Isobutane’s Role in Developing Ultra-Lightweight Structural Materials

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane in Lightweight Materials: Background and Objectives

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has emerged as a key player in the development of ultra-lightweight structural materials. This technological advancement represents a significant leap forward in materials science, with far-reaching implications across various industries. The evolution of lightweight materials has been driven by the increasing demand for energy efficiency, improved performance, and sustainability in sectors such as aerospace, automotive, and construction.

The primary objective of incorporating isobutane into lightweight materials is to achieve a remarkable reduction in overall mass while maintaining or enhancing structural integrity. This goal aligns with the broader industry trends of miniaturization, fuel efficiency, and environmental consciousness. By leveraging the unique properties of isobutane, researchers and engineers aim to create materials that offer an optimal balance between strength, weight, and functionality.

Historically, the pursuit of lightweight materials has progressed through various stages, from the use of aluminum alloys in the early 20th century to the adoption of composite materials in recent decades. The introduction of isobutane-based technologies marks a new chapter in this ongoing quest, promising to push the boundaries of what is possible in material design and engineering.

The technological trajectory of isobutane in lightweight materials is closely linked to advancements in polymer science and chemical engineering. Researchers have been exploring innovative ways to incorporate isobutane into polymer matrices, creating foams and composites with exceptional strength-to-weight ratios. This approach leverages isobutane's low density and its ability to form stable, closed-cell structures within materials.

As the field progresses, the focus is not only on reducing weight but also on enhancing other critical properties such as thermal insulation, acoustic dampening, and impact resistance. The multifaceted nature of these objectives reflects the complex demands placed on modern materials, particularly in high-performance applications.

The development of isobutane-based lightweight materials is also driven by sustainability considerations. As industries face increasing pressure to reduce their carbon footprint, materials that contribute to weight reduction and improved energy efficiency become increasingly valuable. This aligns with global initiatives to combat climate change and promote sustainable development across all sectors.

Looking ahead, the integration of isobutane into ultra-lightweight structural materials is expected to catalyze innovation in material design, manufacturing processes, and application methodologies. The potential for creating materials with unprecedented combinations of properties opens up new possibilities for product design and engineering solutions across a wide range of industries.

The primary objective of incorporating isobutane into lightweight materials is to achieve a remarkable reduction in overall mass while maintaining or enhancing structural integrity. This goal aligns with the broader industry trends of miniaturization, fuel efficiency, and environmental consciousness. By leveraging the unique properties of isobutane, researchers and engineers aim to create materials that offer an optimal balance between strength, weight, and functionality.

Historically, the pursuit of lightweight materials has progressed through various stages, from the use of aluminum alloys in the early 20th century to the adoption of composite materials in recent decades. The introduction of isobutane-based technologies marks a new chapter in this ongoing quest, promising to push the boundaries of what is possible in material design and engineering.

The technological trajectory of isobutane in lightweight materials is closely linked to advancements in polymer science and chemical engineering. Researchers have been exploring innovative ways to incorporate isobutane into polymer matrices, creating foams and composites with exceptional strength-to-weight ratios. This approach leverages isobutane's low density and its ability to form stable, closed-cell structures within materials.

As the field progresses, the focus is not only on reducing weight but also on enhancing other critical properties such as thermal insulation, acoustic dampening, and impact resistance. The multifaceted nature of these objectives reflects the complex demands placed on modern materials, particularly in high-performance applications.

The development of isobutane-based lightweight materials is also driven by sustainability considerations. As industries face increasing pressure to reduce their carbon footprint, materials that contribute to weight reduction and improved energy efficiency become increasingly valuable. This aligns with global initiatives to combat climate change and promote sustainable development across all sectors.

Looking ahead, the integration of isobutane into ultra-lightweight structural materials is expected to catalyze innovation in material design, manufacturing processes, and application methodologies. The potential for creating materials with unprecedented combinations of properties opens up new possibilities for product design and engineering solutions across a wide range of industries.

Market Analysis for Ultra-Lightweight Structural Materials

The market for ultra-lightweight structural materials has experienced significant growth in recent years, driven by increasing demand across various industries. Aerospace and automotive sectors are at the forefront of this trend, seeking materials that can reduce weight without compromising strength and durability. The global market for these materials is projected to expand at a compound annual growth rate of over 7% through 2025.

