How Isobutane Affects Polymer Blend Properties

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane-Polymer Blend Evolution and Objectives

The evolution of isobutane-polymer blends has been a significant area of research in materials science and polymer engineering over the past few decades. This field has seen remarkable progress, driven by the increasing demand for materials with enhanced properties and performance characteristics. The journey began with the recognition of isobutane's potential as a blowing agent in polymer processing, particularly in the production of expanded polystyrene (EPS) and other foam materials.

As the understanding of polymer-gas interactions deepened, researchers began to explore the broader effects of isobutane on various polymer systems. This exploration led to the discovery that isobutane could significantly influence the morphology, crystallization behavior, and mechanical properties of polymer blends. The ability of isobutane to act as a plasticizer in certain polymer systems opened up new avenues for tailoring material properties without the need for chemical modifications.

The technological evolution in this field has been marked by several key milestones. Initially, the focus was on optimizing the foaming process and controlling cell structure in expanded polymers. This was followed by investigations into the solubility and diffusion behavior of isobutane in different polymer matrices, which provided crucial insights into the fundamental mechanisms of isobutane-polymer interactions.

Recent years have witnessed a shift towards more sophisticated applications, such as the development of high-performance polymer blends with enhanced gas barrier properties, improved thermal stability, and controlled release characteristics. The advent of advanced characterization techniques, including in-situ spectroscopy and high-resolution imaging, has enabled researchers to observe and understand the real-time effects of isobutane on polymer blend properties at the molecular level.

The primary objectives of current and future research in this field are multifaceted. Firstly, there is a strong focus on developing environmentally friendly and sustainable polymer blends that incorporate isobutane as a key component. This aligns with the global push towards greener materials and processes. Secondly, researchers aim to achieve precise control over the distribution and behavior of isobutane within polymer matrices to enable the creation of materials with highly tailored properties for specific applications.

Another critical objective is to expand the range of polymers that can be effectively blended with isobutane, potentially opening up new application areas in industries such as packaging, automotive, and construction. Additionally, there is growing interest in leveraging isobutane-polymer interactions to develop smart materials that can respond to environmental stimuli, offering possibilities for self-healing or shape-memory polymers.

As the understanding of polymer-gas interactions deepened, researchers began to explore the broader effects of isobutane on various polymer systems. This exploration led to the discovery that isobutane could significantly influence the morphology, crystallization behavior, and mechanical properties of polymer blends. The ability of isobutane to act as a plasticizer in certain polymer systems opened up new avenues for tailoring material properties without the need for chemical modifications.

The technological evolution in this field has been marked by several key milestones. Initially, the focus was on optimizing the foaming process and controlling cell structure in expanded polymers. This was followed by investigations into the solubility and diffusion behavior of isobutane in different polymer matrices, which provided crucial insights into the fundamental mechanisms of isobutane-polymer interactions.

Recent years have witnessed a shift towards more sophisticated applications, such as the development of high-performance polymer blends with enhanced gas barrier properties, improved thermal stability, and controlled release characteristics. The advent of advanced characterization techniques, including in-situ spectroscopy and high-resolution imaging, has enabled researchers to observe and understand the real-time effects of isobutane on polymer blend properties at the molecular level.

The primary objectives of current and future research in this field are multifaceted. Firstly, there is a strong focus on developing environmentally friendly and sustainable polymer blends that incorporate isobutane as a key component. This aligns with the global push towards greener materials and processes. Secondly, researchers aim to achieve precise control over the distribution and behavior of isobutane within polymer matrices to enable the creation of materials with highly tailored properties for specific applications.

Another critical objective is to expand the range of polymers that can be effectively blended with isobutane, potentially opening up new application areas in industries such as packaging, automotive, and construction. Additionally, there is growing interest in leveraging isobutane-polymer interactions to develop smart materials that can respond to environmental stimuli, offering possibilities for self-healing or shape-memory polymers.

Market Analysis for Isobutane-Modified Polymers

The market for isobutane-modified polymers has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials across various industries. The global market size for these specialized polymers is projected to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) exceeding the average for the broader polymer industry.

