Advanced Analytical Methods for Isobutane Detection

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Detection Background and Objectives

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has gained significant attention in various industries due to its versatile applications. The detection and analysis of isobutane have become increasingly important in fields such as petrochemicals, refrigeration, and environmental monitoring. As a result, the development of advanced analytical methods for isobutane detection has emerged as a critical area of research and technological innovation.

The evolution of isobutane detection techniques can be traced back to the mid-20th century when basic gas chromatography methods were first employed. Since then, the field has witnessed remarkable advancements, driven by the growing demand for more accurate, sensitive, and rapid detection methods. These developments have been fueled by stringent safety regulations, environmental concerns, and the need for process optimization in various industries.

In recent years, the focus has shifted towards the development of more sophisticated analytical techniques that can overcome the limitations of traditional methods. These advanced approaches aim to enhance sensitivity, selectivity, and real-time monitoring capabilities while minimizing interference from other gases. Some of the key areas of innovation include the integration of nanotechnology, the application of spectroscopic techniques, and the development of novel sensor materials.

The primary objectives of advanced analytical methods for isobutane detection are multifaceted. Firstly, there is a pressing need to improve the detection limits, enabling the identification of trace amounts of isobutane in complex gas mixtures. This is particularly crucial in environmental monitoring and leak detection applications. Secondly, researchers are striving to develop portable and robust detection systems that can be deployed in field conditions, facilitating on-site analysis and rapid decision-making.

Another significant goal is to enhance the selectivity of detection methods, ensuring accurate quantification of isobutane in the presence of structurally similar hydrocarbons. This is especially challenging given the similar physical and chemical properties of various alkanes. Additionally, there is a growing emphasis on developing real-time monitoring systems that can provide continuous data on isobutane concentrations, enabling proactive safety measures and process control in industrial settings.

The pursuit of these objectives has led to the exploration of various technological approaches, including but not limited to, advanced spectroscopic methods, electrochemical sensors, and novel nanomaterial-based detection systems. Each of these approaches offers unique advantages and challenges, contributing to the diverse landscape of isobutane detection technologies.

As we delve deeper into the field of advanced analytical methods for isobutane detection, it becomes evident that the ongoing research and development efforts are driven by the need to address specific industry requirements while pushing the boundaries of analytical capabilities. The continuous evolution of these technologies promises to revolutionize isobutane detection, paving the way for safer, more efficient, and environmentally conscious industrial processes.

The evolution of isobutane detection techniques can be traced back to the mid-20th century when basic gas chromatography methods were first employed. Since then, the field has witnessed remarkable advancements, driven by the growing demand for more accurate, sensitive, and rapid detection methods. These developments have been fueled by stringent safety regulations, environmental concerns, and the need for process optimization in various industries.

In recent years, the focus has shifted towards the development of more sophisticated analytical techniques that can overcome the limitations of traditional methods. These advanced approaches aim to enhance sensitivity, selectivity, and real-time monitoring capabilities while minimizing interference from other gases. Some of the key areas of innovation include the integration of nanotechnology, the application of spectroscopic techniques, and the development of novel sensor materials.

The primary objectives of advanced analytical methods for isobutane detection are multifaceted. Firstly, there is a pressing need to improve the detection limits, enabling the identification of trace amounts of isobutane in complex gas mixtures. This is particularly crucial in environmental monitoring and leak detection applications. Secondly, researchers are striving to develop portable and robust detection systems that can be deployed in field conditions, facilitating on-site analysis and rapid decision-making.

Another significant goal is to enhance the selectivity of detection methods, ensuring accurate quantification of isobutane in the presence of structurally similar hydrocarbons. This is especially challenging given the similar physical and chemical properties of various alkanes. Additionally, there is a growing emphasis on developing real-time monitoring systems that can provide continuous data on isobutane concentrations, enabling proactive safety measures and process control in industrial settings.

The pursuit of these objectives has led to the exploration of various technological approaches, including but not limited to, advanced spectroscopic methods, electrochemical sensors, and novel nanomaterial-based detection systems. Each of these approaches offers unique advantages and challenges, contributing to the diverse landscape of isobutane detection technologies.

As we delve deeper into the field of advanced analytical methods for isobutane detection, it becomes evident that the ongoing research and development efforts are driven by the need to address specific industry requirements while pushing the boundaries of analytical capabilities. The continuous evolution of these technologies promises to revolutionize isobutane detection, paving the way for safer, more efficient, and environmentally conscious industrial processes.

