How Isobutane Contributes to Biofuel Development

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane in Biofuels: Background and Objectives

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has emerged as a significant player in the development of biofuels. The journey of isobutane in the biofuel industry began in the early 2000s when researchers started exploring alternative fuel sources to mitigate the environmental impact of fossil fuels. As the global demand for sustainable energy solutions continues to grow, isobutane has gained attention for its potential to enhance biofuel production and performance.

The primary objective of incorporating isobutane into biofuel development is to improve the overall efficiency and quality of renewable fuels. Researchers aim to leverage isobutane's unique properties, such as its high energy density and low boiling point, to create biofuels that can compete with traditional petroleum-based products in terms of performance and cost-effectiveness.

One of the key goals in this field is to develop isobutane-based biofuels that can be seamlessly integrated into existing infrastructure without requiring significant modifications to engines or fuel distribution systems. This compatibility is crucial for widespread adoption and market acceptance of new biofuel technologies.

Another important objective is to optimize the production processes of isobutane-derived biofuels. Scientists are exploring various pathways, including biochemical and thermochemical conversion methods, to efficiently transform biomass into isobutane or its precursors. These efforts aim to increase yield, reduce production costs, and minimize environmental impact throughout the biofuel lifecycle.

The evolution of isobutane in biofuel technology has been marked by several significant milestones. Early research focused on understanding the fundamental chemistry of isobutane and its potential applications in fuel blending. As technology progressed, scientists developed novel catalysts and fermentation techniques to produce isobutane from renewable sources, paving the way for more sustainable production methods.

Recent advancements have led to the creation of isobutane-enriched biofuels that demonstrate improved combustion characteristics and reduced emissions compared to conventional biofuels. These developments have sparked interest from both the scientific community and industry stakeholders, driving further research and investment in this promising field.

Looking ahead, the future of isobutane in biofuel development appears promising. Researchers are exploring innovative approaches to enhance isobutane production from diverse biomass feedstocks, including agricultural waste and algae. Additionally, efforts are underway to integrate isobutane-based biofuels into next-generation engine designs, potentially revolutionizing the transportation sector's approach to sustainable fuel solutions.

The primary objective of incorporating isobutane into biofuel development is to improve the overall efficiency and quality of renewable fuels. Researchers aim to leverage isobutane's unique properties, such as its high energy density and low boiling point, to create biofuels that can compete with traditional petroleum-based products in terms of performance and cost-effectiveness.

One of the key goals in this field is to develop isobutane-based biofuels that can be seamlessly integrated into existing infrastructure without requiring significant modifications to engines or fuel distribution systems. This compatibility is crucial for widespread adoption and market acceptance of new biofuel technologies.

Another important objective is to optimize the production processes of isobutane-derived biofuels. Scientists are exploring various pathways, including biochemical and thermochemical conversion methods, to efficiently transform biomass into isobutane or its precursors. These efforts aim to increase yield, reduce production costs, and minimize environmental impact throughout the biofuel lifecycle.

The evolution of isobutane in biofuel technology has been marked by several significant milestones. Early research focused on understanding the fundamental chemistry of isobutane and its potential applications in fuel blending. As technology progressed, scientists developed novel catalysts and fermentation techniques to produce isobutane from renewable sources, paving the way for more sustainable production methods.

Recent advancements have led to the creation of isobutane-enriched biofuels that demonstrate improved combustion characteristics and reduced emissions compared to conventional biofuels. These developments have sparked interest from both the scientific community and industry stakeholders, driving further research and investment in this promising field.

Looking ahead, the future of isobutane in biofuel development appears promising. Researchers are exploring innovative approaches to enhance isobutane production from diverse biomass feedstocks, including agricultural waste and algae. Additionally, efforts are underway to integrate isobutane-based biofuels into next-generation engine designs, potentially revolutionizing the transportation sector's approach to sustainable fuel solutions.

Market Analysis for Isobutane-Based Biofuels

The market for isobutane-based biofuels is experiencing significant growth and transformation, driven by increasing environmental concerns and the push for sustainable energy solutions. As governments worldwide implement stricter emissions regulations, the demand for cleaner-burning fuels has surged, positioning isobutane-based biofuels as a promising alternative to traditional fossil fuels.

