial role in various engine subsystems, including cooling, lubrication, and fuel management, contributing to overall engine efficiency and reduced environmental impact.

Eco-Friendly Submersible Pump Challenges

The development of eco-friendly maritime engines has become a critical focus in the marine industry, with submersible pumps playing a pivotal role in this evolution. These pumps face several challenges in their adaptation to more environmentally conscious systems. One of the primary obstacles is the need for increased energy efficiency. Traditional submersible pumps often consume significant amounts of power, which can negate the eco-friendly benefits of the engines they support.

Material compatibility presents another hurdle. As maritime engines shift towards using alternative fuels and lubricants with lower environmental impact, submersible pumps must be designed to withstand these new substances without degradation or loss of performance. This requires extensive research into corrosion-resistant materials and innovative sealing technologies.

The issue of heat management is particularly pressing. Eco-friendly engines often operate at different temperature ranges compared to conventional ones, necessitating pumps that can function optimally under these new conditions. Engineers must develop cooling systems that maintain pump efficiency while minimizing energy consumption.

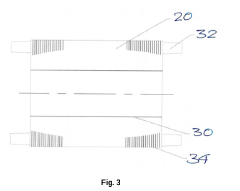

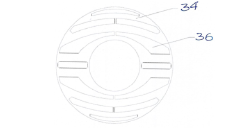

Noise reduction is an additional challenge. As marine ecosystems are increasingly protected, there is a growing demand for quieter submersible pumps to reduce underwater noise pollution. This requires advancements in pump design, including improved impeller geometry and vibration dampening technologies.

Size and weight optimization pose significant difficulties. Eco-friendly maritime engines often aim to reduce overall vessel weight to improve fuel efficiency. Consequently, submersible pumps need to be more compact and lighter without sacrificing performance or durability. This demands innovative materials and design approaches.

Maintenance and longevity are crucial factors. Eco-friendly systems require pumps with extended operational lifespans to reduce the environmental impact of frequent replacements. Developing pumps with improved wear resistance and self-diagnostic capabilities is essential to meet this challenge.

Lastly, the integration of smart technologies presents both an opportunity and a challenge. Submersible pumps in eco-friendly engines must be capable of real-time monitoring and adjustment to optimize performance and reduce environmental impact. This necessitates the development of robust sensors and control systems that can withstand harsh marine environments.

Material compatibility presents another hurdle. As maritime engines shift towards using alternative fuels and lubricants with lower environmental impact, submersible pumps must be designed to withstand these new substances without degradation or loss of performance. This requires extensive research into corrosion-resistant materials and innovative sealing technologies.

The issue of heat management is particularly pressing. Eco-friendly engines often operate at different temperature ranges compared to conventional ones, necessitating pumps that can function optimally under these new conditions. Engineers must develop cooling systems that maintain pump efficiency while minimizing energy consumption.

Noise reduction is an additional challenge. As marine ecosystems are increasingly protected, there is a growing demand for quieter submersible pumps to reduce underwater noise pollution. This requires advancements in pump design, including improved impeller geometry and vibration dampening technologies.

Size and weight optimization pose significant difficulties. Eco-friendly maritime engines often aim to reduce overall vessel weight to improve fuel efficiency. Consequently, submersible pumps need to be more compact and lighter without sacrificing performance or durability. This demands innovative materials and design approaches.

Maintenance and longevity are crucial factors. Eco-friendly systems require pumps with extended operational lifespans to reduce the environmental impact of frequent replacements. Developing pumps with improved wear resistance and self-diagnostic capabilities is essential to meet this challenge.

Lastly, the integration of smart technologies presents both an opportunity and a challenge. Submersible pumps in eco-friendly engines must be capable of real-time monitoring and adjustment to optimize performance and reduce environmental impact. This necessitates the development of robust sensors and control systems that can withstand harsh marine environments.