Key factors contributing to this market expansion include the automotive sector's shift towards lightweight materials for improved fuel efficiency, the growing need for durable and weather-resistant construction materials, and the rising demand for advanced packaging solutions in the food and beverage industry. Isobutane-modified polymers offer enhanced properties such as improved impact resistance, better thermal stability, and increased flexibility, making them attractive for these applications.

In the automotive industry, isobutane-modified polymers are increasingly being used in interior components, under-the-hood applications, and exterior parts. The construction sector is adopting these materials for weatherproofing, insulation, and structural components due to their superior durability and weather resistance. The packaging industry is leveraging isobutane-modified polymers to develop innovative, sustainable packaging solutions that offer better barrier properties and extended shelf life for products.

Geographically, North America and Europe currently dominate the market for isobutane-modified polymers, owing to their advanced manufacturing capabilities and stringent regulations promoting the use of high-performance materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing automotive production, and growing construction activities in countries like China and India.

The market is characterized by intense competition among key players, including major chemical companies and specialized polymer manufacturers. These companies are investing heavily in research and development to create novel formulations and expand their product portfolios. Additionally, strategic partnerships and collaborations between raw material suppliers, polymer manufacturers, and end-users are becoming increasingly common to drive innovation and market penetration.

Challenges facing the isobutane-modified polymer market include fluctuating raw material prices, particularly the volatility in isobutane costs, which can impact profit margins. Environmental concerns and regulatory pressures regarding the use of certain chemical additives also pose potential hurdles for market growth. However, ongoing research into more sustainable production methods and bio-based alternatives presents opportunities for future market expansion.

Key factors contributing to this market expansion include the automotive sector's shift towards lightweight materials for improved fuel efficiency, the growing need for durable and weather-resistant construction materials, and the rising demand for advanced packaging solutions in the food and beverage industry. Isobutane-modified polymers offer enhanced properties such as improved impact resistance, better thermal stability, and increased flexibility, making them attractive for these applications.

In the automotive industry, isobutane-modified polymers are increasingly being used in interior components, under-the-hood applications, and exterior parts. The construction sector is adopting these materials for weatherproofing, insulation, and structural components due to their superior durability and weather resistance. The packaging industry is leveraging isobutane-modified polymers to develop innovative, sustainable packaging solutions that offer better barrier properties and extended shelf life for products.

Geographically, North America and Europe currently dominate the market for isobutane-modified polymers, owing to their advanced manufacturing capabilities and stringent regulations promoting the use of high-performance materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing automotive production, and growing construction activities in countries like China and India.

The market is characterized by intense competition among key players, including major chemical companies and specialized polymer manufacturers. These companies are investing heavily in research and development to create novel formulations and expand their product portfolios. Additionally, strategic partnerships and collaborations between raw material suppliers, polymer manufacturers, and end-users are becoming increasingly common to drive innovation and market penetration.

Challenges facing the isobutane-modified polymer market include fluctuating raw material prices, particularly the volatility in isobutane costs, which can impact profit margins. Environmental concerns and regulatory pressures regarding the use of certain chemical additives also pose potential hurdles for market growth. However, ongoing research into more sustainable production methods and bio-based alternatives presents opportunities for future market expansion.

Current Challenges in Isobutane-Polymer Blending

The blending of isobutane with polymers presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary issues is achieving uniform dispersion of isobutane within the polymer matrix. The volatile nature of isobutane makes it difficult to maintain a consistent distribution throughout the blend, leading to potential inconsistencies in the final product's properties.

Another major challenge lies in controlling the expansion process when isobutane is used as a blowing agent in polymer foams. The rate of gas evolution and bubble formation must be carefully managed to achieve the desired foam structure and density. This becomes particularly complex when dealing with different polymer types, as the interaction between isobutane and various polymers can vary significantly.

The impact of isobutane on the mechanical properties of polymer blends is also a area of concern. While isobutane can enhance certain characteristics, such as flexibility and insulation properties, it may simultaneously compromise others, like tensile strength or dimensional stability. Striking the right balance to optimize overall performance remains a persistent challenge.

Environmental and safety considerations pose additional hurdles in isobutane-polymer blending. Isobutane is a volatile organic compound (VOC) and a potential fire hazard, necessitating stringent safety protocols during processing and storage. Moreover, regulatory pressures to reduce VOC emissions are pushing manufacturers to explore alternative blowing agents or develop more efficient containment methods.

