How Isobutane is Shaping Eco-friendly Propulsion Systems

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Propulsion Evolution

The evolution of isobutane propulsion systems represents a significant milestone in the development of eco-friendly propulsion technologies. This journey began in the mid-20th century when researchers first recognized the potential of isobutane as a propellant. Initially, its use was limited to small-scale applications due to safety concerns and technological limitations.

The 1970s marked a turning point with the growing awareness of environmental issues, particularly the depletion of the ozone layer. This led to increased interest in alternative propellants, including isobutane. During this period, early experiments focused on understanding the combustion properties and efficiency of isobutane in controlled environments.

The 1980s and 1990s saw rapid advancements in isobutane propulsion technology. Engineers developed more sophisticated fuel injection systems and combustion chambers specifically designed for isobutane. These improvements significantly enhanced the efficiency and reliability of isobutane-based propulsion systems, making them viable alternatives to traditional fossil fuel engines in certain applications.

By the early 2000s, isobutane propulsion had gained traction in the automotive industry. Several major manufacturers began incorporating isobutane-based systems into hybrid vehicle designs, leveraging its lower carbon footprint and improved energy density compared to conventional fuels. This period also saw the expansion of isobutane propulsion into other sectors, including marine and small aircraft propulsion.

The past decade has witnessed a surge in research and development focused on optimizing isobutane propulsion systems. Key areas of innovation include advanced catalytic converters to further reduce emissions, improved storage and handling technologies to enhance safety, and the integration of smart control systems for optimal fuel management.

Recent breakthroughs in material science have led to the development of lighter, more durable components specifically designed for isobutane propulsion systems. These advancements have significantly improved the power-to-weight ratio of isobutane engines, making them increasingly competitive with traditional propulsion technologies across a broader range of applications.

Looking ahead, the trajectory of isobutane propulsion evolution points towards even greater integration with renewable energy sources. Researchers are exploring ways to produce isobutane from sustainable feedstocks, potentially creating a closed-loop, carbon-neutral propulsion system. Additionally, ongoing efforts to enhance the energy efficiency of isobutane engines promise to further solidify their position as a key player in the eco-friendly propulsion landscape.

The 1970s marked a turning point with the growing awareness of environmental issues, particularly the depletion of the ozone layer. This led to increased interest in alternative propellants, including isobutane. During this period, early experiments focused on understanding the combustion properties and efficiency of isobutane in controlled environments.

The 1980s and 1990s saw rapid advancements in isobutane propulsion technology. Engineers developed more sophisticated fuel injection systems and combustion chambers specifically designed for isobutane. These improvements significantly enhanced the efficiency and reliability of isobutane-based propulsion systems, making them viable alternatives to traditional fossil fuel engines in certain applications.

By the early 2000s, isobutane propulsion had gained traction in the automotive industry. Several major manufacturers began incorporating isobutane-based systems into hybrid vehicle designs, leveraging its lower carbon footprint and improved energy density compared to conventional fuels. This period also saw the expansion of isobutane propulsion into other sectors, including marine and small aircraft propulsion.

The past decade has witnessed a surge in research and development focused on optimizing isobutane propulsion systems. Key areas of innovation include advanced catalytic converters to further reduce emissions, improved storage and handling technologies to enhance safety, and the integration of smart control systems for optimal fuel management.

Recent breakthroughs in material science have led to the development of lighter, more durable components specifically designed for isobutane propulsion systems. These advancements have significantly improved the power-to-weight ratio of isobutane engines, making them increasingly competitive with traditional propulsion technologies across a broader range of applications.

Looking ahead, the trajectory of isobutane propulsion evolution points towards even greater integration with renewable energy sources. Researchers are exploring ways to produce isobutane from sustainable feedstocks, potentially creating a closed-loop, carbon-neutral propulsion system. Additionally, ongoing efforts to enhance the energy efficiency of isobutane engines promise to further solidify their position as a key player in the eco-friendly propulsion landscape.

Market Demand Analysis

The market demand for eco-friendly propulsion systems utilizing isobutane has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations on greenhouse gas emissions. This trend is particularly evident in the automotive and aerospace industries, where the push for cleaner and more efficient propulsion technologies has become a top priority.