Current Eco-Friendly Submersible Pump Solutions

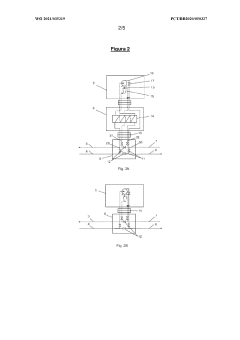

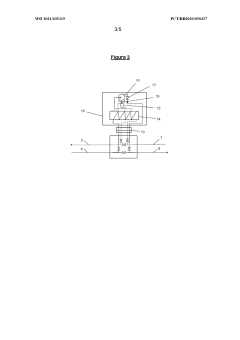

01 Design improvements for submersible pumps

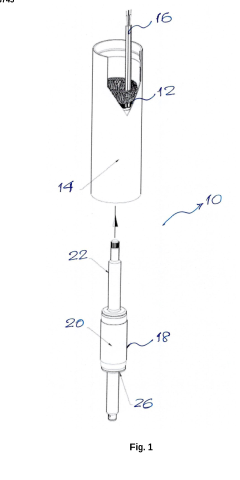

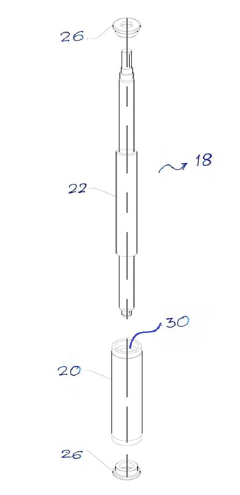

Various design improvements have been made to enhance the performance and efficiency of submersible pumps. These include modifications to the pump housing, impeller design, and motor configuration to optimize fluid flow, increase durability, and improve overall pump efficiency in submerged conditions.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. Their construction typically includes a sealed motor directly coupled to the pump body, allowing for efficient operation in underwater environments. These pumps are engineered to withstand the pressure and corrosive effects of the liquid they are immersed in, making them suitable for various applications such as well pumping, wastewater management, and offshore operations.

- Control systems for submersible pumps: Advanced control systems are implemented in submersible pumps to optimize their performance and efficiency. These systems may include sensors for monitoring pump conditions, variable frequency drives for adjusting motor speed, and remote monitoring capabilities. Such control mechanisms allow for precise regulation of flow rates, pressure, and energy consumption, enhancing the overall reliability and longevity of the pump system.

- Energy efficiency improvements in submersible pumps: Innovations in submersible pump technology focus on improving energy efficiency. This includes the development of high-efficiency motors, optimized impeller designs, and the use of advanced materials to reduce friction and wear. Energy-saving features such as automatic shut-off mechanisms and intelligent power management systems are also incorporated to minimize power consumption during operation.

- Application-specific submersible pump designs: Submersible pumps are tailored for specific applications, such as oil and gas extraction, deep-sea exploration, or municipal water supply. These specialized designs may incorporate features like explosion-proof casings, abrasion-resistant materials, or multi-stage configurations to meet the unique requirements of each application. The pumps are engineered to handle different types of fluids, varying viscosities, and extreme operating conditions.

- Maintenance and reliability enhancements: Improving the maintenance aspects and reliability of submersible pumps is a key focus area. This includes the development of self-diagnostic systems, easy-to-service modular designs, and the use of corrosion-resistant materials. Some innovations aim to extend the service intervals and operational life of the pumps, reducing downtime and maintenance costs. Additionally, advancements in sealing technologies help prevent fluid ingress and protect critical components.

