How Isobutane Sustains Performance in High-Altitude Refrigeration Systems

JUL 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Refrigerant Evolution and Objectives

Isobutane, a hydrocarbon refrigerant, has emerged as a significant player in the evolution of refrigeration systems, particularly in high-altitude applications. The journey of isobutane in refrigeration technology began in the early 20th century but gained prominence in recent decades due to environmental concerns and the need for more efficient cooling solutions.

The development of isobutane as a refrigerant has been driven by the global push to phase out ozone-depleting substances and reduce greenhouse gas emissions. As chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were phased out under the Montreal Protocol, the refrigeration industry sought alternatives that could provide comparable or superior performance while minimizing environmental impact.

Isobutane, also known as R-600a, has proven to be an excellent candidate for high-altitude refrigeration systems due to its unique thermodynamic properties. Its low boiling point and high latent heat of vaporization make it particularly suitable for operating in low-pressure environments, which are characteristic of high-altitude locations.

The evolution of isobutane in refrigeration systems has been marked by continuous improvements in safety measures, system design, and efficiency optimization. Early concerns about flammability have been addressed through advanced engineering solutions, including improved sealing techniques, leak detection systems, and charge reduction strategies.

One of the primary objectives in the development of isobutane-based refrigeration systems for high-altitude applications has been to maintain consistent performance across varying atmospheric pressures. Engineers and researchers have focused on designing compressors and heat exchangers that can operate efficiently at reduced ambient pressures without compromising cooling capacity or energy efficiency.

Another key goal has been to enhance the overall system efficiency to compensate for the challenges posed by high-altitude environments. This has led to innovations in component design, such as more efficient compressors, optimized heat exchangers, and improved expansion devices tailored specifically for isobutane's properties at high altitudes.

The refrigeration industry has also aimed to develop standardized safety protocols and guidelines for the use of isobutane in various applications, including high-altitude systems. This objective has been crucial in promoting wider adoption of isobutane-based solutions and ensuring their safe implementation across different geographical and climatic conditions.

Looking forward, the continued evolution of isobutane in high-altitude refrigeration systems is expected to focus on further improving energy efficiency, reducing refrigerant charge, and developing smart control systems that can adapt to changing environmental conditions. These advancements will be essential in meeting the growing demand for sustainable and high-performance cooling solutions in challenging environments.

The development of isobutane as a refrigerant has been driven by the global push to phase out ozone-depleting substances and reduce greenhouse gas emissions. As chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were phased out under the Montreal Protocol, the refrigeration industry sought alternatives that could provide comparable or superior performance while minimizing environmental impact.

Isobutane, also known as R-600a, has proven to be an excellent candidate for high-altitude refrigeration systems due to its unique thermodynamic properties. Its low boiling point and high latent heat of vaporization make it particularly suitable for operating in low-pressure environments, which are characteristic of high-altitude locations.

The evolution of isobutane in refrigeration systems has been marked by continuous improvements in safety measures, system design, and efficiency optimization. Early concerns about flammability have been addressed through advanced engineering solutions, including improved sealing techniques, leak detection systems, and charge reduction strategies.

One of the primary objectives in the development of isobutane-based refrigeration systems for high-altitude applications has been to maintain consistent performance across varying atmospheric pressures. Engineers and researchers have focused on designing compressors and heat exchangers that can operate efficiently at reduced ambient pressures without compromising cooling capacity or energy efficiency.

Another key goal has been to enhance the overall system efficiency to compensate for the challenges posed by high-altitude environments. This has led to innovations in component design, such as more efficient compressors, optimized heat exchangers, and improved expansion devices tailored specifically for isobutane's properties at high altitudes.

The refrigeration industry has also aimed to develop standardized safety protocols and guidelines for the use of isobutane in various applications, including high-altitude systems. This objective has been crucial in promoting wider adoption of isobutane-based solutions and ensuring their safe implementation across different geographical and climatic conditions.

Looking forward, the continued evolution of isobutane in high-altitude refrigeration systems is expected to focus on further improving energy efficiency, reducing refrigerant charge, and developing smart control systems that can adapt to changing environmental conditions. These advancements will be essential in meeting the growing demand for sustainable and high-performance cooling solutions in challenging environments.

High-Altitude Refrigeration Market Analysis

The high-altitude refrigeration market has been experiencing significant growth in recent years, driven by the increasing demand for efficient cooling solutions in mountainous regions and high-elevation urban areas. This market segment encompasses a wide range of applications, including residential and commercial refrigeration, industrial cooling systems, and specialized equipment for scientific research facilities located at high altitudes.

