Bio-Conversion of Isobutane for Renewable Chemical Applications

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Bioconversion Background and Objectives

The bioconversion of isobutane represents a promising frontier in the pursuit of sustainable chemical production. This technology leverages microbial metabolism to transform isobutane, a hydrocarbon typically derived from fossil fuels, into valuable chemical products. The development of this bioconversion process aligns with the growing global emphasis on renewable resources and circular economy principles.

Historically, isobutane has been primarily utilized in the petrochemical industry as a feedstock for various chemical processes. However, the increasing environmental concerns and the need for sustainable alternatives have driven research into biological conversion methods. The evolution of this technology can be traced back to early studies on hydrocarbon-degrading microorganisms in the 1970s, which laid the groundwork for current bioconversion strategies.

The primary objective of isobutane bioconversion research is to establish efficient and economically viable processes for converting this abundant hydrocarbon into high-value chemicals. This includes the production of biofuels, bioplastics, and other industrially relevant compounds. By harnessing the power of microbial metabolism, researchers aim to develop environmentally friendly alternatives to traditional chemical synthesis routes.

One of the key technological goals is to identify and engineer robust microbial strains capable of efficiently metabolizing isobutane. This involves understanding the biochemical pathways involved in isobutane assimilation and optimizing these pathways for enhanced productivity. Additionally, researchers are focused on developing bioreactor designs and process conditions that maximize conversion rates and product yields.

The potential impact of successful isobutane bioconversion extends beyond environmental benefits. It offers the possibility of diversifying feedstock sources for the chemical industry, reducing dependence on fossil fuels, and creating new value chains in the bioeconomy. Furthermore, this technology could enable the utilization of isobutane from natural gas streams, which is often flared or vented, thereby reducing greenhouse gas emissions.

As the field progresses, interdisciplinary collaboration between microbiologists, biochemists, and chemical engineers is crucial. The integration of advanced genomics, metabolic engineering, and process optimization techniques is expected to drive significant advancements in isobutane bioconversion technology. The ultimate aim is to develop scalable and cost-effective processes that can compete with traditional petrochemical routes, paving the way for a more sustainable chemical industry.

Historically, isobutane has been primarily utilized in the petrochemical industry as a feedstock for various chemical processes. However, the increasing environmental concerns and the need for sustainable alternatives have driven research into biological conversion methods. The evolution of this technology can be traced back to early studies on hydrocarbon-degrading microorganisms in the 1970s, which laid the groundwork for current bioconversion strategies.

The primary objective of isobutane bioconversion research is to establish efficient and economically viable processes for converting this abundant hydrocarbon into high-value chemicals. This includes the production of biofuels, bioplastics, and other industrially relevant compounds. By harnessing the power of microbial metabolism, researchers aim to develop environmentally friendly alternatives to traditional chemical synthesis routes.

One of the key technological goals is to identify and engineer robust microbial strains capable of efficiently metabolizing isobutane. This involves understanding the biochemical pathways involved in isobutane assimilation and optimizing these pathways for enhanced productivity. Additionally, researchers are focused on developing bioreactor designs and process conditions that maximize conversion rates and product yields.

The potential impact of successful isobutane bioconversion extends beyond environmental benefits. It offers the possibility of diversifying feedstock sources for the chemical industry, reducing dependence on fossil fuels, and creating new value chains in the bioeconomy. Furthermore, this technology could enable the utilization of isobutane from natural gas streams, which is often flared or vented, thereby reducing greenhouse gas emissions.

As the field progresses, interdisciplinary collaboration between microbiologists, biochemists, and chemical engineers is crucial. The integration of advanced genomics, metabolic engineering, and process optimization techniques is expected to drive significant advancements in isobutane bioconversion technology. The ultimate aim is to develop scalable and cost-effective processes that can compete with traditional petrochemical routes, paving the way for a more sustainable chemical industry.

Market Analysis for Bio-Based Chemicals

The market for bio-based chemicals has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to petroleum-based products. The global bio-based chemicals market was valued at approximately $85 billion in 2020 and is projected to reach $160 billion by 2025, growing at a CAGR of around 13% during the forecast period.

