What acoustic emission analysis reveals about submersible pumps?

JUL 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AE Analysis Background

Acoustic Emission (AE) analysis is a non-destructive testing technique that has gained significant traction in the field of submersible pump monitoring and diagnostics. This method relies on the detection and analysis of high-frequency elastic waves generated by the rapid release of energy within a material or structure. In the context of submersible pumps, AE analysis provides valuable insights into the operational health and performance of these critical components.

The origins of AE analysis can be traced back to the 1950s when it was first used in materials testing. However, its application to submersible pumps is a more recent development, driven by the increasing demand for reliable and efficient pump systems in various industries. The technique has evolved from simple detection of acoustic events to sophisticated signal processing and pattern recognition methods that can identify specific fault conditions and predict potential failures.

AE analysis offers several advantages over traditional monitoring techniques for submersible pumps. Unlike vibration analysis, which typically requires sensors to be mounted on the pump casing, AE sensors can be placed on the pump discharge pipe or even at the wellhead, making it particularly suitable for deep-well applications. This non-invasive approach allows for continuous monitoring without interfering with pump operation or requiring costly downtime for sensor installation.

The principle behind AE analysis in submersible pumps is based on the fact that various pump components generate acoustic emissions during operation. These emissions can be attributed to normal operational processes, such as fluid flow and mechanical movements, as well as to abnormal conditions like cavitation, bearing wear, or impeller damage. By capturing and analyzing these acoustic signatures, engineers can gain valuable insights into the pump's condition and performance.

Recent advancements in AE analysis technology have significantly enhanced its capabilities. The integration of machine learning algorithms and artificial intelligence has enabled more accurate fault detection and classification. These systems can now learn from historical data and improve their diagnostic accuracy over time, making them increasingly valuable for predictive maintenance strategies.

The application of AE analysis to submersible pumps has expanded across various industries, including oil and gas, water treatment, and mining. In these sectors, the technology has proven particularly useful for early detection of issues such as sand production, gas locking, and pump-off conditions, which can significantly impact pump efficiency and lifespan.

As the technology continues to evolve, researchers are exploring new frontiers in AE analysis for submersible pumps. This includes the development of more sensitive sensors, advanced signal processing techniques, and the integration of AE data with other monitoring parameters to create comprehensive pump health monitoring systems. These advancements promise to further enhance the reliability and efficiency of submersible pump operations across various industrial applications.

The origins of AE analysis can be traced back to the 1950s when it was first used in materials testing. However, its application to submersible pumps is a more recent development, driven by the increasing demand for reliable and efficient pump systems in various industries. The technique has evolved from simple detection of acoustic events to sophisticated signal processing and pattern recognition methods that can identify specific fault conditions and predict potential failures.

AE analysis offers several advantages over traditional monitoring techniques for submersible pumps. Unlike vibration analysis, which typically requires sensors to be mounted on the pump casing, AE sensors can be placed on the pump discharge pipe or even at the wellhead, making it particularly suitable for deep-well applications. This non-invasive approach allows for continuous monitoring without interfering with pump operation or requiring costly downtime for sensor installation.

The principle behind AE analysis in submersible pumps is based on the fact that various pump components generate acoustic emissions during operation. These emissions can be attributed to normal operational processes, such as fluid flow and mechanical movements, as well as to abnormal conditions like cavitation, bearing wear, or impeller damage. By capturing and analyzing these acoustic signatures, engineers can gain valuable insights into the pump's condition and performance.

Recent advancements in AE analysis technology have significantly enhanced its capabilities. The integration of machine learning algorithms and artificial intelligence has enabled more accurate fault detection and classification. These systems can now learn from historical data and improve their diagnostic accuracy over time, making them increasingly valuable for predictive maintenance strategies.

The application of AE analysis to submersible pumps has expanded across various industries, including oil and gas, water treatment, and mining. In these sectors, the technology has proven particularly useful for early detection of issues such as sand production, gas locking, and pump-off conditions, which can significantly impact pump efficiency and lifespan.