The global high-altitude refrigeration market is primarily fueled by the rapid urbanization and development of mountainous regions, particularly in countries like China, India, and Nepal. As populations in these areas grow and living standards improve, there is a rising need for reliable refrigeration systems that can operate effectively in low-pressure environments. Additionally, the expansion of tourism and hospitality industries in high-altitude destinations has further boosted the demand for specialized cooling solutions.

One of the key factors shaping the market is the unique challenges posed by high-altitude environments. At elevations above 2,000 meters, the reduced atmospheric pressure significantly impacts the performance of traditional refrigeration systems. This has led to a growing interest in alternative refrigerants and innovative technologies that can maintain optimal cooling efficiency in these conditions. Isobutane, with its favorable thermodynamic properties, has emerged as a promising solution for high-altitude refrigeration applications.

The market is characterized by a diverse range of products, including household refrigerators, commercial freezers, industrial chillers, and specialized scientific equipment. Manufacturers are increasingly focusing on developing energy-efficient and environmentally friendly solutions to meet the stringent regulations and growing consumer awareness regarding sustainability. This trend has resulted in the introduction of smart refrigeration systems that incorporate advanced sensors and control mechanisms to optimize performance at high altitudes.

In terms of regional distribution, Asia-Pacific dominates the high-altitude refrigeration market, followed by North America and Europe. The rapid economic growth and infrastructure development in countries like China and India are major contributors to this regional dominance. However, other regions with significant mountainous terrain, such as the Andes in South America and the Alps in Europe, are also witnessing increased demand for high-altitude refrigeration solutions.

The market is highly competitive, with both established multinational corporations and local manufacturers vying for market share. Key players are investing heavily in research and development to create innovative products tailored for high-altitude environments. Collaborations between industry players and research institutions are becoming more common, aiming to address the technical challenges associated with refrigeration at high elevations.

The global high-altitude refrigeration market is primarily fueled by the rapid urbanization and development of mountainous regions, particularly in countries like China, India, and Nepal. As populations in these areas grow and living standards improve, there is a rising need for reliable refrigeration systems that can operate effectively in low-pressure environments. Additionally, the expansion of tourism and hospitality industries in high-altitude destinations has further boosted the demand for specialized cooling solutions.

One of the key factors shaping the market is the unique challenges posed by high-altitude environments. At elevations above 2,000 meters, the reduced atmospheric pressure significantly impacts the performance of traditional refrigeration systems. This has led to a growing interest in alternative refrigerants and innovative technologies that can maintain optimal cooling efficiency in these conditions. Isobutane, with its favorable thermodynamic properties, has emerged as a promising solution for high-altitude refrigeration applications.

The market is characterized by a diverse range of products, including household refrigerators, commercial freezers, industrial chillers, and specialized scientific equipment. Manufacturers are increasingly focusing on developing energy-efficient and environmentally friendly solutions to meet the stringent regulations and growing consumer awareness regarding sustainability. This trend has resulted in the introduction of smart refrigeration systems that incorporate advanced sensors and control mechanisms to optimize performance at high altitudes.

In terms of regional distribution, Asia-Pacific dominates the high-altitude refrigeration market, followed by North America and Europe. The rapid economic growth and infrastructure development in countries like China and India are major contributors to this regional dominance. However, other regions with significant mountainous terrain, such as the Andes in South America and the Alps in Europe, are also witnessing increased demand for high-altitude refrigeration solutions.

The market is highly competitive, with both established multinational corporations and local manufacturers vying for market share. Key players are investing heavily in research and development to create innovative products tailored for high-altitude environments. Collaborations between industry players and research institutions are becoming more common, aiming to address the technical challenges associated with refrigeration at high elevations.

Isobutane Performance Challenges at High Altitudes

The performance of isobutane in high-altitude refrigeration systems faces unique challenges due to the reduced atmospheric pressure and lower oxygen levels. At higher elevations, the boiling point of isobutane decreases, which can lead to reduced efficiency and potential system failures if not properly addressed. This phenomenon is particularly pronounced in mountainous regions or high-altitude cities where refrigeration systems are crucial for both residential and commercial applications.

One of the primary challenges is maintaining optimal system pressure. As altitude increases, the ambient pressure decreases, which can cause the isobutane to vaporize at lower temperatures than designed. This premature vaporization can result in reduced cooling capacity and increased energy consumption. To combat this issue, refrigeration systems operating at high altitudes often require modified pressure controls and specialized compressors capable of maintaining the necessary pressure differentials.