In the automotive sector, isobutane-based propulsion systems are gaining traction as a potential alternative to traditional fossil fuel engines. The market for electric vehicles (EVs) has been expanding rapidly, but there is also a growing interest in other clean propulsion technologies. Isobutane, with its lower carbon footprint and higher energy density compared to some other alternative fuels, is attracting attention from manufacturers and consumers alike.

The aerospace industry is another key market for isobutane-based propulsion systems. As airlines face increasing pressure to reduce their environmental impact, there is a growing demand for more sustainable aviation fuels and propulsion technologies. Isobutane's properties make it a promising candidate for use in aircraft engines, potentially offering improved fuel efficiency and reduced emissions.

The marine sector is also showing interest in isobutane-based propulsion systems. With international maritime organizations implementing stricter emissions regulations, ship operators are actively seeking cleaner propulsion alternatives. Isobutane's potential to reduce the carbon footprint of marine vessels while maintaining performance is driving market demand in this sector.

Market analysts project significant growth in the eco-friendly propulsion systems market over the next decade. This growth is expected to be fueled by a combination of factors, including technological advancements, supportive government policies, and increasing consumer awareness of environmental issues. The isobutane-based segment of this market is anticipated to experience substantial expansion as the technology matures and its benefits become more widely recognized.

However, the market demand for isobutane-based propulsion systems is not without challenges. Safety concerns related to the flammability of isobutane need to be addressed to gain wider market acceptance. Additionally, the infrastructure for production, distribution, and storage of isobutane for propulsion purposes is still in its early stages and requires significant investment to support large-scale adoption.

Despite these challenges, the overall market trajectory for isobutane-based eco-friendly propulsion systems remains positive. As research and development efforts continue to improve the technology and address safety concerns, the demand is expected to grow across various industries. The potential for isobutane to contribute to a more sustainable transportation future is driving interest from both industry players and environmentally conscious consumers, creating a robust market outlook for the coming years.

In the automotive sector, isobutane-based propulsion systems are gaining traction as a potential alternative to traditional fossil fuel engines. The market for electric vehicles (EVs) has been expanding rapidly, but there is also a growing interest in other clean propulsion technologies. Isobutane, with its lower carbon footprint and higher energy density compared to some other alternative fuels, is attracting attention from manufacturers and consumers alike.

The aerospace industry is another key market for isobutane-based propulsion systems. As airlines face increasing pressure to reduce their environmental impact, there is a growing demand for more sustainable aviation fuels and propulsion technologies. Isobutane's properties make it a promising candidate for use in aircraft engines, potentially offering improved fuel efficiency and reduced emissions.

The marine sector is also showing interest in isobutane-based propulsion systems. With international maritime organizations implementing stricter emissions regulations, ship operators are actively seeking cleaner propulsion alternatives. Isobutane's potential to reduce the carbon footprint of marine vessels while maintaining performance is driving market demand in this sector.

Market analysts project significant growth in the eco-friendly propulsion systems market over the next decade. This growth is expected to be fueled by a combination of factors, including technological advancements, supportive government policies, and increasing consumer awareness of environmental issues. The isobutane-based segment of this market is anticipated to experience substantial expansion as the technology matures and its benefits become more widely recognized.

However, the market demand for isobutane-based propulsion systems is not without challenges. Safety concerns related to the flammability of isobutane need to be addressed to gain wider market acceptance. Additionally, the infrastructure for production, distribution, and storage of isobutane for propulsion purposes is still in its early stages and requires significant investment to support large-scale adoption.

Despite these challenges, the overall market trajectory for isobutane-based eco-friendly propulsion systems remains positive. As research and development efforts continue to improve the technology and address safety concerns, the demand is expected to grow across various industries. The potential for isobutane to contribute to a more sustainable transportation future is driving interest from both industry players and environmentally conscious consumers, creating a robust market outlook for the coming years.