In the aerospace industry, the push for fuel efficiency and reduced emissions has led to a surge in demand for ultra-lightweight materials. Commercial aircraft manufacturers are incorporating these materials into new designs, aiming to decrease overall weight and improve fuel economy. The automotive sector is similarly motivated by stringent fuel efficiency standards and the growing electric vehicle market, where weight reduction directly translates to extended range.

Beyond transportation, other industries are also recognizing the benefits of ultra-lightweight structural materials. The construction sector is exploring their use in high-rise buildings and infrastructure projects, where reduced weight can lead to significant cost savings and improved seismic performance. The renewable energy sector, particularly wind turbine manufacturers, is adopting these materials to create larger, more efficient blades.

The market is characterized by intense research and development activities, with companies and academic institutions investing heavily in new material formulations and manufacturing processes. Isobutane's potential role in developing ultra-lightweight structural materials has garnered attention due to its unique properties and potential for creating novel foam structures.

Consumer electronics and sporting goods industries represent emerging markets for ultra-lightweight materials. Manufacturers are exploring ways to create thinner, lighter devices and high-performance sports equipment. This diversification of applications is expected to further drive market growth in the coming years.

Geographically, North America and Europe currently lead the market, owing to their strong aerospace and automotive industries. However, the Asia-Pacific region is anticipated to witness the fastest growth, fueled by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China and India.

Challenges in the market include high production costs, which can limit adoption in price-sensitive applications, and the need for extensive testing and certification, particularly in safety-critical industries. Despite these hurdles, the long-term outlook for ultra-lightweight structural materials remains positive, with ongoing technological advancements and expanding applications driving sustained growth.

In the aerospace industry, the push for fuel efficiency and reduced emissions has led to a surge in demand for ultra-lightweight materials. Commercial aircraft manufacturers are incorporating these materials into new designs, aiming to decrease overall weight and improve fuel economy. The automotive sector is similarly motivated by stringent fuel efficiency standards and the growing electric vehicle market, where weight reduction directly translates to extended range.

Beyond transportation, other industries are also recognizing the benefits of ultra-lightweight structural materials. The construction sector is exploring their use in high-rise buildings and infrastructure projects, where reduced weight can lead to significant cost savings and improved seismic performance. The renewable energy sector, particularly wind turbine manufacturers, is adopting these materials to create larger, more efficient blades.

The market is characterized by intense research and development activities, with companies and academic institutions investing heavily in new material formulations and manufacturing processes. Isobutane's potential role in developing ultra-lightweight structural materials has garnered attention due to its unique properties and potential for creating novel foam structures.

Consumer electronics and sporting goods industries represent emerging markets for ultra-lightweight materials. Manufacturers are exploring ways to create thinner, lighter devices and high-performance sports equipment. This diversification of applications is expected to further drive market growth in the coming years.

Geographically, North America and Europe currently lead the market, owing to their strong aerospace and automotive industries. However, the Asia-Pacific region is anticipated to witness the fastest growth, fueled by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China and India.

Challenges in the market include high production costs, which can limit adoption in price-sensitive applications, and the need for extensive testing and certification, particularly in safety-critical industries. Despite these hurdles, the long-term outlook for ultra-lightweight structural materials remains positive, with ongoing technological advancements and expanding applications driving sustained growth.

Current Challenges in Isobutane-Based Material Development

The development of ultra-lightweight structural materials using isobutane faces several significant challenges. One of the primary obstacles is achieving the desired balance between weight reduction and mechanical strength. While isobutane-based materials offer excellent potential for lightweight applications, maintaining structural integrity and load-bearing capacity remains a complex task.

Material stability is another critical issue. Isobutane, being a highly volatile compound, presents difficulties in controlling its behavior during material processing and fabrication. Ensuring consistent material properties and preventing unwanted phase changes or gas escape during manufacturing processes pose substantial technical hurdles.

The scalability of production processes for isobutane-based materials is also a major concern. Current laboratory-scale successes often struggle to translate into large-scale industrial production. Developing efficient, cost-effective, and environmentally friendly manufacturing methods that can be scaled up without compromising material quality is a significant challenge.

Environmental and safety considerations add another layer of complexity. Isobutane is flammable and potentially explosive, necessitating stringent safety protocols in both production and application environments. Additionally, the potential environmental impact of isobutane-based materials, including their carbon footprint and end-of-life disposal, requires careful assessment and mitigation strategies.

