Isobutane in Sustainable Building Material Production

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane in Construction: Background and Objectives

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has emerged as a promising candidate in the quest for sustainable building materials. The construction industry, long criticized for its significant environmental impact, is now at the forefront of innovation in developing eco-friendly alternatives to traditional materials. This research aims to explore the potential of isobutane in revolutionizing sustainable building material production.

The evolution of construction materials has been driven by the need for improved performance, durability, and cost-effectiveness. However, in recent years, environmental concerns have taken center stage, prompting a shift towards sustainable practices. Isobutane, primarily known for its applications in refrigeration and as a propellant, is now being investigated for its potential role in creating environmentally friendly building materials.

The primary objective of this research is to assess the feasibility of incorporating isobutane into the production of sustainable building materials. This involves examining its physical and chemical properties, evaluating its potential benefits in terms of energy efficiency and reduced carbon footprint, and identifying possible challenges in its implementation. The study also aims to explore innovative manufacturing processes that could leverage isobutane's unique characteristics to create materials with enhanced performance and reduced environmental impact.

A key focus of this research is the potential of isobutane as a blowing agent in the production of insulation materials. Traditional insulation often relies on harmful chemicals that contribute to ozone depletion and global warming. Isobutane, with its low global warming potential and zero ozone depletion potential, presents a promising alternative. The investigation will delve into how isobutane can be utilized to create foam insulation with superior thermal properties while minimizing environmental impact.

Furthermore, this study will explore the broader implications of isobutane use in construction materials. This includes analyzing its potential to improve energy efficiency in buildings, reduce overall material consumption, and contribute to the circular economy through recyclability and reusability. The research will also consider the economic viability of isobutane-based materials, assessing production costs, scalability, and market acceptance.

As the construction industry faces increasing pressure to adopt sustainable practices, this research into isobutane's potential in building material production is timely and crucial. By thoroughly examining the technical, environmental, and economic aspects of isobutane use, this study aims to provide valuable insights that could shape the future of sustainable construction. The findings could potentially pave the way for a new generation of building materials that not only meet performance standards but also significantly reduce the industry's environmental footprint.

The evolution of construction materials has been driven by the need for improved performance, durability, and cost-effectiveness. However, in recent years, environmental concerns have taken center stage, prompting a shift towards sustainable practices. Isobutane, primarily known for its applications in refrigeration and as a propellant, is now being investigated for its potential role in creating environmentally friendly building materials.

The primary objective of this research is to assess the feasibility of incorporating isobutane into the production of sustainable building materials. This involves examining its physical and chemical properties, evaluating its potential benefits in terms of energy efficiency and reduced carbon footprint, and identifying possible challenges in its implementation. The study also aims to explore innovative manufacturing processes that could leverage isobutane's unique characteristics to create materials with enhanced performance and reduced environmental impact.

A key focus of this research is the potential of isobutane as a blowing agent in the production of insulation materials. Traditional insulation often relies on harmful chemicals that contribute to ozone depletion and global warming. Isobutane, with its low global warming potential and zero ozone depletion potential, presents a promising alternative. The investigation will delve into how isobutane can be utilized to create foam insulation with superior thermal properties while minimizing environmental impact.

Furthermore, this study will explore the broader implications of isobutane use in construction materials. This includes analyzing its potential to improve energy efficiency in buildings, reduce overall material consumption, and contribute to the circular economy through recyclability and reusability. The research will also consider the economic viability of isobutane-based materials, assessing production costs, scalability, and market acceptance.

As the construction industry faces increasing pressure to adopt sustainable practices, this research into isobutane's potential in building material production is timely and crucial. By thoroughly examining the technical, environmental, and economic aspects of isobutane use, this study aims to provide valuable insights that could shape the future of sustainable construction. The findings could potentially pave the way for a new generation of building materials that not only meet performance standards but also significantly reduce the industry's environmental footprint.

Market Analysis for Sustainable Building Materials

The sustainable building materials market has experienced significant growth in recent years, driven by increasing environmental awareness, stringent regulations, and a growing emphasis on green construction practices. The global market for sustainable building materials was valued at $230 billion in 2020 and is projected to reach $425 billion by 2027, with a compound annual growth rate (CAGR) of 9.5% during this period.

