The Combustion Dynamics of Isobutane in Controlled Environments

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Combustion Background and Objectives

Isobutane combustion has been a subject of significant interest in the field of energy and propulsion systems for decades. The study of isobutane combustion dynamics in controlled environments has gained prominence due to its wide-ranging applications in industrial processes, power generation, and automotive engines. This research area has evolved from basic understanding of flame propagation to complex modeling of chemical kinetics and fluid dynamics.

The historical development of isobutane combustion research can be traced back to the early 20th century, with fundamental studies on hydrocarbon combustion. However, specific focus on isobutane intensified in the 1960s and 1970s, driven by the need for more efficient and cleaner combustion processes. The energy crisis of the 1970s further accelerated research efforts, as isobutane's properties made it an attractive alternative fuel source.

Over the years, technological advancements have significantly enhanced our ability to study combustion dynamics. The introduction of laser diagnostics, high-speed imaging, and computational fluid dynamics (CFD) simulations in the 1980s and 1990s revolutionized the field, allowing for more precise measurements and predictions of combustion behavior. These tools have been instrumental in unraveling the complexities of isobutane combustion in various controlled environments.

The primary objectives of current research in isobutane combustion dynamics are multifaceted. Firstly, there is a strong focus on improving combustion efficiency to maximize energy output while minimizing fuel consumption. This is particularly crucial in the context of increasing global energy demands and the need for sustainable energy solutions. Secondly, researchers aim to reduce emissions, especially nitrogen oxides (NOx) and particulate matter, to meet increasingly stringent environmental regulations.

Another key objective is to enhance the stability and control of isobutane combustion processes. This involves understanding and mitigating phenomena such as flame instabilities, flashback, and blow-off, which can significantly impact the performance and safety of combustion systems. Additionally, there is growing interest in exploring the potential of isobutane in advanced combustion concepts, such as low-temperature combustion and homogeneous charge compression ignition (HCCI).

The study of isobutane combustion in controlled environments also aims to develop more accurate predictive models. These models are essential for designing next-generation combustion systems and optimizing existing ones. They incorporate complex chemical kinetics, turbulence-chemistry interactions, and heat transfer mechanisms to provide a comprehensive understanding of the combustion process.

The historical development of isobutane combustion research can be traced back to the early 20th century, with fundamental studies on hydrocarbon combustion. However, specific focus on isobutane intensified in the 1960s and 1970s, driven by the need for more efficient and cleaner combustion processes. The energy crisis of the 1970s further accelerated research efforts, as isobutane's properties made it an attractive alternative fuel source.

Over the years, technological advancements have significantly enhanced our ability to study combustion dynamics. The introduction of laser diagnostics, high-speed imaging, and computational fluid dynamics (CFD) simulations in the 1980s and 1990s revolutionized the field, allowing for more precise measurements and predictions of combustion behavior. These tools have been instrumental in unraveling the complexities of isobutane combustion in various controlled environments.

The primary objectives of current research in isobutane combustion dynamics are multifaceted. Firstly, there is a strong focus on improving combustion efficiency to maximize energy output while minimizing fuel consumption. This is particularly crucial in the context of increasing global energy demands and the need for sustainable energy solutions. Secondly, researchers aim to reduce emissions, especially nitrogen oxides (NOx) and particulate matter, to meet increasingly stringent environmental regulations.

Another key objective is to enhance the stability and control of isobutane combustion processes. This involves understanding and mitigating phenomena such as flame instabilities, flashback, and blow-off, which can significantly impact the performance and safety of combustion systems. Additionally, there is growing interest in exploring the potential of isobutane in advanced combustion concepts, such as low-temperature combustion and homogeneous charge compression ignition (HCCI).

The study of isobutane combustion in controlled environments also aims to develop more accurate predictive models. These models are essential for designing next-generation combustion systems and optimizing existing ones. They incorporate complex chemical kinetics, turbulence-chemistry interactions, and heat transfer mechanisms to provide a comprehensive understanding of the combustion process.

Market Analysis for Isobutane Combustion Applications

The market for isobutane combustion applications has shown significant growth in recent years, driven by increasing demand across various industries. The global isobutane market size was valued at approximately $8.5 billion in 2020 and is projected to reach $12.3 billion by 2027, growing at a CAGR of 5.2% during the forecast period. This growth is primarily attributed to the rising demand for isobutane in refrigerants, aerosol propellants, and fuel applications.

