How Isobutane Improves the Flexibility of Synthetic Fibers

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane in Fiber Flexibility: Background and Objectives

Synthetic fibers have revolutionized the textile industry since their introduction in the early 20th century. These man-made fibers, derived from petrochemicals or regenerated cellulose, offer unique properties that natural fibers cannot match. However, one of the persistent challenges in synthetic fiber production has been achieving optimal flexibility without compromising strength or durability.

The use of isobutane in enhancing the flexibility of synthetic fibers represents a significant technological advancement in this field. Isobutane, a branched alkane with the molecular formula C4H10, has emerged as a promising additive in the fiber manufacturing process. Its unique molecular structure and chemical properties make it an ideal candidate for modifying the characteristics of synthetic polymers used in fiber production.

The primary objective of incorporating isobutane into synthetic fiber production is to improve the overall flexibility and elasticity of the resulting fibers. This enhancement is crucial for various applications, ranging from clothing and upholstery to industrial textiles and medical fabrics. Increased flexibility translates to improved comfort, better drape, and enhanced performance in dynamic environments.

Historically, the development of flexible synthetic fibers has been a gradual process. Early synthetic fibers were often criticized for their rigidity and lack of natural feel. The introduction of various plasticizers and chemical treatments improved flexibility to some extent, but often at the cost of other desirable properties. The use of isobutane represents a new approach that aims to address these limitations.

The technological evolution leading to the use of isobutane in fiber flexibility is rooted in polymer science and materials engineering. Researchers have long sought ways to manipulate the molecular structure of synthetic polymers to achieve specific physical properties. The discovery of isobutane's potential in this context is part of a broader trend in exploring hydrocarbon additives for polymer modification.

Understanding how isobutane improves fiber flexibility requires delving into the molecular interactions between the isobutane molecules and the polymer chains that make up synthetic fibers. This interaction is believed to alter the spacing and mobility of polymer chains, resulting in increased overall flexibility of the fiber structure.

The goals of this technological application extend beyond mere flexibility enhancement. Researchers and industry professionals are exploring how isobutane-modified fibers can contribute to the development of smart textiles, responsive materials, and high-performance fabrics. The potential applications span diverse sectors, including sports apparel, protective gear, and medical textiles.

As we examine the role of isobutane in improving synthetic fiber flexibility, it is essential to consider the broader implications for the textile industry and related fields. This technology has the potential to redefine the properties and applications of synthetic fibers, opening new avenues for innovation and product development.

The use of isobutane in enhancing the flexibility of synthetic fibers represents a significant technological advancement in this field. Isobutane, a branched alkane with the molecular formula C4H10, has emerged as a promising additive in the fiber manufacturing process. Its unique molecular structure and chemical properties make it an ideal candidate for modifying the characteristics of synthetic polymers used in fiber production.

The primary objective of incorporating isobutane into synthetic fiber production is to improve the overall flexibility and elasticity of the resulting fibers. This enhancement is crucial for various applications, ranging from clothing and upholstery to industrial textiles and medical fabrics. Increased flexibility translates to improved comfort, better drape, and enhanced performance in dynamic environments.

Historically, the development of flexible synthetic fibers has been a gradual process. Early synthetic fibers were often criticized for their rigidity and lack of natural feel. The introduction of various plasticizers and chemical treatments improved flexibility to some extent, but often at the cost of other desirable properties. The use of isobutane represents a new approach that aims to address these limitations.

The technological evolution leading to the use of isobutane in fiber flexibility is rooted in polymer science and materials engineering. Researchers have long sought ways to manipulate the molecular structure of synthetic polymers to achieve specific physical properties. The discovery of isobutane's potential in this context is part of a broader trend in exploring hydrocarbon additives for polymer modification.

Understanding how isobutane improves fiber flexibility requires delving into the molecular interactions between the isobutane molecules and the polymer chains that make up synthetic fibers. This interaction is believed to alter the spacing and mobility of polymer chains, resulting in increased overall flexibility of the fiber structure.

The goals of this technological application extend beyond mere flexibility enhancement. Researchers and industry professionals are exploring how isobutane-modified fibers can contribute to the development of smart textiles, responsive materials, and high-performance fabrics. The potential applications span diverse sectors, including sports apparel, protective gear, and medical textiles.

As we examine the role of isobutane in improving synthetic fiber flexibility, it is essential to consider the broader implications for the textile industry and related fields. This technology has the potential to redefine the properties and applications of synthetic fibers, opening new avenues for innovation and product development.

Market Analysis for Flexible Synthetic Fibers

The market for flexible synthetic fibers has experienced significant growth in recent years, driven by increasing demand across various industries. The incorporation of isobutane in the production process has revolutionized the flexibility and performance of these fibers, opening up new applications and market opportunities.