The demand for sustainable building materials is primarily fueled by the construction industry's shift towards eco-friendly practices and the rising adoption of green building standards such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). Governments worldwide are implementing policies and incentives to promote sustainable construction, further boosting market growth.

Key segments within the sustainable building materials market include structural materials, exterior materials, interior materials, and others. Structural materials, including recycled concrete and sustainable steel, account for the largest market share. However, the exterior materials segment, which includes sustainable insulation products, is expected to witness the highest growth rate in the coming years.

Geographically, North America and Europe currently dominate the sustainable building materials market, owing to stringent environmental regulations and high adoption rates of green building practices. However, the Asia-Pacific region is anticipated to exhibit the fastest growth, driven by rapid urbanization, increasing environmental concerns, and supportive government initiatives in countries like China and India.

The use of isobutane in sustainable building material production represents a niche but growing segment within this market. Isobutane, primarily used as a blowing agent in the production of insulation materials, offers several advantages over traditional agents, including lower global warming potential and improved energy efficiency. The demand for isobutane-based insulation materials is expected to grow as manufacturers seek to comply with increasingly stringent environmental regulations and meet consumer preferences for sustainable products.

Key market players in the sustainable building materials sector include Saint-Gobain, Owens Corning, Kingspan Group, and BASF SE. These companies are investing heavily in research and development to innovate new sustainable materials and improve existing ones. The integration of isobutane into their product lines represents a potential area for competitive differentiation and market expansion.

Challenges in the market include higher initial costs compared to traditional building materials, lack of awareness among consumers and builders, and the need for skilled professionals in sustainable construction techniques. However, these challenges are gradually being addressed through technological advancements, educational initiatives, and supportive policies, paving the way for continued market growth and innovation in sustainable building materials, including those utilizing isobutane.

The demand for sustainable building materials is primarily fueled by the construction industry's shift towards eco-friendly practices and the rising adoption of green building standards such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). Governments worldwide are implementing policies and incentives to promote sustainable construction, further boosting market growth.

Key segments within the sustainable building materials market include structural materials, exterior materials, interior materials, and others. Structural materials, including recycled concrete and sustainable steel, account for the largest market share. However, the exterior materials segment, which includes sustainable insulation products, is expected to witness the highest growth rate in the coming years.

Geographically, North America and Europe currently dominate the sustainable building materials market, owing to stringent environmental regulations and high adoption rates of green building practices. However, the Asia-Pacific region is anticipated to exhibit the fastest growth, driven by rapid urbanization, increasing environmental concerns, and supportive government initiatives in countries like China and India.

The use of isobutane in sustainable building material production represents a niche but growing segment within this market. Isobutane, primarily used as a blowing agent in the production of insulation materials, offers several advantages over traditional agents, including lower global warming potential and improved energy efficiency. The demand for isobutane-based insulation materials is expected to grow as manufacturers seek to comply with increasingly stringent environmental regulations and meet consumer preferences for sustainable products.

Key market players in the sustainable building materials sector include Saint-Gobain, Owens Corning, Kingspan Group, and BASF SE. These companies are investing heavily in research and development to innovate new sustainable materials and improve existing ones. The integration of isobutane into their product lines represents a potential area for competitive differentiation and market expansion.

Challenges in the market include higher initial costs compared to traditional building materials, lack of awareness among consumers and builders, and the need for skilled professionals in sustainable construction techniques. However, these challenges are gradually being addressed through technological advancements, educational initiatives, and supportive policies, paving the way for continued market growth and innovation in sustainable building materials, including those utilizing isobutane.

Current Challenges in Isobutane-Based Construction Materials

The integration of isobutane into sustainable building material production faces several significant challenges that hinder widespread adoption and optimal utilization. One of the primary obstacles is the flammability and volatility of isobutane, which necessitates stringent safety measures throughout the manufacturing process. This inherent risk factor increases production costs and complexity, potentially offsetting some of the environmental benefits.

Another challenge lies in achieving consistent quality and performance in isobutane-based construction materials. The incorporation of this hydrocarbon can affect the mechanical properties, thermal insulation capabilities, and long-term durability of the final products. Ensuring that these materials meet or exceed industry standards while maintaining their sustainability credentials requires extensive research and development efforts.