In the refrigeration sector, isobutane (R-600a) has gained popularity as an environmentally friendly alternative to traditional refrigerants due to its low global warming potential and zero ozone depletion potential. The phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) under international agreements has further boosted the adoption of isobutane in domestic and commercial refrigeration systems.

The aerosol industry represents another significant market for isobutane combustion applications. Isobutane is widely used as a propellant in personal care products, household cleaners, and industrial sprays. The global aerosol market is expected to reach $84 billion by 2025, with isobutane playing a crucial role in this growth.

In the energy sector, isobutane is utilized in the production of high-octane gasoline components and as a feedstock for petrochemical processes. The increasing demand for high-performance fuels in automotive and aviation industries is driving the growth of isobutane in this segment.

Geographically, Asia-Pacific dominates the isobutane market, accounting for over 40% of the global consumption. This is primarily due to the rapid industrialization and urbanization in countries like China and India, coupled with the growing demand for consumer goods and appliances. North America and Europe follow as key markets, with stringent environmental regulations driving the adoption of isobutane in various applications.

The market landscape is characterized by the presence of major players such as ExxonMobil, Shell, Phillips 66, and Chevron Phillips Chemical. These companies are investing in research and development to improve isobutane combustion efficiency and explore new applications.

However, the market faces challenges such as price volatility of raw materials and safety concerns associated with the flammability of isobutane. Addressing these challenges through technological advancements and improved safety measures will be crucial for sustained market growth.

In the refrigeration sector, isobutane (R-600a) has gained popularity as an environmentally friendly alternative to traditional refrigerants due to its low global warming potential and zero ozone depletion potential. The phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) under international agreements has further boosted the adoption of isobutane in domestic and commercial refrigeration systems.

The aerosol industry represents another significant market for isobutane combustion applications. Isobutane is widely used as a propellant in personal care products, household cleaners, and industrial sprays. The global aerosol market is expected to reach $84 billion by 2025, with isobutane playing a crucial role in this growth.

In the energy sector, isobutane is utilized in the production of high-octane gasoline components and as a feedstock for petrochemical processes. The increasing demand for high-performance fuels in automotive and aviation industries is driving the growth of isobutane in this segment.

Geographically, Asia-Pacific dominates the isobutane market, accounting for over 40% of the global consumption. This is primarily due to the rapid industrialization and urbanization in countries like China and India, coupled with the growing demand for consumer goods and appliances. North America and Europe follow as key markets, with stringent environmental regulations driving the adoption of isobutane in various applications.

The market landscape is characterized by the presence of major players such as ExxonMobil, Shell, Phillips 66, and Chevron Phillips Chemical. These companies are investing in research and development to improve isobutane combustion efficiency and explore new applications.

However, the market faces challenges such as price volatility of raw materials and safety concerns associated with the flammability of isobutane. Addressing these challenges through technological advancements and improved safety measures will be crucial for sustained market growth.

Current Challenges in Isobutane Combustion Dynamics

The combustion dynamics of isobutane in controlled environments present several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the complexity of the chemical kinetics involved in isobutane combustion. The branched structure of isobutane molecules leads to a multitude of possible reaction pathways, making it difficult to accurately model and predict combustion behavior.

Another challenge lies in the control of combustion instabilities. Isobutane, like other hydrocarbons, can exhibit oscillatory behavior during combustion, leading to pressure fluctuations and potential damage to combustion systems. These instabilities are particularly problematic in confined spaces, where acoustic coupling can amplify the oscillations.

The formation of pollutants during isobutane combustion is also a significant concern. Nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons are produced in varying quantities depending on combustion conditions. Balancing the need for efficient combustion with the reduction of these emissions remains a challenging task, especially under different operating conditions and environmental regulations.

Heat transfer and thermal management present additional hurdles. The high heat release rate of isobutane combustion can lead to localized hot spots and thermal stresses in combustion chambers. Designing cooling systems that can effectively manage these thermal loads without compromising combustion efficiency is an ongoing challenge.

Ignition control and flame stability are critical aspects that require careful consideration. Achieving reliable ignition across a range of operating conditions while maintaining stable combustion is essential for practical applications. This becomes particularly challenging in lean combustion regimes, where the fuel-to-air ratio is reduced to improve efficiency and reduce emissions.