Another significant challenge is the potential for increased leakage rates. The lower atmospheric pressure at high altitudes can exacerbate any existing micro-leaks in the system, leading to a more rapid loss of refrigerant. This not only impacts the system's performance but also raises environmental concerns due to the release of greenhouse gases. Consequently, high-altitude refrigeration systems using isobutane must be designed with enhanced sealing mechanisms and undergo more frequent leak detection and maintenance procedures.

The reduced air density at high altitudes also affects the heat transfer efficiency of condensers. With less air available to remove heat from the system, condensers may struggle to reject heat effectively, potentially leading to higher operating temperatures and reduced overall system efficiency. This challenge necessitates the use of larger or more efficient condensers, or the implementation of alternative cooling methods such as water-cooled systems in high-altitude applications.

Furthermore, the lower oxygen levels at high altitudes can impact the combustion properties of isobutane, which is a flammable refrigerant. While this is primarily a safety concern, it also affects the design and operation of refrigeration systems. Safety systems and ventilation requirements may need to be adjusted to account for the altered flammability characteristics of isobutane at high altitudes.

Lastly, the extreme temperature fluctuations often experienced in high-altitude environments pose additional challenges. The wide range between daytime and nighttime temperatures can stress refrigeration systems, requiring more robust temperature control mechanisms and potentially more frequent cycling of the compressor. This increased cycling can lead to accelerated wear on system components, necessitating more frequent maintenance and potentially shorter overall system lifespans.

One of the primary challenges is maintaining optimal system pressure. As altitude increases, the ambient pressure decreases, which can cause the isobutane to vaporize at lower temperatures than designed. This premature vaporization can result in reduced cooling capacity and increased energy consumption. To combat this issue, refrigeration systems operating at high altitudes often require modified pressure controls and specialized compressors capable of maintaining the necessary pressure differentials.

Another significant challenge is the potential for increased leakage rates. The lower atmospheric pressure at high altitudes can exacerbate any existing micro-leaks in the system, leading to a more rapid loss of refrigerant. This not only impacts the system's performance but also raises environmental concerns due to the release of greenhouse gases. Consequently, high-altitude refrigeration systems using isobutane must be designed with enhanced sealing mechanisms and undergo more frequent leak detection and maintenance procedures.

The reduced air density at high altitudes also affects the heat transfer efficiency of condensers. With less air available to remove heat from the system, condensers may struggle to reject heat effectively, potentially leading to higher operating temperatures and reduced overall system efficiency. This challenge necessitates the use of larger or more efficient condensers, or the implementation of alternative cooling methods such as water-cooled systems in high-altitude applications.

Furthermore, the lower oxygen levels at high altitudes can impact the combustion properties of isobutane, which is a flammable refrigerant. While this is primarily a safety concern, it also affects the design and operation of refrigeration systems. Safety systems and ventilation requirements may need to be adjusted to account for the altered flammability characteristics of isobutane at high altitudes.

Lastly, the extreme temperature fluctuations often experienced in high-altitude environments pose additional challenges. The wide range between daytime and nighttime temperatures can stress refrigeration systems, requiring more robust temperature control mechanisms and potentially more frequent cycling of the compressor. This increased cycling can lead to accelerated wear on system components, necessitating more frequent maintenance and potentially shorter overall system lifespans.

Current Isobutane-based High-Altitude Solutions

01 Isobutane production methods

Various methods for producing isobutane are described, including catalytic processes, isomerization of n-butane, and dehydrogenation reactions. These methods aim to improve yield, selectivity, and efficiency in isobutane production.- Isobutane production methods: Various methods for producing isobutane are described, including catalytic processes, isomerization of n-butane, and dehydrogenation reactions. These methods aim to improve yield, selectivity, and efficiency in isobutane production.

- Isobutane as a refrigerant: Isobutane is utilized as an environmentally friendly refrigerant in cooling systems. Its performance characteristics, such as low global warming potential and energy efficiency, make it a suitable alternative to traditional refrigerants.

- Isobutane in fuel applications: The use of isobutane in fuel applications is explored, including its role in improving octane ratings, enhancing combustion efficiency, and reducing emissions in internal combustion engines.

- Isobutane in chemical synthesis: Isobutane serves as a key raw material in various chemical synthesis processes, including the production of high-value chemicals, polymers, and specialty materials. Its reactivity and versatility contribute to its importance in industrial chemistry.