In the textile industry, flexible synthetic fibers enhanced with isobutane have gained substantial traction. These fibers offer improved comfort, durability, and moisture-wicking properties, making them ideal for sportswear, athleisure, and high-performance apparel. The global sportswear market, valued at $181 billion in 2022, is expected to grow at a CAGR of 5.1% from 2023 to 2030, presenting a substantial opportunity for flexible synthetic fibers.

The automotive sector has also embraced flexible synthetic fibers for interior applications, such as seat covers, headliners, and carpets. The automotive interiors market is projected to reach $153.8 billion by 2025, growing at a CAGR of 4.2% from 2020 to 2025. The enhanced flexibility and durability of isobutane-treated fibers contribute to improved comfort and longevity of automotive interiors.

In the medical and healthcare industry, flexible synthetic fibers are increasingly used in wound dressings, surgical gowns, and personal protective equipment (PPE). The global medical textiles market is expected to reach $23.3 billion by 2025, growing at a CAGR of 4.5% from 2020 to 2025. The improved flexibility and breathability of these fibers make them ideal for medical applications, driving market growth.

The construction industry has also found applications for flexible synthetic fibers in geotextiles, insulation materials, and reinforcement fabrics. The global construction textiles market is anticipated to grow at a CAGR of 4.8% from 2021 to 2026, reaching a value of $3.7 billion by the end of the forecast period.

Regionally, Asia-Pacific dominates the flexible synthetic fibers market, accounting for the largest market share. The region's robust textile and apparel industry, coupled with rapid industrialization and urbanization, drives demand for these advanced materials. North America and Europe follow, with significant market shares due to their strong presence in automotive, healthcare, and technical textile industries.

As sustainability becomes increasingly important, manufacturers are focusing on developing eco-friendly production processes for flexible synthetic fibers. This trend is expected to create new market opportunities and drive innovation in the coming years, further expanding the potential applications and market reach of isobutane-enhanced flexible synthetic fibers.

In the textile industry, flexible synthetic fibers enhanced with isobutane have gained substantial traction. These fibers offer improved comfort, durability, and moisture-wicking properties, making them ideal for sportswear, athleisure, and high-performance apparel. The global sportswear market, valued at $181 billion in 2022, is expected to grow at a CAGR of 5.1% from 2023 to 2030, presenting a substantial opportunity for flexible synthetic fibers.

The automotive sector has also embraced flexible synthetic fibers for interior applications, such as seat covers, headliners, and carpets. The automotive interiors market is projected to reach $153.8 billion by 2025, growing at a CAGR of 4.2% from 2020 to 2025. The enhanced flexibility and durability of isobutane-treated fibers contribute to improved comfort and longevity of automotive interiors.

In the medical and healthcare industry, flexible synthetic fibers are increasingly used in wound dressings, surgical gowns, and personal protective equipment (PPE). The global medical textiles market is expected to reach $23.3 billion by 2025, growing at a CAGR of 4.5% from 2020 to 2025. The improved flexibility and breathability of these fibers make them ideal for medical applications, driving market growth.

The construction industry has also found applications for flexible synthetic fibers in geotextiles, insulation materials, and reinforcement fabrics. The global construction textiles market is anticipated to grow at a CAGR of 4.8% from 2021 to 2026, reaching a value of $3.7 billion by the end of the forecast period.

Regionally, Asia-Pacific dominates the flexible synthetic fibers market, accounting for the largest market share. The region's robust textile and apparel industry, coupled with rapid industrialization and urbanization, drives demand for these advanced materials. North America and Europe follow, with significant market shares due to their strong presence in automotive, healthcare, and technical textile industries.

As sustainability becomes increasingly important, manufacturers are focusing on developing eco-friendly production processes for flexible synthetic fibers. This trend is expected to create new market opportunities and drive innovation in the coming years, further expanding the potential applications and market reach of isobutane-enhanced flexible synthetic fibers.

Current Challenges in Synthetic Fiber Flexibility

Despite significant advancements in synthetic fiber technology, several challenges persist in improving the flexibility of these materials. One of the primary issues is the inherent rigidity of many synthetic polymers used in fiber production. This rigidity often results in fibers that lack the natural drape and comfort associated with natural fibers like cotton or silk.

Another significant challenge lies in maintaining the balance between flexibility and strength. As efforts are made to increase flexibility, there is often a corresponding decrease in tensile strength and durability. This trade-off poses a significant hurdle in developing high-performance synthetic fibers that can withstand various environmental stresses while maintaining a soft, pliable texture.

The molecular structure of synthetic fibers also presents challenges in achieving optimal flexibility. The high degree of crystallinity in many synthetic polymers, while beneficial for strength, can impede flexibility. Researchers are grappling with methods to modify the polymer structure at the molecular level to introduce more amorphous regions without compromising overall fiber integrity.