The development of accurate diagnostic techniques for real-time monitoring of isobutane combustion dynamics is another area of active research. Current sensors and measurement methods often struggle to capture the rapid and complex processes occurring during combustion, limiting our ability to fully understand and control the combustion process.

Lastly, the scaling of laboratory findings to industrial applications remains a significant challenge. Combustion dynamics observed in controlled, small-scale experiments may not directly translate to larger systems due to changes in flow patterns, heat transfer characteristics, and chemical kinetics at different scales. Bridging this gap requires sophisticated modeling techniques and extensive validation studies.

Another challenge lies in the control of combustion instabilities. Isobutane, like other hydrocarbons, can exhibit oscillatory behavior during combustion, leading to pressure fluctuations and potential damage to combustion systems. These instabilities are particularly problematic in confined spaces, where acoustic coupling can amplify the oscillations.

The formation of pollutants during isobutane combustion is also a significant concern. Nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons are produced in varying quantities depending on combustion conditions. Balancing the need for efficient combustion with the reduction of these emissions remains a challenging task, especially under different operating conditions and environmental regulations.

Heat transfer and thermal management present additional hurdles. The high heat release rate of isobutane combustion can lead to localized hot spots and thermal stresses in combustion chambers. Designing cooling systems that can effectively manage these thermal loads without compromising combustion efficiency is an ongoing challenge.

Ignition control and flame stability are critical aspects that require careful consideration. Achieving reliable ignition across a range of operating conditions while maintaining stable combustion is essential for practical applications. This becomes particularly challenging in lean combustion regimes, where the fuel-to-air ratio is reduced to improve efficiency and reduce emissions.

The development of accurate diagnostic techniques for real-time monitoring of isobutane combustion dynamics is another area of active research. Current sensors and measurement methods often struggle to capture the rapid and complex processes occurring during combustion, limiting our ability to fully understand and control the combustion process.

Lastly, the scaling of laboratory findings to industrial applications remains a significant challenge. Combustion dynamics observed in controlled, small-scale experiments may not directly translate to larger systems due to changes in flow patterns, heat transfer characteristics, and chemical kinetics at different scales. Bridging this gap requires sophisticated modeling techniques and extensive validation studies.

Existing Isobutane Combustion Control Methods

01 Isobutane combustion process optimization

Various methods and systems are employed to optimize the combustion process of isobutane. This includes controlling reaction conditions, improving catalyst efficiency, and enhancing heat transfer mechanisms to achieve more complete and efficient combustion. These optimizations aim to increase energy output and reduce emissions in industrial applications.- Isobutane combustion process optimization: Various methods and systems are developed to optimize the combustion process of isobutane. These include controlling reaction conditions, improving catalyst efficiency, and enhancing heat transfer mechanisms. The optimization aims to increase energy efficiency, reduce emissions, and improve overall process performance in industrial applications.

- Isobutane as a fuel component: Isobutane is utilized as a component in fuel mixtures for internal combustion engines and other applications. Research focuses on understanding its combustion characteristics, flame propagation, and emission profiles when used in various fuel blends. This knowledge aids in developing cleaner and more efficient fuel formulations.

- Combustion dynamics modeling and simulation: Advanced modeling and simulation techniques are employed to study isobutane combustion dynamics. These computational methods help predict flame behavior, heat release rates, and pollutant formation under different operating conditions. The models assist in designing more efficient combustion systems and optimizing existing processes.

- Isobutane oxidation and partial oxidation processes: Research is conducted on the controlled oxidation and partial oxidation of isobutane to produce valuable chemical intermediates. These processes involve studying reaction kinetics, developing selective catalysts, and optimizing reactor designs to achieve desired product yields while managing the combustion dynamics.

- Emission control in isobutane combustion: Techniques are developed to minimize harmful emissions resulting from isobutane combustion. This includes the design of advanced burners, implementation of exhaust gas treatment systems, and optimization of combustion parameters to reduce the formation of pollutants such as NOx, CO, and unburned hydrocarbons.