The long-term stability of isobutane-polymer blends is another area of ongoing research. Over time, there is a risk of isobutane migration or loss from the polymer matrix, which can lead to changes in the material's properties and performance. Developing strategies to enhance the retention of isobutane within the polymer structure is crucial for ensuring product longevity and consistency.

Scalability and cost-effectiveness in production processes represent further challenges. While laboratory-scale blending may yield promising results, translating these to large-scale industrial production while maintaining quality and economic viability is often problematic. This includes optimizing processing parameters, equipment design, and quality control measures to ensure consistent results across different batch sizes.

Lastly, the compatibility of isobutane-polymer blends with other materials and additives used in final products is an area that requires careful consideration. Interactions between isobutane, polymers, and additional components such as fillers, stabilizers, or colorants can lead to unexpected changes in material properties or processing behavior, necessitating extensive testing and formulation adjustments.

Another major challenge lies in controlling the expansion process when isobutane is used as a blowing agent in polymer foams. The rate of gas evolution and bubble formation must be carefully managed to achieve the desired foam structure and density. This becomes particularly complex when dealing with different polymer types, as the interaction between isobutane and various polymers can vary significantly.

The impact of isobutane on the mechanical properties of polymer blends is also a area of concern. While isobutane can enhance certain characteristics, such as flexibility and insulation properties, it may simultaneously compromise others, like tensile strength or dimensional stability. Striking the right balance to optimize overall performance remains a persistent challenge.

Environmental and safety considerations pose additional hurdles in isobutane-polymer blending. Isobutane is a volatile organic compound (VOC) and a potential fire hazard, necessitating stringent safety protocols during processing and storage. Moreover, regulatory pressures to reduce VOC emissions are pushing manufacturers to explore alternative blowing agents or develop more efficient containment methods.

The long-term stability of isobutane-polymer blends is another area of ongoing research. Over time, there is a risk of isobutane migration or loss from the polymer matrix, which can lead to changes in the material's properties and performance. Developing strategies to enhance the retention of isobutane within the polymer structure is crucial for ensuring product longevity and consistency.

Scalability and cost-effectiveness in production processes represent further challenges. While laboratory-scale blending may yield promising results, translating these to large-scale industrial production while maintaining quality and economic viability is often problematic. This includes optimizing processing parameters, equipment design, and quality control measures to ensure consistent results across different batch sizes.

Lastly, the compatibility of isobutane-polymer blends with other materials and additives used in final products is an area that requires careful consideration. Interactions between isobutane, polymers, and additional components such as fillers, stabilizers, or colorants can lead to unexpected changes in material properties or processing behavior, necessitating extensive testing and formulation adjustments.

Existing Isobutane-Polymer Blending Techniques

01 Mechanical properties of polymer blends

Polymer blends can exhibit improved mechanical properties compared to individual polymers. The combination of different polymers can result in enhanced strength, toughness, and flexibility. The properties of the blend can be tailored by adjusting the composition and processing conditions.- Mechanical properties of polymer blends: Polymer blends can exhibit improved mechanical properties compared to individual polymers. The combination of different polymers can result in enhanced strength, toughness, and flexibility. The properties of the blend can be tailored by adjusting the composition and processing conditions.

- Thermal properties of polymer blends: Blending polymers can lead to changes in thermal properties such as melting point, glass transition temperature, and thermal stability. The thermal behavior of the blend can be influenced by the compatibility and interactions between the component polymers.

- Compatibility and miscibility in polymer blends: The compatibility and miscibility of polymers in a blend significantly affect its properties. Miscible blends tend to have homogeneous structures and exhibit properties intermediate between those of the constituent polymers. Compatibilizers can be used to improve the miscibility of otherwise immiscible polymer pairs.

- Morphology and phase behavior of polymer blends: The morphology and phase behavior of polymer blends play a crucial role in determining their properties. Factors such as composition, processing conditions, and interfacial interactions influence the blend morphology, which can range from dispersed droplets to co-continuous structures.