02 Control systems for submersible pumps

Advanced control systems have been developed for submersible pumps to enhance their operation and monitoring capabilities. These systems may include sensors, data analysis algorithms, and remote monitoring features to optimize pump performance, detect faults, and enable predictive maintenance.Expand Specific Solutions03 Energy-efficient submersible pump technologies

Innovations in submersible pump technology have focused on improving energy efficiency. This includes the development of high-efficiency motors, variable speed drives, and intelligent control systems that adjust pump operation based on demand, resulting in reduced energy consumption and operational costs.Expand Specific Solutions04 Specialized submersible pumps for specific applications

Submersible pumps have been designed for specific applications such as oil and gas extraction, wastewater treatment, and deep-sea operations. These specialized pumps incorporate features tailored to their intended use, such as corrosion-resistant materials, high-pressure capabilities, or the ability to handle abrasive fluids.Expand Specific Solutions05 Historical developments in submersible pump technology

The evolution of submersible pump technology can be traced through various historical patents. These documents showcase early innovations in pump design, sealing mechanisms, and motor integration that laid the foundation for modern submersible pump systems.Expand Specific Solutions

Key Players in Maritime Pump Industry

The submersible pump market for eco-friendly maritime engines is in a growth phase, driven by increasing environmental regulations and demand for sustainable marine technologies. The market size is expanding, with significant potential in both commercial and recreational maritime sectors. Technologically, the field is advancing rapidly, with companies like Baker Hughes, Schlumberger, and Flowserve leading innovation. These firms are developing more efficient, durable, and environmentally friendly submersible pump solutions. Emerging players such as Alfred Kärcher and BWT AG are also contributing to technological advancements, particularly in areas of energy efficiency and water treatment integration. The competitive landscape is characterized by a mix of established industrial giants and specialized pump manufacturers, all vying to capture market share in this evolving eco-friendly maritime segment.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced submersible pump systems specifically designed for eco-friendly maritime engines. Their technology focuses on energy-efficient electric submersible pumps (ESPs) that can operate in harsh underwater environments. These pumps utilize high-performance permanent magnet motors and advanced power electronics to maximize efficiency and reduce power consumption [1]. The company has also integrated smart sensors and real-time monitoring capabilities into their submersible pumps, allowing for predictive maintenance and optimization of pump performance in maritime applications [2]. Additionally, Schlumberger has developed specialized coatings and materials for their submersible pumps that resist corrosion and biofouling, extending the operational life of the pumps in marine environments [3].

Strengths: Advanced energy-efficient designs, smart monitoring capabilities, and specialized materials for marine use. Weaknesses: Higher initial costs compared to traditional pumps, and potential complexity in maintenance and repairs.

Sulzer Management AG

Technical Solution: Sulzer has developed a range of submersible pumps tailored for eco-friendly maritime engines, focusing on energy efficiency and environmental protection. Their submersible pump technology incorporates advanced hydraulic designs that optimize flow and reduce power consumption [4]. Sulzer's pumps feature high-efficiency motors with variable speed drives, allowing for precise control and adaptation to varying operating conditions in maritime applications [5]. The company has also implemented innovative sealing systems that prevent leakage of environmentally harmful fluids. Furthermore, Sulzer has developed a line of biodegradable lubricants for their submersible pumps, reducing the risk of marine pollution in case of accidental leaks [6].

Strengths: High energy efficiency, adaptable performance, and environmentally friendly design features. Weaknesses: May require specialized maintenance and potentially higher upfront costs.

Core Innovations in Pump Efficiency

Submersible pump-set for underwater use for supply of water with constant water flow at defined voltage range

PatentPendingIN202321063745A

Innovation

- The improved submersible pump-set employs a rotor assembly with aluminum cage-filled slots for starting torque and a synchronous reluctance torque mechanism, combined with an aluminum die casting process, to maintain constant speed and power at defined voltage ranges, eliminating rotor losses and enhancing efficiency.

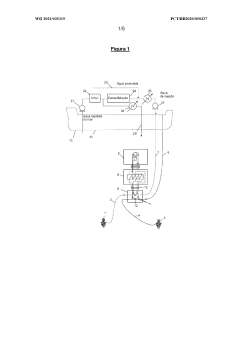

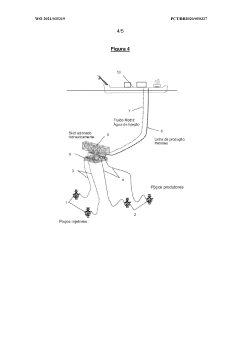

Integrated system for subsea heating and pumping of oil and injection of water for reservoir pressurization, and method for hydraulically actuated subsea heating and pumping and injection of water

PatentWO2021035319A1

Innovation

- An integrated subsea pumping system driven hydraulically by injection water, which includes a recoverable pumping module connected to a subsea base, a heating module, and an injection well, using heated water to drive a turbine and pump set, and optionally providing heat to the produced oil, thereby reducing line lengths and environmental impact.

