The Impact of Isobutane on Geothermal Conversion Efficiencies

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Energy Background and Objectives

Geothermal energy has emerged as a promising renewable energy source, harnessing the Earth's internal heat to generate electricity and provide direct heating. This clean, sustainable power source has been utilized for decades, with its roots tracing back to the early 20th century. The technology has evolved significantly, moving from simple direct use applications to sophisticated power generation systems.

The geothermal industry has seen steady growth, driven by increasing global demand for clean energy solutions and the need to reduce greenhouse gas emissions. As of 2021, the global installed geothermal power capacity reached approximately 15.6 GW, with countries like the United States, Indonesia, and the Philippines leading in geothermal electricity production.

Despite its potential, geothermal energy faces several challenges that have limited its widespread adoption. These include high upfront costs for exploration and drilling, geological risks, and the geographical constraints of suitable geothermal resources. However, recent technological advancements have opened up new possibilities for expanding geothermal energy utilization.

One such advancement is the use of binary cycle power plants, which allow for electricity generation from lower-temperature geothermal resources. This technology has significantly broadened the potential for geothermal power production in areas previously considered unsuitable. Within this context, the use of isobutane as a working fluid in binary cycle systems has gained attention due to its potential to enhance conversion efficiencies.

The primary objective of this technical research is to investigate the impact of isobutane on geothermal conversion efficiencies. This involves a comprehensive analysis of how isobutane, when used as a working fluid in binary cycle geothermal power plants, affects the overall system performance and energy output compared to traditional working fluids.

Key areas of focus include the thermodynamic properties of isobutane, its behavior under various temperature and pressure conditions typical in geothermal applications, and its interaction with geothermal fluids and plant components. The research aims to quantify the potential improvements in conversion efficiency, identify any technical challenges or limitations associated with isobutane use, and assess its economic and environmental implications.

Furthermore, this study seeks to explore the broader implications of enhanced conversion efficiencies on the geothermal energy landscape. This includes evaluating how improved efficiencies could expand the viability of geothermal resources, potentially opening up new geographical areas for development and increasing the competitiveness of geothermal energy in the global renewable energy market.

By thoroughly examining the role of isobutane in geothermal systems, this research aims to contribute to the ongoing efforts to optimize geothermal power generation, ultimately supporting the industry's growth and its role in the transition to a sustainable energy future.

The geothermal industry has seen steady growth, driven by increasing global demand for clean energy solutions and the need to reduce greenhouse gas emissions. As of 2021, the global installed geothermal power capacity reached approximately 15.6 GW, with countries like the United States, Indonesia, and the Philippines leading in geothermal electricity production.

Despite its potential, geothermal energy faces several challenges that have limited its widespread adoption. These include high upfront costs for exploration and drilling, geological risks, and the geographical constraints of suitable geothermal resources. However, recent technological advancements have opened up new possibilities for expanding geothermal energy utilization.

One such advancement is the use of binary cycle power plants, which allow for electricity generation from lower-temperature geothermal resources. This technology has significantly broadened the potential for geothermal power production in areas previously considered unsuitable. Within this context, the use of isobutane as a working fluid in binary cycle systems has gained attention due to its potential to enhance conversion efficiencies.

The primary objective of this technical research is to investigate the impact of isobutane on geothermal conversion efficiencies. This involves a comprehensive analysis of how isobutane, when used as a working fluid in binary cycle geothermal power plants, affects the overall system performance and energy output compared to traditional working fluids.

Key areas of focus include the thermodynamic properties of isobutane, its behavior under various temperature and pressure conditions typical in geothermal applications, and its interaction with geothermal fluids and plant components. The research aims to quantify the potential improvements in conversion efficiency, identify any technical challenges or limitations associated with isobutane use, and assess its economic and environmental implications.

Furthermore, this study seeks to explore the broader implications of enhanced conversion efficiencies on the geothermal energy landscape. This includes evaluating how improved efficiencies could expand the viability of geothermal resources, potentially opening up new geographical areas for development and increasing the competitiveness of geothermal energy in the global renewable energy market.

By thoroughly examining the role of isobutane in geothermal systems, this research aims to contribute to the ongoing efforts to optimize geothermal power generation, ultimately supporting the industry's growth and its role in the transition to a sustainable energy future.

