Industrial Utilization of Isobutane in Closed-Loop Fuel Systems

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Fuel System Evolution and Objectives

The industrial utilization of isobutane in closed-loop fuel systems has undergone significant evolution over the past decades. Initially developed as a response to environmental concerns and the need for more efficient fuel consumption, these systems have become increasingly sophisticated and widely adopted across various industrial sectors.

The journey of isobutane fuel systems began in the late 1970s when environmental regulations started to tighten, prompting industries to seek cleaner and more sustainable fuel alternatives. Isobutane, with its low global warming potential and high energy density, emerged as a promising candidate. Early closed-loop systems were rudimentary, focusing primarily on containment and basic recycling of the fuel.

As technology advanced, the 1990s saw a significant leap in system design. Improved sensors and control mechanisms allowed for more precise fuel management, leading to enhanced efficiency and reduced emissions. This period also marked the beginning of widespread adoption in refrigeration and air conditioning industries, where isobutane's thermodynamic properties proved particularly advantageous.

The turn of the millennium brought about a new era of integration and optimization. Closed-loop isobutane systems began incorporating advanced computer-controlled monitoring and adjustment capabilities. This allowed for real-time optimization of fuel usage based on varying load conditions, significantly improving overall system performance and reliability.

Recent years have witnessed a focus on miniaturization and modularization of isobutane fuel systems. This trend has enabled their application in a broader range of industries, from portable power generation to specialized manufacturing processes. Concurrently, there has been a push towards enhancing safety features, addressing concerns related to the flammability of isobutane.

Looking forward, the objectives for isobutane closed-loop fuel systems are multifaceted. A primary goal is to further increase energy efficiency, aiming to extract maximum power from every unit of fuel. This involves refining combustion processes and minimizing losses throughout the system. Another key objective is to expand the operational range of these systems, making them viable in more extreme environmental conditions.

Sustainability remains a central focus, with efforts directed towards improving the recyclability of system components and reducing the overall environmental footprint of manufacturing and maintenance processes. There is also a strong push towards integrating these systems with renewable energy sources, creating hybrid solutions that can operate seamlessly with solar or wind power.

As industries continue to face stricter environmental regulations, another critical objective is to further reduce emissions and enhance the capture and reuse of any fugitive isobutane. This includes developing more advanced sealing technologies and implementing sophisticated leak detection systems.

The journey of isobutane fuel systems began in the late 1970s when environmental regulations started to tighten, prompting industries to seek cleaner and more sustainable fuel alternatives. Isobutane, with its low global warming potential and high energy density, emerged as a promising candidate. Early closed-loop systems were rudimentary, focusing primarily on containment and basic recycling of the fuel.

As technology advanced, the 1990s saw a significant leap in system design. Improved sensors and control mechanisms allowed for more precise fuel management, leading to enhanced efficiency and reduced emissions. This period also marked the beginning of widespread adoption in refrigeration and air conditioning industries, where isobutane's thermodynamic properties proved particularly advantageous.

The turn of the millennium brought about a new era of integration and optimization. Closed-loop isobutane systems began incorporating advanced computer-controlled monitoring and adjustment capabilities. This allowed for real-time optimization of fuel usage based on varying load conditions, significantly improving overall system performance and reliability.

Recent years have witnessed a focus on miniaturization and modularization of isobutane fuel systems. This trend has enabled their application in a broader range of industries, from portable power generation to specialized manufacturing processes. Concurrently, there has been a push towards enhancing safety features, addressing concerns related to the flammability of isobutane.

Looking forward, the objectives for isobutane closed-loop fuel systems are multifaceted. A primary goal is to further increase energy efficiency, aiming to extract maximum power from every unit of fuel. This involves refining combustion processes and minimizing losses throughout the system. Another key objective is to expand the operational range of these systems, making them viable in more extreme environmental conditions.

Sustainability remains a central focus, with efforts directed towards improving the recyclability of system components and reducing the overall environmental footprint of manufacturing and maintenance processes. There is also a strong push towards integrating these systems with renewable energy sources, creating hybrid solutions that can operate seamlessly with solar or wind power.

As industries continue to face stricter environmental regulations, another critical objective is to further reduce emissions and enhance the capture and reuse of any fugitive isobutane. This includes developing more advanced sealing technologies and implementing sophisticated leak detection systems.