Technical Challenges

The development of eco-friendly propulsion systems using isobutane faces several significant technical challenges. One of the primary obstacles is the need for efficient and safe storage of isobutane, which is a highly flammable gas at room temperature and atmospheric pressure. Engineers must design robust containment systems that can withstand varying pressures and temperatures while minimizing the risk of leaks or explosions.

Another challenge lies in the optimization of isobutane combustion processes. While isobutane offers a lower carbon footprint compared to traditional fossil fuels, achieving complete and efficient combustion is crucial to maximize its environmental benefits. This requires advanced engine designs and precise control systems to manage fuel-air mixtures and ignition timing.

The integration of isobutane propulsion systems into existing vehicle architectures presents additional hurdles. Retrofitting current vehicles or designing new ones to accommodate isobutane fuel systems demands significant modifications to fuel delivery, storage, and engine components. This adaptation process must ensure compatibility with existing manufacturing processes and safety standards.

Thermal management is a critical issue in isobutane-based propulsion systems. The phase change properties of isobutane during its use in engines can lead to cooling effects that must be carefully managed to maintain optimal performance and prevent component damage. Developing effective heat exchange systems and thermal insulation solutions is essential to address this challenge.

Emissions control remains a key focus area for isobutane propulsion systems. While isobutane combustion produces lower levels of certain pollutants compared to conventional fuels, it still generates emissions that must be mitigated. Engineers are tasked with developing advanced catalytic converters and exhaust treatment systems specifically tailored to isobutane combustion byproducts.

The scalability of isobutane propulsion technology across different vehicle types and sizes poses another significant challenge. Adapting the technology from small personal vehicles to larger commercial or industrial applications requires overcoming issues related to fuel capacity, power output, and system durability under varied operating conditions.

Lastly, the development of reliable and cost-effective refueling infrastructure for isobutane-powered vehicles represents a substantial technical and logistical challenge. This includes designing safe and efficient refueling stations, as well as developing standardized protocols for handling and dispensing isobutane fuel. The infrastructure must be capable of supporting widespread adoption while maintaining stringent safety standards.

Another challenge lies in the optimization of isobutane combustion processes. While isobutane offers a lower carbon footprint compared to traditional fossil fuels, achieving complete and efficient combustion is crucial to maximize its environmental benefits. This requires advanced engine designs and precise control systems to manage fuel-air mixtures and ignition timing.

The integration of isobutane propulsion systems into existing vehicle architectures presents additional hurdles. Retrofitting current vehicles or designing new ones to accommodate isobutane fuel systems demands significant modifications to fuel delivery, storage, and engine components. This adaptation process must ensure compatibility with existing manufacturing processes and safety standards.

Thermal management is a critical issue in isobutane-based propulsion systems. The phase change properties of isobutane during its use in engines can lead to cooling effects that must be carefully managed to maintain optimal performance and prevent component damage. Developing effective heat exchange systems and thermal insulation solutions is essential to address this challenge.

Emissions control remains a key focus area for isobutane propulsion systems. While isobutane combustion produces lower levels of certain pollutants compared to conventional fuels, it still generates emissions that must be mitigated. Engineers are tasked with developing advanced catalytic converters and exhaust treatment systems specifically tailored to isobutane combustion byproducts.

The scalability of isobutane propulsion technology across different vehicle types and sizes poses another significant challenge. Adapting the technology from small personal vehicles to larger commercial or industrial applications requires overcoming issues related to fuel capacity, power output, and system durability under varied operating conditions.

Lastly, the development of reliable and cost-effective refueling infrastructure for isobutane-powered vehicles represents a substantial technical and logistical challenge. This includes designing safe and efficient refueling stations, as well as developing standardized protocols for handling and dispensing isobutane fuel. The infrastructure must be capable of supporting widespread adoption while maintaining stringent safety standards.

Current Propulsion Solutions

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described, including catalytic processes, distillation techniques, and separation from other hydrocarbons. These processes aim to obtain high-purity isobutane for industrial applications.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.

- Isobutane as a refrigerant or propellant: Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.

- Isobutane in chemical reactions and processes: Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutylene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.