The bio-conversion of isobutane for renewable chemical applications represents a promising segment within this market. Isobutane, traditionally derived from fossil fuels, is a key feedstock for various chemical processes. The development of bio-based alternatives has gained traction due to the potential for reduced carbon footprint and enhanced sustainability.

Key market drivers for bio-based chemicals, including those derived from isobutane, include stringent environmental regulations, growing consumer awareness, and the need for energy security. Government initiatives and policies promoting the use of renewable resources have further bolstered market growth. For instance, the European Union's Renewable Energy Directive (RED II) sets targets for renewable energy use in transportation, creating opportunities for bio-based chemicals.

The automotive and packaging industries are among the largest end-users of bio-based chemicals. The automotive sector, in particular, has shown increasing interest in bio-based materials for lightweight components and sustainable fuel additives. The packaging industry is adopting bio-based plastics and coatings to meet consumer demands for eco-friendly products.

Challenges in the market include high production costs compared to conventional petrochemicals and the need for technological advancements to improve efficiency and scalability. However, ongoing research and development efforts are addressing these issues, with several companies investing in innovative production methods.

Regionally, North America and Europe lead the bio-based chemicals market, with Asia-Pacific showing the fastest growth. The United States, in particular, has seen significant investments in bio-refineries and research facilities focused on renewable chemical production.

The bio-conversion of isobutane aligns well with the broader trend towards circular economy principles in the chemical industry. As companies seek to reduce their environmental impact and meet sustainability goals, the demand for bio-based alternatives to traditional petrochemicals is expected to continue its upward trajectory.

The bio-conversion of isobutane for renewable chemical applications represents a promising segment within this market. Isobutane, traditionally derived from fossil fuels, is a key feedstock for various chemical processes. The development of bio-based alternatives has gained traction due to the potential for reduced carbon footprint and enhanced sustainability.

Key market drivers for bio-based chemicals, including those derived from isobutane, include stringent environmental regulations, growing consumer awareness, and the need for energy security. Government initiatives and policies promoting the use of renewable resources have further bolstered market growth. For instance, the European Union's Renewable Energy Directive (RED II) sets targets for renewable energy use in transportation, creating opportunities for bio-based chemicals.

The automotive and packaging industries are among the largest end-users of bio-based chemicals. The automotive sector, in particular, has shown increasing interest in bio-based materials for lightweight components and sustainable fuel additives. The packaging industry is adopting bio-based plastics and coatings to meet consumer demands for eco-friendly products.

Challenges in the market include high production costs compared to conventional petrochemicals and the need for technological advancements to improve efficiency and scalability. However, ongoing research and development efforts are addressing these issues, with several companies investing in innovative production methods.

Regionally, North America and Europe lead the bio-based chemicals market, with Asia-Pacific showing the fastest growth. The United States, in particular, has seen significant investments in bio-refineries and research facilities focused on renewable chemical production.

The bio-conversion of isobutane aligns well with the broader trend towards circular economy principles in the chemical industry. As companies seek to reduce their environmental impact and meet sustainability goals, the demand for bio-based alternatives to traditional petrochemicals is expected to continue its upward trajectory.

Current Challenges in Isobutane Bioconversion

The bioconversion of isobutane presents several significant challenges that hinder its widespread adoption for renewable chemical applications. One of the primary obstacles is the low solubility of isobutane in aqueous media, which limits its bioavailability to microorganisms. This poor solubility necessitates the development of advanced bioreactor designs and mass transfer strategies to enhance the contact between the gaseous substrate and the microbial cells.

Another major challenge is the limited number of known microorganisms capable of efficiently metabolizing isobutane. The isolation and characterization of novel isobutane-utilizing bacteria or the genetic engineering of existing strains to improve their isobutane conversion capabilities remain ongoing research priorities. Additionally, the enzymes involved in isobutane metabolism, particularly the monooxygenases responsible for the initial oxidation step, often exhibit low specificity and activity towards isobutane, leading to suboptimal conversion rates.