Market Demand for Isobutane Detection Solutions

The market demand for isobutane detection solutions has been steadily growing due to increasing safety concerns and regulatory requirements across various industries. Isobutane, a highly flammable gas used in refrigeration, aerosol propellants, and petrochemical processes, poses significant safety risks if not properly monitored and controlled. This has led to a surge in demand for advanced analytical methods capable of accurately detecting and measuring isobutane concentrations in diverse environments.

The oil and gas industry represents a major market segment for isobutane detection solutions. With the expansion of natural gas processing facilities and the growing use of isobutane in enhanced oil recovery techniques, there is a pressing need for reliable detection methods to ensure workplace safety and prevent potential leaks or explosions. The petrochemical sector also contributes significantly to market demand, as isobutane is a key component in the production of various chemicals and plastics.

In the refrigeration and air conditioning industry, the shift towards more environmentally friendly refrigerants has increased the use of isobutane as a substitute for hydrofluorocarbons (HFCs). This transition has created a new market for detection solutions in manufacturing, installation, and maintenance processes to ensure compliance with safety standards and regulations.

The consumer goods sector, particularly in the production of aerosol products, has also seen a rise in demand for isobutane detection methods. As isobutane is commonly used as a propellant in aerosol sprays, manufacturers require accurate detection systems to maintain quality control and adhere to safety protocols during production and packaging.

Environmental monitoring and regulatory compliance have become key drivers for market growth. Stringent regulations imposed by agencies such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have mandated the implementation of robust gas detection systems in industrial settings. This regulatory landscape has spurred investments in advanced analytical methods for isobutane detection across various sectors.

The global market for gas detection equipment, including isobutane detection solutions, is projected to experience substantial growth in the coming years. Factors such as increasing industrialization, growing awareness of workplace safety, and the implementation of stringent safety regulations are expected to fuel this expansion. Emerging economies in Asia-Pacific and Latin America are anticipated to offer significant growth opportunities due to rapid industrial development and increasing adoption of safety measures.

The oil and gas industry represents a major market segment for isobutane detection solutions. With the expansion of natural gas processing facilities and the growing use of isobutane in enhanced oil recovery techniques, there is a pressing need for reliable detection methods to ensure workplace safety and prevent potential leaks or explosions. The petrochemical sector also contributes significantly to market demand, as isobutane is a key component in the production of various chemicals and plastics.

In the refrigeration and air conditioning industry, the shift towards more environmentally friendly refrigerants has increased the use of isobutane as a substitute for hydrofluorocarbons (HFCs). This transition has created a new market for detection solutions in manufacturing, installation, and maintenance processes to ensure compliance with safety standards and regulations.

The consumer goods sector, particularly in the production of aerosol products, has also seen a rise in demand for isobutane detection methods. As isobutane is commonly used as a propellant in aerosol sprays, manufacturers require accurate detection systems to maintain quality control and adhere to safety protocols during production and packaging.

Environmental monitoring and regulatory compliance have become key drivers for market growth. Stringent regulations imposed by agencies such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have mandated the implementation of robust gas detection systems in industrial settings. This regulatory landscape has spurred investments in advanced analytical methods for isobutane detection across various sectors.

The global market for gas detection equipment, including isobutane detection solutions, is projected to experience substantial growth in the coming years. Factors such as increasing industrialization, growing awareness of workplace safety, and the implementation of stringent safety regulations are expected to fuel this expansion. Emerging economies in Asia-Pacific and Latin America are anticipated to offer significant growth opportunities due to rapid industrial development and increasing adoption of safety measures.

Current Challenges in Isobutane Analysis

Despite significant advancements in analytical techniques, the detection and quantification of isobutane continue to present several challenges for researchers and industry professionals. One of the primary obstacles is the low concentration of isobutane in many environmental and industrial samples, often requiring highly sensitive detection methods. This is particularly problematic in air quality monitoring and leak detection scenarios, where trace amounts of isobutane need to be accurately measured.

Another significant challenge lies in the selectivity of analytical methods. Isobutane shares similar chemical properties with other hydrocarbons, especially its isomers like n-butane, making it difficult to distinguish and quantify in complex mixtures. This issue is exacerbated in petrochemical processes and natural gas analysis, where multiple hydrocarbon species are present simultaneously.

The stability and reactivity of isobutane pose additional challenges for analytical methods. Its volatility can lead to sample loss during collection and preparation stages, potentially resulting in underestimation of concentrations. Moreover, isobutane's reactivity with certain materials used in analytical instruments can cause interference or degradation of the sample, affecting the accuracy and reliability of measurements.

In field applications, the need for portable and robust analytical devices presents another hurdle. Many current high-precision methods for isobutane detection rely on large, stationary laboratory equipment, limiting their use in on-site monitoring and rapid response situations. Developing miniaturized, field-deployable instruments that maintain high sensitivity and selectivity remains a significant challenge.