As the technology continues to evolve, researchers are exploring new frontiers in AE analysis for submersible pumps. This includes the development of more sensitive sensors, advanced signal processing techniques, and the integration of AE data with other monitoring parameters to create comprehensive pump health monitoring systems. These advancements promise to further enhance the reliability and efficiency of submersible pump operations across various industrial applications.

Submersible Pump Market

The submersible pump market has been experiencing significant growth in recent years, driven by increasing demand across various industries such as oil and gas, water and wastewater management, and mining. This market is characterized by its diverse applications and the continuous technological advancements in pump design and efficiency.

The global submersible pump market size was valued at approximately $12.5 billion in 2020 and is projected to reach $19.8 billion by 2027, growing at a CAGR of 6.8% during the forecast period. This growth is primarily attributed to the rising need for water and wastewater management solutions in both developed and developing countries, as well as the expanding oil and gas exploration activities worldwide.

Geographically, Asia-Pacific dominates the submersible pump market, accounting for the largest market share. This is due to rapid industrialization, urbanization, and increasing investments in infrastructure development in countries like China and India. North America and Europe follow closely, with substantial market shares driven by the replacement of aging water infrastructure and the adoption of energy-efficient pumping solutions.

The market is highly competitive, with several key players vying for market share. Some of the prominent companies in the submersible pump market include Grundfos, Xylem, Sulzer, KSB Group, and Ebara Corporation. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

In terms of product types, the market can be segmented into electric submersible pumps and hydraulic submersible pumps. Electric submersible pumps hold the largest market share due to their wide range of applications and energy efficiency. However, hydraulic submersible pumps are gaining traction in specific industries where high-pressure applications are required.

The integration of smart technologies and IoT-enabled solutions in submersible pumps is a growing trend in the market. These advancements allow for real-time monitoring, predictive maintenance, and improved operational efficiency, which are becoming increasingly important factors for end-users in selecting pumping solutions.

The global submersible pump market size was valued at approximately $12.5 billion in 2020 and is projected to reach $19.8 billion by 2027, growing at a CAGR of 6.8% during the forecast period. This growth is primarily attributed to the rising need for water and wastewater management solutions in both developed and developing countries, as well as the expanding oil and gas exploration activities worldwide.

Geographically, Asia-Pacific dominates the submersible pump market, accounting for the largest market share. This is due to rapid industrialization, urbanization, and increasing investments in infrastructure development in countries like China and India. North America and Europe follow closely, with substantial market shares driven by the replacement of aging water infrastructure and the adoption of energy-efficient pumping solutions.

The market is highly competitive, with several key players vying for market share. Some of the prominent companies in the submersible pump market include Grundfos, Xylem, Sulzer, KSB Group, and Ebara Corporation. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

In terms of product types, the market can be segmented into electric submersible pumps and hydraulic submersible pumps. Electric submersible pumps hold the largest market share due to their wide range of applications and energy efficiency. However, hydraulic submersible pumps are gaining traction in specific industries where high-pressure applications are required.

The integration of smart technologies and IoT-enabled solutions in submersible pumps is a growing trend in the market. These advancements allow for real-time monitoring, predictive maintenance, and improved operational efficiency, which are becoming increasingly important factors for end-users in selecting pumping solutions.

AE Technology Challenges

Acoustic Emission (AE) analysis in submersible pumps faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complex operating environment of submersible pumps, which are often submerged in fluids and subjected to high pressures and temperatures. These conditions can interfere with the accuracy and reliability of AE signals, making it difficult to distinguish between genuine fault indicators and environmental noise.

The interpretation of AE data in submersible pumps is another major challenge. The diverse range of potential faults, including cavitation, bearing failures, and impeller damage, each produce unique acoustic signatures. Developing robust algorithms capable of accurately identifying and classifying these various fault types remains an ongoing area of research. The need for extensive baseline data and fault libraries further complicates this process, as each pump model and operating condition may produce different acoustic profiles.