The formation of toxic intermediates during isobutane bioconversion poses another significant hurdle. Some metabolic pathways can produce compounds that inhibit microbial growth or enzyme activity, necessitating the development of robust strains or process strategies to mitigate these effects. Furthermore, the energetics of isobutane metabolism present challenges, as the initial activation of the molecule requires a considerable input of energy, which can limit overall process efficiency.

Scale-up and process integration issues also persist in isobutane bioconversion. Maintaining optimal conditions for microbial growth and activity while efficiently supplying and mixing gaseous isobutane in large-scale bioreactors remains technically challenging. The recovery and purification of desired products from the fermentation broth, especially when dealing with volatile compounds, adds another layer of complexity to the process design.

Lastly, the economic viability of isobutane bioconversion processes is a significant concern. The current low price of petroleum-derived isobutane and its derivatives makes it difficult for bio-based alternatives to compete in the market. Overcoming this economic barrier requires substantial improvements in conversion efficiency, product yield, and downstream processing to reduce overall production costs. Additionally, the development of high-value products from isobutane bioconversion could potentially improve the economic outlook of these processes.

Another major challenge is the limited number of known microorganisms capable of efficiently metabolizing isobutane. The isolation and characterization of novel isobutane-utilizing bacteria or the genetic engineering of existing strains to improve their isobutane conversion capabilities remain ongoing research priorities. Additionally, the enzymes involved in isobutane metabolism, particularly the monooxygenases responsible for the initial oxidation step, often exhibit low specificity and activity towards isobutane, leading to suboptimal conversion rates.

The formation of toxic intermediates during isobutane bioconversion poses another significant hurdle. Some metabolic pathways can produce compounds that inhibit microbial growth or enzyme activity, necessitating the development of robust strains or process strategies to mitigate these effects. Furthermore, the energetics of isobutane metabolism present challenges, as the initial activation of the molecule requires a considerable input of energy, which can limit overall process efficiency.

Scale-up and process integration issues also persist in isobutane bioconversion. Maintaining optimal conditions for microbial growth and activity while efficiently supplying and mixing gaseous isobutane in large-scale bioreactors remains technically challenging. The recovery and purification of desired products from the fermentation broth, especially when dealing with volatile compounds, adds another layer of complexity to the process design.

Lastly, the economic viability of isobutane bioconversion processes is a significant concern. The current low price of petroleum-derived isobutane and its derivatives makes it difficult for bio-based alternatives to compete in the market. Overcoming this economic barrier requires substantial improvements in conversion efficiency, product yield, and downstream processing to reduce overall production costs. Additionally, the development of high-value products from isobutane bioconversion could potentially improve the economic outlook of these processes.

Existing Isobutane Bioconversion Methods

01 Microbial conversion of isobutane

Microorganisms can be used to convert isobutane into valuable products through bioconversion processes. This approach utilizes the metabolic capabilities of specific microbes to transform isobutane into various compounds, offering a potentially more environmentally friendly and efficient method compared to traditional chemical processes.- Microbial conversion of isobutane: Microorganisms can be used to convert isobutane into valuable products through bioconversion processes. This approach utilizes the metabolic capabilities of specific microbes to transform isobutane into various compounds, offering a potentially more environmentally friendly and efficient method compared to traditional chemical processes.

- Catalytic conversion of isobutane: Catalytic processes can be employed to convert isobutane into other hydrocarbons or value-added products. These methods often involve the use of specific catalysts and reaction conditions to facilitate the transformation of isobutane, potentially improving yield and selectivity compared to non-catalytic approaches.

- Isobutane dehydrogenation: Dehydrogenation of isobutane is a key process for producing isobutene, an important industrial chemical. This conversion involves the removal of hydrogen from isobutane molecules, often using catalysts and specific reaction conditions to optimize the yield and selectivity of the desired product.

- Isobutane isomerization: Isomerization processes can be used to convert isobutane into other isomers or related compounds. These methods typically involve rearranging the molecular structure of isobutane, often with the aid of catalysts, to produce desired products or improve the properties of the resulting mixture.