The dynamic nature of isobutane emissions in various environments also complicates analysis. Temporal variations in concentration, influenced by factors such as temperature, pressure, and industrial processes, require continuous monitoring capabilities. However, many current analytical methods are better suited for discrete sampling, making it difficult to capture real-time fluctuations accurately.

Calibration and standardization of isobutane detection methods across different laboratories and industries present ongoing challenges. The lack of universally accepted reference materials and standardized protocols can lead to discrepancies in results between different analytical techniques or laboratories, hindering cross-comparison of data and regulatory compliance efforts.

Lastly, the cost and complexity of advanced analytical methods for isobutane detection remain significant barriers to widespread adoption, particularly for smaller organizations or in developing regions. Balancing the need for high-performance analysis with cost-effectiveness and ease of use continues to be a challenge for instrument developers and analytical chemists working in this field.

Another significant challenge lies in the selectivity of analytical methods. Isobutane shares similar chemical properties with other hydrocarbons, especially its isomers like n-butane, making it difficult to distinguish and quantify in complex mixtures. This issue is exacerbated in petrochemical processes and natural gas analysis, where multiple hydrocarbon species are present simultaneously.

The stability and reactivity of isobutane pose additional challenges for analytical methods. Its volatility can lead to sample loss during collection and preparation stages, potentially resulting in underestimation of concentrations. Moreover, isobutane's reactivity with certain materials used in analytical instruments can cause interference or degradation of the sample, affecting the accuracy and reliability of measurements.

In field applications, the need for portable and robust analytical devices presents another hurdle. Many current high-precision methods for isobutane detection rely on large, stationary laboratory equipment, limiting their use in on-site monitoring and rapid response situations. Developing miniaturized, field-deployable instruments that maintain high sensitivity and selectivity remains a significant challenge.

The dynamic nature of isobutane emissions in various environments also complicates analysis. Temporal variations in concentration, influenced by factors such as temperature, pressure, and industrial processes, require continuous monitoring capabilities. However, many current analytical methods are better suited for discrete sampling, making it difficult to capture real-time fluctuations accurately.

Calibration and standardization of isobutane detection methods across different laboratories and industries present ongoing challenges. The lack of universally accepted reference materials and standardized protocols can lead to discrepancies in results between different analytical techniques or laboratories, hindering cross-comparison of data and regulatory compliance efforts.

Lastly, the cost and complexity of advanced analytical methods for isobutane detection remain significant barriers to widespread adoption, particularly for smaller organizations or in developing regions. Balancing the need for high-performance analysis with cost-effectiveness and ease of use continues to be a challenge for instrument developers and analytical chemists working in this field.

Existing Advanced Analytical Techniques

01 Gas chromatography for isobutane detection

Gas chromatography is a widely used method for detecting isobutane. This technique separates and analyzes volatile compounds in a gas mixture, allowing for precise identification and quantification of isobutane. The method typically involves using a specialized column and detector to separate and measure the concentration of isobutane in a sample.- Gas chromatography for isobutane detection: Gas chromatography is a widely used method for detecting isobutane. This technique separates and analyzes volatile compounds in a gas mixture, allowing for precise identification and quantification of isobutane. The method typically involves using a specialized column and detector to separate and measure the concentration of isobutane in a sample.

- Optical spectroscopy for isobutane detection: Optical spectroscopy techniques, such as infrared spectroscopy or laser-based methods, can be used to detect isobutane. These methods rely on the unique spectral absorption or emission characteristics of isobutane molecules. By analyzing the interaction between light and the gas sample, the presence and concentration of isobutane can be determined.

- Electrochemical sensors for isobutane detection: Electrochemical sensors can be used to detect isobutane by measuring the electrical current generated when the gas interacts with a specific electrode material. These sensors typically consist of electrodes coated with a catalyst that selectively reacts with isobutane, producing an electrical signal proportional to the gas concentration.

- Mass spectrometry for isobutane detection: Mass spectrometry is a powerful analytical technique that can be used to detect and quantify isobutane. This method involves ionizing the gas sample and separating the resulting ions based on their mass-to-charge ratio. The unique mass spectrum of isobutane allows for its identification and quantification in complex gas mixtures.

- Portable and continuous monitoring devices for isobutane: Portable and continuous monitoring devices have been developed for real-time detection of isobutane in various environments. These devices often incorporate one or more of the aforementioned detection methods in a compact, user-friendly format. They may include features such as alarms, data logging, and wireless communication for remote monitoring and safety applications.