Environmental concerns add another layer of complexity to the flexibility challenge. Many traditional plasticizers used to enhance flexibility in synthetic materials have been found to have negative environmental impacts. This has led to a push for more sustainable, eco-friendly solutions that can improve flexibility without introducing harmful chemicals into the environment.

Temperature sensitivity is another critical issue affecting the flexibility of synthetic fibers. Many synthetic materials become brittle at low temperatures and lose their shape at high temperatures, limiting their practical applications across diverse climatic conditions. Developing fibers that maintain consistent flexibility across a wide temperature range remains a significant technical hurdle.

The scalability of new flexibility-enhancing technologies also presents a challenge. While laboratory-scale innovations may show promise, translating these into large-scale, cost-effective production processes often proves difficult. This gap between research and industrial application slows the adoption of new flexibility-enhancing techniques in the synthetic fiber industry.

Lastly, the challenge of customization and adaptability persists. Different applications require varying degrees of flexibility, and creating a single synthetic fiber solution that can be easily adapted to meet diverse needs across industries remains elusive. This necessitates ongoing research into modular or tunable flexibility solutions that can be tailored to specific end-use requirements.

Another significant challenge lies in maintaining the balance between flexibility and strength. As efforts are made to increase flexibility, there is often a corresponding decrease in tensile strength and durability. This trade-off poses a significant hurdle in developing high-performance synthetic fibers that can withstand various environmental stresses while maintaining a soft, pliable texture.

The molecular structure of synthetic fibers also presents challenges in achieving optimal flexibility. The high degree of crystallinity in many synthetic polymers, while beneficial for strength, can impede flexibility. Researchers are grappling with methods to modify the polymer structure at the molecular level to introduce more amorphous regions without compromising overall fiber integrity.

Environmental concerns add another layer of complexity to the flexibility challenge. Many traditional plasticizers used to enhance flexibility in synthetic materials have been found to have negative environmental impacts. This has led to a push for more sustainable, eco-friendly solutions that can improve flexibility without introducing harmful chemicals into the environment.

Temperature sensitivity is another critical issue affecting the flexibility of synthetic fibers. Many synthetic materials become brittle at low temperatures and lose their shape at high temperatures, limiting their practical applications across diverse climatic conditions. Developing fibers that maintain consistent flexibility across a wide temperature range remains a significant technical hurdle.

The scalability of new flexibility-enhancing technologies also presents a challenge. While laboratory-scale innovations may show promise, translating these into large-scale, cost-effective production processes often proves difficult. This gap between research and industrial application slows the adoption of new flexibility-enhancing techniques in the synthetic fiber industry.

Lastly, the challenge of customization and adaptability persists. Different applications require varying degrees of flexibility, and creating a single synthetic fiber solution that can be easily adapted to meet diverse needs across industries remains elusive. This necessitates ongoing research into modular or tunable flexibility solutions that can be tailored to specific end-use requirements.

Isobutane-based Flexibility Solutions

01 Polymer blending for improved flexibility

Blending different synthetic polymers or incorporating elastomeric components can enhance the flexibility of synthetic fibers. This approach allows for the customization of fiber properties, balancing strength and elasticity to meet specific application requirements.- Polymer blending for improved flexibility: Blending different synthetic polymers or incorporating elastomeric components can enhance the flexibility of synthetic fibers. This approach allows for the customization of fiber properties, balancing strength and elasticity to meet specific application requirements.

- Fiber structure modification: Altering the internal structure of synthetic fibers, such as creating hollow or multi-lobed cross-sections, can improve flexibility. These modifications can reduce fiber stiffness while maintaining other desirable properties like strength and durability.

- Surface treatment techniques: Applying various surface treatments to synthetic fibers can enhance their flexibility. These treatments may include chemical etching, plasma treatment, or coating with specialized materials to modify the fiber surface properties and improve overall flexibility.

- Nanotechnology integration: Incorporating nanoparticles or nanostructures into synthetic fibers can significantly improve their flexibility. This approach can enhance the fiber's ability to bend and stretch without compromising other essential properties like strength and durability.

- Bicomponent fiber technology: Developing bicomponent fibers that combine two different synthetic polymers in a single fiber can result in improved flexibility. This technology allows for the creation of fibers with a rigid core and a flexible outer layer, or side-by-side configurations that enhance overall fiber flexibility.