- Isobutane oxidation: Oxidation of isobutane can be used to produce various oxygenated compounds, such as alcohols, aldehydes, or acids. This process involves the controlled addition of oxygen to isobutane molecules, often using catalysts or specific reaction conditions to achieve the desired product distribution and selectivity.

02 Catalytic conversion of isobutane

Catalytic processes can be employed to convert isobutane into other hydrocarbons or value-added products. These methods often involve the use of specific catalysts and reaction conditions to facilitate the transformation of isobutane, potentially improving yield and selectivity compared to non-catalytic approaches.Expand Specific Solutions03 Isobutane dehydrogenation

Dehydrogenation of isobutane is a key process for producing isobutene, an important industrial chemical. This conversion involves the removal of hydrogen from isobutane molecules, typically using catalysts and specific reaction conditions to optimize the yield and selectivity of the desired product.Expand Specific Solutions04 Isobutane isomerization

Isomerization processes can be used to convert isobutane into other isomers or related compounds. These methods often involve rearranging the molecular structure of isobutane to produce different hydrocarbon products, which may have various industrial applications.Expand Specific Solutions05 Isobutane oxidation

Oxidation of isobutane can lead to the production of various oxygenated compounds, such as alcohols, aldehydes, or acids. This process involves the controlled addition of oxygen to isobutane molecules, often using catalysts or specific reaction conditions to achieve desired product selectivity.Expand Specific Solutions

Key Players in Bioconversion Industry

The bio-conversion of isobutane for renewable chemical applications is an emerging field in the early stages of development, with a growing market potential driven by the increasing demand for sustainable chemical production. The technology's maturity is still evolving, with several key players making significant strides. Companies like Gevo, Inc. and Genomatica, Inc. are at the forefront, developing proprietary biocatalysts and processes for isobutanol production. Established petrochemical giants such as China Petroleum & Chemical Corp. and BASF Corp. are also investing in this area, leveraging their extensive resources and industry expertise. Academic institutions like Tianjin University and the University of California are contributing to fundamental research, while specialized biotechnology firms like Global Bioenergies SA are focusing on innovative fermentation processes for hydrocarbon production from renewable resources.

Gevo, Inc.

Technical Solution: Gevo has developed a proprietary fermentation technology for the bio-conversion of isobutanol, which can be further converted to isobutane. Their process utilizes renewable feedstocks like corn and biomass to produce isobutanol through engineered yeast strains. The company has successfully scaled up their technology to commercial production levels, with a capacity of up to 1 million gallons per year at their demonstration plant[1]. Gevo's approach involves integrating their isobutanol production into existing ethanol facilities, allowing for cost-effective retrofitting and production[2]. The produced isobutanol can be further dehydrated to isobutene, which can then be hydrogenated to isobutane for various chemical applications.

Strengths: Renewable feedstock utilization, integration with existing infrastructure, and proven commercial-scale production. Weaknesses: Dependence on agricultural feedstocks and potential competition from petrochemical-derived isobutane.

Genomatica, Inc.

Technical Solution: Genomatica has developed a bio-based process for producing isobutanol, which can be converted to isobutane. Their approach utilizes metabolic engineering and synthetic biology to create microorganisms capable of efficiently converting sugars into isobutanol. The company's GENO BDO™ process, while primarily focused on 1,4-butanediol production, demonstrates their expertise in bio-based chemical production[3]. Genomatica's technology platform allows for the development of customized microorganisms optimized for specific feedstocks and products, potentially including isobutane precursors. They have successfully scaled their bio-based processes to commercial levels, with a reported annual capacity of 30,000 tons for their GENO BDO™ process[4]. This expertise could be leveraged for isobutane production from renewable sources.

Strengths: Advanced metabolic engineering capabilities, proven scale-up experience, and flexibility in feedstock utilization. Weaknesses: Primary focus on other bio-based chemicals may limit resources for isobutane-specific development.