The regulatory landscape presents an additional hurdle. Many countries have strict regulations governing the use of volatile organic compounds (VOCs) in building materials. Isobutane, being a VOC, falls under these regulations, which can limit its application in certain regions or require manufacturers to implement costly emission control systems.

Environmental concerns also pose challenges. While isobutane has a lower global warming potential compared to some traditional blowing agents, its production still relies on fossil fuel sources. This dependency conflicts with the overarching goal of creating truly sustainable building materials, prompting the need for more environmentally friendly production methods or alternative sources.

The scalability of isobutane-based production processes is another significant challenge. Transitioning from laboratory-scale experiments to full-scale industrial production often reveals unforeseen issues related to material handling, process control, and quality assurance. Overcoming these scaling challenges requires substantial investment in research, equipment, and expertise.

Furthermore, the construction industry's inherent conservatism and slow adoption of new technologies present a barrier to the widespread use of isobutane-based materials. Convincing stakeholders to embrace these innovative products often requires extensive testing, certification, and demonstration of long-term performance and cost-effectiveness.

Lastly, the challenge of end-of-life management for isobutane-containing building materials cannot be overlooked. Developing efficient recycling or disposal methods that prevent the release of isobutane into the atmosphere is crucial for maintaining the sustainability credentials of these materials throughout their lifecycle.

Another challenge lies in achieving consistent quality and performance in isobutane-based construction materials. The incorporation of this hydrocarbon can affect the mechanical properties, thermal insulation capabilities, and long-term durability of the final products. Ensuring that these materials meet or exceed industry standards while maintaining their sustainability credentials requires extensive research and development efforts.

The regulatory landscape presents an additional hurdle. Many countries have strict regulations governing the use of volatile organic compounds (VOCs) in building materials. Isobutane, being a VOC, falls under these regulations, which can limit its application in certain regions or require manufacturers to implement costly emission control systems.

Environmental concerns also pose challenges. While isobutane has a lower global warming potential compared to some traditional blowing agents, its production still relies on fossil fuel sources. This dependency conflicts with the overarching goal of creating truly sustainable building materials, prompting the need for more environmentally friendly production methods or alternative sources.

The scalability of isobutane-based production processes is another significant challenge. Transitioning from laboratory-scale experiments to full-scale industrial production often reveals unforeseen issues related to material handling, process control, and quality assurance. Overcoming these scaling challenges requires substantial investment in research, equipment, and expertise.

Furthermore, the construction industry's inherent conservatism and slow adoption of new technologies present a barrier to the widespread use of isobutane-based materials. Convincing stakeholders to embrace these innovative products often requires extensive testing, certification, and demonstration of long-term performance and cost-effectiveness.

Lastly, the challenge of end-of-life management for isobutane-containing building materials cannot be overlooked. Developing efficient recycling or disposal methods that prevent the release of isobutane into the atmosphere is crucial for maintaining the sustainability credentials of these materials throughout their lifecycle.

Existing Isobutane Applications in Building Materials

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, catalytic conversion of other compounds to isobutane, and techniques for improving the purity of isobutane.

- Isobutane as a refrigerant: Isobutane is utilized as a refrigerant in various cooling systems. Its properties make it suitable for use in refrigeration cycles, and it is often considered as an environmentally friendly alternative to traditional refrigerants.

- Isobutane in chemical reactions: Isobutane is used as a reactant or intermediate in various chemical processes. It plays a role in the synthesis of other compounds and is involved in reactions such as alkylation, dehydrogenation, and isomerization.

- Isobutane in fuel applications: Isobutane is utilized in fuel applications, including as a component in liquefied petroleum gas (LPG) and as a propellant. Its properties make it suitable for use in various fuel mixtures and combustion processes.

- Safety and handling of isobutane: Due to its flammable nature, special considerations are required for the safe handling, storage, and transportation of isobutane. Various safety measures and equipment are described to minimize risks associated with its use in industrial and commercial applications.