- Isobutane purification and separation: Techniques for purifying and separating isobutane from mixed hydrocarbon streams are discussed. These methods aim to improve the purity and quality of isobutane for various applications, including its use as a feedstock or in specialized industrial processes.

02 Isobutane as a refrigerant

Isobutane is utilized as an environmentally friendly refrigerant in cooling systems. Its performance characteristics, such as low global warming potential and energy efficiency, make it a suitable alternative to traditional refrigerants.Expand Specific Solutions03 Isobutane in fuel applications

The use of isobutane in fuel applications is explored, including its role in improving octane ratings, enhancing combustion efficiency, and reducing emissions in internal combustion engines.Expand Specific Solutions04 Isobutane purification and separation

Techniques for purifying and separating isobutane from mixed hydrocarbon streams are discussed. These methods aim to improve the purity and quality of isobutane for various industrial applications.Expand Specific Solutions05 Isobutane in chemical synthesis

Isobutane serves as a valuable feedstock in chemical synthesis processes. Its reactivity and structure make it suitable for producing various chemical compounds, including polymers, additives, and specialty chemicals.Expand Specific Solutions

Key Players in High-Altitude Refrigeration Industry

The competition landscape for high-altitude refrigeration systems using isobutane is evolving as the industry enters a growth phase. The market size is expanding due to increasing demand for efficient cooling solutions in challenging environments. Technologically, the field is advancing rapidly, with companies like LG Electronics, Daikin Industries, and Mitsubishi Electric leading innovation in compressor design and system optimization. These firms are leveraging their expertise in refrigeration to develop specialized solutions for high-altitude applications. Other players such as Bayer AG and BASF Corp. are contributing to material advancements, potentially improving isobutane's performance characteristics. As the technology matures, we can expect increased competition and further refinements in system efficiency and reliability for high-altitude refrigeration applications.

LG Electronics, Inc.

Technical Solution: LG Electronics has engineered a high-altitude refrigeration system that utilizes isobutane (R600a) to maintain performance in low-pressure environments. Their solution incorporates a dual-cooling system with separate evaporators for the freezer and refrigerator compartments, allowing for more precise temperature control[2]. LG has also developed a smart inverter compressor that can operate efficiently at various speeds, adapting to the reduced air density at high altitudes[4]. The system includes an advanced defrosting mechanism that accounts for the lower humidity typically found at higher elevations, preventing excessive frost buildup and maintaining energy efficiency[6].

Strengths: Precise temperature control, energy-efficient operation, adaptable to varying altitudes. Weaknesses: Potentially higher initial cost due to advanced technology, may require specialized maintenance.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a high-altitude refrigeration system using isobutane (R600a) that focuses on maintaining cooling performance in low-pressure environments. Their approach includes a specially designed compressor with an optimized motor and valve system to handle the lower atmospheric pressure at high altitudes[7]. The company has also implemented an advanced electronic expansion valve that precisely controls refrigerant flow based on altitude and ambient conditions[8]. Mitsubishi's system incorporates a high-efficiency heat exchanger with a larger surface area and improved fin design to enhance heat transfer in the thinner air found at higher elevations[9].

Strengths: Robust performance at various altitudes, precise refrigerant control, improved heat transfer efficiency. Weaknesses: Potential complexity in system design, may require specialized technicians for maintenance and repair.

Core Innovations in Isobutane Refrigeration Systems

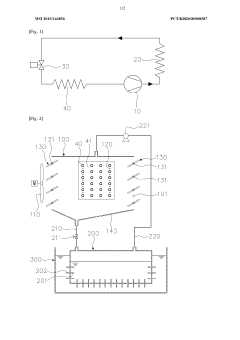

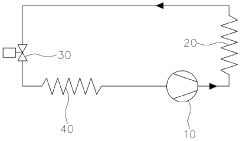

Working mixture for refrigeration machinery

PatentWO1995029210A1

Innovation

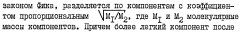

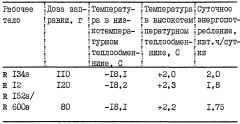

- A working mixture comprising dihydroethane (60-75%) and isobutane (25-40%) is proposed, with a molecular weight ratio closer to dihydroethane than the previous mixture, ensuring azeotropic characteristics and improved energy efficiency, while maintaining zero ozone-depleting potential.