Innovative Enzyme Engineering Approaches

Fermentive production of four carbon alcohols

PatentActiveUS20110313206A1

Innovation

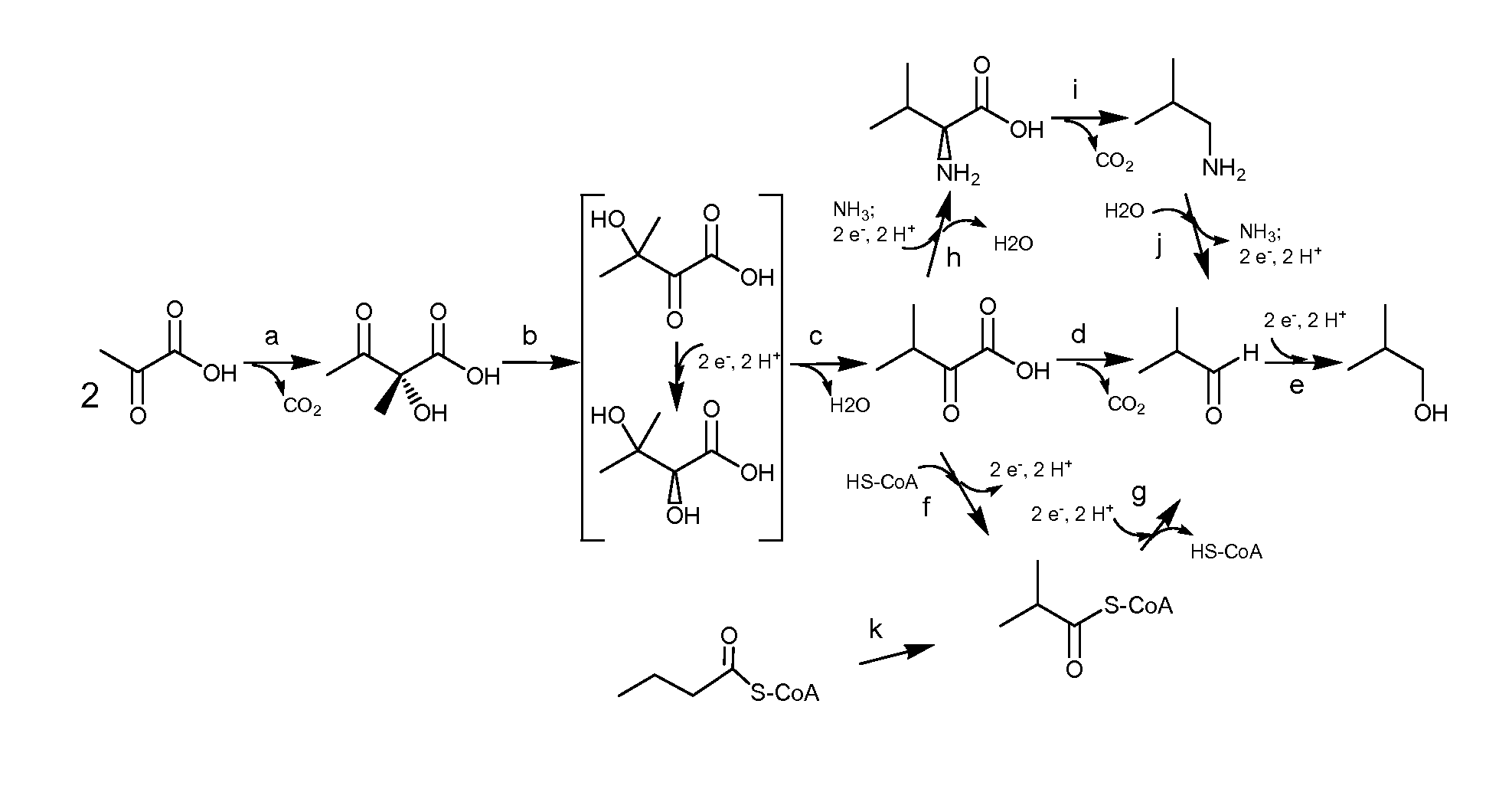

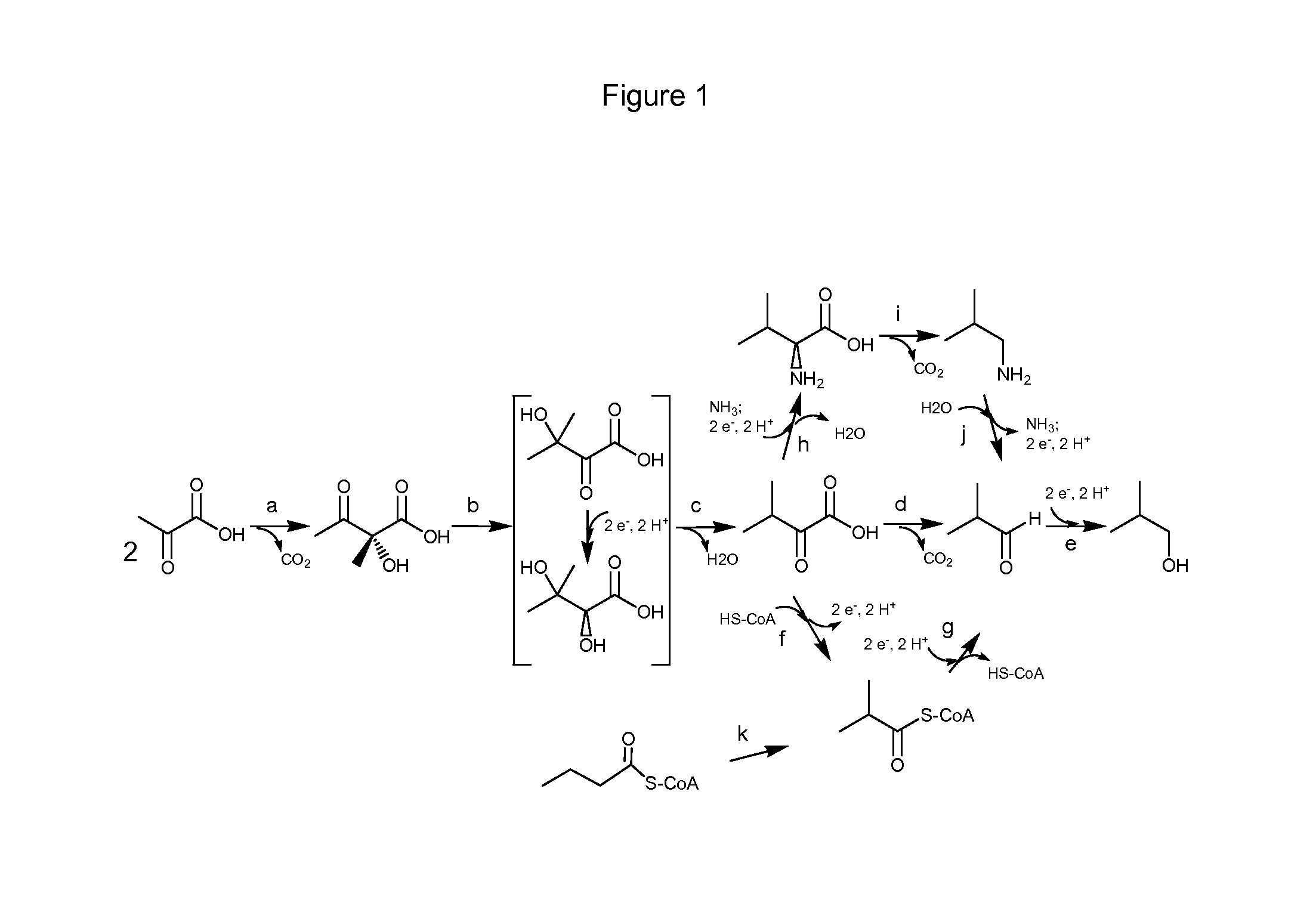

- A recombinant microbial production host with an engineered isobutanol biosynthetic pathway is used, involving specific substrate to product conversions, including pyruvate to isobutanol, utilizing a recombinant microorganism with gene inactivation in competing pathways, and employing enzymes such as acetolactate synthase, acetohydroxy acid isomeroreductase, and branched-chain α-keto acid decarboxylase, to produce isobutanol from plant-derived carbon sources.