02 Optical spectroscopy for isobutane detection

Optical spectroscopy techniques, such as infrared spectroscopy or Raman spectroscopy, can be used to detect isobutane. These methods rely on the unique spectral fingerprint of isobutane molecules when interacting with light. By analyzing the absorption or scattering of light at specific wavelengths, the presence and concentration of isobutane can be determined.Expand Specific Solutions03 Electrochemical sensors for isobutane detection

Electrochemical sensors can be used to detect isobutane by measuring changes in electrical properties when the gas interacts with the sensor's electrode surface. These sensors typically consist of electrodes coated with specific materials that react with isobutane, producing a measurable electrical signal proportional to the gas concentration.Expand Specific Solutions04 Mass spectrometry for isobutane detection

Mass spectrometry is a powerful analytical technique that can be used to detect and quantify isobutane. This method involves ionizing the gas molecules and separating them based on their mass-to-charge ratio. The resulting mass spectrum provides a unique fingerprint for isobutane, allowing for its identification and quantification in complex gas mixtures.Expand Specific Solutions05 Portable and handheld isobutane detectors

Portable and handheld devices have been developed for on-site detection of isobutane. These devices often incorporate miniaturized versions of detection technologies such as infrared sensors or electrochemical cells. They provide rapid and convenient means for detecting isobutane in various environments, including industrial settings and leak detection applications.Expand Specific Solutions

Key Players in Isobutane Detection Industry

The advanced analytical methods for isobutane detection market is in a growth phase, driven by increasing demand for precise gas detection across industries. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, the field is rapidly evolving, with companies like China Petroleum & Chemical Corp., PetroChina, and ExxonMobil leading in research and development. These industry giants, along with specialized firms like Langxi Instrument and Bio-Rad Laboratories, are pushing the boundaries of detection sensitivity, accuracy, and real-time monitoring capabilities. Academic institutions such as Johns Hopkins University and Arizona State University are also contributing significantly to technological advancements in this domain.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a multi-component gas analysis system for isobutane detection in refinery processes. Their method utilizes a combination of Fourier-transform infrared (FTIR) spectroscopy and chemometric algorithms for quantitative analysis[2]. Sinopec has also implemented advanced optical sensing technologies, including tunable diode laser absorption spectroscopy (TDLAS), for in-situ monitoring of isobutane in gas streams[4]. Furthermore, the company has explored the use of miniaturized gas sensors based on metal oxide semiconductors for portable isobutane detection applications in field operations[6].

Strengths: High accuracy in multi-component analysis, non-invasive in-situ monitoring, and potential for miniaturization. Weaknesses: Complexity in data interpretation and potential interference from other hydrocarbons.

BP Oil International Ltd.

Technical Solution: BP has developed advanced analytical methods for isobutane detection using a combination of gas chromatography and flame ionization detection (GC-FID). Their approach incorporates a specialized column configuration for improved separation of isobutane from other light hydrocarbons[7]. BP has also implemented online monitoring systems using Raman spectroscopy for continuous isobutane detection in refinery processes, allowing for real-time process control and optimization[9]. Additionally, the company has explored the use of photoacoustic spectroscopy for trace-level isobutane detection in environmental monitoring applications[11].

Strengths: High precision in isobutane quantification, continuous online monitoring capabilities, and applicability in both process and environmental contexts. Weaknesses: Potential sensitivity to sample matrix effects and need for regular calibration.