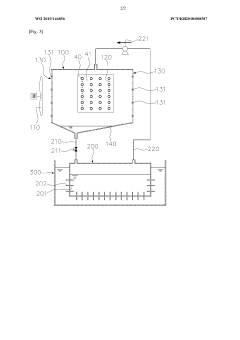

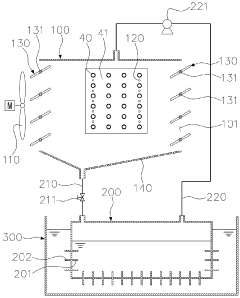

Freezing apparatus using isobutane refrigerant

PatentWO2019146856A1

Innovation

- A refrigeration device design that utilizes the sensible heat of condensed defrost water and latent heat of condensation, employing a sealed defrost water storage tank, vacuum pump, and heat exchange fins to efficiently defrost the evaporator surface, reducing overall defrost time even at low temperatures.

Environmental Impact of Isobutane Refrigerants

The use of isobutane as a refrigerant in high-altitude refrigeration systems has significant environmental implications. Isobutane (R-600a) is a hydrocarbon refrigerant that has gained popularity due to its low global warming potential (GWP) and zero ozone depletion potential (ODP). These properties make it an environmentally friendly alternative to traditional refrigerants like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs).

In high-altitude environments, where atmospheric pressure is lower, isobutane's performance characteristics become particularly advantageous. Its low boiling point and high vapor pressure allow it to maintain efficient heat transfer even in reduced pressure conditions. This results in sustained cooling performance without the need for increased energy consumption, which indirectly contributes to lower greenhouse gas emissions from power generation.

However, the environmental impact of isobutane refrigerants extends beyond their direct effects on the atmosphere. The production and transportation of isobutane have their own carbon footprint, although it is generally lower than that of synthetic refrigerants. The extraction and refining processes for isobutane, which is derived from natural gas or petroleum, do contribute to some level of environmental impact.

One of the primary environmental concerns with isobutane refrigerants is their flammability. While this property does not directly affect the environment during normal operation, it does pose potential risks in case of leaks or improper handling. Stringent safety measures and proper disposal protocols are essential to mitigate these risks and prevent accidental releases that could contribute to local air pollution or fire hazards.

From a lifecycle perspective, isobutane refrigerants offer environmental benefits in terms of energy efficiency and end-of-life management. High-altitude refrigeration systems using isobutane typically require less refrigerant charge compared to systems using other refrigerants, reducing the potential for leaks and emissions over the equipment's lifespan. Additionally, at the end of the system's life, isobutane can be more easily recovered and recycled compared to complex synthetic refrigerants.

The adoption of isobutane in high-altitude refrigeration systems also aligns with global efforts to phase down hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol. By transitioning to low-GWP alternatives like isobutane, industries operating in high-altitude regions can contribute to the reduction of greenhouse gas emissions and comply with increasingly stringent environmental regulations.

In conclusion, while isobutane refrigerants present some environmental challenges, particularly in terms of flammability and production-related emissions, their overall environmental impact in high-altitude refrigeration systems is generally positive. The combination of low GWP, zero ODP, and sustained performance at high altitudes makes isobutane a valuable tool in the ongoing effort to create more sustainable cooling solutions for challenging environments.

In high-altitude environments, where atmospheric pressure is lower, isobutane's performance characteristics become particularly advantageous. Its low boiling point and high vapor pressure allow it to maintain efficient heat transfer even in reduced pressure conditions. This results in sustained cooling performance without the need for increased energy consumption, which indirectly contributes to lower greenhouse gas emissions from power generation.

However, the environmental impact of isobutane refrigerants extends beyond their direct effects on the atmosphere. The production and transportation of isobutane have their own carbon footprint, although it is generally lower than that of synthetic refrigerants. The extraction and refining processes for isobutane, which is derived from natural gas or petroleum, do contribute to some level of environmental impact.

One of the primary environmental concerns with isobutane refrigerants is their flammability. While this property does not directly affect the environment during normal operation, it does pose potential risks in case of leaks or improper handling. Stringent safety measures and proper disposal protocols are essential to mitigate these risks and prevent accidental releases that could contribute to local air pollution or fire hazards.

From a lifecycle perspective, isobutane refrigerants offer environmental benefits in terms of energy efficiency and end-of-life management. High-altitude refrigeration systems using isobutane typically require less refrigerant charge compared to systems using other refrigerants, reducing the potential for leaks and emissions over the equipment's lifespan. Additionally, at the end of the system's life, isobutane can be more easily recovered and recycled compared to complex synthetic refrigerants.