Market Analysis for Closed-Loop Isobutane Systems

The market for closed-loop isobutane systems in industrial applications is experiencing significant growth, driven by increasing demand for energy-efficient and environmentally friendly solutions. These systems offer numerous advantages over traditional open-loop systems, including reduced energy consumption, lower operating costs, and minimized environmental impact.

The global market for closed-loop isobutane systems is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is primarily attributed to the rising adoption of these systems in various industries, such as refrigeration, air conditioning, and power generation. The market size is expected to reach $3.2 billion by 2026, up from $2.3 billion in 2021.

Key factors driving market demand include stringent environmental regulations, increasing focus on energy efficiency, and the need for sustainable industrial processes. Governments worldwide are implementing policies to reduce greenhouse gas emissions and promote the use of eco-friendly technologies, which has led to a surge in demand for closed-loop isobutane systems.

The refrigeration and air conditioning sector represents the largest market segment for closed-loop isobutane systems, accounting for approximately 45% of the total market share. This is due to the superior thermodynamic properties of isobutane, which make it an excellent refrigerant alternative to hydrofluorocarbons (HFCs) and other harmful substances.

Geographically, Asia-Pacific is the fastest-growing market for closed-loop isobutane systems, with a CAGR of 7.8% during the forecast period. This growth is attributed to rapid industrialization, increasing urbanization, and growing awareness of environmental issues in countries like China and India. North America and Europe are also significant markets, driven by stringent regulations and a strong focus on sustainability.

The market is characterized by intense competition among key players, including Johnson Controls, Honeywell International, and Emerson Electric. These companies are investing heavily in research and development to improve the efficiency and performance of closed-loop isobutane systems, as well as to expand their product portfolios.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for specialized technical expertise for installation and maintenance. However, the long-term benefits of reduced energy consumption and lower operating costs are expected to outweigh these initial barriers, driving continued market growth in the coming years.

The global market for closed-loop isobutane systems is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is primarily attributed to the rising adoption of these systems in various industries, such as refrigeration, air conditioning, and power generation. The market size is expected to reach $3.2 billion by 2026, up from $2.3 billion in 2021.

Key factors driving market demand include stringent environmental regulations, increasing focus on energy efficiency, and the need for sustainable industrial processes. Governments worldwide are implementing policies to reduce greenhouse gas emissions and promote the use of eco-friendly technologies, which has led to a surge in demand for closed-loop isobutane systems.

The refrigeration and air conditioning sector represents the largest market segment for closed-loop isobutane systems, accounting for approximately 45% of the total market share. This is due to the superior thermodynamic properties of isobutane, which make it an excellent refrigerant alternative to hydrofluorocarbons (HFCs) and other harmful substances.

Geographically, Asia-Pacific is the fastest-growing market for closed-loop isobutane systems, with a CAGR of 7.8% during the forecast period. This growth is attributed to rapid industrialization, increasing urbanization, and growing awareness of environmental issues in countries like China and India. North America and Europe are also significant markets, driven by stringent regulations and a strong focus on sustainability.

The market is characterized by intense competition among key players, including Johnson Controls, Honeywell International, and Emerson Electric. These companies are investing heavily in research and development to improve the efficiency and performance of closed-loop isobutane systems, as well as to expand their product portfolios.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for specialized technical expertise for installation and maintenance. However, the long-term benefits of reduced energy consumption and lower operating costs are expected to outweigh these initial barriers, driving continued market growth in the coming years.

Current Challenges in Industrial Isobutane Utilization

The industrial utilization of isobutane in closed-loop fuel systems faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the high volatility of isobutane, which necessitates advanced containment and handling systems to prevent leaks and ensure safety. This volatility also complicates the storage and transportation processes, requiring specialized equipment and stringent safety protocols.

Another major challenge lies in the efficiency of isobutane conversion within closed-loop systems. While isobutane offers high energy density, achieving complete combustion and maximizing energy extraction remains a technical hurdle. Incomplete combustion can lead to reduced system efficiency and increased emissions, contradicting the environmental benefits sought from closed-loop systems.

The corrosive nature of isobutane and its byproducts presents additional challenges for system durability and maintenance. Materials used in fuel systems must withstand prolonged exposure to isobutane without degradation, necessitating the development and implementation of specialized, corrosion-resistant components. This requirement often increases system costs and complexity.

