Isobutane Leak Prevention Techniques in Residential Areas

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Safety Overview

Isobutane, a highly flammable hydrocarbon gas, poses significant safety risks in residential areas. This overview examines the key aspects of isobutane safety, focusing on its properties, potential hazards, and the importance of proper handling and leak prevention techniques.

Isobutane is commonly used as a refrigerant in household appliances and as a propellant in aerosol products. Its low boiling point and high vapor pressure make it efficient for these applications, but also contribute to its volatility and potential for rapid dispersion in the event of a leak. At room temperature, isobutane exists as a colorless, odorless gas, which can accumulate in low-lying areas due to its density being greater than that of air.

The primary safety concern with isobutane is its high flammability. It has a lower explosive limit (LEL) of 1.8% and an upper explosive limit (UEL) of 8.4% by volume in air. This relatively narrow range means that even small leaks can create potentially explosive atmospheres. Ignition sources such as electrical sparks, open flames, or hot surfaces can easily trigger an explosion or fire if isobutane concentrations reach these levels.

In addition to fire and explosion risks, isobutane can also act as an asphyxiant by displacing oxygen in confined spaces. While not toxic in itself, high concentrations can lead to dizziness, disorientation, and loss of consciousness due to oxygen deprivation. This risk is particularly relevant in poorly ventilated areas or basements where leaked gas may accumulate.

Given these hazards, proper storage, handling, and leak prevention are crucial in residential settings. Appliances and products containing isobutane should be regularly inspected for signs of wear or damage. Adequate ventilation must be maintained in areas where isobutane-containing devices are used or stored. Installation and maintenance of such appliances should only be performed by qualified professionals familiar with the specific safety requirements for isobutane.

Early detection is key to preventing serious incidents. While isobutane is naturally odorless, many manufacturers add odorants to aid in leak detection. However, reliance on odor alone is insufficient, and the use of gas detectors specifically calibrated for isobutane is strongly recommended in residential areas where this gas is present.

In the event of a suspected leak, immediate action is critical. Residents should be educated on proper emergency procedures, including evacuation protocols, avoiding the use of electrical devices or open flames, and contacting emergency services. Clear communication and coordination with local fire departments and emergency responders are essential components of a comprehensive isobutane safety strategy in residential areas.

Isobutane is commonly used as a refrigerant in household appliances and as a propellant in aerosol products. Its low boiling point and high vapor pressure make it efficient for these applications, but also contribute to its volatility and potential for rapid dispersion in the event of a leak. At room temperature, isobutane exists as a colorless, odorless gas, which can accumulate in low-lying areas due to its density being greater than that of air.

The primary safety concern with isobutane is its high flammability. It has a lower explosive limit (LEL) of 1.8% and an upper explosive limit (UEL) of 8.4% by volume in air. This relatively narrow range means that even small leaks can create potentially explosive atmospheres. Ignition sources such as electrical sparks, open flames, or hot surfaces can easily trigger an explosion or fire if isobutane concentrations reach these levels.

In addition to fire and explosion risks, isobutane can also act as an asphyxiant by displacing oxygen in confined spaces. While not toxic in itself, high concentrations can lead to dizziness, disorientation, and loss of consciousness due to oxygen deprivation. This risk is particularly relevant in poorly ventilated areas or basements where leaked gas may accumulate.

Given these hazards, proper storage, handling, and leak prevention are crucial in residential settings. Appliances and products containing isobutane should be regularly inspected for signs of wear or damage. Adequate ventilation must be maintained in areas where isobutane-containing devices are used or stored. Installation and maintenance of such appliances should only be performed by qualified professionals familiar with the specific safety requirements for isobutane.

Early detection is key to preventing serious incidents. While isobutane is naturally odorless, many manufacturers add odorants to aid in leak detection. However, reliance on odor alone is insufficient, and the use of gas detectors specifically calibrated for isobutane is strongly recommended in residential areas where this gas is present.

In the event of a suspected leak, immediate action is critical. Residents should be educated on proper emergency procedures, including evacuation protocols, avoiding the use of electrical devices or open flames, and contacting emergency services. Clear communication and coordination with local fire departments and emergency responders are essential components of a comprehensive isobutane safety strategy in residential areas.

Residential Gas Demand

The demand for residential gas, particularly isobutane, has been steadily increasing in recent years due to its widespread use in household appliances and heating systems. This growth is driven by factors such as urbanization, improved living standards, and the shift towards cleaner energy sources. In many residential areas, isobutane has become a preferred choice for cooking, water heating, and space heating due to its efficiency and relatively lower environmental impact compared to other fossil fuels.