Environmental Regulations Impact

Environmental regulations have significantly impacted the development and adoption of submersible pumps within eco-friendly maritime engines. The maritime industry has faced increasing pressure to reduce its environmental footprint, particularly in terms of emissions and water pollution. This has led to a surge in demand for more sustainable technologies, including advanced submersible pump systems.

International Maritime Organization (IMO) regulations, such as the International Convention for the Prevention of Pollution from Ships (MARPOL), have set stringent standards for ship emissions and waste management. These regulations have driven the need for more efficient and environmentally friendly engine systems, where submersible pumps play a crucial role in managing various fluids and reducing environmental impact.

The implementation of Emission Control Areas (ECAs) in coastal regions has further accelerated the adoption of eco-friendly technologies. Submersible pumps have been instrumental in supporting the use of alternative fuels, such as liquefied natural gas (LNG), by efficiently managing fuel transfer and storage processes. This has enabled ships to comply with stricter emission limits while maintaining operational efficiency.

Water ballast management regulations have also influenced the design and application of submersible pumps. The Ballast Water Management Convention requires ships to treat ballast water before discharge, preventing the spread of invasive aquatic species. Advanced submersible pump systems have been developed to facilitate efficient ballast water treatment processes, ensuring compliance with these environmental standards.

The push for energy efficiency in maritime operations, driven by regulations like the Energy Efficiency Design Index (EEDI), has led to innovations in submersible pump technology. Manufacturers have focused on developing pumps with higher efficiency ratings and lower power consumption, contributing to overall vessel energy efficiency and reduced carbon footprint.

Noise pollution regulations have also influenced submersible pump design. With increasing concerns about underwater noise and its impact on marine life, pump manufacturers have invested in developing quieter systems. This has resulted in the creation of submersible pumps with advanced noise reduction features, aligning with environmental protection goals.

As environmental regulations continue to evolve, the role of submersible pumps in eco-friendly maritime engines is expected to grow. Future regulations may focus on further reducing greenhouse gas emissions, improving water quality, and enhancing overall environmental performance in maritime operations. This regulatory landscape will likely drive continued innovation in submersible pump technology, emphasizing sustainability, efficiency, and environmental compatibility.

International Maritime Organization (IMO) regulations, such as the International Convention for the Prevention of Pollution from Ships (MARPOL), have set stringent standards for ship emissions and waste management. These regulations have driven the need for more efficient and environmentally friendly engine systems, where submersible pumps play a crucial role in managing various fluids and reducing environmental impact.

The implementation of Emission Control Areas (ECAs) in coastal regions has further accelerated the adoption of eco-friendly technologies. Submersible pumps have been instrumental in supporting the use of alternative fuels, such as liquefied natural gas (LNG), by efficiently managing fuel transfer and storage processes. This has enabled ships to comply with stricter emission limits while maintaining operational efficiency.

Water ballast management regulations have also influenced the design and application of submersible pumps. The Ballast Water Management Convention requires ships to treat ballast water before discharge, preventing the spread of invasive aquatic species. Advanced submersible pump systems have been developed to facilitate efficient ballast water treatment processes, ensuring compliance with these environmental standards.

The push for energy efficiency in maritime operations, driven by regulations like the Energy Efficiency Design Index (EEDI), has led to innovations in submersible pump technology. Manufacturers have focused on developing pumps with higher efficiency ratings and lower power consumption, contributing to overall vessel energy efficiency and reduced carbon footprint.