The integration of isobutane-based materials with existing structural components and systems presents compatibility challenges. Ensuring seamless interfaces between these novel materials and conventional materials, as well as developing appropriate joining and fastening techniques, requires extensive research and testing.

Long-term performance and durability of isobutane-based ultra-lightweight materials remain uncertain. Understanding and predicting their behavior under various environmental conditions, stress levels, and over extended periods is crucial for their adoption in critical applications, particularly in aerospace and automotive industries.

Regulatory compliance and standardization pose additional hurdles. The novelty of these materials means that existing standards and regulations may not adequately address their unique properties and applications. Developing new standards and obtaining necessary certifications for use in regulated industries can be a time-consuming and resource-intensive process.

Lastly, the economic viability of isobutane-based ultra-lightweight materials is a significant consideration. The cost of raw materials, specialized production equipment, and the need for highly skilled personnel may currently limit their competitiveness against established lightweight materials. Overcoming these economic barriers is essential for widespread adoption and commercialization.

Material stability is another critical issue. Isobutane, being a highly volatile compound, presents difficulties in controlling its behavior during material processing and fabrication. Ensuring consistent material properties and preventing unwanted phase changes or gas escape during manufacturing processes pose substantial technical hurdles.

The scalability of production processes for isobutane-based materials is also a major concern. Current laboratory-scale successes often struggle to translate into large-scale industrial production. Developing efficient, cost-effective, and environmentally friendly manufacturing methods that can be scaled up without compromising material quality is a significant challenge.

Environmental and safety considerations add another layer of complexity. Isobutane is flammable and potentially explosive, necessitating stringent safety protocols in both production and application environments. Additionally, the potential environmental impact of isobutane-based materials, including their carbon footprint and end-of-life disposal, requires careful assessment and mitigation strategies.

The integration of isobutane-based materials with existing structural components and systems presents compatibility challenges. Ensuring seamless interfaces between these novel materials and conventional materials, as well as developing appropriate joining and fastening techniques, requires extensive research and testing.

Long-term performance and durability of isobutane-based ultra-lightweight materials remain uncertain. Understanding and predicting their behavior under various environmental conditions, stress levels, and over extended periods is crucial for their adoption in critical applications, particularly in aerospace and automotive industries.

Regulatory compliance and standardization pose additional hurdles. The novelty of these materials means that existing standards and regulations may not adequately address their unique properties and applications. Developing new standards and obtaining necessary certifications for use in regulated industries can be a time-consuming and resource-intensive process.

Lastly, the economic viability of isobutane-based ultra-lightweight materials is a significant consideration. The cost of raw materials, specialized production equipment, and the need for highly skilled personnel may currently limit their competitiveness against established lightweight materials. Overcoming these economic barriers is essential for widespread adoption and commercialization.

Existing Isobutane-Derived Lightweight Material Solutions

01 Isobutane molecular weight and properties

Isobutane is a hydrocarbon with a molecular weight of 58.12 g/mol. It is a colorless, odorless gas at room temperature and pressure. Its low molecular weight contributes to its high volatility and low boiling point, making it useful in various applications such as refrigerants and propellants.- Isobutane molecular weight and properties: Isobutane is a hydrocarbon with the molecular formula C4H10 and a molecular weight of approximately 58.12 g/mol. It is a colorless, odorless gas at room temperature and pressure, with a boiling point of -11.7°C. Its low molecular weight and gaseous nature make it useful in various applications, including as a refrigerant and propellant.

- Isobutane in separation and purification processes: Isobutane is often involved in separation and purification processes in the petrochemical industry. Its weight and physical properties are crucial factors in designing distillation columns, absorption towers, and other separation equipment. The differences in weight and boiling point between isobutane and other hydrocarbons are exploited to achieve efficient separation.

- Isobutane as a feedstock in chemical processes: The weight of isobutane is an important consideration when using it as a feedstock in various chemical processes. Its relatively low molecular weight makes it reactive and suitable for producing a range of chemicals, including isobutylene, methyl tertiary butyl ether (MTBE), and other petrochemical products. The weight affects reaction stoichiometry and process design.

- Isobutane in refrigeration and aerosol applications: The low molecular weight of isobutane makes it suitable for use in refrigeration systems and as a propellant in aerosol products. Its weight influences its vapor pressure and heat transfer properties, which are crucial for these applications. The weight also affects the amount of isobutane required in formulations to achieve desired performance characteristics.