Innovative Approaches in Isobutane Detection

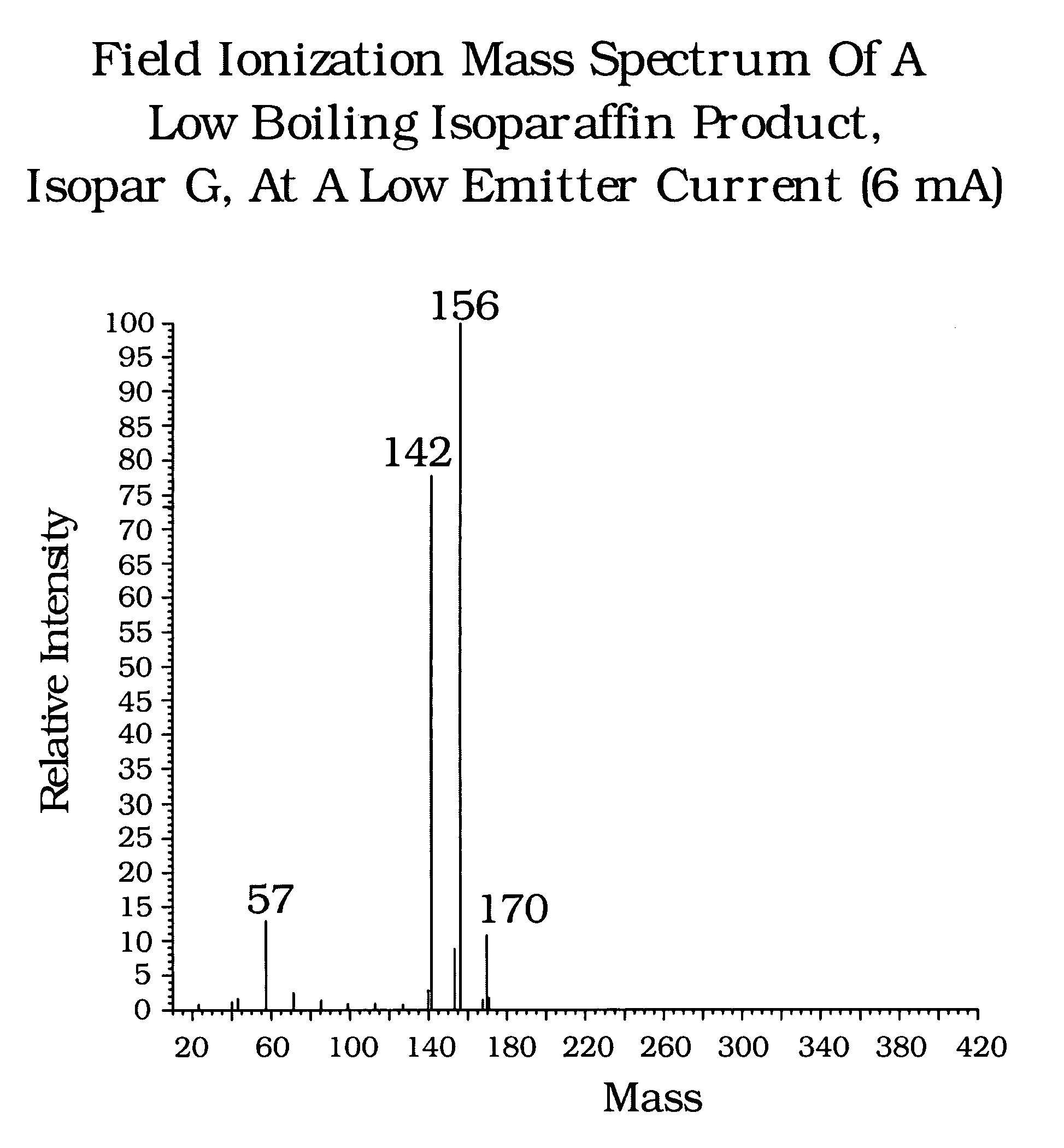

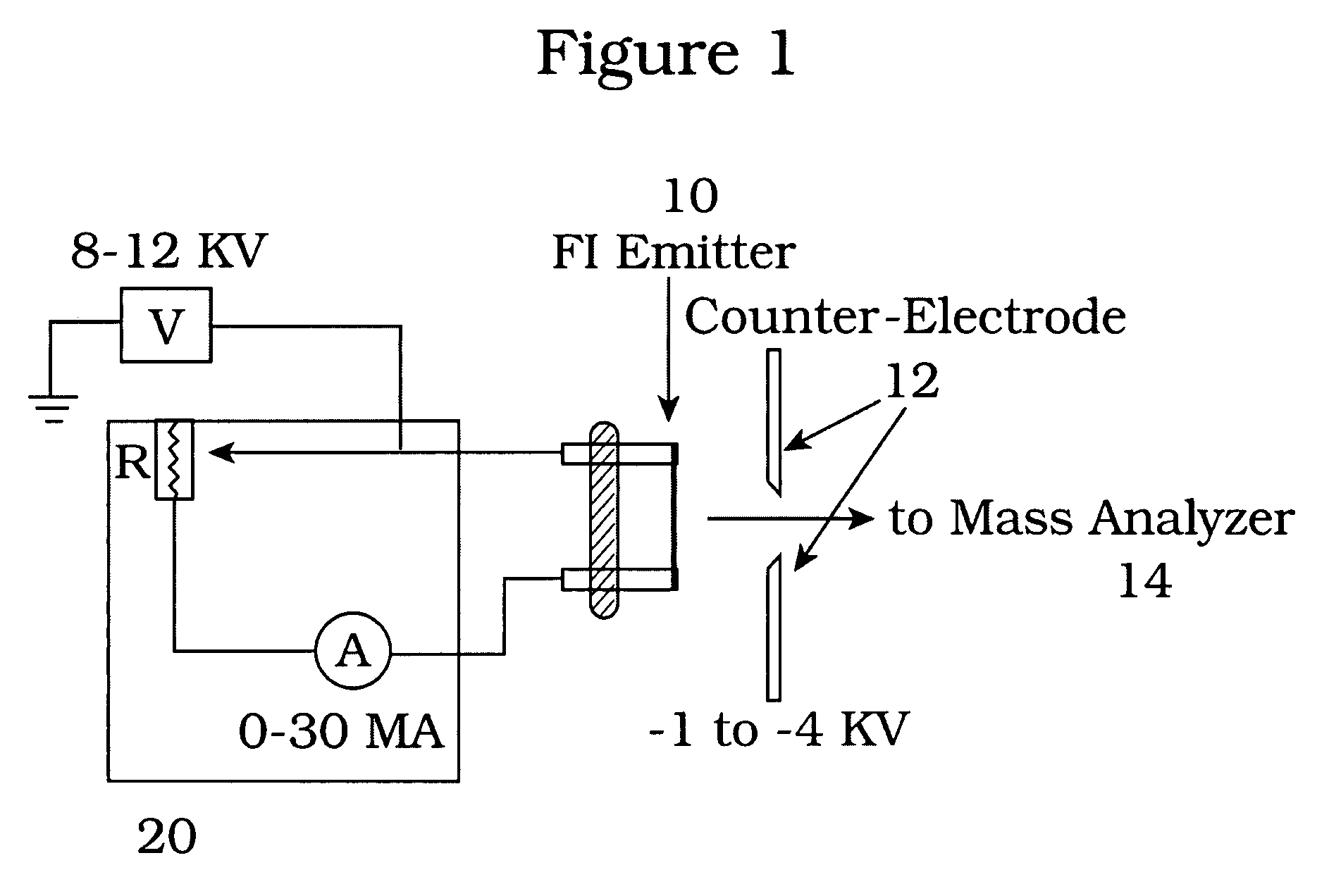

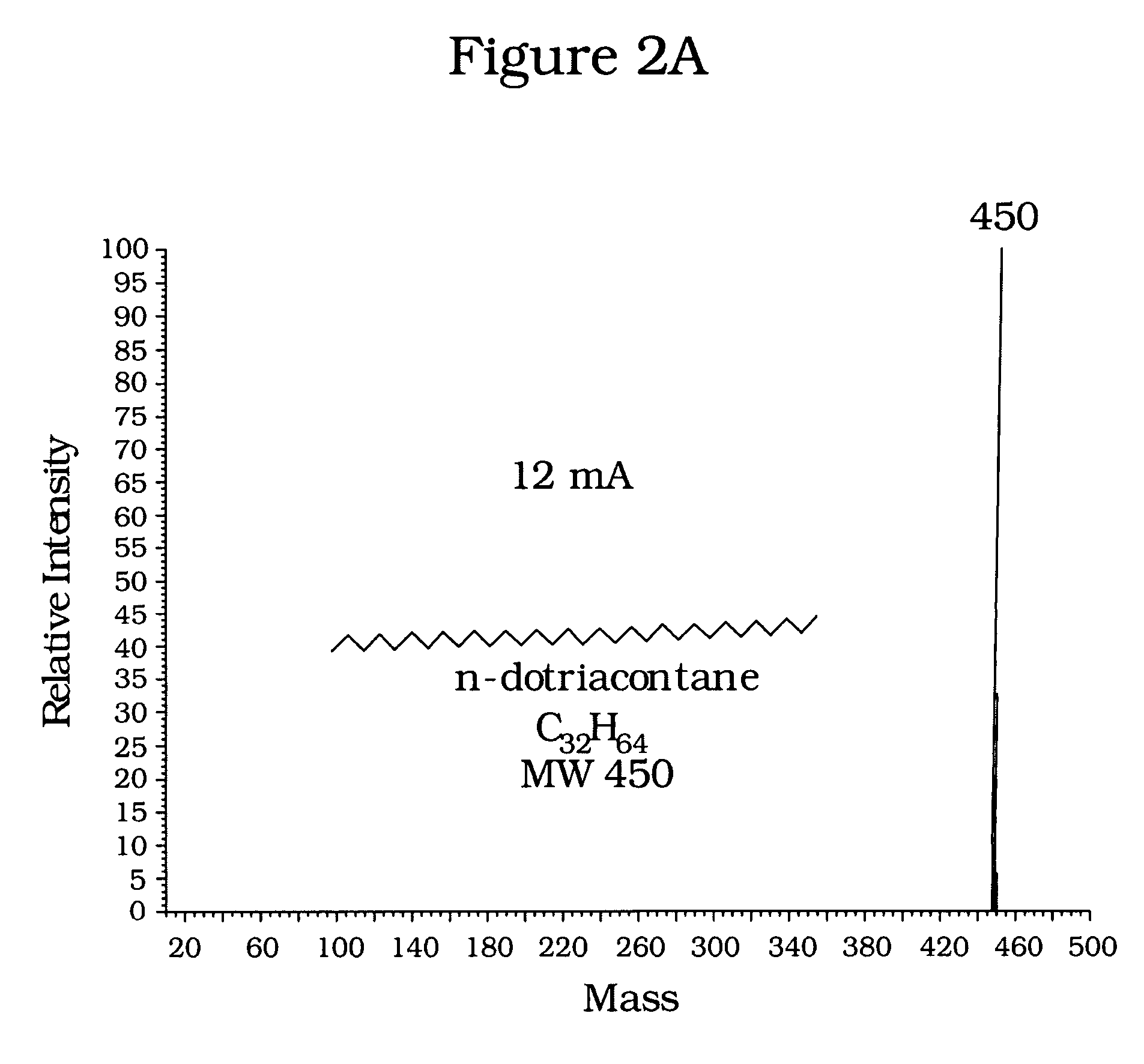

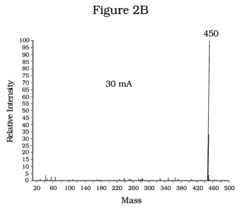

Method of producing molecular profiles of isoparaffins by low emitter current field ionization mass spectrometry

PatentInactiveUS7671328B2

Innovation

- Reducing the in-scan emitter current in a field ionization mass spectrometer below a threshold value to substantially reduce or eliminate fragmentation of isoparaffin molecular ions, allowing for direct measurement of carbon numbers and molecular weights.

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

Regulatory Framework for Isobutane Detection

The regulatory framework for isobutane detection plays a crucial role in ensuring safety and compliance across various industries. Governments and international organizations have established comprehensive guidelines and standards to regulate the detection and monitoring of isobutane, a highly flammable gas with potential health and environmental risks.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for isobutane in workplace environments. The current PEL is 800 parts per million (ppm) as an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) recommends a lower exposure limit of 800 ppm for up to a 10-hour workday. These regulations necessitate accurate and reliable detection methods to ensure compliance and worker safety.