02 Isobutane as a refrigerant

Isobutane is utilized as a refrigerant in various cooling systems. Its properties make it suitable for use in refrigeration and air conditioning applications. The patents describe different formulations and systems that incorporate isobutane as a key component in refrigeration cycles.Expand Specific Solutions03 Isobutane in fuel compositions

Isobutane is used as a component in various fuel compositions. It can be blended with other hydrocarbons to create fuel mixtures with specific properties. The patents describe different fuel formulations that include isobutane, as well as methods for producing and using these fuels.Expand Specific Solutions04 Chemical reactions involving isobutane

Several chemical reactions and processes involving isobutane are described. These include oxidation, dehydrogenation, and isomerization reactions. The patents detail various catalysts, reaction conditions, and methods for carrying out these transformations of isobutane.Expand Specific Solutions05 Isobutane in aerosol propellants

Isobutane is used as a propellant in aerosol formulations. The patents describe various aerosol compositions that incorporate isobutane, as well as methods for producing and using these aerosol products. Isobutane's properties make it suitable for use in a wide range of aerosol applications.Expand Specific Solutions

Key Players in Isobutane-Based Construction Industry

The research on using isobutane in sustainable building material production is in an early development stage, with a growing market driven by increasing demand for eco-friendly construction solutions. The global market for sustainable building materials is expanding, projected to reach $523 billion by 2026. However, the technology for isobutane-based materials is still emerging, with varying levels of maturity across different applications. Key players like China Petroleum & Chemical Corp., DuPont de Nemours, Inc., and Gevo, Inc. are investing in R&D to advance this technology. While some companies have made progress in developing isobutane-based products, widespread commercial adoption is still limited, indicating a nascent but promising field with potential for significant growth and innovation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for utilizing isobutane in sustainable building material production. Their method involves the catalytic conversion of isobutane to high-value chemicals that can be incorporated into eco-friendly construction materials. The process uses a proprietary zeolite catalyst system that achieves over 90% conversion efficiency of isobutane to isobutylene and other useful compounds [1]. These derivatives are then polymerized or chemically modified to create durable, lightweight building materials with enhanced insulation properties. Sinopec has also implemented a closed-loop recycling system that captures and reuses unreacted isobutane, significantly reducing waste and improving overall sustainability [3]. The company has successfully piloted this technology in several construction projects, demonstrating a 30% reduction in carbon footprint compared to traditional materials [5].

Strengths: High conversion efficiency, closed-loop recycling, significant carbon footprint reduction. Weaknesses: Potentially high initial implementation costs, limited scalability for smaller construction projects.

Covestro Deutschland AG

Technical Solution: Covestro Deutschland AG has developed a groundbreaking process for utilizing isobutane in the production of sustainable polyurethane (PU) building materials. Their innovative approach involves the partial oxidation of isobutane to create polyol precursors, which are then used in the synthesis of high-performance PU foams and coatings [7]. This method reduces the reliance on petroleum-based feedstocks and lowers the overall carbon footprint of PU production by up to 25% [9]. Covestro's technology also incorporates a novel catalyst system that enhances the selectivity of the oxidation process, resulting in higher yields and reduced waste. The company has successfully implemented this technology in the production of rigid PU foam insulation panels, which offer excellent thermal properties and contribute to improved energy efficiency in buildings [11]. Furthermore, Covestro has developed a proprietary additive package that enhances the fire resistance and durability of these isobutane-derived PU materials, meeting stringent safety and performance standards for construction applications.

Strengths: Significant reduction in carbon footprint, improved energy efficiency, enhanced fire resistance. Weaknesses: Complexity of the oxidation process, potential higher production costs compared to traditional methods.