Isobutane Market Analysis in Geothermal Applications

The isobutane market in geothermal applications has experienced significant growth in recent years, driven by the increasing demand for efficient and environmentally friendly energy solutions. Geothermal power plants utilizing isobutane as a working fluid have gained traction due to their ability to operate at lower temperatures compared to traditional water-based systems, thus expanding the potential for geothermal energy exploitation.

The global market for isobutane in geothermal applications is closely tied to the overall growth of the geothermal energy sector. As of 2021, the geothermal power market was valued at approximately $5 billion, with projections indicating a compound annual growth rate (CAGR) of around 5% through 2026. Within this market, the demand for isobutane as a working fluid is expected to grow at an even faster rate, driven by its superior thermodynamic properties and efficiency in binary cycle power plants.

Key factors influencing the isobutane market in geothermal applications include government incentives for renewable energy development, increasing awareness of environmental sustainability, and technological advancements in geothermal power plant design. Countries with significant geothermal resources, such as the United States, Indonesia, Philippines, and Turkey, are expected to be major contributors to market growth.

The isobutane market for geothermal applications is characterized by a relatively small number of suppliers, with major players including Chevron Phillips Chemical, Exxon Mobil, and Shell. These companies are investing in research and development to improve the purity and performance of isobutane for geothermal applications, further driving market growth.

Challenges facing the isobutane market in geothermal applications include price volatility of raw materials, stringent environmental regulations regarding the use and handling of hydrocarbons, and competition from alternative working fluids such as pentane and R-245fa. However, the superior thermodynamic properties of isobutane, particularly its low boiling point and high vapor pressure, continue to make it an attractive option for geothermal power plant operators.

Looking ahead, the isobutane market in geothermal applications is poised for continued growth, with emerging markets in Asia-Pacific and Latin America expected to provide significant opportunities. Technological advancements, such as the development of enhanced geothermal systems (EGS) and the integration of geothermal power with other renewable energy sources, are likely to further boost demand for isobutane as a working fluid in the coming years.

The global market for isobutane in geothermal applications is closely tied to the overall growth of the geothermal energy sector. As of 2021, the geothermal power market was valued at approximately $5 billion, with projections indicating a compound annual growth rate (CAGR) of around 5% through 2026. Within this market, the demand for isobutane as a working fluid is expected to grow at an even faster rate, driven by its superior thermodynamic properties and efficiency in binary cycle power plants.

Key factors influencing the isobutane market in geothermal applications include government incentives for renewable energy development, increasing awareness of environmental sustainability, and technological advancements in geothermal power plant design. Countries with significant geothermal resources, such as the United States, Indonesia, Philippines, and Turkey, are expected to be major contributors to market growth.

The isobutane market for geothermal applications is characterized by a relatively small number of suppliers, with major players including Chevron Phillips Chemical, Exxon Mobil, and Shell. These companies are investing in research and development to improve the purity and performance of isobutane for geothermal applications, further driving market growth.

Challenges facing the isobutane market in geothermal applications include price volatility of raw materials, stringent environmental regulations regarding the use and handling of hydrocarbons, and competition from alternative working fluids such as pentane and R-245fa. However, the superior thermodynamic properties of isobutane, particularly its low boiling point and high vapor pressure, continue to make it an attractive option for geothermal power plant operators.

Looking ahead, the isobutane market in geothermal applications is poised for continued growth, with emerging markets in Asia-Pacific and Latin America expected to provide significant opportunities. Technological advancements, such as the development of enhanced geothermal systems (EGS) and the integration of geothermal power with other renewable energy sources, are likely to further boost demand for isobutane as a working fluid in the coming years.

Isobutane Challenges in Geothermal Systems

The utilization of isobutane in geothermal power systems presents several significant challenges that impact overall conversion efficiencies. One of the primary issues is the thermal stability of isobutane at high temperatures typically encountered in geothermal applications. As temperatures increase, isobutane can undergo thermal decomposition, leading to the formation of unwanted byproducts and reducing the overall efficiency of the system.

Another challenge is the corrosive nature of geothermal fluids, which can interact with isobutane and the system components. This corrosion can lead to material degradation, increased maintenance requirements, and potential safety hazards. The presence of dissolved minerals and gases in geothermal fluids can also cause scaling and fouling of heat exchangers, further reducing heat transfer efficiency and system performance.

The high operating pressures required for isobutane in geothermal systems pose additional challenges. These elevated pressures necessitate robust equipment design and stringent safety measures, which can increase capital and operational costs. Furthermore, the potential for leaks and emissions of isobutane, a potent greenhouse gas, raises environmental concerns and requires careful monitoring and containment strategies.