Engineered yeast for production of renewable chemicals

PatentWO2013173412A2

Innovation

- Engineering recombinant yeast microorganisms to overexpress or mutate the MAC1 transcriptional activator gene and its regulated proteins to enhance the activity of iron-sulfur cluster containing proteins, specifically DHAD, by increasing expression and activity levels, and optimizing protein localization and regulation.

Environmental Impact Assessment

The bio-conversion of isobutane for renewable chemical applications presents both opportunities and challenges from an environmental perspective. This process, which utilizes microbial systems to convert isobutane into value-added chemicals, has the potential to significantly reduce the carbon footprint associated with traditional petrochemical production methods.

One of the primary environmental benefits of this bio-conversion process is the reduction in greenhouse gas emissions. By utilizing renewable feedstocks and biological processes, the production of chemicals through isobutane bio-conversion can potentially decrease reliance on fossil fuel-derived resources. This shift could lead to a substantial reduction in carbon dioxide emissions associated with chemical manufacturing.

Furthermore, the bio-conversion process often operates under milder conditions compared to conventional chemical synthesis methods. This typically results in lower energy requirements and reduced waste generation. The use of ambient temperatures and pressures in many bio-conversion processes contributes to improved energy efficiency and decreased environmental impact.

However, it is crucial to consider the potential environmental risks associated with large-scale implementation of isobutane bio-conversion. The release of genetically modified organisms (GMOs) used in the bio-conversion process could pose ecological risks if not properly contained. Stringent biosafety measures and risk assessment protocols must be implemented to prevent unintended environmental consequences.

Water usage and wastewater management are additional environmental factors to consider. While bio-conversion processes generally require less water than traditional chemical synthesis methods, the treatment and disposal of wastewater containing biological materials and residual chemicals must be carefully managed to prevent water pollution and ecosystem disruption.

The sourcing of feedstocks for isobutane bio-conversion also warrants environmental scrutiny. If agricultural resources are diverted for this purpose, it could potentially lead to land-use changes and competition with food production. Sustainable sourcing practices and the use of waste materials as feedstocks should be prioritized to mitigate these concerns.

Life cycle assessment (LCA) studies are essential to comprehensively evaluate the environmental impact of isobutane bio-conversion technologies. These assessments should consider all stages of the process, from feedstock production to end-of-life disposal of the resulting chemicals. LCA results can guide the optimization of the bio-conversion process to minimize its overall environmental footprint.

In conclusion, while the bio-conversion of isobutane for renewable chemical applications offers promising environmental benefits, particularly in terms of reduced greenhouse gas emissions and energy consumption, careful consideration must be given to potential ecological risks, resource management, and sustainable practices throughout the entire production chain.

One of the primary environmental benefits of this bio-conversion process is the reduction in greenhouse gas emissions. By utilizing renewable feedstocks and biological processes, the production of chemicals through isobutane bio-conversion can potentially decrease reliance on fossil fuel-derived resources. This shift could lead to a substantial reduction in carbon dioxide emissions associated with chemical manufacturing.

Furthermore, the bio-conversion process often operates under milder conditions compared to conventional chemical synthesis methods. This typically results in lower energy requirements and reduced waste generation. The use of ambient temperatures and pressures in many bio-conversion processes contributes to improved energy efficiency and decreased environmental impact.

However, it is crucial to consider the potential environmental risks associated with large-scale implementation of isobutane bio-conversion. The release of genetically modified organisms (GMOs) used in the bio-conversion process could pose ecological risks if not properly contained. Stringent biosafety measures and risk assessment protocols must be implemented to prevent unintended environmental consequences.