The global biofuels market has been expanding rapidly, with a compound annual growth rate (CAGR) exceeding 5% in recent years. Within this broader context, isobutane-based biofuels are carving out a niche due to their superior energy density and compatibility with existing infrastructure. This segment is expected to grow at an even faster rate, potentially reaching double-digit CAGR over the next five years.

Key market drivers include the automotive industry's shift towards more fuel-efficient and environmentally friendly vehicles, as well as the aviation sector's search for sustainable jet fuel alternatives. The marine industry is also showing increased interest in isobutane-based biofuels as a means to comply with new international maritime emission standards.

Geographically, North America and Europe are currently the largest markets for isobutane-based biofuels, owing to their stringent environmental regulations and well-developed biofuel production infrastructure. However, Asia-Pacific is emerging as the fastest-growing region, with countries like China and India investing heavily in biofuel technology and production capacity.

Market challenges include the volatility of feedstock prices, which can significantly impact production costs and market competitiveness. Additionally, the need for specialized handling and storage infrastructure due to isobutane's flammability presents both a barrier to entry and an opportunity for companies with expertise in this area.

Consumer acceptance and awareness remain critical factors in market growth. As more consumers become environmentally conscious, the demand for green transportation options is rising. This trend is particularly pronounced among younger demographics, who are more likely to prioritize sustainability in their purchasing decisions.

The competitive landscape is characterized by a mix of established energy companies diversifying into biofuels and innovative startups focusing exclusively on isobutane-based solutions. Strategic partnerships between fuel producers, automotive manufacturers, and technology providers are becoming increasingly common, driving innovation and market expansion.

Looking ahead, the market for isobutane-based biofuels is poised for substantial growth. Technological advancements in production processes are expected to improve efficiency and reduce costs, making these fuels more competitive with traditional options. As governments continue to incentivize the adoption of renewable energy sources, the market is likely to see increased investment and accelerated commercialization of isobutane-based biofuel technologies.

The global biofuels market has been expanding rapidly, with a compound annual growth rate (CAGR) exceeding 5% in recent years. Within this broader context, isobutane-based biofuels are carving out a niche due to their superior energy density and compatibility with existing infrastructure. This segment is expected to grow at an even faster rate, potentially reaching double-digit CAGR over the next five years.

Key market drivers include the automotive industry's shift towards more fuel-efficient and environmentally friendly vehicles, as well as the aviation sector's search for sustainable jet fuel alternatives. The marine industry is also showing increased interest in isobutane-based biofuels as a means to comply with new international maritime emission standards.

Geographically, North America and Europe are currently the largest markets for isobutane-based biofuels, owing to their stringent environmental regulations and well-developed biofuel production infrastructure. However, Asia-Pacific is emerging as the fastest-growing region, with countries like China and India investing heavily in biofuel technology and production capacity.

Market challenges include the volatility of feedstock prices, which can significantly impact production costs and market competitiveness. Additionally, the need for specialized handling and storage infrastructure due to isobutane's flammability presents both a barrier to entry and an opportunity for companies with expertise in this area.

Consumer acceptance and awareness remain critical factors in market growth. As more consumers become environmentally conscious, the demand for green transportation options is rising. This trend is particularly pronounced among younger demographics, who are more likely to prioritize sustainability in their purchasing decisions.

The competitive landscape is characterized by a mix of established energy companies diversifying into biofuels and innovative startups focusing exclusively on isobutane-based solutions. Strategic partnerships between fuel producers, automotive manufacturers, and technology providers are becoming increasingly common, driving innovation and market expansion.

Looking ahead, the market for isobutane-based biofuels is poised for substantial growth. Technological advancements in production processes are expected to improve efficiency and reduce costs, making these fuels more competitive with traditional options. As governments continue to incentivize the adoption of renewable energy sources, the market is likely to see increased investment and accelerated commercialization of isobutane-based biofuel technologies.

Current State and Challenges in Isobutane Biofuel Production

The current state of isobutane biofuel production is characterized by significant progress in research and development, yet it faces several challenges that hinder widespread commercial adoption. Isobutane, a branched-chain alkane, has gained attention in the biofuel industry due to its potential as a high-energy-density fuel component. Recent advancements in metabolic engineering and synthetic biology have enabled the production of isobutane in microbial systems, particularly in engineered Escherichia coli strains.