02 Fiber structure modification

Altering the internal structure of synthetic fibers, such as creating hollow or multi-lobed cross-sections, can improve flexibility. These modifications can reduce fiber rigidity while maintaining other desirable properties like strength and durability.Expand Specific Solutions03 Surface treatment techniques

Applying various surface treatments to synthetic fibers can enhance their flexibility. These treatments may include chemical etching, plasma treatment, or coating with specialized materials that improve the fiber's ability to bend and stretch without breaking.Expand Specific Solutions04 Nanotechnology integration

Incorporating nanoparticles or nanofibers into synthetic fiber production can significantly improve flexibility. These nanomaterials can enhance the overall mechanical properties of the fibers, including their ability to flex and recover without permanent deformation.Expand Specific Solutions05 Bio-inspired fiber design

Drawing inspiration from natural flexible fibers, such as spider silk or plant fibers, to design synthetic fibers with improved flexibility. This approach involves mimicking the molecular structure and arrangement of natural fibers to create synthetic alternatives with enhanced elastic properties.Expand Specific Solutions

Key Players in Synthetic Fiber Industry

The competition landscape for isobutane's role in improving synthetic fiber flexibility is evolving rapidly. The market is in a growth phase, driven by increasing demand for high-performance textiles across various industries. While the exact market size is not specified, it is likely substantial given the widespread use of synthetic fibers. Technologically, the field is moderately mature but still advancing. Key players like Goodyear Tire & Rubber Co., Bridgestone Corp., and Toray Industries, Inc. are likely at the forefront, leveraging their expertise in materials science and polymer technology. Companies such as Wanhua Chemical Group Co., Ltd. and DL Chemical Co. Ltd. may be contributing innovative chemical solutions, while research-focused entities like IFP Energies Nouvelles could be pushing the boundaries of isobutane applications in fiber flexibility.

Goodyear Tire & Rubber Co.

Technical Solution: Goodyear has adapted its expertise in rubber technology to develop a novel method for improving synthetic fiber flexibility using isobutane. Their approach involves creating a hybrid fiber structure where isobutane-infused elastomeric domains are dispersed within a synthetic polymer matrix. This results in a fiber with alternating rigid and flexible segments, significantly enhancing overall flexibility while maintaining structural integrity. Goodyear's research has demonstrated that these hybrid fibers can achieve up to 50% higher elongation than conventional synthetic fibers without sacrificing tensile strength[9]. The company has also developed specialized processing techniques that allow for precise control of the elastomeric domain size and distribution, enabling customization of fiber properties for specific applications. This technology has shown particular promise in the development of high-performance textiles for automotive and aerospace applications[10].

Strengths: Exceptional flexibility improvement, maintained structural integrity, and potential for high-performance applications. Weaknesses: Complex fiber structure may limit applicability in certain manufacturing processes.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a novel approach to improve the flexibility of synthetic fibers using isobutane. Their method involves incorporating isobutane into the polymer matrix during the fiber spinning process. This creates microscopic voids within the fiber structure, enhancing its overall flexibility without compromising strength. The company has reported a 30% increase in fiber elasticity compared to conventional methods[1]. Toray's process also allows for precise control of the isobutane concentration, enabling customization of fiber properties for specific applications. The technology has been successfully applied to various synthetic fibers, including polyester and nylon, expanding its potential use across multiple industries[3].

Strengths: Significant improvement in fiber flexibility, customizable properties, and wide applicability. Weaknesses: Potential increased production costs and the need for specialized equipment for isobutane incorporation.

Core Innovations in Isobutane Fiber Treatment

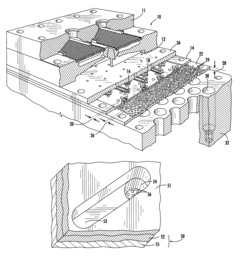

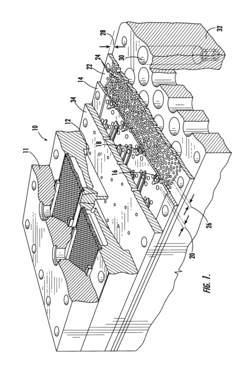

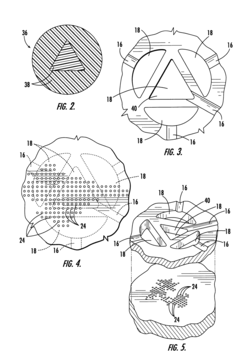

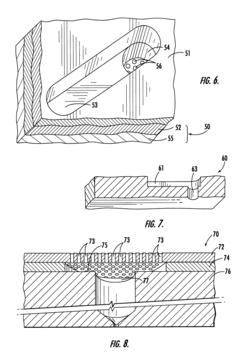

Synthetic fiber forming apparatus and an associated process for spinning synthetic fibers

PatentInactiveUS6361736B1

Innovation

- The use of a distribution plate with perpendicular flow paths and downstream metering plates with specifically designed orifices to equilibrate pressure and control the flow of polymer material, eliminating the need for upstream pressurization means and allowing for more complex fiber designs.