- Electrical and optical properties of polymer blends: Blending polymers can result in unique electrical and optical properties. Conductive polymers can be blended with insulating polymers to create materials with tailored conductivity. Optical properties such as transparency and refractive index can also be modified through polymer blending.

02 Thermal properties of polymer blends

The thermal properties of polymer blends, such as melting temperature, glass transition temperature, and thermal stability, can be modified by blending different polymers. This allows for the creation of materials with specific thermal characteristics suitable for various applications.Expand Specific Solutions03 Compatibility and miscibility in polymer blends

The compatibility and miscibility of different polymers in a blend significantly affect its properties. Techniques such as compatibilization and the use of compatibilizers can improve the miscibility of otherwise immiscible polymers, leading to enhanced overall properties of the blend.Expand Specific Solutions04 Electrical and optical properties of polymer blends

Polymer blends can be designed to exhibit specific electrical and optical properties. By combining polymers with different electrical conductivities or optical characteristics, materials with tailored electrical or optical properties can be created for various applications in electronics and optics.Expand Specific Solutions05 Processing and morphology of polymer blends

The processing conditions and resulting morphology of polymer blends play a crucial role in determining their final properties. Factors such as mixing method, temperature, and shear rate during processing can affect the phase structure and distribution of components in the blend, influencing its overall performance.Expand Specific Solutions

Key Industry Players in Polymer Blending

The competition landscape for isobutane's impact on polymer blend properties is in a mature phase, with established players like BASF, ExxonMobil, and Dow Global Technologies dominating the market. The global polymer blends market size is substantial, estimated to reach $7.5 billion by 2027. Technologically, the field is well-developed, with companies like 3M Innovative Properties and Eastman Chemical Co. continuously advancing research. Universities such as Beijing University of Chemical Technology and École Polytechnique Fédérale de Lausanne contribute to academic advancements, while industry leaders like SABIC and Wanhua Chemical Group focus on commercial applications, driving innovation in polymer blend formulations and processing techniques.

BASF Corp.

Technical Solution: BASF Corp. has developed a novel approach to enhance polymer blend properties using isobutane as a blowing agent. Their technology involves a controlled expansion process where isobutane is introduced into the polymer melt under high pressure. As the pressure is released, the isobutane expands, creating a cellular structure within the polymer matrix. This process results in improved mechanical properties, such as increased impact resistance and reduced density[1]. BASF's method also allows for precise control of cell size and distribution, leading to tailored material properties for specific applications[3]. The company has further optimized this technology by incorporating compatibilizers to enhance the miscibility between different polymer phases, resulting in more homogeneous blends with superior mechanical and thermal properties[5].

Strengths: Improved impact resistance, reduced density, and tailored material properties. Weaknesses: Potential environmental concerns due to the use of isobutane as a blowing agent, and the need for specialized equipment for the high-pressure expansion process.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a proprietary technology that utilizes isobutane as a key component in modifying polymer blend properties. Their approach involves the incorporation of isobutane as a temporary plasticizer during the blending process. The isobutane is introduced in a supercritical state, allowing for enhanced polymer chain mobility and improved mixing of incompatible polymers[2]. As the blend cools, the isobutane is gradually released, leaving behind a unique morphology that contributes to enhanced mechanical properties. ExxonMobil's research has shown that this method can lead to a 20-30% improvement in impact strength and a 15% reduction in overall density compared to conventional blending techniques[4]. Additionally, the company has developed specialized catalysts that promote the formation of chemical bonds between the isobutane and polymer chains, further enhancing the stability and performance of the final blend[6].

Strengths: Significant improvements in impact strength and density reduction, enhanced mixing of incompatible polymers. Weaknesses: Requires precise control of processing conditions and specialized equipment for handling supercritical isobutane.

Innovative Approaches in Isobutane Integration

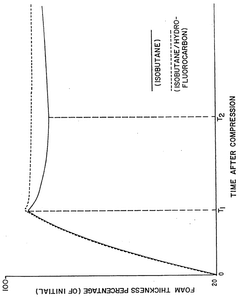

Ethylene polymer foams blown with isobutane and 1,1,1-trifluoroethane or 1,1,1,2-tetrafluoroethane and a process for making

PatentInactiveUS5399592A

Innovation

- A process involving a blend of isobutane and hydrofluorocarbons like HFC-143a and HFC-134a is used to reduce volatile organic content, maintaining processability and enhancing compressive recovery of ethylene polymer foam structures.