Sensor placement and durability present additional technical hurdles. The optimal positioning of AE sensors to capture relevant signals while withstanding the harsh underwater environment is crucial. Ensuring long-term reliability and performance of these sensors under continuous submersion and exposure to potentially corrosive fluids is a significant engineering challenge. Moreover, the transmission of AE data from submerged pumps to monitoring systems poses difficulties, often requiring specialized communication protocols and hardware.

The integration of AE analysis with existing pump monitoring and control systems is another area of concern. Many industrial setups rely on established monitoring techniques, and incorporating AE analysis into these systems requires careful consideration of compatibility, data processing capabilities, and user interface design. The potential for information overload and the need for real-time analysis further complicate this integration process.

Lastly, the cost-effectiveness of implementing AE technology in submersible pumps remains a challenge. The expenses associated with high-quality sensors, data acquisition systems, and advanced signal processing software can be substantial. Demonstrating a clear return on investment through improved pump reliability, reduced downtime, and enhanced maintenance scheduling is crucial for widespread industry adoption. Balancing the costs of implementation against the potential benefits of early fault detection and predictive maintenance continues to be a key consideration for pump operators and manufacturers alike.

The interpretation of AE data in submersible pumps is another major challenge. The diverse range of potential faults, including cavitation, bearing failures, and impeller damage, each produce unique acoustic signatures. Developing robust algorithms capable of accurately identifying and classifying these various fault types remains an ongoing area of research. The need for extensive baseline data and fault libraries further complicates this process, as each pump model and operating condition may produce different acoustic profiles.

Sensor placement and durability present additional technical hurdles. The optimal positioning of AE sensors to capture relevant signals while withstanding the harsh underwater environment is crucial. Ensuring long-term reliability and performance of these sensors under continuous submersion and exposure to potentially corrosive fluids is a significant engineering challenge. Moreover, the transmission of AE data from submerged pumps to monitoring systems poses difficulties, often requiring specialized communication protocols and hardware.

The integration of AE analysis with existing pump monitoring and control systems is another area of concern. Many industrial setups rely on established monitoring techniques, and incorporating AE analysis into these systems requires careful consideration of compatibility, data processing capabilities, and user interface design. The potential for information overload and the need for real-time analysis further complicate this integration process.

Lastly, the cost-effectiveness of implementing AE technology in submersible pumps remains a challenge. The expenses associated with high-quality sensors, data acquisition systems, and advanced signal processing software can be substantial. Demonstrating a clear return on investment through improved pump reliability, reduced downtime, and enhanced maintenance scheduling is crucial for widespread industry adoption. Balancing the costs of implementation against the potential benefits of early fault detection and predictive maintenance continues to be a key consideration for pump operators and manufacturers alike.

Current AE Solutions

01 Acoustic emission monitoring for submersible pumps

Acoustic emission sensors are used to monitor the condition and performance of submersible pumps. These sensors detect and analyze sound waves generated by the pump's operation, allowing for early detection of potential issues such as cavitation, bearing wear, or impeller damage. This non-invasive monitoring technique helps in predictive maintenance and optimizing pump efficiency.- Acoustic emission monitoring for submersible pumps: Acoustic emission sensors are used to monitor the operational status and detect potential issues in submersible pumps. These sensors can capture and analyze sound waves generated by the pump's components, providing valuable insights into its performance and helping to identify early signs of wear or malfunction.

- Vibration analysis in submersible pump systems: Vibration analysis techniques are employed to assess the condition of submersible pumps. By measuring and analyzing vibration patterns, operators can detect abnormalities, predict maintenance needs, and optimize pump performance. This approach helps in preventing unexpected failures and extending the lifespan of the equipment.

- Acoustic-based leak detection in submersible pumps: Acoustic emission technology is utilized for detecting leaks in submersible pump systems. By analyzing acoustic signatures, operators can identify and locate leaks in pipelines or pump casings, allowing for prompt maintenance and preventing potential environmental hazards or system inefficiencies.

- Noise reduction techniques for submersible pumps: Various methods are employed to reduce noise emissions from submersible pumps. These techniques may include design modifications, use of sound-absorbing materials, or implementation of active noise control systems. Reducing acoustic emissions improves the overall efficiency and environmental impact of pump operations.