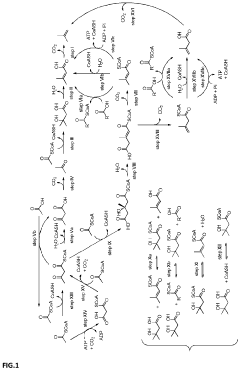

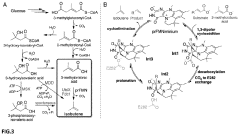

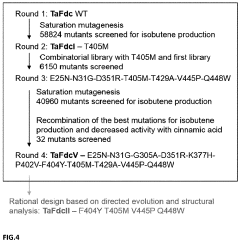

One of the primary achievements in this field has been the successful implementation of the mevalonate pathway for isobutane biosynthesis. This pathway, originally found in eukaryotes and some bacteria, has been optimized for microbial production through genetic modifications and enzyme engineering. Researchers have made significant strides in improving the efficiency of key enzymes involved in the pathway, such as HMG-CoA reductase and mevalonate diphosphate decarboxylase.

Despite these advancements, the current production yields of isobutane remain relatively low, posing a major challenge for industrial-scale applications. The metabolic burden on host organisms and the toxicity of isobutane to microbial cells are significant hurdles that need to be overcome. Scientists are exploring various strategies to address these issues, including the development of more robust host strains and the implementation of in situ product removal techniques.

Another challenge in isobutane biofuel production is the competition for metabolic precursors between the isobutane biosynthesis pathway and essential cellular processes. This competition often results in growth inhibition and reduced overall productivity. Researchers are investigating methods to balance cellular metabolism and redirect carbon flux towards isobutane production without compromising cell viability.

The scalability of isobutane production processes presents another significant challenge. While laboratory-scale experiments have shown promising results, translating these findings to industrial-scale fermentation systems has proven difficult. Issues such as maintaining optimal growth conditions, managing gas-liquid mass transfer, and preventing product loss through evaporation need to be addressed for successful scale-up.

From a geographical perspective, research on isobutane biofuel production is primarily concentrated in developed countries with advanced biotechnology sectors. The United States, European Union, and Japan are at the forefront of this technology, with several academic institutions and biotech companies actively engaged in research and development efforts. However, there is a growing interest in emerging economies, particularly in countries with significant biofuel industries, to explore isobutane as a potential advanced biofuel component.

In conclusion, while isobutane biofuel production has made notable progress, it still faces significant technical and practical challenges. Overcoming these hurdles will require continued research efforts, interdisciplinary collaborations, and substantial investments in process development and scale-up technologies.

One of the primary achievements in this field has been the successful implementation of the mevalonate pathway for isobutane biosynthesis. This pathway, originally found in eukaryotes and some bacteria, has been optimized for microbial production through genetic modifications and enzyme engineering. Researchers have made significant strides in improving the efficiency of key enzymes involved in the pathway, such as HMG-CoA reductase and mevalonate diphosphate decarboxylase.

Despite these advancements, the current production yields of isobutane remain relatively low, posing a major challenge for industrial-scale applications. The metabolic burden on host organisms and the toxicity of isobutane to microbial cells are significant hurdles that need to be overcome. Scientists are exploring various strategies to address these issues, including the development of more robust host strains and the implementation of in situ product removal techniques.

Another challenge in isobutane biofuel production is the competition for metabolic precursors between the isobutane biosynthesis pathway and essential cellular processes. This competition often results in growth inhibition and reduced overall productivity. Researchers are investigating methods to balance cellular metabolism and redirect carbon flux towards isobutane production without compromising cell viability.

The scalability of isobutane production processes presents another significant challenge. While laboratory-scale experiments have shown promising results, translating these findings to industrial-scale fermentation systems has proven difficult. Issues such as maintaining optimal growth conditions, managing gas-liquid mass transfer, and preventing product loss through evaporation need to be addressed for successful scale-up.

From a geographical perspective, research on isobutane biofuel production is primarily concentrated in developed countries with advanced biotechnology sectors. The United States, European Union, and Japan are at the forefront of this technology, with several academic institutions and biotech companies actively engaged in research and development efforts. However, there is a growing interest in emerging economies, particularly in countries with significant biofuel industries, to explore isobutane as a potential advanced biofuel component.