The Environmental Protection Agency (EPA) regulates isobutane emissions under the Clean Air Act, classifying it as a volatile organic compound (VOC). Industries using or producing isobutane must adhere to strict emission standards and implement appropriate detection and monitoring systems. The EPA also mandates specific analytical methods for isobutane detection, such as Method 18 for the measurement of gaseous organic compound emissions.

Internationally, the European Union has implemented the ATEX Directive (2014/34/EU) for equipment and protective systems intended for use in potentially explosive atmospheres. This directive directly impacts isobutane detection systems, requiring them to meet specific safety and performance standards. The International Electrotechnical Commission (IEC) has also developed standards for gas detection equipment, including those used for isobutane, under the IEC 60079 series.

In the transportation sector, regulations such as the International Maritime Dangerous Goods (IMDG) Code and the International Civil Aviation Organization (ICAO) Technical Instructions govern the handling and transportation of isobutane. These regulations require appropriate detection and monitoring systems to be in place during storage and transport.

The regulatory landscape for isobutane detection is continually evolving, with increasing emphasis on real-time monitoring and data reporting. Recent trends include the integration of Internet of Things (IoT) technologies for remote monitoring and the development of smart sensors capable of detecting multiple gases simultaneously. These advancements are driving the need for updated regulations that address the capabilities and potential vulnerabilities of these new technologies.

As environmental concerns grow, there is a push towards more stringent regulations on greenhouse gas emissions, including isobutane. This trend is likely to result in lower permissible emission levels and more frequent monitoring requirements, further emphasizing the importance of advanced analytical methods for isobutane detection.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for isobutane in workplace environments. The current PEL is 800 parts per million (ppm) as an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) recommends a lower exposure limit of 800 ppm for up to a 10-hour workday. These regulations necessitate accurate and reliable detection methods to ensure compliance and worker safety.

The Environmental Protection Agency (EPA) regulates isobutane emissions under the Clean Air Act, classifying it as a volatile organic compound (VOC). Industries using or producing isobutane must adhere to strict emission standards and implement appropriate detection and monitoring systems. The EPA also mandates specific analytical methods for isobutane detection, such as Method 18 for the measurement of gaseous organic compound emissions.

Internationally, the European Union has implemented the ATEX Directive (2014/34/EU) for equipment and protective systems intended for use in potentially explosive atmospheres. This directive directly impacts isobutane detection systems, requiring them to meet specific safety and performance standards. The International Electrotechnical Commission (IEC) has also developed standards for gas detection equipment, including those used for isobutane, under the IEC 60079 series.