- Acoustic telemetry for submersible pump communication: Acoustic telemetry systems are used to transmit data and control signals between submersible pumps and surface equipment. This technology enables real-time monitoring and control of pump operations in challenging environments where traditional communication methods may be ineffective.

02 Submersible pump design for reduced acoustic emissions

Innovative designs for submersible pumps focus on reducing acoustic emissions during operation. This includes optimizing impeller geometry, using sound-absorbing materials, and implementing vibration dampening techniques. These design improvements not only reduce noise pollution but also contribute to increased pump longevity and efficiency.Expand Specific Solutions03 Acoustic emission-based fault detection in submersible pumps

Advanced algorithms and signal processing techniques are employed to analyze acoustic emissions from submersible pumps for fault detection. This approach enables the identification of specific pump issues based on unique acoustic signatures, allowing for more accurate diagnostics and targeted maintenance interventions.Expand Specific Solutions04 Integration of acoustic emission sensors in pump control systems

Acoustic emission sensors are integrated into submersible pump control systems to provide real-time monitoring and automated response capabilities. This integration allows for immediate adjustments to pump operation based on acoustic feedback, optimizing performance and preventing potential damage.Expand Specific Solutions05 Underwater acoustic communication for submersible pump systems

Acoustic emission technology is utilized for underwater communication in submersible pump systems. This enables data transmission between submerged pumps and surface control units without the need for physical connections, facilitating remote monitoring and control of pump operations in challenging underwater environments.Expand Specific Solutions

Key AE Equipment Makers

The acoustic emission analysis of submersible pumps is an emerging field in a rapidly evolving industry. The market is in its growth phase, with increasing demand for predictive maintenance solutions in various sectors, particularly oil and gas, water management, and industrial applications. The global market size for this technology is expanding, driven by the need for improved pump efficiency and reduced downtime. Technologically, the field is advancing, with companies like Baker Hughes, Halliburton, and Schlumberger leading the way in developing sophisticated acoustic monitoring systems. Academic institutions such as the Chinese Academy of Sciences Institute of Acoustics and Nanjing Tech University are contributing to research advancements, while specialized firms like Silixa Ltd. are focusing on innovative fiber optic monitoring solutions for pump systems.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed advanced acoustic emission analysis techniques for submersible pumps. Their approach utilizes high-frequency sensors to detect and analyze acoustic signals generated by pump components during operation. The company employs machine learning algorithms to process the acoustic data, enabling real-time fault detection and predictive maintenance[1]. Their system can identify issues such as cavitation, bearing wear, and impeller damage with high accuracy. Baker Hughes has also integrated this technology with their downhole monitoring systems, allowing for comprehensive pump health assessment in challenging environments like deep-sea oil wells[3].

Strengths: Comprehensive fault detection, real-time monitoring, integration with existing systems. Weaknesses: May require significant data processing power, potential for false positives in noisy environments.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a proprietary acoustic emission analysis system for submersible pumps called "AcousticSense". This technology uses an array of high-sensitivity piezoelectric sensors strategically placed on the pump assembly to capture a wide range of acoustic frequencies. The system employs advanced signal processing techniques, including wavelet transforms and neural networks, to analyze the acoustic signatures in real-time[2]. Halliburton's approach can detect subtle changes in pump performance, such as the onset of sand production or gas interference, allowing for proactive maintenance and optimization of pump operations[4]. The company has also integrated this technology with their "LifeLink" production optimization platform, enabling remote monitoring and control of submersible pumps in challenging offshore environments.

Strengths: High sensitivity to subtle changes, integration with production optimization platforms, remote monitoring capabilities. Weaknesses: May require specialized training for operators, potential for interference from external noise sources.