In conclusion, while isobutane biofuel production has made notable progress, it still faces significant technical and practical challenges. Overcoming these hurdles will require continued research efforts, interdisciplinary collaborations, and substantial investments in process development and scale-up technologies.

Existing Isobutane Biofuel Production Methods

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.

- Isobutane as a refrigerant or propellant: Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.

- Isobutane in chemical reactions and processes: Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.

- Isobutane in fuel compositions: Isobutane is incorporated into fuel compositions, particularly for use in internal combustion engines. It can be blended with other hydrocarbons to improve fuel properties such as octane rating or combustion characteristics. Various formulations and methods for preparing these fuel compositions are presented.

- Isobutane handling and safety: Given the flammable nature of isobutane, safety considerations and handling procedures are crucial. This includes methods for storing, transporting, and using isobutane in industrial settings. Safety systems, containment strategies, and risk mitigation approaches for working with isobutane are described.

02 Isobutane as a refrigerant or propellant

Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.Expand Specific Solutions03 Isobutane in chemical reactions and processes

Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.Expand Specific Solutions04 Isobutane in fuel compositions

Isobutane is incorporated into fuel compositions for various applications. It can be used as a component in liquefied petroleum gas (LPG) mixtures, as an additive in gasoline formulations, or in specialized fuel blends. The addition of isobutane can improve fuel properties such as octane rating or combustion characteristics.Expand Specific Solutions05 Safety and handling of isobutane

Due to its flammability and potential hazards, specific safety measures and handling procedures are required for isobutane. This includes proper storage methods, transportation guidelines, and safety systems for facilities handling isobutane. Additionally, detection and monitoring systems for isobutane leaks are described to ensure safe usage in various applications.Expand Specific Solutions

Key Players in Isobutane Biofuel Industry

The development of isobutane-based biofuels is in its early stages, with the market still emerging and technology evolving rapidly. The global biofuels market is projected to reach $218.7 billion by 2026, driven by increasing environmental concerns and government mandates. Key players like Gevo, Inc. and Global Bioenergies SA are at the forefront of isobutane-based biofuel research, while established petrochemical companies such as China Petroleum & Chemical Corp. and DuPont de Nemours, Inc. are also investing in this area. The technology is still maturing, with ongoing research focused on improving production efficiency and scalability. Collaborations between academic institutions like the University of California and industry partners are accelerating progress in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to biofuel production utilizing isobutane as a key component. Their process involves the catalytic conversion of biomass-derived sugars to isobutanol, which is then dehydrated to isobutene. This isobutene is subsequently oligomerized and hydrogenated to produce high-quality renewable jet fuel and diesel [1]. The company has invested in large-scale pilot plants to demonstrate the commercial viability of this technology, with reported yields of up to 90% conversion of biomass to biofuel [3]. Sinopec's method also incorporates a proprietary catalyst system that enhances the selectivity towards isobutanol production, minimizing unwanted byproducts and improving overall process efficiency [5].

Strengths: High conversion efficiency, integration with existing petrochemical infrastructure, and potential for large-scale production. Weaknesses: Dependence on biomass feedstock availability and potential competition with food crops.

Gevo, Inc.

Technical Solution: Gevo, Inc. has pioneered an innovative approach to biofuel production using isobutanol as a key intermediate. Their patented GIFT® (Gevo Integrated Fermentation Technology) process combines genetically engineered yeast strains with advanced separation technology to produce isobutanol from renewable feedstocks [2]. This isobutanol is then converted to isobutylene, which serves as a versatile building block for various biofuels and chemicals. Gevo's process can utilize a wide range of feedstocks, including corn, sugar cane, and cellulosic biomass, making it highly adaptable to different regional resources [4]. The company has successfully scaled up its technology, operating a commercial-scale facility in Luverne, Minnesota, with a capacity of 1.5 million gallons per year of isobutanol [6].

Strengths: Versatile feedstock options, established commercial-scale production, and potential for high-value co-products. Weaknesses: Relatively high production costs compared to conventional fuels and regulatory hurdles in some markets.