The residential gas market has seen a significant expansion, with isobutane playing a crucial role in meeting household energy needs. This demand is particularly pronounced in regions with cold climates, where gas-powered heating systems are essential for maintaining comfortable living conditions. Additionally, the growing popularity of gas-powered appliances, such as stoves and ovens, has further contributed to the increased demand for isobutane in residential settings.

Market analysis indicates that the residential gas sector accounts for a substantial portion of overall gas consumption in many countries. This trend is expected to continue as more households transition from traditional energy sources to gas-based systems. The convenience, cost-effectiveness, and reliability of gas-powered appliances have made them increasingly attractive to consumers, further driving the demand for isobutane in residential areas.

However, the rising demand for residential gas also brings challenges, particularly in terms of safety and infrastructure development. As more households rely on isobutane for their daily energy needs, the importance of implementing robust leak prevention techniques becomes paramount. This has led to increased focus on developing and implementing advanced safety measures to mitigate the risks associated with gas leaks in residential areas.

The growing awareness of environmental issues has also influenced the residential gas demand landscape. While isobutane is considered cleaner than some alternatives, there is an ongoing push for even more sustainable energy solutions. This has resulted in efforts to improve the efficiency of gas-powered appliances and explore ways to integrate renewable gas sources into existing residential gas networks.

In response to the increasing demand and safety concerns, regulatory bodies have implemented stricter guidelines for residential gas installations and usage. These regulations aim to ensure proper handling, storage, and distribution of isobutane in residential areas, further emphasizing the need for effective leak prevention techniques. The intersection of growing demand and safety requirements has created a dynamic market for innovative solutions in residential gas leak prevention and management.

The residential gas market has seen a significant expansion, with isobutane playing a crucial role in meeting household energy needs. This demand is particularly pronounced in regions with cold climates, where gas-powered heating systems are essential for maintaining comfortable living conditions. Additionally, the growing popularity of gas-powered appliances, such as stoves and ovens, has further contributed to the increased demand for isobutane in residential settings.

Market analysis indicates that the residential gas sector accounts for a substantial portion of overall gas consumption in many countries. This trend is expected to continue as more households transition from traditional energy sources to gas-based systems. The convenience, cost-effectiveness, and reliability of gas-powered appliances have made them increasingly attractive to consumers, further driving the demand for isobutane in residential areas.

However, the rising demand for residential gas also brings challenges, particularly in terms of safety and infrastructure development. As more households rely on isobutane for their daily energy needs, the importance of implementing robust leak prevention techniques becomes paramount. This has led to increased focus on developing and implementing advanced safety measures to mitigate the risks associated with gas leaks in residential areas.

The growing awareness of environmental issues has also influenced the residential gas demand landscape. While isobutane is considered cleaner than some alternatives, there is an ongoing push for even more sustainable energy solutions. This has resulted in efforts to improve the efficiency of gas-powered appliances and explore ways to integrate renewable gas sources into existing residential gas networks.

In response to the increasing demand and safety concerns, regulatory bodies have implemented stricter guidelines for residential gas installations and usage. These regulations aim to ensure proper handling, storage, and distribution of isobutane in residential areas, further emphasizing the need for effective leak prevention techniques. The intersection of growing demand and safety requirements has created a dynamic market for innovative solutions in residential gas leak prevention and management.

Leak Detection Challenges

Detecting isobutane leaks in residential areas presents several significant challenges due to the unique properties of the gas and the complex nature of residential environments. One of the primary difficulties is the low odor threshold of isobutane, which makes it difficult for human senses to detect small leaks before they become dangerous. This necessitates the use of sophisticated detection equipment, which can be costly and may require frequent calibration and maintenance.

The variability of residential structures further complicates leak detection efforts. Homes come in various sizes, layouts, and construction materials, each affecting how isobutane gas may accumulate or disperse. This diversity makes it challenging to develop a one-size-fits-all detection strategy and often requires customized approaches for different types of dwellings.

Environmental factors also play a crucial role in the effectiveness of leak detection techniques. Temperature fluctuations, air currents, and humidity levels can all influence the behavior of isobutane gas, potentially masking leaks or creating false positives. These variables necessitate detection systems that can adapt to changing conditions and filter out environmental noise.