- Isobutane in fuel blends and energy applications: Isobutane's weight is a significant factor in its use in fuel blends and energy applications. Its relatively low molecular weight contributes to a high energy density, making it valuable in liquefied petroleum gas (LPG) mixtures and as a component in some specialized fuels. The weight affects the overall energy content and combustion characteristics of the fuel blends.

02 Isobutane in separation and purification processes

Isobutane's unique properties make it valuable in separation and purification processes. Its molecular weight and boiling point differences from other hydrocarbons allow for effective distillation and fractionation. These processes are used in the petrochemical industry to isolate and purify isobutane from mixed hydrocarbon streams.Expand Specific Solutions03 Isobutane as a feedstock in chemical synthesis

The molecular weight and structure of isobutane make it an important feedstock in various chemical synthesis processes. It is used in the production of high-octane gasoline components, petrochemicals, and specialty chemicals. Its reactivity and ability to undergo various transformations contribute to its versatility in industrial applications.Expand Specific Solutions04 Isobutane in refrigeration and aerosol applications

The low molecular weight of isobutane contributes to its effectiveness as a refrigerant and propellant. Its high vapor pressure and low boiling point make it suitable for use in refrigeration systems and aerosol products. These properties allow for efficient heat transfer and propellant action in various consumer and industrial applications.Expand Specific Solutions05 Isobutane in fuel blends and energy applications

Isobutane's molecular weight and energy content make it valuable in fuel blends and energy applications. It is used as a component in liquefied petroleum gas (LPG) and as a blending agent in gasoline to improve octane ratings. Its combustion properties and energy density contribute to its use in various fuel and energy-related applications.Expand Specific Solutions

Key Players in Isobutane-Based Material Industry

The development of ultra-lightweight structural materials using isobutane is in its early stages, with the market still emerging and showing significant growth potential. The technology's maturity is relatively low, indicating ample room for innovation and advancement. Key players in this field include major petrochemical companies like China Petroleum & Chemical Corp. and BASF Corp., which are leveraging their expertise in chemical processing. Research institutions such as the University of Akron and Massachusetts Institute of Technology are also contributing to the advancement of this technology. The involvement of diverse industries, including aerospace (Boeing) and automotive (Goodyear), suggests a wide range of potential applications, driving market expansion and technological progress.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been exploring the use of isobutane in developing ultra-lightweight structural materials. Their approach involves utilizing isobutane as a blowing agent in the production of high-performance foams. These foams are engineered to have a closed-cell structure, which provides excellent strength-to-weight ratios[1]. Sinopec's research focuses on optimizing the foam's density and cell size distribution to achieve superior mechanical properties. They have developed a proprietary process that allows for precise control of the isobutane expansion, resulting in uniform cell structures with enhanced load-bearing capabilities[3]. This technology has potential applications in aerospace, automotive, and construction industries where weight reduction is critical.

Strengths: Extensive petrochemical expertise, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Potential environmental concerns associated with hydrocarbon-based blowing agents, and competition from alternative lightweight materials.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to utilizing isobutane in the creation of ultra-lightweight structural materials. Their technology centers on the incorporation of isobutane into polymer matrices to create microcellular structures. By carefully controlling the solubility and diffusion of isobutane within the polymer, BASF has achieved a fine balance between weight reduction and mechanical strength[2]. The company's process involves a supercritical fluid-assisted injection molding technique, where isobutane acts as both a blowing agent and a plasticizer[4]. This dual functionality allows for the production of parts with complex geometries and tailored density gradients. BASF has successfully applied this technology to produce automotive components that offer up to 30% weight reduction compared to traditional materials while maintaining comparable mechanical properties[5].

Strengths: Extensive polymer expertise, global presence, and established relationships with major industries. Weaknesses: Dependence on petroleum-based raw materials and potential regulatory challenges related to VOC emissions.

Innovative Approaches in Isobutane Material Engineering

Rubber composition, crosslinked rubber composition, pneumatic tire, and method for producing isobutylene polymer

PatentInactiveUS20140194576A1

Innovation

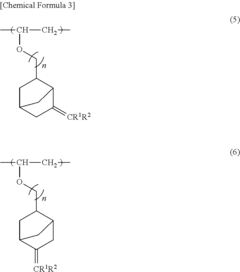

- A crosslinked rubber composition incorporating an isobutylene polymer with specific structural units and a rubber component, where the isobutylene polymer has a controlled low molecular weight content and is crosslinked with the rubber component, enhancing dynamic viscoelastic characteristics and abrasion resistance, and suitable for use in both tread and inner liner parts of tires.