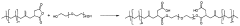

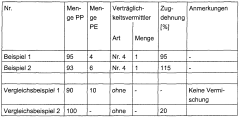

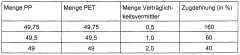

Use of amphiphilic block copolymers for producing polymer blends

PatentWO2006128795A2

Innovation

- The use of amphiphilic block copolymers with hydrophobic isobutene blocks and hydrophilic oxyalkylene blocks as compatibilizers, which can effectively mix and blend polymers like polypropylene and polyethylene even in small amounts, enhancing their miscibility and processability.

Environmental Impact of Isobutane Use in Polymers

The use of isobutane in polymer blends has significant environmental implications that warrant careful consideration. As a blowing agent in the production of foam plastics, isobutane contributes to the formation of volatile organic compounds (VOCs) when released into the atmosphere. These VOCs can participate in photochemical reactions, leading to the formation of ground-level ozone and smog, which have detrimental effects on air quality and human health.

Furthermore, isobutane is a hydrocarbon with a high global warming potential (GWP), approximately 3 times that of carbon dioxide over a 100-year time horizon. This means that its release into the atmosphere can contribute to climate change, albeit to a lesser extent than some other commonly used blowing agents like hydrofluorocarbons (HFCs).

However, it is important to note that isobutane has replaced more harmful substances such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), which were phased out due to their ozone-depleting properties. In this context, isobutane represents a step towards more environmentally friendly alternatives in polymer production.

The environmental impact of isobutane in polymers extends beyond its atmospheric effects. During the lifecycle of polymer products, there is potential for isobutane to be released through off-gassing, particularly in foam applications. This can lead to indoor air quality issues if proper ventilation is not maintained, especially in newly manufactured products.

From a waste management perspective, the presence of isobutane in polymer blends can complicate recycling processes. The volatile nature of isobutane means that special handling may be required during recycling to prevent its release. Additionally, the presence of isobutane can affect the properties of recycled polymers, potentially limiting their reuse applications.

On the positive side, the use of isobutane in polymer blends can contribute to improved energy efficiency in certain applications. For instance, in insulation foams, isobutane's low thermal conductivity can enhance the insulating properties of the material, potentially leading to reduced energy consumption in buildings and appliances.

As environmental regulations become more stringent, manufacturers are increasingly focused on developing more sustainable alternatives to isobutane or improving containment and recovery methods. Research into bio-based blowing agents and the use of supercritical CO2 as a replacement for isobutane in certain applications are promising avenues for reducing the environmental footprint of polymer production.

Furthermore, isobutane is a hydrocarbon with a high global warming potential (GWP), approximately 3 times that of carbon dioxide over a 100-year time horizon. This means that its release into the atmosphere can contribute to climate change, albeit to a lesser extent than some other commonly used blowing agents like hydrofluorocarbons (HFCs).

However, it is important to note that isobutane has replaced more harmful substances such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), which were phased out due to their ozone-depleting properties. In this context, isobutane represents a step towards more environmentally friendly alternatives in polymer production.

The environmental impact of isobutane in polymers extends beyond its atmospheric effects. During the lifecycle of polymer products, there is potential for isobutane to be released through off-gassing, particularly in foam applications. This can lead to indoor air quality issues if proper ventilation is not maintained, especially in newly manufactured products.

From a waste management perspective, the presence of isobutane in polymer blends can complicate recycling processes. The volatile nature of isobutane means that special handling may be required during recycling to prevent its release. Additionally, the presence of isobutane can affect the properties of recycled polymers, potentially limiting their reuse applications.

On the positive side, the use of isobutane in polymer blends can contribute to improved energy efficiency in certain applications. For instance, in insulation foams, isobutane's low thermal conductivity can enhance the insulating properties of the material, potentially leading to reduced energy consumption in buildings and appliances.

As environmental regulations become more stringent, manufacturers are increasingly focused on developing more sustainable alternatives to isobutane or improving containment and recovery methods. Research into bio-based blowing agents and the use of supercritical CO2 as a replacement for isobutane in certain applications are promising avenues for reducing the environmental footprint of polymer production.