Another significant challenge is the potential for interference from other household gases and chemicals. Common substances like cleaning products, cooking fumes, and even certain building materials can emit volatile organic compounds (VOCs) that may trigger false alarms in less sophisticated detection systems. This requires the development of highly selective sensors capable of distinguishing isobutane from other airborne substances.

The placement of detection devices presents an additional hurdle. Isobutane is heavier than air and tends to accumulate at lower levels, making it crucial to position sensors appropriately. However, the dynamic nature of residential activities and furniture arrangements can obstruct ideal sensor placement or create dead zones where leaks might go undetected.

Continuous monitoring is essential for effective leak prevention, but this raises concerns about power consumption and the reliability of detection systems during power outages. Developing energy-efficient sensors and ensuring backup power sources are critical considerations in addressing this challenge.

Lastly, the integration of leak detection systems with smart home technologies presents both opportunities and challenges. While it offers the potential for real-time alerts and remote monitoring, it also introduces cybersecurity risks and the need for robust, user-friendly interfaces that can be easily understood and operated by residents of all ages and technical abilities.

The variability of residential structures further complicates leak detection efforts. Homes come in various sizes, layouts, and construction materials, each affecting how isobutane gas may accumulate or disperse. This diversity makes it challenging to develop a one-size-fits-all detection strategy and often requires customized approaches for different types of dwellings.

Environmental factors also play a crucial role in the effectiveness of leak detection techniques. Temperature fluctuations, air currents, and humidity levels can all influence the behavior of isobutane gas, potentially masking leaks or creating false positives. These variables necessitate detection systems that can adapt to changing conditions and filter out environmental noise.

Another significant challenge is the potential for interference from other household gases and chemicals. Common substances like cleaning products, cooking fumes, and even certain building materials can emit volatile organic compounds (VOCs) that may trigger false alarms in less sophisticated detection systems. This requires the development of highly selective sensors capable of distinguishing isobutane from other airborne substances.

The placement of detection devices presents an additional hurdle. Isobutane is heavier than air and tends to accumulate at lower levels, making it crucial to position sensors appropriately. However, the dynamic nature of residential activities and furniture arrangements can obstruct ideal sensor placement or create dead zones where leaks might go undetected.

Continuous monitoring is essential for effective leak prevention, but this raises concerns about power consumption and the reliability of detection systems during power outages. Developing energy-efficient sensors and ensuring backup power sources are critical considerations in addressing this challenge.

Lastly, the integration of leak detection systems with smart home technologies presents both opportunities and challenges. While it offers the potential for real-time alerts and remote monitoring, it also introduces cybersecurity risks and the need for robust, user-friendly interfaces that can be easily understood and operated by residents of all ages and technical abilities.

Current Prevention Methods

01 Leak detection systems

Advanced leak detection systems are crucial for preventing isobutane leaks. These systems utilize sensors and monitoring devices to detect the presence of isobutane gas in the environment. Early detection allows for prompt response and mitigation of potential leaks, enhancing overall safety and preventing accidents.- Leak detection systems: Advanced leak detection systems are crucial for preventing isobutane leaks. These systems utilize sensors and monitoring devices to detect the presence of isobutane gas in the environment. Early detection allows for prompt response and mitigation of potential leaks, enhancing overall safety in industrial settings where isobutane is used or stored.

- Improved sealing and valve technologies: Developing and implementing enhanced sealing and valve technologies is essential for preventing isobutane leaks. This includes the use of high-quality gaskets, advanced valve designs, and robust sealing materials that can withstand the pressures and temperatures associated with isobutane storage and transport. These improvements help minimize the risk of leaks at connection points and valves.

- Regular maintenance and inspection protocols: Establishing and adhering to rigorous maintenance and inspection protocols is critical for preventing isobutane leaks. This includes regular checks of equipment, pipelines, and storage facilities to identify potential weak points or areas of wear. Proactive maintenance helps address issues before they escalate into leaks, ensuring the integrity of the isobutane containment systems.

- Pressure relief and safety systems: Implementing effective pressure relief and safety systems is crucial for preventing catastrophic failures that could lead to isobutane leaks. This includes the use of pressure relief valves, rupture discs, and emergency shutdown systems. These safety measures help manage excessive pressure buildup and provide controlled release mechanisms to prevent uncontrolled leaks or explosions.

- Training and safety protocols for handling isobutane: Developing comprehensive training programs and safety protocols for personnel handling isobutane is essential for leak prevention. This includes educating workers on proper handling procedures, emergency response measures, and the use of personal protective equipment. Well-trained staff can identify potential leak risks and respond effectively to prevent or mitigate leaks.