Isobutane's thermodynamic properties, while generally favorable for geothermal applications, can present optimization challenges. The critical point of isobutane is relatively low, which can limit the maximum operating temperature of the system and potentially reduce overall conversion efficiency in high-temperature geothermal resources.

The handling and storage of isobutane also present logistical challenges. As a flammable substance, it requires specialized storage facilities and transportation methods, adding complexity to the supply chain and increasing operational risks. Additionally, the cost and availability of isobutane can fluctuate, impacting the economic viability of geothermal projects.

Lastly, the regulatory landscape surrounding the use of isobutane in geothermal systems can be complex. Environmental regulations, safety standards, and permitting requirements may vary across different regions, adding administrative burdens and potential project delays. Compliance with these regulations often requires significant investment in monitoring equipment and safety systems, further impacting the overall cost-effectiveness of isobutane-based geothermal power generation.

Another challenge is the corrosive nature of geothermal fluids, which can interact with isobutane and the system components. This corrosion can lead to material degradation, increased maintenance requirements, and potential safety hazards. The presence of dissolved minerals and gases in geothermal fluids can also cause scaling and fouling of heat exchangers, further reducing heat transfer efficiency and system performance.

The high operating pressures required for isobutane in geothermal systems pose additional challenges. These elevated pressures necessitate robust equipment design and stringent safety measures, which can increase capital and operational costs. Furthermore, the potential for leaks and emissions of isobutane, a potent greenhouse gas, raises environmental concerns and requires careful monitoring and containment strategies.

Isobutane's thermodynamic properties, while generally favorable for geothermal applications, can present optimization challenges. The critical point of isobutane is relatively low, which can limit the maximum operating temperature of the system and potentially reduce overall conversion efficiency in high-temperature geothermal resources.

The handling and storage of isobutane also present logistical challenges. As a flammable substance, it requires specialized storage facilities and transportation methods, adding complexity to the supply chain and increasing operational risks. Additionally, the cost and availability of isobutane can fluctuate, impacting the economic viability of geothermal projects.

Lastly, the regulatory landscape surrounding the use of isobutane in geothermal systems can be complex. Environmental regulations, safety standards, and permitting requirements may vary across different regions, adding administrative burdens and potential project delays. Compliance with these regulations often requires significant investment in monitoring equipment and safety systems, further impacting the overall cost-effectiveness of isobutane-based geothermal power generation.

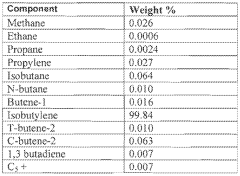

Current Isobutane-based Geothermal Solutions

01 Catalytic conversion of isobutane

Various catalytic processes are employed to convert isobutane into more valuable products. These processes often involve the use of specific catalysts and reaction conditions to achieve high conversion efficiencies. The catalytic conversion of isobutane can lead to the production of important petrochemical intermediates and fuel components.- Catalytic conversion of isobutane: Various catalytic processes are employed to convert isobutane into more valuable products. These processes often involve the use of specific catalysts and reaction conditions to achieve high conversion efficiencies. The catalysts may include zeolites, metal oxides, or other materials that promote the desired reactions.

- Dehydrogenation of isobutane: Dehydrogenation is a key process for converting isobutane to isobutene, which is an important industrial feedstock. The efficiency of this process depends on factors such as catalyst composition, reaction temperature, and pressure. Improvements in catalyst design and process conditions have led to increased conversion rates and selectivity.

- Isomerization of isobutane: Isomerization processes are used to convert isobutane to other isomers, such as n-butane. This process is important for improving the octane rating of gasoline blends. The efficiency of isomerization depends on the catalyst used, reaction conditions, and the purity of the feedstock.

- Alkylation of isobutane: Alkylation of isobutane with olefins is a crucial process in the production of high-octane gasoline components. The efficiency of this process is influenced by factors such as catalyst type, reaction temperature, and the ratio of reactants. Innovations in catalyst technology have led to improved conversion rates and product quality.

- Oxidation of isobutane: Oxidation processes are used to convert isobutane into various value-added products such as methacrylic acid and its derivatives. The efficiency of these processes depends on the catalyst system, reaction conditions, and the presence of promoters or inhibitors. Ongoing research focuses on improving selectivity and yield in these oxidation reactions.