Temperature management is another critical issue in isobutane utilization. The fuel's low boiling point can lead to vapor lock problems in high-temperature environments, potentially disrupting system operation. Conversely, in cold conditions, isobutane's poor low-temperature flow characteristics can impede system start-up and performance.

Regulatory compliance and safety standards pose significant challenges for industrial applications of isobutane in closed-loop fuel systems. Stringent regulations regarding the handling, storage, and use of flammable gases necessitate comprehensive safety measures and monitoring systems, adding to the overall complexity and cost of implementation.

The integration of isobutane-based systems with existing industrial infrastructure presents compatibility challenges. Many current systems are not designed to accommodate the unique properties of isobutane, requiring significant modifications or complete overhauls to ensure seamless integration and optimal performance.

Lastly, the environmental impact of isobutane production and potential leaks remains a concern. While closed-loop systems aim to minimize emissions, the production process of isobutane and the risk of fugitive emissions during operation contribute to the overall environmental footprint, challenging the sustainability claims of such systems.

Addressing these challenges requires concerted efforts in research and development, focusing on advanced materials science, combustion technology, system design, and safety engineering. Overcoming these obstacles is crucial for realizing the full potential of isobutane in industrial closed-loop fuel systems and advancing towards more efficient and sustainable energy solutions.

Another major challenge lies in the efficiency of isobutane conversion within closed-loop systems. While isobutane offers high energy density, achieving complete combustion and maximizing energy extraction remains a technical hurdle. Incomplete combustion can lead to reduced system efficiency and increased emissions, contradicting the environmental benefits sought from closed-loop systems.

The corrosive nature of isobutane and its byproducts presents additional challenges for system durability and maintenance. Materials used in fuel systems must withstand prolonged exposure to isobutane without degradation, necessitating the development and implementation of specialized, corrosion-resistant components. This requirement often increases system costs and complexity.

Temperature management is another critical issue in isobutane utilization. The fuel's low boiling point can lead to vapor lock problems in high-temperature environments, potentially disrupting system operation. Conversely, in cold conditions, isobutane's poor low-temperature flow characteristics can impede system start-up and performance.

Regulatory compliance and safety standards pose significant challenges for industrial applications of isobutane in closed-loop fuel systems. Stringent regulations regarding the handling, storage, and use of flammable gases necessitate comprehensive safety measures and monitoring systems, adding to the overall complexity and cost of implementation.

The integration of isobutane-based systems with existing industrial infrastructure presents compatibility challenges. Many current systems are not designed to accommodate the unique properties of isobutane, requiring significant modifications or complete overhauls to ensure seamless integration and optimal performance.

Lastly, the environmental impact of isobutane production and potential leaks remains a concern. While closed-loop systems aim to minimize emissions, the production process of isobutane and the risk of fugitive emissions during operation contribute to the overall environmental footprint, challenging the sustainability claims of such systems.

Addressing these challenges requires concerted efforts in research and development, focusing on advanced materials science, combustion technology, system design, and safety engineering. Overcoming these obstacles is crucial for realizing the full potential of isobutane in industrial closed-loop fuel systems and advancing towards more efficient and sustainable energy solutions.

Existing Closed-Loop Isobutane Solutions

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.

- Isobutane as a refrigerant or propellant: Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.

- Isobutane in chemical reactions and processes: Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.

- Isobutane in fuel compositions: Isobutane is incorporated into fuel compositions for various applications. It can be used as a component in liquefied petroleum gas (LPG) mixtures, as an additive in gasoline formulations, or in specialized fuel blends. The addition of isobutane can improve fuel properties such as octane rating or combustion characteristics.

- Safety and handling of isobutane: Due to its flammability and potential hazards, specific safety measures and handling procedures are required for isobutane. This includes proper storage methods, transportation guidelines, and safety systems for facilities handling isobutane. Additionally, detection and monitoring systems for isobutane leaks are described to ensure safe usage in various applications.