02 Improved sealing and valve technologies

Enhancing sealing mechanisms and valve technologies is essential for isobutane leak prevention. This includes the development of high-quality gaskets, seals, and advanced valve designs that can withstand the pressures and properties of isobutane. These improvements help to maintain system integrity and reduce the likelihood of leaks at connection points and valves.Expand Specific Solutions03 Regular maintenance and inspection protocols

Implementing rigorous maintenance and inspection protocols is critical for preventing isobutane leaks. This involves scheduled checks of equipment, pipelines, and storage facilities to identify potential weak points or areas of wear. Regular maintenance ensures that all components are in optimal condition, reducing the risk of leaks due to equipment failure or degradation.Expand Specific Solutions04 Pressure management systems

Effective pressure management systems are crucial for preventing isobutane leaks. These systems monitor and regulate the pressure within storage tanks, pipelines, and processing equipment. By maintaining appropriate pressure levels and implementing safety relief mechanisms, the risk of leaks due to overpressurization can be significantly reduced.Expand Specific Solutions05 Training and safety protocols

Comprehensive training programs and strict safety protocols are essential for preventing isobutane leaks. This includes educating personnel on proper handling procedures, emergency response techniques, and the use of personal protective equipment. Implementing and enforcing safety guidelines ensures that human error-related leaks are minimized and that staff are prepared to respond effectively in case of an incident.Expand Specific Solutions

Key Industry Players

The isobutane leak prevention techniques in residential areas market is in a growth phase, driven by increasing safety concerns and regulatory pressures. The market size is expanding as more residential areas implement advanced leak detection and prevention systems. Technologically, the field is advancing rapidly, with companies like BASF Corp., Honeywell International Technologies Ltd., and PetroChina Co., Ltd. leading innovation. These firms are developing sophisticated sensors, monitoring systems, and leak-resistant materials. Academic institutions such as Beijing Institute of Technology and Huazhong University of Science & Technology are contributing to research and development efforts, enhancing the overall technological maturity of the sector.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced leak detection and prevention techniques for isobutane in residential areas. Their approach includes the use of high-sensitivity gas sensors combined with IoT technology for real-time monitoring[1]. The company has also introduced a proprietary sealant material specifically designed for isobutane applications, which can be applied to potential leak points in household appliances and gas lines[3]. Additionally, BASF has implemented a machine learning algorithm that analyzes sensor data to predict potential leak risks before they occur, allowing for proactive maintenance[5].

Strengths: Comprehensive approach combining hardware and software solutions, industry-leading sealant technology. Weaknesses: Potentially higher implementation costs, may require specialized training for installation and maintenance.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated isobutane leak prevention system for residential areas. Their solution incorporates advanced gas detection sensors with a proprietary algorithm that can differentiate between isobutane and other gases, reducing false alarms[2]. The system is connected to a smart home network, allowing for immediate alerts to homeowners and emergency services. Honeywell has also introduced a self-sealing valve technology that automatically shuts off gas flow when a leak is detected[4]. Furthermore, they have developed a mobile app that provides real-time monitoring and remote control capabilities for users[6].

Strengths: High accuracy in leak detection, integration with smart home systems, user-friendly interface. Weaknesses: May require professional installation, potential for system complexity leading to maintenance challenges.

Innovative Sensor Tech

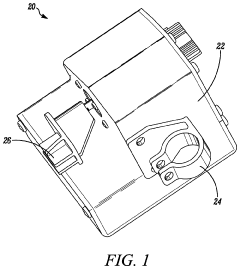

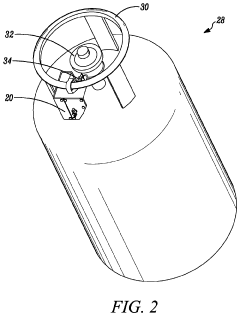

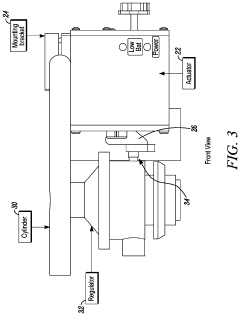

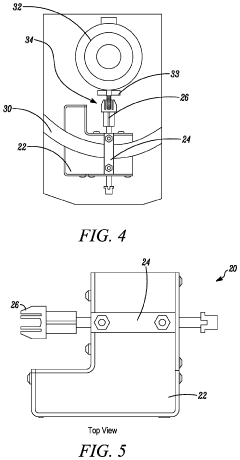

Systems and methods for leak detection and remote, non-intrusive, automatic shutoff in residential regulators

PatentActiveUS10619849B2

Innovation

- A shutoff device mounted on residential LPG regulators that detects leaks and automatically shuts off the valve using a transceiver for remote communication, an actuator to rotate the valve knob, and sensors to determine the valve position, enabling remote, non-intrusive, and automatic control of the leak.