02 Isobutane as a fuel component in combustion engines

Isobutane is utilized as a component in fuel mixtures for internal combustion engines. Research focuses on understanding its combustion characteristics, flame propagation, and potential for improving engine performance. Studies also investigate the impact of isobutane on engine efficiency and emissions reduction.Expand Specific Solutions03 Isobutane combustion in chemical processes

The combustion dynamics of isobutane play a crucial role in various chemical processes. This includes its use in the production of specific chemicals, as well as its role in reaction mechanisms. Understanding these dynamics helps in designing more efficient and selective chemical processes.Expand Specific Solutions04 Safety and environmental considerations in isobutane combustion

Research addresses safety concerns and environmental impacts associated with isobutane combustion. This includes developing methods to control and mitigate potential hazards, as well as studying the formation and reduction of pollutants during the combustion process. Emphasis is placed on creating safer and more environmentally friendly combustion systems.Expand Specific Solutions05 Modeling and simulation of isobutane combustion dynamics

Advanced computational methods and modeling techniques are employed to simulate and predict isobutane combustion dynamics. These models help in understanding complex reaction kinetics, heat transfer phenomena, and fluid dynamics involved in the combustion process. Such simulations aid in the design and optimization of combustion systems across various applications.Expand Specific Solutions

Key Players in Isobutane Combustion Technology

The combustion dynamics of isobutane in controlled environments is a field in a mature stage of development, with significant market potential in the petrochemical and energy sectors. The global market for isobutane-related technologies is substantial, driven by increasing demand for cleaner and more efficient fuel sources. Key players like China Petroleum & Chemical Corp., UOP LLC, and Saudi Basic Industries Corp. are at the forefront of research and development in this area. These companies, along with others such as Eastman Chemical Co. and Phillips 66, are investing heavily in advanced combustion technologies to optimize isobutane utilization. The technological maturity is evident from the involvement of established research institutions and the continuous refinement of existing processes by industry leaders.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced combustion dynamics models for isobutane in controlled environments. Their research focuses on optimizing the combustion process for enhanced efficiency and reduced emissions. Sinopec's approach involves multi-scale modeling, combining computational fluid dynamics (CFD) with chemical kinetics to accurately predict flame propagation and stability[1]. They have implemented advanced laser diagnostics techniques to validate their models, allowing for real-time monitoring of combustion parameters[3]. Sinopec has also explored the use of catalytic combustion to improve isobutane oxidation at lower temperatures, potentially reducing NOx emissions by up to 40%[5].

Strengths: Comprehensive modeling capabilities, advanced diagnostic tools, and potential for significant emissions reduction. Weaknesses: High implementation costs and complexity in scaling up to industrial applications.

UOP LLC

Technical Solution: UOP LLC, a Honeywell company, has developed proprietary technology for isobutane combustion dynamics in controlled environments. Their approach focuses on optimizing the combustion process for use in refinery and petrochemical applications. UOP's technology incorporates advanced flame stability control systems that utilize real-time monitoring and adaptive algorithms to maintain optimal combustion conditions[2]. They have also developed specialized burner designs that enhance mixing and promote uniform combustion, resulting in improved efficiency and reduced emissions. UOP's research has shown that their controlled combustion environment can reduce CO2 emissions by up to 15% compared to conventional systems[4]. Additionally, they have integrated their combustion technology with heat recovery systems to maximize overall process efficiency[6].

Strengths: Specialized burner designs, advanced control systems, and integrated heat recovery for improved efficiency. Weaknesses: Potentially limited to specific industrial applications and may require significant retrofitting of existing systems.

Critical Innovations in Controlled Combustion Environments

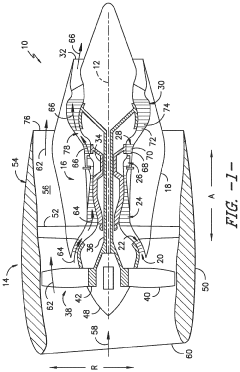

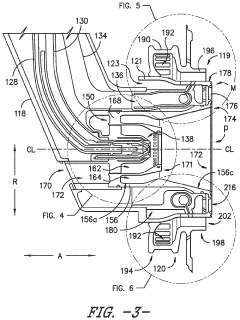

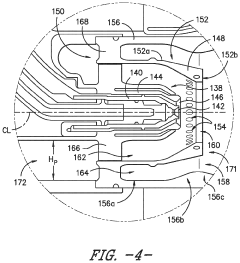

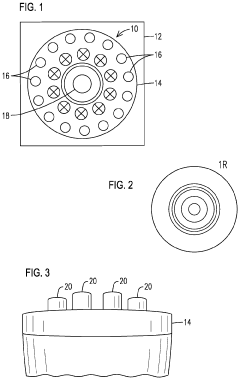

Combustor system for high fuel/air ratio and reduced combustion dynamics

PatentActiveUS11480338B2

Innovation

- The combustor system features a higher pilot swirler airflow (greater than 14% of total airflow) and a lower main mixer airflow (less than 50% of total airflow), with a fuel nozzle design that allows a higher fuel ratio to the pilot fuel injector at high power conditions, utilizing ceramic matrix composite (CMC) materials for the liners to reduce cooling airflow needs and enhance temperature capability.