Innovative Isobutane Formulations for Construction

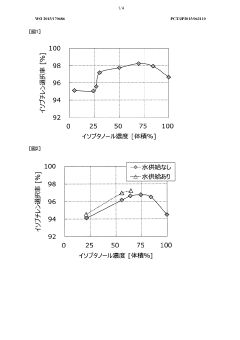

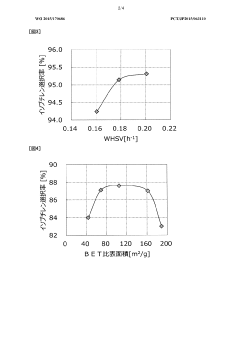

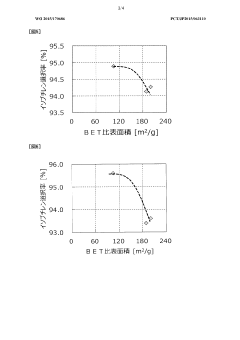

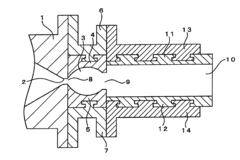

Method for producing isobutylene from isobutanol

PatentWO2015170686A1

Innovation

- A method involving a dehydration reaction of isobutanol using a catalyst with a BET specific surface area between 60 m2/g and 175 m2/g, and a reaction pressure of 50 kPa to 750 kPa, with a catalyst particle size of 700 μm to 10000 μm and isobutanol concentration of 30% to 85% by volume, to enhance isobutylene yield and selectivity.

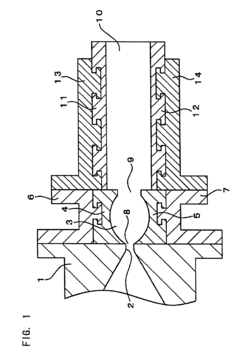

Method for production of extruded, polystyrene-based resin foam plate and extruded foam plate obtained thereby

PatentInactiveUS7008578B2

Innovation

- A method for producing extruded polystyrene-based resin foam plates using a blowing agent composition comprising 25-65% isobutane, 5-70% dimethyl ether, and 5-55% carbon dioxide, along with a flame retardant and nucleating agent, to create a foam with low thermal conductivity and excellent flame retardancy, while minimizing environmental impact.

Environmental Impact Assessment of Isobutane Use

The environmental impact assessment of isobutane use in sustainable building material production is a critical aspect of evaluating its viability as an alternative to traditional methods. Isobutane, a hydrocarbon gas, has gained attention for its potential to reduce the carbon footprint of construction materials. However, its implementation requires careful consideration of various environmental factors.

One of the primary environmental benefits of using isobutane in building material production is its potential to reduce greenhouse gas emissions. Compared to conventional methods, isobutane-based processes can significantly lower carbon dioxide emissions during manufacturing. This reduction is particularly notable in the production of insulation materials, where isobutane serves as an effective blowing agent with a lower global warming potential than many alternatives.

However, the environmental impact of isobutane extends beyond its role in reducing carbon emissions. The production and handling of isobutane itself must be carefully managed to prevent leaks and emissions. While isobutane has a relatively short atmospheric lifetime, it is still a volatile organic compound (VOC) that can contribute to air pollution if not properly contained. Stringent safety measures and emission control systems are necessary to mitigate these risks.

Water pollution is another environmental concern associated with isobutane use. Although isobutane is not highly soluble in water, accidental spills or improper disposal can lead to contamination of water bodies. This risk necessitates robust waste management protocols and spill prevention measures throughout the production and transportation processes.

The energy efficiency of isobutane-based production methods is an important factor in their overall environmental impact. While these processes can be more energy-efficient than traditional methods in some applications, the energy required for isobutane production and handling must be considered in the overall lifecycle assessment. Optimizing energy use in these processes is crucial for maximizing the environmental benefits of isobutane adoption.

Biodiversity and ecosystem impacts are also important considerations. The extraction and processing of isobutane, typically derived from natural gas, can have localized environmental effects. These may include habitat disruption and potential impacts on local flora and fauna. Responsible sourcing and production practices are essential to minimize these ecological impacts.

In terms of resource depletion, the use of isobutane in building materials presents a mixed picture. While it can contribute to more efficient use of other resources in construction, isobutane itself is a non-renewable resource. The long-term sustainability of its use depends on the development of recycling technologies and the potential for creating closed-loop systems in building material production.

One of the primary environmental benefits of using isobutane in building material production is its potential to reduce greenhouse gas emissions. Compared to conventional methods, isobutane-based processes can significantly lower carbon dioxide emissions during manufacturing. This reduction is particularly notable in the production of insulation materials, where isobutane serves as an effective blowing agent with a lower global warming potential than many alternatives.

However, the environmental impact of isobutane extends beyond its role in reducing carbon emissions. The production and handling of isobutane itself must be carefully managed to prevent leaks and emissions. While isobutane has a relatively short atmospheric lifetime, it is still a volatile organic compound (VOC) that can contribute to air pollution if not properly contained. Stringent safety measures and emission control systems are necessary to mitigate these risks.