Environmental Impact of Isobutane in Material Production

The environmental impact of isobutane in the production of ultra-lightweight structural materials is a critical consideration for sustainable manufacturing practices. Isobutane, a hydrocarbon compound, plays a significant role in the development of these advanced materials, but its use comes with potential environmental consequences that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with isobutane in material production is its contribution to greenhouse gas emissions. As a volatile organic compound (VOC), isobutane can escape into the atmosphere during manufacturing processes, contributing to the formation of ground-level ozone and smog. These emissions can have detrimental effects on air quality and human health, particularly in urban areas where industrial activities are concentrated.

Furthermore, the production of isobutane itself requires energy-intensive processes, often relying on fossil fuel sources. This indirect environmental impact extends the carbon footprint of ultra-lightweight structural materials beyond the immediate manufacturing phase. The extraction and refining of isobutane from natural gas or petroleum also pose risks of environmental contamination through potential spills or leaks.

However, it is important to note that the use of isobutane in developing ultra-lightweight materials can also have positive environmental implications. These materials, when used in transportation and construction industries, can significantly reduce overall energy consumption and emissions through weight reduction. For instance, lighter vehicles require less fuel, leading to decreased carbon emissions over their lifecycle.

To address the environmental challenges associated with isobutane use, manufacturers are exploring various mitigation strategies. These include implementing closed-loop systems to capture and recycle isobutane during production, improving process efficiencies to reduce overall consumption, and investing in advanced emission control technologies. Additionally, research is ongoing to develop alternative, more environmentally friendly compounds that could potentially replace isobutane in certain applications.

The regulatory landscape surrounding isobutane use in material production is also evolving. Many countries have implemented strict emissions standards and reporting requirements for VOCs, including isobutane. Compliance with these regulations often drives innovation in cleaner production methods and encourages the adoption of best practices in environmental management.

As the demand for ultra-lightweight structural materials continues to grow, balancing their performance benefits with environmental considerations becomes increasingly crucial. Life cycle assessments (LCAs) are being employed to comprehensively evaluate the environmental impact of these materials from raw material extraction to end-of-life disposal. These assessments help in identifying hotspots for environmental improvement and inform decision-making processes in material selection and production methods.

In conclusion, while isobutane plays a vital role in the development of ultra-lightweight structural materials, its environmental impact necessitates careful management and continuous improvement in production processes. The industry's focus on sustainable practices and technological advancements offers promising avenues for minimizing the environmental footprint of these innovative materials.

One of the primary environmental concerns associated with isobutane in material production is its contribution to greenhouse gas emissions. As a volatile organic compound (VOC), isobutane can escape into the atmosphere during manufacturing processes, contributing to the formation of ground-level ozone and smog. These emissions can have detrimental effects on air quality and human health, particularly in urban areas where industrial activities are concentrated.

Furthermore, the production of isobutane itself requires energy-intensive processes, often relying on fossil fuel sources. This indirect environmental impact extends the carbon footprint of ultra-lightweight structural materials beyond the immediate manufacturing phase. The extraction and refining of isobutane from natural gas or petroleum also pose risks of environmental contamination through potential spills or leaks.

However, it is important to note that the use of isobutane in developing ultra-lightweight materials can also have positive environmental implications. These materials, when used in transportation and construction industries, can significantly reduce overall energy consumption and emissions through weight reduction. For instance, lighter vehicles require less fuel, leading to decreased carbon emissions over their lifecycle.

To address the environmental challenges associated with isobutane use, manufacturers are exploring various mitigation strategies. These include implementing closed-loop systems to capture and recycle isobutane during production, improving process efficiencies to reduce overall consumption, and investing in advanced emission control technologies. Additionally, research is ongoing to develop alternative, more environmentally friendly compounds that could potentially replace isobutane in certain applications.

The regulatory landscape surrounding isobutane use in material production is also evolving. Many countries have implemented strict emissions standards and reporting requirements for VOCs, including isobutane. Compliance with these regulations often drives innovation in cleaner production methods and encourages the adoption of best practices in environmental management.

As the demand for ultra-lightweight structural materials continues to grow, balancing their performance benefits with environmental considerations becomes increasingly crucial. Life cycle assessments (LCAs) are being employed to comprehensively evaluate the environmental impact of these materials from raw material extraction to end-of-life disposal. These assessments help in identifying hotspots for environmental improvement and inform decision-making processes in material selection and production methods.