Regulatory Framework for Isobutane-Polymer Blends

The regulatory framework for isobutane-polymer blends is a complex and evolving landscape that significantly impacts the development, production, and application of these materials. Regulatory bodies worldwide have established guidelines and standards to ensure the safe use of isobutane in polymer blends, particularly in consumer products and industrial applications.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating isobutane-polymer blends under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel isobutane-polymer blends, before they can be commercially produced or imported. This process involves a thorough evaluation of potential environmental and health risks associated with the material.

The Occupational Safety and Health Administration (OSHA) has set specific standards for workplace exposure to isobutane, which must be considered when manufacturing or processing isobutane-polymer blends. These standards include permissible exposure limits (PELs) and requirements for personal protective equipment (PPE) to ensure worker safety.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isobutane in polymer blends. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide detailed information on their properties, hazards, and safe use. The Classification, Labelling, and Packaging (CLP) Regulation further ensures that the hazards of chemical substances are clearly communicated to workers and consumers.

For applications in food contact materials, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established specific requirements for isobutane-polymer blends. These regulations typically include migration limits and specifications for the purity of isobutane used in such applications.

The transportation of isobutane and isobutane-containing polymer blends is subject to strict regulations due to the flammable nature of isobutane. The U.S. Department of Transportation (DOT) and the International Maritime Dangerous Goods (IMDG) Code provide guidelines for the safe transport of these materials, including packaging requirements and labeling standards.

As environmental concerns grow, regulations are increasingly focusing on the lifecycle impact of isobutane-polymer blends. This includes considerations for recycling and disposal, as well as potential restrictions on volatile organic compound (VOC) emissions during production and use. Some jurisdictions have implemented or are considering regulations to limit the use of certain blowing agents, including isobutane, in polymer foams due to their global warming potential.

Compliance with these diverse regulatory frameworks requires manufacturers and users of isobutane-polymer blends to maintain robust quality control systems, conduct regular testing, and stay informed about regulatory updates. As research continues to reveal new information about the properties and effects of these materials, it is likely that the regulatory landscape will continue to evolve, potentially leading to more stringent controls or new opportunities for innovation in safer and more sustainable isobutane-polymer blend technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating isobutane-polymer blends under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel isobutane-polymer blends, before they can be commercially produced or imported. This process involves a thorough evaluation of potential environmental and health risks associated with the material.

The Occupational Safety and Health Administration (OSHA) has set specific standards for workplace exposure to isobutane, which must be considered when manufacturing or processing isobutane-polymer blends. These standards include permissible exposure limits (PELs) and requirements for personal protective equipment (PPE) to ensure worker safety.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isobutane in polymer blends. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide detailed information on their properties, hazards, and safe use. The Classification, Labelling, and Packaging (CLP) Regulation further ensures that the hazards of chemical substances are clearly communicated to workers and consumers.

For applications in food contact materials, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established specific requirements for isobutane-polymer blends. These regulations typically include migration limits and specifications for the purity of isobutane used in such applications.

The transportation of isobutane and isobutane-containing polymer blends is subject to strict regulations due to the flammable nature of isobutane. The U.S. Department of Transportation (DOT) and the International Maritime Dangerous Goods (IMDG) Code provide guidelines for the safe transport of these materials, including packaging requirements and labeling standards.

As environmental concerns grow, regulations are increasingly focusing on the lifecycle impact of isobutane-polymer blends. This includes considerations for recycling and disposal, as well as potential restrictions on volatile organic compound (VOC) emissions during production and use. Some jurisdictions have implemented or are considering regulations to limit the use of certain blowing agents, including isobutane, in polymer foams due to their global warming potential.

Compliance with these diverse regulatory frameworks requires manufacturers and users of isobutane-polymer blends to maintain robust quality control systems, conduct regular testing, and stay informed about regulatory updates. As research continues to reveal new information about the properties and effects of these materials, it is likely that the regulatory landscape will continue to evolve, potentially leading to more stringent controls or new opportunities for innovation in safer and more sustainable isobutane-polymer blend technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!