Core AE Innovations

Electric submersible pump

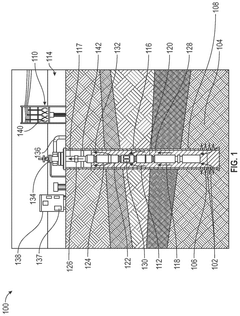

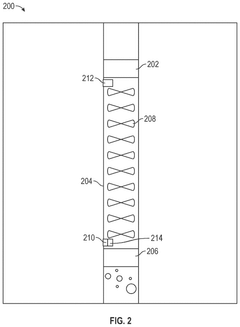

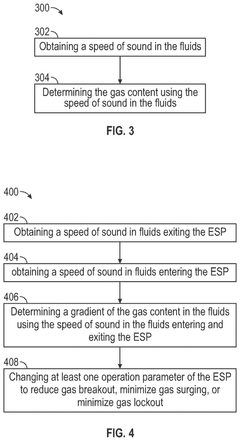

PatentActiveUS12104474B2

Innovation

- Incorporating acoustic transducers at the intake and discharge of the ESP to measure the speed of sound in fluids, allowing for the calculation of gas volume fraction differences across the pump, which serves as feedback to control the ESP operation and prevent gas surging and locking.

AE Data Interpretation

Acoustic emission (AE) data interpretation is a critical aspect of analyzing submersible pump performance and health. The analysis of AE signals provides valuable insights into the pump's operational characteristics, potential faults, and overall condition. By examining the frequency, amplitude, and pattern of acoustic emissions, engineers can detect and diagnose various issues within the pump system.

One key aspect of AE data interpretation is the identification of specific fault signatures. Different pump components and failure modes generate distinct acoustic patterns. For instance, cavitation events produce high-frequency bursts, while bearing wear may result in continuous low-frequency emissions. By developing a comprehensive database of these signatures, analysts can quickly pinpoint the source and severity of problems within the pump.

Signal processing techniques play a crucial role in extracting meaningful information from raw AE data. Time-domain analysis helps identify transient events and overall signal trends, while frequency-domain analysis reveals the spectral content of the emissions. Advanced methods such as wavelet transforms and pattern recognition algorithms further enhance the ability to detect subtle changes in pump behavior.

The interpretation of AE data also involves correlating acoustic emissions with other operational parameters. By synchronizing AE measurements with pump speed, flow rate, and pressure data, analysts can gain a more comprehensive understanding of the pump's performance under various conditions. This multi-parameter approach enables the detection of complex issues that may not be apparent from acoustic data alone.

Machine learning and artificial intelligence techniques are increasingly being applied to AE data interpretation. These methods can automatically classify fault types, predict remaining useful life, and even suggest optimal maintenance schedules based on historical data and current acoustic signatures. As these algorithms become more sophisticated, they promise to revolutionize the field of submersible pump diagnostics.

Challenges in AE data interpretation include dealing with background noise, distinguishing between multiple simultaneous faults, and accounting for variations in pump design and operating conditions. Overcoming these obstacles requires a combination of advanced signal processing, domain expertise, and continuous refinement of interpretation methodologies.

One key aspect of AE data interpretation is the identification of specific fault signatures. Different pump components and failure modes generate distinct acoustic patterns. For instance, cavitation events produce high-frequency bursts, while bearing wear may result in continuous low-frequency emissions. By developing a comprehensive database of these signatures, analysts can quickly pinpoint the source and severity of problems within the pump.

Signal processing techniques play a crucial role in extracting meaningful information from raw AE data. Time-domain analysis helps identify transient events and overall signal trends, while frequency-domain analysis reveals the spectral content of the emissions. Advanced methods such as wavelet transforms and pattern recognition algorithms further enhance the ability to detect subtle changes in pump behavior.

The interpretation of AE data also involves correlating acoustic emissions with other operational parameters. By synchronizing AE measurements with pump speed, flow rate, and pressure data, analysts can gain a more comprehensive understanding of the pump's performance under various conditions. This multi-parameter approach enables the detection of complex issues that may not be apparent from acoustic data alone.

Machine learning and artificial intelligence techniques are increasingly being applied to AE data interpretation. These methods can automatically classify fault types, predict remaining useful life, and even suggest optimal maintenance schedules based on historical data and current acoustic signatures. As these algorithms become more sophisticated, they promise to revolutionize the field of submersible pump diagnostics.