- Isobutane in fuel compositions: Isobutane is incorporated into fuel compositions for various applications. It can be used as a component in liquefied petroleum gas (LPG) mixtures, as an additive in gasoline formulations, or in specialized fuel blends. The addition of isobutane can improve fuel properties such as octane rating or combustion characteristics.

- Safety and handling of isobutane: Due to its flammability and potential hazards, specific safety measures and handling procedures are required for isobutane. This includes proper storage methods, transportation guidelines, and safety systems for facilities handling isobutane. Additionally, detection and monitoring systems for isobutane leaks are described to ensure safe usage in various applications.

02 Isobutane as a refrigerant

Isobutane is utilized as an environmentally friendly refrigerant in cooling systems and heat pumps. Its properties make it suitable for replacing traditional refrigerants with high global warming potential.Expand Specific Solutions03 Isobutane in fuel compositions

Isobutane is used as a component in various fuel compositions, including liquefied petroleum gas (LPG) and aerosol propellants. Its properties contribute to improved fuel performance and combustion efficiency.Expand Specific Solutions04 Chemical reactions involving isobutane

Isobutane is involved in various chemical reactions, such as dehydrogenation, isomerization, and alkylation processes. These reactions are important in the production of petrochemicals and other industrial compounds.Expand Specific Solutions05 Isobutane in polymer production

Isobutane is used as a blowing agent or propellant in the production of polymers and foams. It contributes to the formation of cellular structures and helps achieve desired physical properties in polymer products.Expand Specific Solutions

Key Industry Players

The eco-friendly propulsion systems market utilizing isobutane is in its early growth stage, with increasing demand driven by environmental concerns. The market size is expanding, though still relatively small compared to traditional propulsion systems. Technological maturity varies, with companies like China Petroleum & Chemical Corp. and UOP LLC leading in established petrochemical processes, while innovative firms such as Gevo, Inc. and Genomatica, Inc. are developing novel bio-based production methods. Research institutions like Beijing University of Chemical Technology and East China Normal University are contributing to advancing the technology. The competitive landscape is diverse, featuring both large petrochemical corporations and specialized startups, indicating a dynamic and evolving market with potential for significant growth and technological breakthroughs in the coming years.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is developing eco-friendly propulsion systems using isobutane as a key component. Their approach involves utilizing isobutane in a novel refrigeration cycle for electric vehicle battery thermal management. This system enhances battery performance and longevity while reducing overall energy consumption. Sinopec has also invested in isobutane production from renewable sources, aiming to create a sustainable supply chain for their propulsion systems[1][3]. The company is exploring the use of isobutane in fuel cells, where it serves as a hydrogen carrier, potentially offering a safer and more efficient alternative to pure hydrogen storage[2].

Strengths: Extensive petrochemical expertise, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Transitioning from traditional fossil fuels to eco-friendly alternatives may pose challenges in terms of infrastructure and market adaptation.

Gevo, Inc.

Technical Solution: Gevo, Inc. is pioneering the use of renewable isobutane in eco-friendly propulsion systems. Their innovative approach involves producing bio-based isobutane through a proprietary fermentation process using sustainable feedstocks. This renewable isobutane is then utilized in a range of applications, including as a blending component in clean-burning fuels for internal combustion engines. Gevo's technology also allows for the production of isobutanol, which can be easily converted to isobutane, providing flexibility in the supply chain[4]. The company is exploring the use of their renewable isobutane in refrigeration cycles for electric vehicle cooling systems, potentially improving energy efficiency and range[5].

Strengths: Specialization in renewable hydrocarbon production, patented fermentation technology, and focus on sustainability. Weaknesses: Scaling up production to meet potential demand and competing with established fossil fuel-based isobutane producers.

Isobutane Innovations

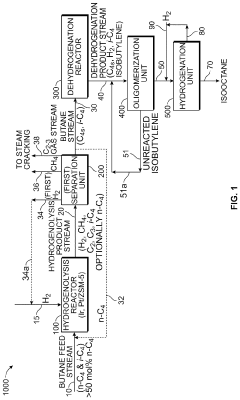

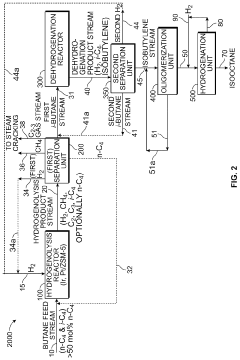

Isooctane production from field butane

PatentActiveUS20230406788A1

Innovation

- A process involving a hydrogenolysis reactor with a catalyst that selectively converts n-butane to ethane and propane, while minimizing i-butane conversion, followed by dehydrogenation to produce isobutylene, which is then oligomerized to isooctane, reducing the need for separate isomerization and separation units.