Water usage and wastewater management are additional environmental factors to consider. While bio-conversion processes generally require less water than traditional chemical synthesis methods, the treatment and disposal of wastewater containing biological materials and residual chemicals must be carefully managed to prevent water pollution and ecosystem disruption.

The sourcing of feedstocks for isobutane bio-conversion also warrants environmental scrutiny. If agricultural resources are diverted for this purpose, it could potentially lead to land-use changes and competition with food production. Sustainable sourcing practices and the use of waste materials as feedstocks should be prioritized to mitigate these concerns.

Life cycle assessment (LCA) studies are essential to comprehensively evaluate the environmental impact of isobutane bio-conversion technologies. These assessments should consider all stages of the process, from feedstock production to end-of-life disposal of the resulting chemicals. LCA results can guide the optimization of the bio-conversion process to minimize its overall environmental footprint.

In conclusion, while the bio-conversion of isobutane for renewable chemical applications offers promising environmental benefits, particularly in terms of reduced greenhouse gas emissions and energy consumption, careful consideration must be given to potential ecological risks, resource management, and sustainable practices throughout the entire production chain.

Regulatory Framework for Bio-Based Chemicals

The regulatory framework for bio-based chemicals plays a crucial role in shaping the development and adoption of innovative technologies such as the bio-conversion of isobutane for renewable chemical applications. This framework encompasses a complex web of regulations, standards, and policies that govern the production, distribution, and use of bio-based chemicals across various jurisdictions.

At the international level, organizations like the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) provide guidelines and recommendations for the sustainable management of chemicals. These frameworks often emphasize the importance of life cycle assessments and risk evaluations for new bio-based products.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of bio-based chemicals under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including those derived from bio-conversion processes. Additionally, the U.S. Department of Agriculture's BioPreferred program promotes the purchase and use of bio-based products through federal procurement preferences and voluntary labeling.

The European Union has implemented the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, which applies to both traditional and bio-based chemicals. REACH mandates that companies register chemical substances and provide safety data, ensuring a high level of protection for human health and the environment. The EU has also established specific regulations for bio-based products, such as the Renewable Energy Directive (RED II), which sets targets for renewable energy use in transportation.

Many countries have introduced their own regulatory frameworks to support the development of bio-based chemicals. For instance, Brazil has implemented policies to promote the use of bio-based materials in its chemical industry, leveraging its abundant biomass resources. Similarly, China has incorporated bio-based chemical production into its national strategic plans, aiming to reduce dependence on fossil fuels and promote sustainable development.

As the field of bio-conversion technologies advances, regulatory frameworks are evolving to address new challenges and opportunities. Key areas of focus include the development of standardized testing methods for bio-based content, the establishment of clear labeling requirements, and the harmonization of regulations across different regions to facilitate international trade in bio-based chemicals.

At the international level, organizations like the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) provide guidelines and recommendations for the sustainable management of chemicals. These frameworks often emphasize the importance of life cycle assessments and risk evaluations for new bio-based products.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of bio-based chemicals under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including those derived from bio-conversion processes. Additionally, the U.S. Department of Agriculture's BioPreferred program promotes the purchase and use of bio-based products through federal procurement preferences and voluntary labeling.

The European Union has implemented the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, which applies to both traditional and bio-based chemicals. REACH mandates that companies register chemical substances and provide safety data, ensuring a high level of protection for human health and the environment. The EU has also established specific regulations for bio-based products, such as the Renewable Energy Directive (RED II), which sets targets for renewable energy use in transportation.

Many countries have introduced their own regulatory frameworks to support the development of bio-based chemicals. For instance, Brazil has implemented policies to promote the use of bio-based materials in its chemical industry, leveraging its abundant biomass resources. Similarly, China has incorporated bio-based chemical production into its national strategic plans, aiming to reduce dependence on fossil fuels and promote sustainable development.

As the field of bio-conversion technologies advances, regulatory frameworks are evolving to address new challenges and opportunities. Key areas of focus include the development of standardized testing methods for bio-based content, the establishment of clear labeling requirements, and the harmonization of regulations across different regions to facilitate international trade in bio-based chemicals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!