Challenges in AE data interpretation include dealing with background noise, distinguishing between multiple simultaneous faults, and accounting for variations in pump design and operating conditions. Overcoming these obstacles requires a combination of advanced signal processing, domain expertise, and continuous refinement of interpretation methodologies.

AE Regulatory Compliance

Acoustic Emission (AE) analysis in submersible pumps is subject to various regulatory compliance requirements to ensure safety, reliability, and environmental protection. These regulations are established by governmental bodies and industry organizations to set standards for the use of AE technology in monitoring and assessing the condition of submersible pumps.

The primary regulatory bodies overseeing AE analysis in submersible pumps include the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), and the American Petroleum Institute (API). These organizations have developed specific standards and guidelines for the application of AE technology in industrial settings, including submersible pump operations.

ISO 22096:2007 is a key standard that provides guidelines for AE monitoring and diagnostics of machines. It outlines the general principles for using AE techniques in condition monitoring and diagnostics of machines, including submersible pumps. This standard ensures that AE analysis is conducted consistently and reliably across different industries and applications.

ASTM E1930-97 is another important standard that focuses on the examination of fluid systems using acoustic emission. It provides guidelines for the detection and location of leaks in pressurized systems, which is particularly relevant for submersible pumps operating in challenging underwater environments.

The API has also developed standards specific to the oil and gas industry, where submersible pumps are frequently used. API RP 17N, for instance, provides recommendations for subsea production system reliability and technical risk management, which includes the use of AE analysis for monitoring submersible pump performance.

Regulatory compliance in AE analysis for submersible pumps also extends to environmental protection. Many countries have implemented regulations to monitor and control underwater noise pollution, which can be generated by submersible pumps. AE analysis plays a crucial role in ensuring that pump operations comply with these environmental regulations by detecting and mitigating excessive noise emissions.

Furthermore, safety regulations in various industries require regular inspection and maintenance of submersible pumps. AE analysis is recognized as a non-destructive testing method that can be used to meet these regulatory requirements. It allows for the early detection of potential failures, thus preventing accidents and ensuring compliance with safety standards.

To maintain regulatory compliance, organizations using AE analysis for submersible pumps must ensure that their personnel are properly trained and certified. Certification programs, such as those offered by the American Society for Nondestructive Testing (ASNT), provide the necessary qualifications for technicians performing AE analysis in accordance with regulatory standards.

The primary regulatory bodies overseeing AE analysis in submersible pumps include the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), and the American Petroleum Institute (API). These organizations have developed specific standards and guidelines for the application of AE technology in industrial settings, including submersible pump operations.

ISO 22096:2007 is a key standard that provides guidelines for AE monitoring and diagnostics of machines. It outlines the general principles for using AE techniques in condition monitoring and diagnostics of machines, including submersible pumps. This standard ensures that AE analysis is conducted consistently and reliably across different industries and applications.

ASTM E1930-97 is another important standard that focuses on the examination of fluid systems using acoustic emission. It provides guidelines for the detection and location of leaks in pressurized systems, which is particularly relevant for submersible pumps operating in challenging underwater environments.

The API has also developed standards specific to the oil and gas industry, where submersible pumps are frequently used. API RP 17N, for instance, provides recommendations for subsea production system reliability and technical risk management, which includes the use of AE analysis for monitoring submersible pump performance.

Regulatory compliance in AE analysis for submersible pumps also extends to environmental protection. Many countries have implemented regulations to monitor and control underwater noise pollution, which can be generated by submersible pumps. AE analysis plays a crucial role in ensuring that pump operations comply with these environmental regulations by detecting and mitigating excessive noise emissions.

Furthermore, safety regulations in various industries require regular inspection and maintenance of submersible pumps. AE analysis is recognized as a non-destructive testing method that can be used to meet these regulatory requirements. It allows for the early detection of potential failures, thus preventing accidents and ensuring compliance with safety standards.

To maintain regulatory compliance, organizations using AE analysis for submersible pumps must ensure that their personnel are properly trained and certified. Certification programs, such as those offered by the American Society for Nondestructive Testing (ASNT), provide the necessary qualifications for technicians performing AE analysis in accordance with regulatory standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!