Noise pollution regulations have also influenced submersible pump design. With increasing concerns about underwater noise and its impact on marine life, pump manufacturers have invested in developing quieter systems. This has resulted in the creation of submersible pumps with advanced noise reduction features, aligning with environmental protection goals.

As environmental regulations continue to evolve, the role of submersible pumps in eco-friendly maritime engines is expected to grow. Future regulations may focus on further reducing greenhouse gas emissions, improving water quality, and enhancing overall environmental performance in maritime operations. This regulatory landscape will likely drive continued innovation in submersible pump technology, emphasizing sustainability, efficiency, and environmental compatibility.

Lifecycle Assessment of Submersible Pumps

The lifecycle assessment of submersible pumps in eco-friendly maritime engines encompasses a comprehensive evaluation of their environmental impact from production to disposal. This assessment begins with the extraction and processing of raw materials, primarily metals and polymers, used in pump manufacturing. The production phase involves energy-intensive processes, including casting, machining, and assembly, which contribute significantly to the pump's carbon footprint.

During the operational phase, submersible pumps play a crucial role in enhancing the efficiency of maritime engines. They facilitate the circulation of coolants and lubricants, ensuring optimal engine performance and reducing fuel consumption. This efficiency gain translates to lower emissions over the engine's lifespan, partially offsetting the initial environmental costs of pump production.

Maintenance and repair activities form an integral part of the pump's lifecycle. Regular servicing, including the replacement of wear parts and seals, extends the pump's operational life but also introduces additional material and energy inputs. The frequency and extent of maintenance depend on factors such as operating conditions, water quality, and pump design, all of which influence the overall environmental impact.

End-of-life considerations for submersible pumps are particularly important in the context of maritime applications. Proper disposal or recycling of pumps is essential to minimize environmental harm. Many components, especially metal parts, can be recycled, reducing the need for virgin materials in future production cycles. However, certain materials, such as specialized polymers or electronic components, may pose recycling challenges.

The lifecycle assessment also considers the pump's role in improving overall engine efficiency and reducing emissions. By enabling more effective cooling and lubrication, submersible pumps contribute to extended engine life and improved fuel efficiency. This indirect environmental benefit must be weighed against the direct impacts of pump production and operation.

Advancements in pump design and materials science offer opportunities for reducing environmental impact. The development of more durable materials can extend pump lifespan, while improvements in energy efficiency can reduce operational environmental costs. Additionally, the integration of smart technologies for predictive maintenance can optimize servicing schedules, further extending pump life and reducing waste.

During the operational phase, submersible pumps play a crucial role in enhancing the efficiency of maritime engines. They facilitate the circulation of coolants and lubricants, ensuring optimal engine performance and reducing fuel consumption. This efficiency gain translates to lower emissions over the engine's lifespan, partially offsetting the initial environmental costs of pump production.

Maintenance and repair activities form an integral part of the pump's lifecycle. Regular servicing, including the replacement of wear parts and seals, extends the pump's operational life but also introduces additional material and energy inputs. The frequency and extent of maintenance depend on factors such as operating conditions, water quality, and pump design, all of which influence the overall environmental impact.

End-of-life considerations for submersible pumps are particularly important in the context of maritime applications. Proper disposal or recycling of pumps is essential to minimize environmental harm. Many components, especially metal parts, can be recycled, reducing the need for virgin materials in future production cycles. However, certain materials, such as specialized polymers or electronic components, may pose recycling challenges.

The lifecycle assessment also considers the pump's role in improving overall engine efficiency and reducing emissions. By enabling more effective cooling and lubrication, submersible pumps contribute to extended engine life and improved fuel efficiency. This indirect environmental benefit must be weighed against the direct impacts of pump production and operation.

Advancements in pump design and materials science offer opportunities for reducing environmental impact. The development of more durable materials can extend pump lifespan, while improvements in energy efficiency can reduce operational environmental costs. Additionally, the integration of smart technologies for predictive maintenance can optimize servicing schedules, further extending pump life and reducing waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!