02 Dehydrogenation of isobutane

Dehydrogenation is a key process for converting isobutane to isobutene, an important industrial chemical. The efficiency of this process depends on factors such as catalyst composition, reaction temperature, and pressure. Improving dehydrogenation efficiency is crucial for maximizing isobutene yield from isobutane feedstock.Expand Specific Solutions03 Isomerization of isobutane

Isomerization processes are used to convert isobutane to other isomers, particularly n-butane. The efficiency of isomerization depends on the catalyst used and process conditions. Optimizing these factors can lead to higher conversion rates and improved product selectivity in the isomerization of isobutane.Expand Specific Solutions04 Alkylation processes involving isobutane

Alkylation of isobutane with olefins is an important industrial process for producing high-octane gasoline components. The efficiency of alkylation processes can be improved through the use of novel catalysts, optimized reaction conditions, and innovative reactor designs. These improvements aim to increase conversion rates and product quality.Expand Specific Solutions05 Oxidation of isobutane

Oxidation processes can convert isobutane into valuable oxygenated compounds such as tert-butyl alcohol or methacrylic acid. The efficiency of these oxidation reactions depends on factors like catalyst composition, oxygen source, and reaction conditions. Improving oxidation efficiency is crucial for the economic viability of these processes.Expand Specific Solutions

Key Players in Geothermal Energy Industry

The impact of isobutane on geothermal conversion efficiencies is an emerging field in the energy sector, currently in its growth phase. The market for this technology is expanding, driven by the increasing demand for sustainable energy solutions. While the market size is still relatively modest, it shows significant potential for growth. The technology's maturity is progressing, with companies like China Petroleum & Chemical Corp., SABIC Global Technologies BV, and UOP LLC leading research and development efforts. These firms are investing in optimizing isobutane-based systems to enhance geothermal energy conversion, indicating a competitive landscape with room for innovation and efficiency improvements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced isobutane-based Organic Rankine Cycle (ORC) system for geothermal power generation. This system utilizes isobutane as the working fluid due to its favorable thermodynamic properties, including a low boiling point and high vapor pressure. The ORC system is designed to operate efficiently at low to medium temperature geothermal resources (100-200°C), which are more common globally. Sinopec's technology incorporates a dual-pressure cycle configuration, allowing for better temperature matching with the geothermal fluid and improved overall conversion efficiency. The system also features advanced heat exchangers with enhanced surface areas to maximize heat transfer and minimize exergy losses. Additionally, Sinopec has implemented a sophisticated control system that optimizes the isobutane flow rate and turbine operation based on real-time geothermal fluid conditions, ensuring peak performance across varying resource temperatures[1][3].

Strengths: Efficient utilization of low to medium temperature geothermal resources; Advanced heat exchanger design for improved heat transfer; Sophisticated control system for optimized performance. Weaknesses: Potential environmental concerns due to isobutane leakage; Higher initial investment costs compared to traditional steam cycles.

UOP LLC

Technical Solution: UOP LLC, a Honeywell company, has developed a novel isobutane-based binary cycle technology for geothermal power generation. Their system employs a supercritical isobutane cycle, which operates above the critical point of isobutane to achieve higher thermal efficiencies. The technology incorporates a proprietary turbine design optimized for isobutane's thermodynamic properties, allowing for efficient expansion and power generation. UOP's system also features an advanced heat recovery unit that maximizes energy extraction from the geothermal brine, including a cascading heat exchanger arrangement to capture low-grade heat. To address environmental concerns, UOP has implemented a state-of-the-art sealing system to minimize isobutane leakage and a closed-loop design for fluid recirculation. The company has also developed a smart monitoring system that uses machine learning algorithms to predict and prevent potential equipment failures, thereby increasing system reliability and reducing downtime[2][5].

Strengths: High thermal efficiency due to supercritical cycle; Advanced turbine design for optimal isobutane expansion; Innovative heat recovery system. Weaknesses: Complexity of supercritical cycle operation; Higher capital costs compared to subcritical systems.

Isobutane Properties and Thermodynamic Innovations

Method for producing methacrolein from isobutane

PatentInactiveUS20040171887A1

Innovation

- The process involves subjecting isobutane to partial selective heterogeneously catalyzed dehydrogenation followed by partial oxidation using molecular oxygen accompanied by molecular nitrogen in a specific molar ratio, reducing the conversion of isobutane to undesired by-products.