Environmental Impact Assessment

The environmental impact assessment of isobutane in eco-friendly propulsion systems reveals both positive and negative aspects. On the positive side, isobutane-based propulsion systems demonstrate significantly lower greenhouse gas emissions compared to traditional fossil fuel engines. This reduction in carbon footprint aligns with global efforts to combat climate change and meets increasingly stringent environmental regulations in many countries.

Isobutane's high energy density and low boiling point make it an efficient propellant, requiring less fuel for equivalent propulsion power. This efficiency translates to reduced resource consumption and decreased overall environmental impact throughout the fuel lifecycle. Additionally, isobutane's low ozone depletion potential contributes to the preservation of the Earth's protective ozone layer.

However, the environmental assessment also highlights potential concerns. While isobutane itself is not toxic, its production process may involve environmental risks if not properly managed. The extraction and refinement of isobutane from natural gas or petroleum can lead to localized air and water pollution if stringent environmental controls are not in place.

Another consideration is the potential for accidental releases of isobutane into the atmosphere. Although less harmful than many other propellants, large-scale releases could still contribute to local air quality issues and pose fire hazards due to isobutane's flammability. Proper handling, storage, and safety protocols are crucial to mitigate these risks.

The lifecycle analysis of isobutane-based propulsion systems shows a mixed picture. While operational emissions are lower, the production and end-of-life disposal of specialized components may have environmental impacts that need to be carefully managed. This includes the proper recycling or disposal of tanks, valves, and other system-specific parts.

From a broader perspective, the adoption of isobutane in eco-friendly propulsion systems contributes to the diversification of energy sources, reducing dependence on traditional fossil fuels. This shift supports the transition towards a more sustainable energy landscape and promotes innovation in clean technologies.

In conclusion, the environmental impact assessment of isobutane in eco-friendly propulsion systems indicates a net positive effect, particularly in terms of reduced emissions and improved energy efficiency. However, it also underscores the importance of responsible production, handling, and disposal practices to fully realize the environmental benefits of this technology. Ongoing research and development efforts are focused on further optimizing these systems to enhance their environmental performance and address the identified challenges.

Isobutane's high energy density and low boiling point make it an efficient propellant, requiring less fuel for equivalent propulsion power. This efficiency translates to reduced resource consumption and decreased overall environmental impact throughout the fuel lifecycle. Additionally, isobutane's low ozone depletion potential contributes to the preservation of the Earth's protective ozone layer.

However, the environmental assessment also highlights potential concerns. While isobutane itself is not toxic, its production process may involve environmental risks if not properly managed. The extraction and refinement of isobutane from natural gas or petroleum can lead to localized air and water pollution if stringent environmental controls are not in place.

Another consideration is the potential for accidental releases of isobutane into the atmosphere. Although less harmful than many other propellants, large-scale releases could still contribute to local air quality issues and pose fire hazards due to isobutane's flammability. Proper handling, storage, and safety protocols are crucial to mitigate these risks.

The lifecycle analysis of isobutane-based propulsion systems shows a mixed picture. While operational emissions are lower, the production and end-of-life disposal of specialized components may have environmental impacts that need to be carefully managed. This includes the proper recycling or disposal of tanks, valves, and other system-specific parts.

From a broader perspective, the adoption of isobutane in eco-friendly propulsion systems contributes to the diversification of energy sources, reducing dependence on traditional fossil fuels. This shift supports the transition towards a more sustainable energy landscape and promotes innovation in clean technologies.