In conclusion, while isobutane plays a vital role in the development of ultra-lightweight structural materials, its environmental impact necessitates careful management and continuous improvement in production processes. The industry's focus on sustainable practices and technological advancements offers promising avenues for minimizing the environmental footprint of these innovative materials.

Safety Regulations for Isobutane-Based Material Manufacturing

The development of ultra-lightweight structural materials using isobutane requires strict adherence to safety regulations throughout the manufacturing process. These regulations are designed to mitigate the risks associated with the flammable and potentially explosive nature of isobutane.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established comprehensive guidelines for handling and processing isobutane. These guidelines encompass various aspects of the manufacturing process, including storage, handling, and disposal of isobutane and related materials.

One of the primary safety concerns in isobutane-based material manufacturing is the prevention of fire and explosions. Manufacturers are required to implement robust fire suppression systems and maintain proper ventilation in all areas where isobutane is present. Additionally, specialized equipment designed to prevent spark generation and static electricity buildup is mandatory in these environments.

Personal protective equipment (PPE) regulations are particularly stringent for workers involved in isobutane-based manufacturing. This includes the use of flame-resistant clothing, anti-static footwear, and respiratory protection when necessary. Regular training programs on the proper use of PPE and emergency response procedures are also mandated by safety regulations.

Environmental regulations play a crucial role in isobutane-based material manufacturing. Strict emission control measures must be implemented to prevent the release of isobutane into the atmosphere, as it is a volatile organic compound (VOC) that can contribute to air pollution. Manufacturers are required to install and maintain advanced air filtration systems and conduct regular emissions monitoring.

Storage and transportation of isobutane and isobutane-based materials are subject to specific safety regulations. These include the use of specialized pressure vessels, proper labeling of containers, and adherence to transportation safety protocols. Regular inspections of storage facilities and transportation vehicles are mandatory to ensure compliance with these regulations.

Emergency response planning is another critical aspect of safety regulations in isobutane-based manufacturing. Facilities must have comprehensive emergency action plans in place, including evacuation procedures, spill response protocols, and coordination with local emergency services. Regular drills and simulations are required to ensure all personnel are prepared for potential incidents.

As the development of ultra-lightweight structural materials using isobutane continues to advance, regulatory bodies are likely to update and refine safety regulations. Manufacturers must stay informed about these changes and adapt their processes accordingly to maintain compliance and ensure the safety of their workers and the environment.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established comprehensive guidelines for handling and processing isobutane. These guidelines encompass various aspects of the manufacturing process, including storage, handling, and disposal of isobutane and related materials.

One of the primary safety concerns in isobutane-based material manufacturing is the prevention of fire and explosions. Manufacturers are required to implement robust fire suppression systems and maintain proper ventilation in all areas where isobutane is present. Additionally, specialized equipment designed to prevent spark generation and static electricity buildup is mandatory in these environments.

Personal protective equipment (PPE) regulations are particularly stringent for workers involved in isobutane-based manufacturing. This includes the use of flame-resistant clothing, anti-static footwear, and respiratory protection when necessary. Regular training programs on the proper use of PPE and emergency response procedures are also mandated by safety regulations.

Environmental regulations play a crucial role in isobutane-based material manufacturing. Strict emission control measures must be implemented to prevent the release of isobutane into the atmosphere, as it is a volatile organic compound (VOC) that can contribute to air pollution. Manufacturers are required to install and maintain advanced air filtration systems and conduct regular emissions monitoring.

Storage and transportation of isobutane and isobutane-based materials are subject to specific safety regulations. These include the use of specialized pressure vessels, proper labeling of containers, and adherence to transportation safety protocols. Regular inspections of storage facilities and transportation vehicles are mandatory to ensure compliance with these regulations.

Emergency response planning is another critical aspect of safety regulations in isobutane-based manufacturing. Facilities must have comprehensive emergency action plans in place, including evacuation procedures, spill response protocols, and coordination with local emergency services. Regular drills and simulations are required to ensure all personnel are prepared for potential incidents.

As the development of ultra-lightweight structural materials using isobutane continues to advance, regulatory bodies are likely to update and refine safety regulations. Manufacturers must stay informed about these changes and adapt their processes accordingly to maintain compliance and ensure the safety of their workers and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!