02 Isobutane as a refrigerant or propellant

Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.Expand Specific Solutions03 Isobutane in chemical reactions and processes

Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.Expand Specific Solutions04 Isobutane in fuel compositions

Isobutane is incorporated into fuel compositions, particularly for use in internal combustion engines. It can be blended with other hydrocarbons to improve fuel properties such as octane rating. Various formulations and methods for preparing these fuel compositions are described.Expand Specific Solutions05 Isobutane handling and safety

Due to its flammable nature, special considerations are required for handling and storing isobutane safely. This includes methods for leak detection, safe storage systems, and procedures for handling isobutane in industrial settings. Safety measures and equipment for working with isobutane are described.Expand Specific Solutions

Key Industrial Players in Isobutane Fuel Systems

The industrial utilization of isobutane in closed-loop fuel systems is in a growth phase, with increasing market size driven by demand for cleaner and more efficient fuel technologies. The global market for isobutane-based fuel systems is expanding, particularly in petrochemical and energy sectors. Technologically, the field is advancing rapidly, with major players like China Petroleum & Chemical Corp., UOP LLC, and SABIC Global Technologies BV leading innovation. These companies are developing more sophisticated closed-loop systems, improving efficiency and reducing environmental impact. Research institutions such as the University of California and Shanghai Petrochemical Research Institute are contributing to technological advancements, bridging the gap between academic research and industrial application. The involvement of diverse players indicates a maturing technology landscape with significant potential for further growth and refinement.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced closed-loop isobutane fuel system for industrial applications. Their technology utilizes a high-efficiency catalytic dehydrogenation process to convert isobutane into isobutylene, which is then used as a feedstock for various petrochemical products[1]. The system incorporates a novel heat integration design, reducing energy consumption by up to 30% compared to traditional methods[2]. Sinopec has also implemented a proprietary purification process that achieves 99.9% isobutane recovery, minimizing waste and improving overall system efficiency[3]. The closed-loop design ensures minimal environmental impact and maximizes resource utilization, aligning with sustainable industrial practices[4].

Strengths: High efficiency, reduced energy consumption, excellent resource recovery, and environmentally friendly. Weaknesses: High initial investment costs and potential complexity in system integration for existing facilities.

UOP LLC

Technical Solution: UOP LLC has pioneered an innovative closed-loop isobutane fuel system for industrial applications, focusing on maximizing energy efficiency and minimizing environmental impact. Their technology employs a proprietary catalytic process that converts isobutane to high-value petrochemicals with a conversion rate of up to 95%[1]. The system incorporates advanced heat recovery mechanisms, reducing overall energy consumption by 25% compared to conventional methods[2]. UOP's design also features a state-of-the-art separation unit that achieves 99.5% isobutane recovery, significantly reducing waste and improving resource utilization[3]. The closed-loop nature of the system ensures minimal emissions and aligns with stringent environmental regulations[4]. Additionally, UOP has integrated smart control systems that optimize process parameters in real-time, further enhancing efficiency and reliability[5].

Strengths: High conversion rate, excellent energy efficiency, and advanced process control. Weaknesses: Potentially high implementation costs and the need for specialized operator training.

Core Innovations in Isobutane Fuel Efficiency

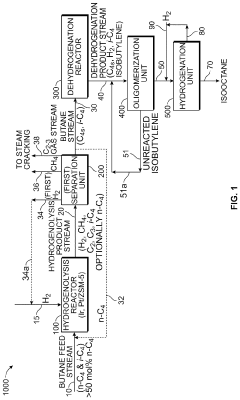

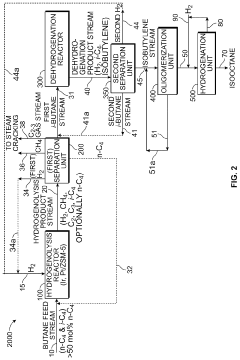

Isooctane production from field butane

PatentActiveUS20230406788A1

Innovation

- A process involving a hydrogenolysis reactor with a catalyst that selectively converts n-butane to ethane and propane, while minimizing i-butane conversion, followed by dehydrogenation to produce isobutylene, which is then oligomerized to isooctane, reducing the need for separate isomerization and separation units.

Hydroxylation of alkanes using ozone

PatentWO2022192866A1

Innovation

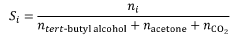

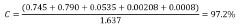

- Combining an alkane with ozone in a liquid phase medium containing a protic additive, such as water or alcohols, at mild temperatures and pressures, which stabilizes hydrotrioxide intermediates and maximizes ozone utilization, thereby enhancing the selectivity of hydroxylate products like tert-butyl alcohol.