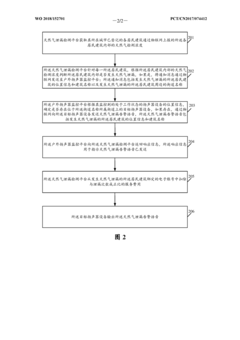

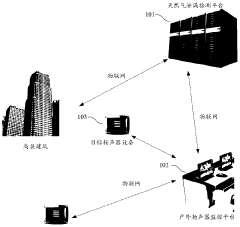

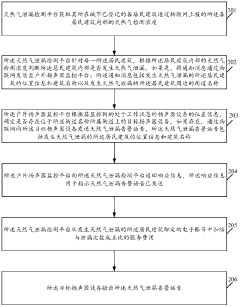

System and method for detecting natural gas leak in residential building

PatentWO2018152701A1

Innovation

- A natural gas leakage detection system for residential buildings is designed. It uses Internet of Things technology to obtain the detection concentration of natural gas inside the building, determine whether a leak has occurred, and send alarm information to outdoor speakers through the Internet of Things to ensure the communication of the leakage location and building name, and Service fees will be deducted from the relevant account when a leak occurs.

Regulatory Framework

The regulatory framework surrounding isobutane leak prevention in residential areas is a critical aspect of ensuring public safety and environmental protection. In the United States, the Environmental Protection Agency (EPA) plays a pivotal role in establishing and enforcing regulations related to hazardous substances, including isobutane. The Clean Air Act and the Emergency Planning and Community Right-to-Know Act (EPCRA) provide the legal basis for many of these regulations.

At the federal level, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including the handling and storage of flammable gases like isobutane. These standards outline requirements for proper ventilation, storage containers, and emergency response procedures. The Department of Transportation (DOT) regulates the transportation of hazardous materials, including isobutane, through its Pipeline and Hazardous Materials Safety Administration (PHMSA).

State and local governments often have additional regulations that complement federal standards. For instance, many states have adopted more stringent requirements for leak detection and prevention in residential areas. These may include mandatory installation of gas detectors, regular inspections of appliances and storage systems, and specific zoning requirements for properties using or storing isobutane.

Building codes and fire safety regulations also play a crucial role in isobutane leak prevention. The International Code Council (ICC) develops model codes that are widely adopted by local jurisdictions. These codes include provisions for the safe installation and maintenance of appliances that use isobutane, such as refrigerators and air conditioners.

Industry standards, while not legally binding, often inform regulatory decisions and best practices. Organizations like the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and the National Fire Protection Association (NFPA) provide guidelines that are frequently incorporated into local regulations.

Enforcement of these regulations typically involves a combination of periodic inspections, reporting requirements, and penalties for non-compliance. Local fire departments and building inspectors often take the lead in ensuring that residential properties meet the necessary safety standards for isobutane use and storage.

As awareness of the potential dangers of isobutane leaks grows, there is an ongoing trend towards more comprehensive and stringent regulations. This includes increased focus on public education, emergency response planning, and the development of new technologies for leak detection and prevention. The regulatory landscape continues to evolve, with a growing emphasis on proactive measures to prevent leaks before they occur.

At the federal level, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including the handling and storage of flammable gases like isobutane. These standards outline requirements for proper ventilation, storage containers, and emergency response procedures. The Department of Transportation (DOT) regulates the transportation of hazardous materials, including isobutane, through its Pipeline and Hazardous Materials Safety Administration (PHMSA).

State and local governments often have additional regulations that complement federal standards. For instance, many states have adopted more stringent requirements for leak detection and prevention in residential areas. These may include mandatory installation of gas detectors, regular inspections of appliances and storage systems, and specific zoning requirements for properties using or storing isobutane.

Building codes and fire safety regulations also play a crucial role in isobutane leak prevention. The International Code Council (ICC) develops model codes that are widely adopted by local jurisdictions. These codes include provisions for the safe installation and maintenance of appliances that use isobutane, such as refrigerators and air conditioners.