In the transportation sector, regulations such as the International Maritime Dangerous Goods (IMDG) Code and the International Civil Aviation Organization (ICAO) Technical Instructions govern the handling and transportation of isobutane. These regulations require appropriate detection and monitoring systems to be in place during storage and transport.

The regulatory landscape for isobutane detection is continually evolving, with increasing emphasis on real-time monitoring and data reporting. Recent trends include the integration of Internet of Things (IoT) technologies for remote monitoring and the development of smart sensors capable of detecting multiple gases simultaneously. These advancements are driving the need for updated regulations that address the capabilities and potential vulnerabilities of these new technologies.

As environmental concerns grow, there is a push towards more stringent regulations on greenhouse gas emissions, including isobutane. This trend is likely to result in lower permissible emission levels and more frequent monitoring requirements, further emphasizing the importance of advanced analytical methods for isobutane detection.

Environmental Impact of Isobutane Detection Methods

The environmental impact of isobutane detection methods is a critical consideration in the development and implementation of advanced analytical techniques. Traditional methods for detecting isobutane, such as gas chromatography and mass spectrometry, often require the use of harmful chemicals and generate significant amounts of waste. These processes can contribute to air and water pollution, as well as pose risks to human health and ecosystems.

More recent advancements in isobutane detection have focused on developing environmentally friendly alternatives. Optical sensing technologies, including infrared spectroscopy and laser-based methods, offer reduced environmental impact by eliminating the need for chemical reagents and minimizing waste generation. These methods also consume less energy, further reducing their carbon footprint.

Electrochemical sensors represent another promising approach with lower environmental impact. These sensors operate on principles that require minimal sample preparation and produce negligible waste. Additionally, they can be miniaturized, leading to reduced material consumption in their production and deployment.

The development of portable and real-time monitoring devices for isobutane detection has also contributed to positive environmental outcomes. These tools enable more efficient leak detection and rapid response to potential environmental hazards, preventing large-scale releases of isobutane into the atmosphere. This proactive approach significantly reduces the potential for ozone depletion and climate change impacts associated with isobutane emissions.

Advancements in data analytics and artificial intelligence have further enhanced the environmental benefits of isobutane detection methods. By improving the accuracy and sensitivity of detection systems, these technologies help minimize false alarms and unnecessary interventions, thereby reducing resource consumption and potential environmental disturbances associated with response activities.

However, it is important to note that the production and disposal of advanced detection equipment can still have environmental implications. The use of rare earth elements and specialized materials in some sensors may contribute to resource depletion and generate electronic waste. Efforts are ongoing to address these challenges through the development of more sustainable manufacturing processes and improved recycling techniques for end-of-life devices.

In conclusion, the evolution of isobutane detection methods has generally trended towards more environmentally friendly approaches. As research continues, it is expected that future innovations will further minimize the environmental footprint of these essential analytical tools, aligning with global sustainability goals and regulatory requirements for environmental protection.

More recent advancements in isobutane detection have focused on developing environmentally friendly alternatives. Optical sensing technologies, including infrared spectroscopy and laser-based methods, offer reduced environmental impact by eliminating the need for chemical reagents and minimizing waste generation. These methods also consume less energy, further reducing their carbon footprint.

Electrochemical sensors represent another promising approach with lower environmental impact. These sensors operate on principles that require minimal sample preparation and produce negligible waste. Additionally, they can be miniaturized, leading to reduced material consumption in their production and deployment.

The development of portable and real-time monitoring devices for isobutane detection has also contributed to positive environmental outcomes. These tools enable more efficient leak detection and rapid response to potential environmental hazards, preventing large-scale releases of isobutane into the atmosphere. This proactive approach significantly reduces the potential for ozone depletion and climate change impacts associated with isobutane emissions.

Advancements in data analytics and artificial intelligence have further enhanced the environmental benefits of isobutane detection methods. By improving the accuracy and sensitivity of detection systems, these technologies help minimize false alarms and unnecessary interventions, thereby reducing resource consumption and potential environmental disturbances associated with response activities.

However, it is important to note that the production and disposal of advanced detection equipment can still have environmental implications. The use of rare earth elements and specialized materials in some sensors may contribute to resource depletion and generate electronic waste. Efforts are ongoing to address these challenges through the development of more sustainable manufacturing processes and improved recycling techniques for end-of-life devices.

In conclusion, the evolution of isobutane detection methods has generally trended towards more environmentally friendly approaches. As research continues, it is expected that future innovations will further minimize the environmental footprint of these essential analytical tools, aligning with global sustainability goals and regulatory requirements for environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!