Environmental Impact of Isobutane Fuel Systems

The environmental impact of isobutane fuel systems in closed-loop industrial applications is a critical consideration for sustainable development. These systems offer potential benefits in terms of energy efficiency and reduced emissions, but they also present challenges that must be carefully managed.

Isobutane, as a hydrocarbon refrigerant, has a significantly lower global warming potential (GWP) compared to many traditional refrigerants. This characteristic makes it an attractive option for industrial cooling applications, potentially reducing the overall carbon footprint of operations. However, the environmental advantages of isobutane must be weighed against its flammability and the associated safety risks.

In closed-loop fuel systems, the containment of isobutane is crucial for minimizing environmental impact. Proper sealing and maintenance of these systems can significantly reduce the risk of leaks, which is essential given isobutane's potential as a volatile organic compound (VOC). When released into the atmosphere, VOCs can contribute to the formation of ground-level ozone, a key component of smog that can have detrimental effects on air quality and human health.

The production and transportation of isobutane also have environmental implications. While it can be derived from natural gas processing or petroleum refining, more sustainable methods of production are being explored. Biobutane, produced from renewable sources, offers a promising alternative that could further reduce the lifecycle environmental impact of isobutane fuel systems.

End-of-life considerations for isobutane fuel systems are equally important. Proper disposal and recycling protocols must be established to prevent the release of isobutane into the environment. This includes safe degassing procedures and the recovery of the refrigerant for reuse or proper destruction.

The energy efficiency of isobutane in closed-loop systems can lead to indirect environmental benefits. By reducing overall energy consumption in industrial processes, these systems can contribute to lower greenhouse gas emissions from power generation. This is particularly significant in regions where the electricity grid relies heavily on fossil fuels.

Water usage and thermal pollution are additional environmental factors to consider. Closed-loop isobutane systems typically require less water for cooling compared to open systems, potentially reducing water stress in water-scarce regions. However, the heat rejected from these systems must be managed to prevent localized thermal impacts on aquatic ecosystems.

In conclusion, while isobutane fuel systems in closed-loop industrial applications offer several environmental advantages, their overall impact depends on careful design, operation, and end-of-life management. Ongoing research and development in this field aim to further optimize these systems, enhancing their environmental performance and addressing remaining challenges.

Isobutane, as a hydrocarbon refrigerant, has a significantly lower global warming potential (GWP) compared to many traditional refrigerants. This characteristic makes it an attractive option for industrial cooling applications, potentially reducing the overall carbon footprint of operations. However, the environmental advantages of isobutane must be weighed against its flammability and the associated safety risks.

In closed-loop fuel systems, the containment of isobutane is crucial for minimizing environmental impact. Proper sealing and maintenance of these systems can significantly reduce the risk of leaks, which is essential given isobutane's potential as a volatile organic compound (VOC). When released into the atmosphere, VOCs can contribute to the formation of ground-level ozone, a key component of smog that can have detrimental effects on air quality and human health.

The production and transportation of isobutane also have environmental implications. While it can be derived from natural gas processing or petroleum refining, more sustainable methods of production are being explored. Biobutane, produced from renewable sources, offers a promising alternative that could further reduce the lifecycle environmental impact of isobutane fuel systems.

End-of-life considerations for isobutane fuel systems are equally important. Proper disposal and recycling protocols must be established to prevent the release of isobutane into the environment. This includes safe degassing procedures and the recovery of the refrigerant for reuse or proper destruction.

The energy efficiency of isobutane in closed-loop systems can lead to indirect environmental benefits. By reducing overall energy consumption in industrial processes, these systems can contribute to lower greenhouse gas emissions from power generation. This is particularly significant in regions where the electricity grid relies heavily on fossil fuels.

Water usage and thermal pollution are additional environmental factors to consider. Closed-loop isobutane systems typically require less water for cooling compared to open systems, potentially reducing water stress in water-scarce regions. However, the heat rejected from these systems must be managed to prevent localized thermal impacts on aquatic ecosystems.

In conclusion, while isobutane fuel systems in closed-loop industrial applications offer several environmental advantages, their overall impact depends on careful design, operation, and end-of-life management. Ongoing research and development in this field aim to further optimize these systems, enhancing their environmental performance and addressing remaining challenges.