Industry standards, while not legally binding, often inform regulatory decisions and best practices. Organizations like the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and the National Fire Protection Association (NFPA) provide guidelines that are frequently incorporated into local regulations.

Enforcement of these regulations typically involves a combination of periodic inspections, reporting requirements, and penalties for non-compliance. Local fire departments and building inspectors often take the lead in ensuring that residential properties meet the necessary safety standards for isobutane use and storage.

As awareness of the potential dangers of isobutane leaks grows, there is an ongoing trend towards more comprehensive and stringent regulations. This includes increased focus on public education, emergency response planning, and the development of new technologies for leak detection and prevention. The regulatory landscape continues to evolve, with a growing emphasis on proactive measures to prevent leaks before they occur.

Environmental Impact

Isobutane leaks in residential areas pose significant environmental risks that extend beyond immediate safety concerns. The release of isobutane into the atmosphere contributes to the formation of ground-level ozone, a key component of smog. This can lead to reduced air quality, particularly in urban and suburban settings where residential areas are densely populated. Prolonged exposure to elevated ozone levels can harm vegetation, including crops and forests, potentially impacting local ecosystems and biodiversity.

Furthermore, isobutane is a potent greenhouse gas with a global warming potential significantly higher than carbon dioxide. While the quantities released from individual residential leaks may be small, the cumulative effect of multiple leaks across numerous households can contribute to climate change. This underscores the importance of effective leak prevention techniques not only for immediate safety but also for long-term environmental protection.

Soil contamination is another environmental concern associated with isobutane leaks. When leaked gas permeates the soil, it can alter soil chemistry and potentially harm soil microorganisms. This can lead to reduced soil fertility and impact the growth of plants in affected areas. In cases of significant leaks, the gas may reach groundwater, potentially contaminating local water supplies and aquatic ecosystems.

The environmental impact of isobutane leaks extends to wildlife as well. Birds and small mammals in residential areas may be affected by direct exposure to leaked gas or through the consumption of contaminated vegetation or water. This can lead to various health issues in local fauna, potentially disrupting ecological balance in urban and suburban ecosystems.

Addressing the environmental impact of isobutane leaks requires a multifaceted approach. This includes implementing robust leak detection systems, regular maintenance of appliances and gas lines, and educating residents about proper gas handling and the importance of prompt leak reporting. Additionally, the development of more environmentally friendly alternatives to isobutane in residential applications could significantly reduce the potential for environmental harm.

Regulatory bodies play a crucial role in mitigating the environmental impact of isobutane leaks. Stringent standards for gas storage, transportation, and use in residential areas can help prevent leaks and minimize their environmental consequences. Furthermore, encouraging the adoption of renewable energy sources in residential settings can reduce reliance on isobutane and other fossil fuels, thereby decreasing the overall environmental risk associated with their use.

Furthermore, isobutane is a potent greenhouse gas with a global warming potential significantly higher than carbon dioxide. While the quantities released from individual residential leaks may be small, the cumulative effect of multiple leaks across numerous households can contribute to climate change. This underscores the importance of effective leak prevention techniques not only for immediate safety but also for long-term environmental protection.

Soil contamination is another environmental concern associated with isobutane leaks. When leaked gas permeates the soil, it can alter soil chemistry and potentially harm soil microorganisms. This can lead to reduced soil fertility and impact the growth of plants in affected areas. In cases of significant leaks, the gas may reach groundwater, potentially contaminating local water supplies and aquatic ecosystems.

The environmental impact of isobutane leaks extends to wildlife as well. Birds and small mammals in residential areas may be affected by direct exposure to leaked gas or through the consumption of contaminated vegetation or water. This can lead to various health issues in local fauna, potentially disrupting ecological balance in urban and suburban ecosystems.

Addressing the environmental impact of isobutane leaks requires a multifaceted approach. This includes implementing robust leak detection systems, regular maintenance of appliances and gas lines, and educating residents about proper gas handling and the importance of prompt leak reporting. Additionally, the development of more environmentally friendly alternatives to isobutane in residential applications could significantly reduce the potential for environmental harm.

Regulatory bodies play a crucial role in mitigating the environmental impact of isobutane leaks. Stringent standards for gas storage, transportation, and use in residential areas can help prevent leaks and minimize their environmental consequences. Furthermore, encouraging the adoption of renewable energy sources in residential settings can reduce reliance on isobutane and other fossil fuels, thereby decreasing the overall environmental risk associated with their use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!