Innovative Approaches in Isobutane Biofuel Research

Organisms producing less crotonic acid

PatentInactiveEP4144838A1

Innovation

- A recombinant organism with a decreased pool of crotonic acid is engineered by reducing the conversion of acetaldehyde into crotonaldehyde and crotonyl-CoA into crotonaldehyde, thereby minimizing crotonic acid production and enhancing the efficiency of isobutene production through the action of ferulic acid decarboxylase.

Environmental Impact of Isobutane-Based Biofuels

The environmental impact of isobutane-based biofuels is a critical consideration in the development and adoption of these alternative energy sources. Isobutane, a key component in certain biofuel formulations, offers potential benefits in terms of energy density and combustion efficiency. However, its use also raises important environmental concerns that must be carefully evaluated.

One of the primary advantages of isobutane-based biofuels is their potential to reduce greenhouse gas emissions compared to traditional fossil fuels. When derived from renewable biomass sources, these biofuels can contribute to a more sustainable energy cycle. The production process can be designed to capture and utilize carbon dioxide, potentially resulting in a lower overall carbon footprint.

However, the environmental impact of isobutane-based biofuels extends beyond carbon emissions. The production of these fuels requires significant agricultural inputs, including water, fertilizers, and pesticides. This intensive cultivation can lead to soil degradation, water pollution, and loss of biodiversity if not managed sustainably. Additionally, the conversion of land for biofuel crop production may compete with food crops, potentially impacting food security and prices.

The refining and processing of isobutane-based biofuels also present environmental challenges. The production facilities may consume substantial amounts of energy and water, and generate waste products that require proper disposal. Ensuring the safe handling and storage of isobutane, which is highly flammable, is crucial to prevent accidental releases that could harm local ecosystems.

When used in vehicles or other applications, isobutane-based biofuels may have different emission profiles compared to conventional fuels. While they generally produce lower levels of certain pollutants, such as particulate matter and sulfur dioxide, they may increase emissions of other compounds, including volatile organic compounds (VOCs). The overall air quality impact depends on the specific formulation and combustion characteristics of the biofuel.

The lifecycle assessment of isobutane-based biofuels is essential for understanding their true environmental impact. This includes evaluating the energy and resources required for production, transportation, and end-use, as well as considering the potential for recycling or reuse of byproducts. Advanced production techniques and efficient supply chains can significantly improve the environmental performance of these biofuels.

As the technology evolves, ongoing research is focused on optimizing the environmental profile of isobutane-based biofuels. This includes developing more efficient production methods, exploring sustainable feedstock options, and improving end-use technologies to maximize energy efficiency and minimize emissions. The goal is to create a biofuel that not only reduces dependence on fossil fuels but also provides a net positive environmental impact throughout its lifecycle.

One of the primary advantages of isobutane-based biofuels is their potential to reduce greenhouse gas emissions compared to traditional fossil fuels. When derived from renewable biomass sources, these biofuels can contribute to a more sustainable energy cycle. The production process can be designed to capture and utilize carbon dioxide, potentially resulting in a lower overall carbon footprint.

However, the environmental impact of isobutane-based biofuels extends beyond carbon emissions. The production of these fuels requires significant agricultural inputs, including water, fertilizers, and pesticides. This intensive cultivation can lead to soil degradation, water pollution, and loss of biodiversity if not managed sustainably. Additionally, the conversion of land for biofuel crop production may compete with food crops, potentially impacting food security and prices.

The refining and processing of isobutane-based biofuels also present environmental challenges. The production facilities may consume substantial amounts of energy and water, and generate waste products that require proper disposal. Ensuring the safe handling and storage of isobutane, which is highly flammable, is crucial to prevent accidental releases that could harm local ecosystems.

When used in vehicles or other applications, isobutane-based biofuels may have different emission profiles compared to conventional fuels. While they generally produce lower levels of certain pollutants, such as particulate matter and sulfur dioxide, they may increase emissions of other compounds, including volatile organic compounds (VOCs). The overall air quality impact depends on the specific formulation and combustion characteristics of the biofuel.

The lifecycle assessment of isobutane-based biofuels is essential for understanding their true environmental impact. This includes evaluating the energy and resources required for production, transportation, and end-use, as well as considering the potential for recycling or reuse of byproducts. Advanced production techniques and efficient supply chains can significantly improve the environmental performance of these biofuels.