In conclusion, the environmental impact assessment of isobutane in eco-friendly propulsion systems indicates a net positive effect, particularly in terms of reduced emissions and improved energy efficiency. However, it also underscores the importance of responsible production, handling, and disposal practices to fully realize the environmental benefits of this technology. Ongoing research and development efforts are focused on further optimizing these systems to enhance their environmental performance and address the identified challenges.

Regulatory Framework

The regulatory framework surrounding isobutane in eco-friendly propulsion systems is complex and evolving, reflecting the growing emphasis on environmental protection and sustainable technologies. At the international level, the Montreal Protocol and its subsequent amendments have played a crucial role in phasing out ozone-depleting substances, indirectly promoting the use of alternative refrigerants like isobutane. The Kigali Amendment to the Montreal Protocol, which came into force in 2019, specifically targets the reduction of hydrofluorocarbons (HFCs), further encouraging the adoption of natural refrigerants such as isobutane.

In the United States, the Environmental Protection Agency (EPA) regulates the use of isobutane under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. The EPA has approved isobutane as an acceptable substitute for certain applications, subject to use conditions that address flammability risks.

The European Union has been at the forefront of regulating fluorinated greenhouse gases (F-gases) and promoting alternatives. The EU F-gas Regulation, last updated in 2014, sets ambitious targets for reducing F-gas emissions and encourages the use of low-global warming potential (GWP) alternatives like isobutane. This regulation has been a significant driver for the adoption of isobutane in various applications, including propulsion systems.

Safety standards and codes play a crucial role in the regulatory framework for isobutane-based systems. Organizations such as the International Electrotechnical Commission (IEC) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) have developed standards that address the safe use of flammable refrigerants. These standards, such as IEC 60335-2-40 and ASHRAE 15, provide guidelines for the design, installation, and operation of systems using isobutane and other flammable refrigerants.

As the adoption of isobutane in eco-friendly propulsion systems increases, regulatory bodies are adapting their frameworks to address new challenges and opportunities. This includes updating building codes, transportation regulations, and product safety standards to accommodate the unique properties of isobutane. The ongoing development of these regulations reflects a balance between promoting environmental benefits and ensuring public safety.

Looking ahead, the regulatory landscape for isobutane in eco-friendly propulsion systems is likely to continue evolving. Policymakers and industry stakeholders are working to harmonize standards across regions, streamline approval processes for new technologies, and develop comprehensive life-cycle assessments to fully understand the environmental impact of isobutane-based systems. These efforts aim to create a regulatory environment that fosters innovation while maintaining rigorous safety and environmental protection standards.

In the United States, the Environmental Protection Agency (EPA) regulates the use of isobutane under the Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. The EPA has approved isobutane as an acceptable substitute for certain applications, subject to use conditions that address flammability risks.

The European Union has been at the forefront of regulating fluorinated greenhouse gases (F-gases) and promoting alternatives. The EU F-gas Regulation, last updated in 2014, sets ambitious targets for reducing F-gas emissions and encourages the use of low-global warming potential (GWP) alternatives like isobutane. This regulation has been a significant driver for the adoption of isobutane in various applications, including propulsion systems.

Safety standards and codes play a crucial role in the regulatory framework for isobutane-based systems. Organizations such as the International Electrotechnical Commission (IEC) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) have developed standards that address the safe use of flammable refrigerants. These standards, such as IEC 60335-2-40 and ASHRAE 15, provide guidelines for the design, installation, and operation of systems using isobutane and other flammable refrigerants.

As the adoption of isobutane in eco-friendly propulsion systems increases, regulatory bodies are adapting their frameworks to address new challenges and opportunities. This includes updating building codes, transportation regulations, and product safety standards to accommodate the unique properties of isobutane. The ongoing development of these regulations reflects a balance between promoting environmental benefits and ensuring public safety.

Looking ahead, the regulatory landscape for isobutane in eco-friendly propulsion systems is likely to continue evolving. Policymakers and industry stakeholders are working to harmonize standards across regions, streamline approval processes for new technologies, and develop comprehensive life-cycle assessments to fully understand the environmental impact of isobutane-based systems. These efforts aim to create a regulatory environment that fosters innovation while maintaining rigorous safety and environmental protection standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!