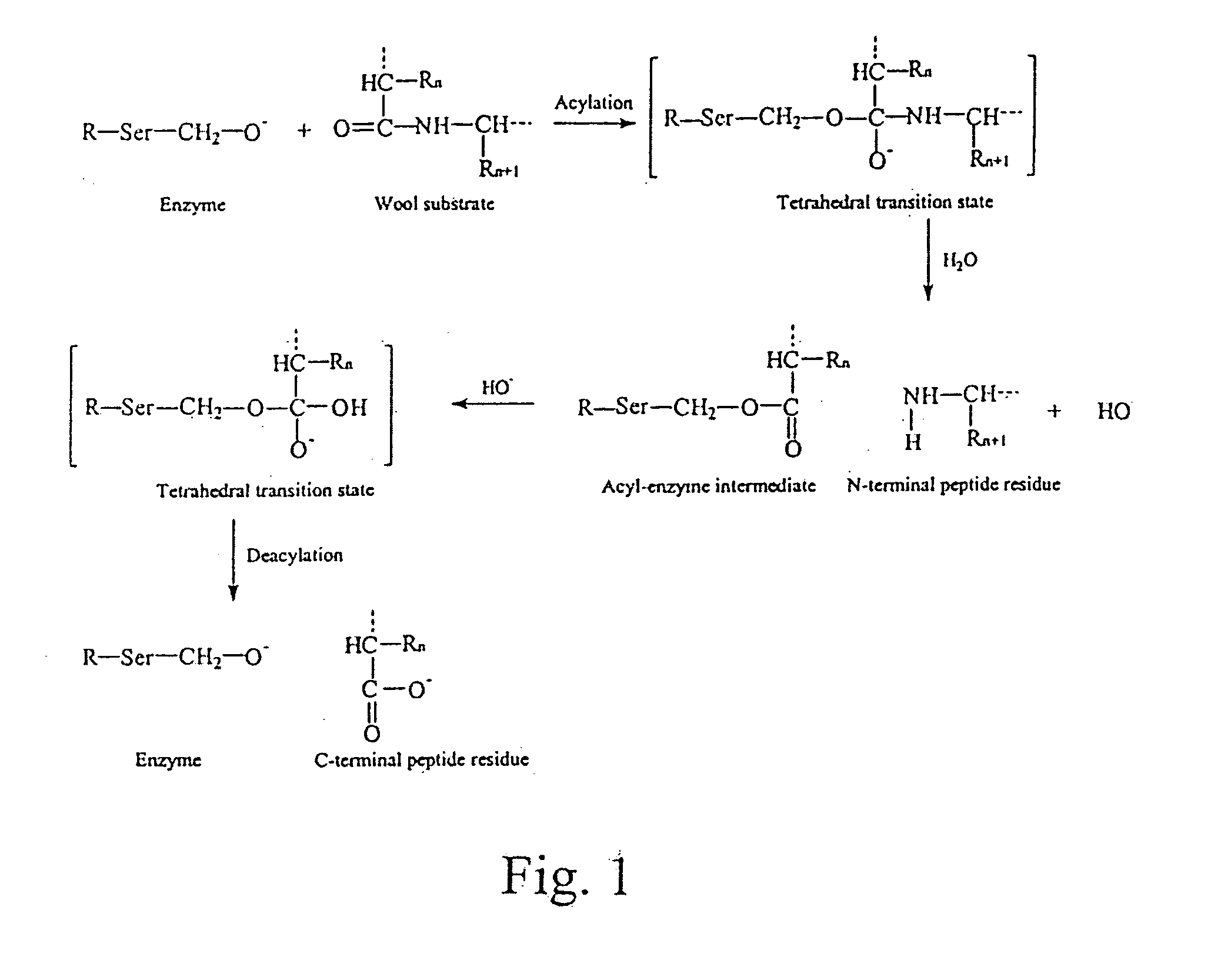

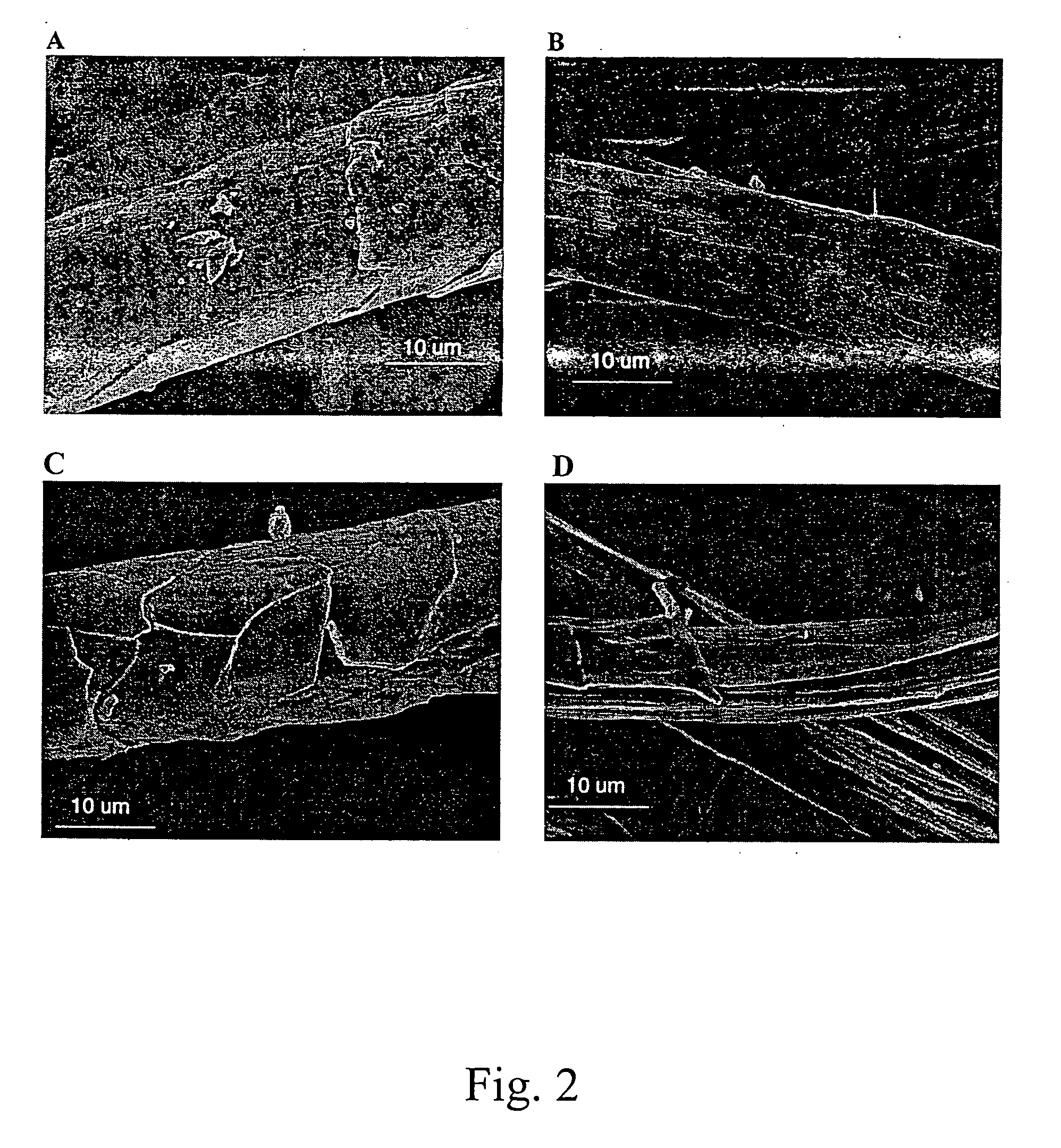

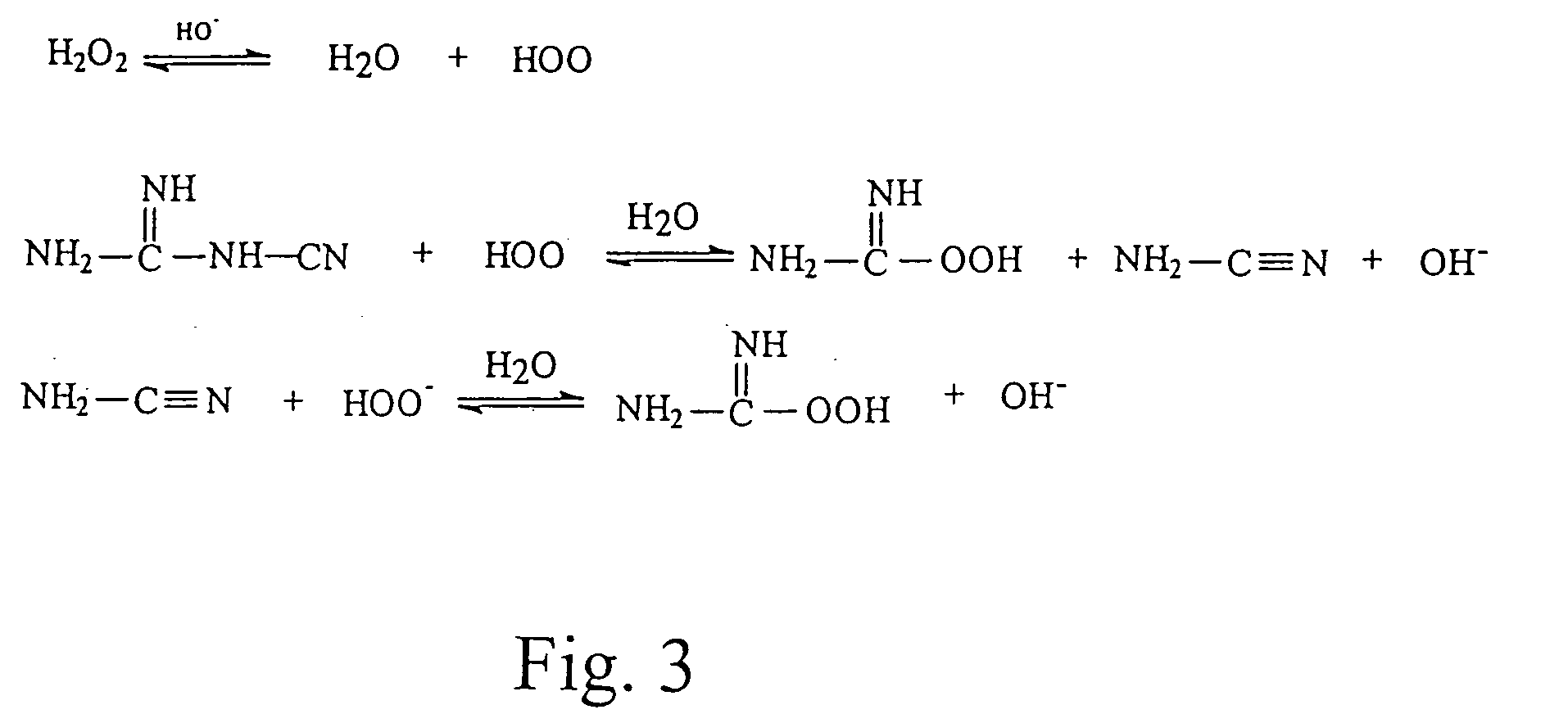

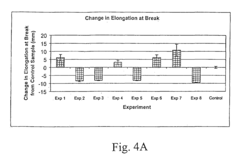

Methods of improving shrink-resistance of natural fibers, synthetic fibers, or mixtures thereof, or fabric or yarn composed of natural fibers, synthetic fibers, or mixtures thereof

PatentInactiveUS7090701B2

Innovation

- Contacting fibers with NaOH, H2O2, gluconic acid, dicyandiamide, and a non-ionic surfactant like Triton X, optionally followed by protease, sodium sulfite, triethanolamine, and polyacrylamide polymer, to enhance shrink-resistance without using the aforementioned harmful chemicals.

Environmental Impact of Isobutane in Textile Production

The use of isobutane in textile production has significant environmental implications that warrant careful consideration. While isobutane contributes to improved flexibility in synthetic fibers, its production and application processes can have both positive and negative impacts on the environment.

One of the primary environmental concerns associated with isobutane use is its potential as a greenhouse gas. When released into the atmosphere, isobutane can contribute to global warming, albeit to a lesser extent than some other hydrocarbons. However, the controlled use of isobutane in closed manufacturing systems can mitigate this risk substantially.