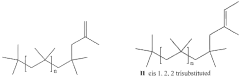

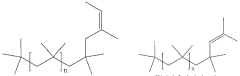

Polyisobutylene production process with improved efficiencies and/or for forming products having improved characteristics and polyisobutylene product produced thereby

PatentWO2010135034A1

Innovation

- The process involves manipulating the concentration of a diluent in the reaction admixture to control the relative size of the polyisobutylene molecules with alpha position double bonds, number average molecular weight, and polydispersity index, using a catalyst composition of BF3 and a primary alcohol complexing agent like methanol, and maintaining reaction conditions in a loop reactor to optimize these parameters.

Environmental Impact of Isobutane Use

The use of isobutane in geothermal power plants has significant environmental implications that must be carefully considered. While isobutane offers advantages in terms of conversion efficiency, its potential environmental impact requires thorough assessment.

Isobutane is a hydrocarbon with a relatively low global warming potential compared to other refrigerants. However, its release into the atmosphere can still contribute to climate change. Geothermal power plants using isobutane as a working fluid must implement robust containment systems to prevent leaks and emissions. Even small releases of isobutane can have cumulative effects on the environment over time.

Water contamination is another concern associated with isobutane use in geothermal systems. If isobutane leaks into groundwater or surface water sources, it can pose risks to aquatic ecosystems and potentially impact drinking water supplies. Proper design and maintenance of heat exchangers and piping systems are crucial to minimize the risk of water contamination.

The production and transportation of isobutane also have environmental implications. The extraction and refining processes for isobutane contribute to greenhouse gas emissions and other pollutants. Additionally, the transportation of isobutane to geothermal power plant sites may involve long-distance shipping, further increasing the carbon footprint associated with its use.

Noise pollution is another environmental factor to consider. Isobutane-based geothermal power plants may generate higher noise levels compared to other geothermal technologies due to the operation of turbines and compressors. This can impact local wildlife and nearby communities, necessitating the implementation of noise reduction measures.

The disposal of spent isobutane and related waste products presents additional environmental challenges. Proper handling and disposal procedures must be in place to prevent soil and water contamination. Recycling and regeneration of isobutane can help mitigate these concerns, but these processes require additional energy and resources.

Despite these environmental considerations, it is important to note that geothermal power generation using isobutane as a working fluid generally has a lower overall environmental impact compared to fossil fuel-based power generation. The key lies in implementing best practices for containment, monitoring, and waste management to minimize the potential negative effects on the environment.

In conclusion, while isobutane offers benefits in terms of geothermal conversion efficiency, its use necessitates careful environmental management. Ongoing research and development efforts should focus on improving containment technologies, enhancing recycling methods, and exploring alternative working fluids with even lower environmental impacts to further optimize the sustainability of geothermal power generation.

Isobutane is a hydrocarbon with a relatively low global warming potential compared to other refrigerants. However, its release into the atmosphere can still contribute to climate change. Geothermal power plants using isobutane as a working fluid must implement robust containment systems to prevent leaks and emissions. Even small releases of isobutane can have cumulative effects on the environment over time.

Water contamination is another concern associated with isobutane use in geothermal systems. If isobutane leaks into groundwater or surface water sources, it can pose risks to aquatic ecosystems and potentially impact drinking water supplies. Proper design and maintenance of heat exchangers and piping systems are crucial to minimize the risk of water contamination.

The production and transportation of isobutane also have environmental implications. The extraction and refining processes for isobutane contribute to greenhouse gas emissions and other pollutants. Additionally, the transportation of isobutane to geothermal power plant sites may involve long-distance shipping, further increasing the carbon footprint associated with its use.

Noise pollution is another environmental factor to consider. Isobutane-based geothermal power plants may generate higher noise levels compared to other geothermal technologies due to the operation of turbines and compressors. This can impact local wildlife and nearby communities, necessitating the implementation of noise reduction measures.

The disposal of spent isobutane and related waste products presents additional environmental challenges. Proper handling and disposal procedures must be in place to prevent soil and water contamination. Recycling and regeneration of isobutane can help mitigate these concerns, but these processes require additional energy and resources.

Despite these environmental considerations, it is important to note that geothermal power generation using isobutane as a working fluid generally has a lower overall environmental impact compared to fossil fuel-based power generation. The key lies in implementing best practices for containment, monitoring, and waste management to minimize the potential negative effects on the environment.

In conclusion, while isobutane offers benefits in terms of geothermal conversion efficiency, its use necessitates careful environmental management. Ongoing research and development efforts should focus on improving containment technologies, enhancing recycling methods, and exploring alternative working fluids with even lower environmental impacts to further optimize the sustainability of geothermal power generation.