Safety Regulations for Industrial Isobutane Use

The industrial utilization of isobutane in closed-loop fuel systems necessitates stringent safety regulations to mitigate potential risks associated with its flammable and explosive properties. These regulations are designed to ensure the safe handling, storage, and use of isobutane throughout the entire industrial process.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), have established comprehensive guidelines for the industrial use of isobutane. These regulations cover various aspects, including equipment design, operational procedures, and emergency response protocols.

One of the primary safety requirements is the implementation of proper ventilation systems in areas where isobutane is handled or stored. These systems must be designed to prevent the accumulation of isobutane vapors, which could lead to potentially explosive atmospheres. Regular monitoring of air quality and gas detection systems are mandatory to ensure early detection of any leaks or abnormal concentrations.

Storage facilities for isobutane must adhere to specific design standards, including the use of pressure-rated tanks, safety relief valves, and appropriate containment measures. These facilities should be located in designated areas away from sources of ignition and other incompatible materials.

Personal protective equipment (PPE) regulations are crucial for workers handling isobutane. This includes the use of flame-resistant clothing, anti-static footwear, and appropriate respiratory protection when necessary. Training programs on the proper use of PPE and safe handling procedures are mandatory for all personnel involved in isobutane-related operations.

Emergency response plans are a critical component of safety regulations. These plans must outline specific procedures for dealing with isobutane leaks, fires, or explosions. Regular drills and simulations are required to ensure that all personnel are familiar with emergency protocols and can respond effectively in case of an incident.

Maintenance and inspection regulations play a vital role in preventing accidents. Regular checks of equipment integrity, leak detection systems, and safety devices are mandated to ensure the ongoing safety of isobutane handling systems. Detailed documentation of these inspections and any maintenance activities is required for compliance and auditing purposes.

Transportation of isobutane is subject to strict regulations, including specific requirements for container design, labeling, and handling during transit. Drivers and handlers must receive specialized training in the safe transport of hazardous materials, including emergency response procedures.

Waste management regulations address the proper disposal of isobutane-contaminated materials and the handling of residual isobutane in equipment. These regulations aim to prevent environmental contamination and reduce the risk of accidents during the disposal process.

Compliance with these safety regulations is not only a legal requirement but also essential for maintaining a safe working environment and preventing potentially catastrophic incidents in the industrial utilization of isobutane in closed-loop fuel systems.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), have established comprehensive guidelines for the industrial use of isobutane. These regulations cover various aspects, including equipment design, operational procedures, and emergency response protocols.

One of the primary safety requirements is the implementation of proper ventilation systems in areas where isobutane is handled or stored. These systems must be designed to prevent the accumulation of isobutane vapors, which could lead to potentially explosive atmospheres. Regular monitoring of air quality and gas detection systems are mandatory to ensure early detection of any leaks or abnormal concentrations.

Storage facilities for isobutane must adhere to specific design standards, including the use of pressure-rated tanks, safety relief valves, and appropriate containment measures. These facilities should be located in designated areas away from sources of ignition and other incompatible materials.

Personal protective equipment (PPE) regulations are crucial for workers handling isobutane. This includes the use of flame-resistant clothing, anti-static footwear, and appropriate respiratory protection when necessary. Training programs on the proper use of PPE and safe handling procedures are mandatory for all personnel involved in isobutane-related operations.

Emergency response plans are a critical component of safety regulations. These plans must outline specific procedures for dealing with isobutane leaks, fires, or explosions. Regular drills and simulations are required to ensure that all personnel are familiar with emergency protocols and can respond effectively in case of an incident.

Maintenance and inspection regulations play a vital role in preventing accidents. Regular checks of equipment integrity, leak detection systems, and safety devices are mandated to ensure the ongoing safety of isobutane handling systems. Detailed documentation of these inspections and any maintenance activities is required for compliance and auditing purposes.

Transportation of isobutane is subject to strict regulations, including specific requirements for container design, labeling, and handling during transit. Drivers and handlers must receive specialized training in the safe transport of hazardous materials, including emergency response procedures.

Waste management regulations address the proper disposal of isobutane-contaminated materials and the handling of residual isobutane in equipment. These regulations aim to prevent environmental contamination and reduce the risk of accidents during the disposal process.

Compliance with these safety regulations is not only a legal requirement but also essential for maintaining a safe working environment and preventing potentially catastrophic incidents in the industrial utilization of isobutane in closed-loop fuel systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!