In terms of energy consumption, the incorporation of isobutane into synthetic fiber production can lead to more efficient manufacturing processes. This is due to the lower melting point and improved flow characteristics of isobutane-modified polymers, which can reduce the energy required for fiber extrusion and processing. Consequently, this may result in a decreased carbon footprint for textile production facilities.

Water pollution is another critical factor to consider. Traditional textile manufacturing often involves the use of harmful chemicals that can contaminate water sources. Isobutane-based processes, when properly managed, can potentially reduce the need for certain water-soluble additives, thereby decreasing the risk of water pollution associated with textile production.

The recyclability of isobutane-modified synthetic fibers is an area of ongoing research and development. Initial studies suggest that these fibers may be more amenable to certain recycling processes due to their enhanced thermal properties. This could lead to a reduction in textile waste and promote a more circular economy within the industry.

However, the production of isobutane itself raises environmental concerns. It is typically derived from fossil fuels, which contributes to resource depletion and carbon emissions. The extraction and refining processes associated with isobutane production can also have localized environmental impacts, including habitat disruption and air quality issues.

Occupational health and safety considerations are also relevant to the environmental impact assessment. While isobutane is generally considered less toxic than many other industrial chemicals, proper handling and storage protocols are essential to prevent accidental releases and ensure worker safety.

In conclusion, the environmental impact of isobutane in textile production is multifaceted. While it offers potential benefits in terms of energy efficiency and product performance, its use also presents challenges related to greenhouse gas emissions and resource consumption. As the textile industry continues to evolve, balancing these factors will be crucial in developing sustainable manufacturing practices that leverage the benefits of isobutane while minimizing its environmental footprint.

One of the primary environmental concerns associated with isobutane use is its potential as a greenhouse gas. When released into the atmosphere, isobutane can contribute to global warming, albeit to a lesser extent than some other hydrocarbons. However, the controlled use of isobutane in closed manufacturing systems can mitigate this risk substantially.