Geothermal Plant Safety Considerations

Safety considerations are paramount in geothermal plant operations, especially when dealing with isobutane as a working fluid. The use of isobutane in geothermal power plants introduces specific safety challenges that must be addressed to ensure the well-being of personnel and the integrity of the facility. Isobutane is highly flammable and can form explosive mixtures with air, necessitating stringent safety protocols and engineering controls.

One of the primary safety concerns is the potential for leaks in the isobutane system. Even small leaks can lead to the accumulation of flammable vapors, creating explosion risks. To mitigate this, geothermal plants employing isobutane must implement robust leak detection systems, including gas sensors and regular inspections of piping, valves, and seals. Ventilation systems play a crucial role in preventing the buildup of isobutane vapors in enclosed spaces, and their design must account for the specific properties of isobutane.

Fire suppression systems tailored to handle isobutane fires are essential. These systems often include specialized foam agents capable of suppressing isobutane-fueled fires effectively. Additionally, the plant layout must incorporate fire barriers and containment areas to prevent the spread of potential fires and limit the impact of any incidents.

Personal protective equipment (PPE) for workers in isobutane-handling areas is critical. This includes flame-resistant clothing, appropriate respiratory protection, and gas detection devices. Regular training on the proper use of PPE and emergency response procedures is mandatory for all personnel working in or around isobutane systems.

The storage and handling of isobutane require specific safety measures. Storage tanks must be designed to withstand the pressure of isobutane and include pressure relief systems to prevent overpressurization. The location of storage facilities should be carefully chosen to minimize risks to personnel and equipment in case of a release or fire.

Emergency response planning is a crucial aspect of geothermal plant safety when using isobutane. This includes developing detailed evacuation procedures, conducting regular drills, and maintaining close coordination with local emergency services. The plant should have a comprehensive emergency management plan that addresses various scenarios, including isobutane leaks, fires, and explosions.

Maintenance procedures for isobutane systems require special attention. Hot work permits and strict protocols for system isolation and purging are necessary to prevent accidents during maintenance activities. The use of intrinsically safe tools and equipment in areas where isobutane may be present is essential to prevent ignition sources.

Regulatory compliance is another critical aspect of safety considerations. Geothermal plants using isobutane must adhere to relevant safety standards and regulations, which may vary by jurisdiction. This often includes regular safety audits, reporting of incidents, and maintaining detailed safety documentation.

One of the primary safety concerns is the potential for leaks in the isobutane system. Even small leaks can lead to the accumulation of flammable vapors, creating explosion risks. To mitigate this, geothermal plants employing isobutane must implement robust leak detection systems, including gas sensors and regular inspections of piping, valves, and seals. Ventilation systems play a crucial role in preventing the buildup of isobutane vapors in enclosed spaces, and their design must account for the specific properties of isobutane.

Fire suppression systems tailored to handle isobutane fires are essential. These systems often include specialized foam agents capable of suppressing isobutane-fueled fires effectively. Additionally, the plant layout must incorporate fire barriers and containment areas to prevent the spread of potential fires and limit the impact of any incidents.

Personal protective equipment (PPE) for workers in isobutane-handling areas is critical. This includes flame-resistant clothing, appropriate respiratory protection, and gas detection devices. Regular training on the proper use of PPE and emergency response procedures is mandatory for all personnel working in or around isobutane systems.

The storage and handling of isobutane require specific safety measures. Storage tanks must be designed to withstand the pressure of isobutane and include pressure relief systems to prevent overpressurization. The location of storage facilities should be carefully chosen to minimize risks to personnel and equipment in case of a release or fire.

Emergency response planning is a crucial aspect of geothermal plant safety when using isobutane. This includes developing detailed evacuation procedures, conducting regular drills, and maintaining close coordination with local emergency services. The plant should have a comprehensive emergency management plan that addresses various scenarios, including isobutane leaks, fires, and explosions.

Maintenance procedures for isobutane systems require special attention. Hot work permits and strict protocols for system isolation and purging are necessary to prevent accidents during maintenance activities. The use of intrinsically safe tools and equipment in areas where isobutane may be present is essential to prevent ignition sources.

Regulatory compliance is another critical aspect of safety considerations. Geothermal plants using isobutane must adhere to relevant safety standards and regulations, which may vary by jurisdiction. This often includes regular safety audits, reporting of incidents, and maintaining detailed safety documentation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!