As the technology evolves, ongoing research is focused on optimizing the environmental profile of isobutane-based biofuels. This includes developing more efficient production methods, exploring sustainable feedstock options, and improving end-use technologies to maximize energy efficiency and minimize emissions. The goal is to create a biofuel that not only reduces dependence on fossil fuels but also provides a net positive environmental impact throughout its lifecycle.

Policy Framework for Isobutane Biofuel Development

The development of isobutane-based biofuels requires a comprehensive policy framework to support research, production, and market adoption. This framework should address several key areas to ensure sustainable growth and integration of isobutane biofuels into the existing energy landscape.

Firstly, research and development policies are crucial. Governments should establish dedicated funding programs and tax incentives for academic institutions and private companies engaged in isobutane biofuel research. These policies should prioritize projects focused on improving production efficiency, reducing costs, and enhancing the environmental benefits of isobutane-based biofuels.

Regulatory policies must be adapted to accommodate the unique properties of isobutane biofuels. This includes updating fuel standards and specifications to include isobutane-based alternatives, as well as modifying existing regulations on fuel storage, transportation, and distribution to ensure safety and compatibility with current infrastructure.

Environmental policies play a vital role in promoting isobutane biofuels. Implementing carbon pricing mechanisms or cap-and-trade systems can create economic incentives for the adoption of cleaner fuels. Additionally, lifecycle assessment requirements should be established to accurately measure and report the environmental impact of isobutane biofuels compared to conventional fossil fuels.

Market development policies are essential for creating demand and fostering industry growth. Governments can introduce blending mandates, requiring a certain percentage of isobutane biofuels in conventional fuel mixtures. Financial incentives, such as tax credits or subsidies for producers and consumers, can help overcome initial cost barriers and stimulate market adoption.

Infrastructure development policies are necessary to support the widespread use of isobutane biofuels. This includes providing grants or low-interest loans for the construction of production facilities, as well as incentives for retrofitting existing fuel stations to accommodate isobutane biofuel storage and dispensing.

International cooperation policies should be established to facilitate knowledge sharing, technology transfer, and harmonization of standards across borders. This can help accelerate global adoption and create a more robust market for isobutane biofuels.

Lastly, education and public awareness policies are crucial for gaining public support and acceptance. Governments should invest in public information campaigns and educational programs to inform consumers about the benefits and proper use of isobutane biofuels.

Firstly, research and development policies are crucial. Governments should establish dedicated funding programs and tax incentives for academic institutions and private companies engaged in isobutane biofuel research. These policies should prioritize projects focused on improving production efficiency, reducing costs, and enhancing the environmental benefits of isobutane-based biofuels.

Regulatory policies must be adapted to accommodate the unique properties of isobutane biofuels. This includes updating fuel standards and specifications to include isobutane-based alternatives, as well as modifying existing regulations on fuel storage, transportation, and distribution to ensure safety and compatibility with current infrastructure.

Environmental policies play a vital role in promoting isobutane biofuels. Implementing carbon pricing mechanisms or cap-and-trade systems can create economic incentives for the adoption of cleaner fuels. Additionally, lifecycle assessment requirements should be established to accurately measure and report the environmental impact of isobutane biofuels compared to conventional fossil fuels.

Market development policies are essential for creating demand and fostering industry growth. Governments can introduce blending mandates, requiring a certain percentage of isobutane biofuels in conventional fuel mixtures. Financial incentives, such as tax credits or subsidies for producers and consumers, can help overcome initial cost barriers and stimulate market adoption.

Infrastructure development policies are necessary to support the widespread use of isobutane biofuels. This includes providing grants or low-interest loans for the construction of production facilities, as well as incentives for retrofitting existing fuel stations to accommodate isobutane biofuel storage and dispensing.

International cooperation policies should be established to facilitate knowledge sharing, technology transfer, and harmonization of standards across borders. This can help accelerate global adoption and create a more robust market for isobutane biofuels.

Lastly, education and public awareness policies are crucial for gaining public support and acceptance. Governments should invest in public information campaigns and educational programs to inform consumers about the benefits and proper use of isobutane biofuels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!