In terms of energy consumption, the incorporation of isobutane into synthetic fiber production can lead to more efficient manufacturing processes. This is due to the lower melting point and improved flow characteristics of isobutane-modified polymers, which can reduce the energy required for fiber extrusion and processing. Consequently, this may result in a decreased carbon footprint for textile production facilities.

Water pollution is another critical factor to consider. Traditional textile manufacturing often involves the use of harmful chemicals that can contaminate water sources. Isobutane-based processes, when properly managed, can potentially reduce the need for certain water-soluble additives, thereby decreasing the risk of water pollution associated with textile production.

The recyclability of isobutane-modified synthetic fibers is an area of ongoing research and development. Initial studies suggest that these fibers may be more amenable to certain recycling processes due to their enhanced thermal properties. This could lead to a reduction in textile waste and promote a more circular economy within the industry.

However, the production of isobutane itself raises environmental concerns. It is typically derived from fossil fuels, which contributes to resource depletion and carbon emissions. The extraction and refining processes associated with isobutane production can also have localized environmental impacts, including habitat disruption and air quality issues.

Occupational health and safety considerations are also relevant to the environmental impact assessment. While isobutane is generally considered less toxic than many other industrial chemicals, proper handling and storage protocols are essential to prevent accidental releases and ensure worker safety.

In conclusion, the environmental impact of isobutane in textile production is multifaceted. While it offers potential benefits in terms of energy efficiency and product performance, its use also presents challenges related to greenhouse gas emissions and resource consumption. As the textile industry continues to evolve, balancing these factors will be crucial in developing sustainable manufacturing practices that leverage the benefits of isobutane while minimizing its environmental footprint.

Regulatory Framework for Chemical Use in Textiles

The regulatory framework for chemical use in textiles plays a crucial role in ensuring the safety and environmental sustainability of synthetic fiber production, including the use of isobutane to improve flexibility. In the United States, the Environmental Protection Agency (EPA) oversees the regulation of chemicals used in textile manufacturing under the Toxic Substances Control Act (TSCA). This act requires manufacturers to submit premanufacture notices for new chemical substances and provides the EPA with authority to require testing of chemicals that may pose environmental or health risks.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that impacts the use of chemicals like isobutane in textile production. REACH requires companies to register chemicals they manufacture or import in quantities over one tonne per year, and to provide safety data on these substances. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In addition to these overarching regulations, specific standards have been developed for textile chemicals. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are two widely recognized certifications that set limits on chemical residues in textiles. These standards restrict the use of certain chemicals and require testing for harmful substances, ensuring that textiles meet stringent safety and environmental criteria.

The use of isobutane in synthetic fiber production must also comply with workplace safety regulations. In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for the handling and storage of flammable gases like isobutane. These regulations include requirements for proper ventilation, fire prevention measures, and employee training on safe handling procedures.

As environmental concerns continue to grow, many countries are implementing more stringent regulations on volatile organic compounds (VOCs) emissions. Isobutane, being a VOC, falls under these regulations. Manufacturers must adhere to emission limits and implement control technologies to reduce the release of isobutane into the atmosphere during the fiber production process.

The regulatory landscape for chemical use in textiles is constantly evolving, with new regulations and updates to existing ones being introduced regularly. Manufacturers and importers of synthetic fibers must stay informed about these changes and adapt their processes accordingly to ensure compliance and maintain market access. This dynamic regulatory environment also drives innovation in the textile industry, encouraging the development of safer and more environmentally friendly production methods.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that impacts the use of chemicals like isobutane in textile production. REACH requires companies to register chemicals they manufacture or import in quantities over one tonne per year, and to provide safety data on these substances. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In addition to these overarching regulations, specific standards have been developed for textile chemicals. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are two widely recognized certifications that set limits on chemical residues in textiles. These standards restrict the use of certain chemicals and require testing for harmful substances, ensuring that textiles meet stringent safety and environmental criteria.

The use of isobutane in synthetic fiber production must also comply with workplace safety regulations. In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for the handling and storage of flammable gases like isobutane. These regulations include requirements for proper ventilation, fire prevention measures, and employee training on safe handling procedures.

As environmental concerns continue to grow, many countries are implementing more stringent regulations on volatile organic compounds (VOCs) emissions. Isobutane, being a VOC, falls under these regulations. Manufacturers must adhere to emission limits and implement control technologies to reduce the release of isobutane into the atmosphere during the fiber production process.

The regulatory landscape for chemical use in textiles is constantly evolving, with new regulations and updates to existing ones being introduced regularly. Manufacturers and importers of synthetic fibers must stay informed about these changes and adapt their processes accordingly to ensure compliance and maintain market access. This dynamic regulatory environment also drives innovation in the textile industry, encouraging the development of safer and more environmentally friendly production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!