The adoption of isobutane in high-altitude refrigeration systems also aligns with global efforts to phase down hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol. By transitioning to low-GWP alternatives like isobutane, industries operating in high-altitude regions can contribute to the reduction of greenhouse gas emissions and comply with increasingly stringent environmental regulations.

In conclusion, while isobutane refrigerants present some environmental challenges, particularly in terms of flammability and production-related emissions, their overall environmental impact in high-altitude refrigeration systems is generally positive. The combination of low GWP, zero ODP, and sustained performance at high altitudes makes isobutane a valuable tool in the ongoing effort to create more sustainable cooling solutions for challenging environments.

Safety Regulations for Isobutane in Refrigeration

The use of isobutane in refrigeration systems, particularly in high-altitude environments, necessitates stringent safety regulations due to its flammable nature. These regulations are designed to mitigate risks associated with the handling, storage, and operation of isobutane-based systems. At the international level, organizations such as the International Electrotechnical Commission (IEC) have established standards like IEC 60335-2-24, which outlines safety requirements for household refrigerating appliances using flammable refrigerants.

In the United States, the Environmental Protection Agency (EPA) regulates the use of isobutane under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. The EPA has approved isobutane for use in domestic refrigeration, subject to use conditions that address flammability risks.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in ensuring workplace safety when dealing with isobutane in refrigeration systems. OSHA's Process Safety Management (PSM) standard applies to processes involving flammable gases, including isobutane, above certain threshold quantities. This standard requires employers to develop and implement a comprehensive safety management system to prevent or minimize the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals.

Specific safety measures mandated by regulations include charge size limitations, leak detection systems, and proper ventilation. For instance, the maximum charge size for isobutane in domestic refrigeration appliances is typically limited to 150 grams. This restriction helps minimize the potential impact of a leak or ignition event. Additionally, regulations often require the installation of leak detection systems capable of identifying small leaks before they become significant hazards.

Proper labeling and marking of equipment containing isobutane are also essential components of safety regulations. Clear warnings about the presence of a flammable refrigerant must be displayed on the appliance and in user manuals. Furthermore, technicians working with isobutane-based systems must receive specialized training in handling flammable refrigerants, as mandated by various regulatory bodies.

In high-altitude environments, safety regulations may need to be adapted to account for the unique challenges posed by reduced atmospheric pressure. This could include modifications to charge size calculations, ventilation requirements, and leak detection thresholds. However, specific high-altitude regulations for isobutane refrigeration systems are not as well-developed as general safety standards, highlighting an area for potential regulatory development.

As the use of isobutane in refrigeration continues to grow, particularly in environmentally sensitive applications like high-altitude systems, it is likely that safety regulations will evolve to address emerging challenges and incorporate new technological advancements in safety systems and monitoring.

In the United States, the Environmental Protection Agency (EPA) regulates the use of isobutane under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. The EPA has approved isobutane for use in domestic refrigeration, subject to use conditions that address flammability risks.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in ensuring workplace safety when dealing with isobutane in refrigeration systems. OSHA's Process Safety Management (PSM) standard applies to processes involving flammable gases, including isobutane, above certain threshold quantities. This standard requires employers to develop and implement a comprehensive safety management system to prevent or minimize the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals.

Specific safety measures mandated by regulations include charge size limitations, leak detection systems, and proper ventilation. For instance, the maximum charge size for isobutane in domestic refrigeration appliances is typically limited to 150 grams. This restriction helps minimize the potential impact of a leak or ignition event. Additionally, regulations often require the installation of leak detection systems capable of identifying small leaks before they become significant hazards.

Proper labeling and marking of equipment containing isobutane are also essential components of safety regulations. Clear warnings about the presence of a flammable refrigerant must be displayed on the appliance and in user manuals. Furthermore, technicians working with isobutane-based systems must receive specialized training in handling flammable refrigerants, as mandated by various regulatory bodies.

In high-altitude environments, safety regulations may need to be adapted to account for the unique challenges posed by reduced atmospheric pressure. This could include modifications to charge size calculations, ventilation requirements, and leak detection thresholds. However, specific high-altitude regulations for isobutane refrigeration systems are not as well-developed as general safety standards, highlighting an area for potential regulatory development.

As the use of isobutane in refrigeration continues to grow, particularly in environmentally sensitive applications like high-altitude systems, it is likely that safety regulations will evolve to address emerging challenges and incorporate new technological advancements in safety systems and monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!