Water pollution is another environmental concern associated with isobutane use. Although isobutane is not highly soluble in water, accidental spills or improper disposal can lead to contamination of water bodies. This risk necessitates robust waste management protocols and spill prevention measures throughout the production and transportation processes.

The energy efficiency of isobutane-based production methods is an important factor in their overall environmental impact. While these processes can be more energy-efficient than traditional methods in some applications, the energy required for isobutane production and handling must be considered in the overall lifecycle assessment. Optimizing energy use in these processes is crucial for maximizing the environmental benefits of isobutane adoption.

Biodiversity and ecosystem impacts are also important considerations. The extraction and processing of isobutane, typically derived from natural gas, can have localized environmental effects. These may include habitat disruption and potential impacts on local flora and fauna. Responsible sourcing and production practices are essential to minimize these ecological impacts.

In terms of resource depletion, the use of isobutane in building materials presents a mixed picture. While it can contribute to more efficient use of other resources in construction, isobutane itself is a non-renewable resource. The long-term sustainability of its use depends on the development of recycling technologies and the potential for creating closed-loop systems in building material production.

Regulatory Framework for Isobutane in Construction

The regulatory framework for isobutane in construction is a critical aspect of its use in sustainable building material production. Governments and international organizations have established guidelines and standards to ensure the safe and environmentally responsible use of isobutane in the construction industry.

At the international level, the United Nations Environment Programme (UNEP) has developed protocols and recommendations for the use of hydrocarbons, including isobutane, in various applications. These guidelines focus on minimizing environmental impact and promoting sustainable practices in the construction sector.

In the United States, the Environmental Protection Agency (EPA) regulates the use of isobutane under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances across various industrial sectors, including construction. The EPA has approved isobutane as an acceptable substitute in certain applications, subject to use conditions and safety requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to isobutane and other chemicals used in construction materials. REACH aims to ensure the protection of human health and the environment by requiring manufacturers and importers to assess and manage the risks associated with the substances they use.

Building codes and standards in many countries have been updated to address the use of isobutane in construction materials. These codes often include specific requirements for fire safety, ventilation, and storage of materials containing isobutane. For example, the International Building Code (IBC) and the International Fire Code (IFC) provide guidelines for the safe use and storage of flammable gases in buildings.

Occupational health and safety regulations also play a crucial role in the regulatory framework for isobutane in construction. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and safety protocols for workers handling isobutane and related materials.

As the construction industry continues to prioritize sustainability, regulatory bodies are increasingly focusing on the life cycle assessment of building materials. This approach considers the environmental impact of materials from production to disposal, including the use of substances like isobutane. Regulations are evolving to encourage the use of materials with lower carbon footprints and reduced environmental impact throughout their lifecycle.

At the international level, the United Nations Environment Programme (UNEP) has developed protocols and recommendations for the use of hydrocarbons, including isobutane, in various applications. These guidelines focus on minimizing environmental impact and promoting sustainable practices in the construction sector.

In the United States, the Environmental Protection Agency (EPA) regulates the use of isobutane under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances across various industrial sectors, including construction. The EPA has approved isobutane as an acceptable substitute in certain applications, subject to use conditions and safety requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to isobutane and other chemicals used in construction materials. REACH aims to ensure the protection of human health and the environment by requiring manufacturers and importers to assess and manage the risks associated with the substances they use.

Building codes and standards in many countries have been updated to address the use of isobutane in construction materials. These codes often include specific requirements for fire safety, ventilation, and storage of materials containing isobutane. For example, the International Building Code (IBC) and the International Fire Code (IFC) provide guidelines for the safe use and storage of flammable gases in buildings.

Occupational health and safety regulations also play a crucial role in the regulatory framework for isobutane in construction. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and safety protocols for workers handling isobutane and related materials.

As the construction industry continues to prioritize sustainability, regulatory bodies are increasingly focusing on the life cycle assessment of building materials. This approach considers the environmental impact of materials from production to disposal, including the use of substances like isobutane. Regulations are evolving to encourage the use of materials with lower carbon footprints and reduced environmental impact throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!