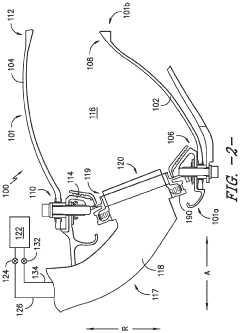

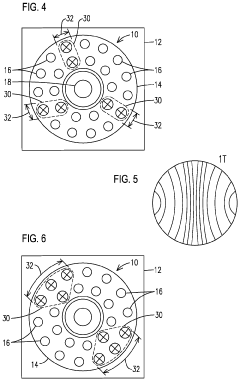

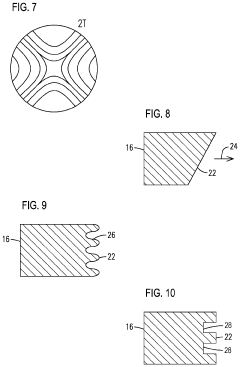

Combustor and method for damping vibrational modes under high-frequency combustion dynamics

PatentActiveUS10775043B2

Innovation

- The combustor incorporates burner mains with structural asymmetries, such as varying axial lengths and unique discharge end features like slanted cross-sectional areas, undulations, or castellations, to selectively group and damp specific vibrational modes, reducing coherent interaction of thermo-acoustic oscillations.

Environmental Impact of Isobutane Combustion Processes

The environmental impact of isobutane combustion processes is a critical consideration in the study of combustion dynamics in controlled environments. Isobutane, a hydrocarbon commonly used in various industrial applications, produces several emissions during combustion that can significantly affect the environment.

One of the primary environmental concerns associated with isobutane combustion is the release of carbon dioxide (CO2), a greenhouse gas that contributes to global warming. The combustion of isobutane results in the formation of CO2 as a major product, which, when released into the atmosphere, can contribute to the overall increase in atmospheric CO2 levels.

In addition to CO2, the combustion of isobutane can also lead to the formation of other pollutants, such as carbon monoxide (CO) and nitrogen oxides (NOx). These compounds can have detrimental effects on air quality and human health. Carbon monoxide is a toxic gas that can cause severe health issues when inhaled in high concentrations, while nitrogen oxides contribute to the formation of smog and acid rain.

The incomplete combustion of isobutane may result in the release of unburned hydrocarbons and particulate matter. These emissions can have adverse effects on both human health and the environment, contributing to respiratory problems and the formation of ground-level ozone.

The environmental impact of isobutane combustion processes extends beyond air pollution. The production and transportation of isobutane for use in combustion applications can also have environmental consequences, including energy consumption and potential leaks or spills during handling and storage.

To mitigate the environmental impact of isobutane combustion, various strategies have been developed and implemented. These include improving combustion efficiency to reduce emissions, implementing emission control technologies such as catalytic converters, and exploring alternative fuels or energy sources with lower environmental impacts.

Regulatory frameworks and environmental standards play a crucial role in managing the environmental impact of isobutane combustion processes. Many countries have established emission limits and monitoring requirements for industrial facilities that utilize isobutane combustion, aiming to minimize the release of harmful pollutants into the environment.

Research and development efforts continue to focus on optimizing isobutane combustion processes to reduce their environmental footprint. This includes exploring advanced combustion technologies, developing more efficient catalysts, and investigating the potential for carbon capture and storage systems to mitigate CO2 emissions from isobutane combustion.

One of the primary environmental concerns associated with isobutane combustion is the release of carbon dioxide (CO2), a greenhouse gas that contributes to global warming. The combustion of isobutane results in the formation of CO2 as a major product, which, when released into the atmosphere, can contribute to the overall increase in atmospheric CO2 levels.

In addition to CO2, the combustion of isobutane can also lead to the formation of other pollutants, such as carbon monoxide (CO) and nitrogen oxides (NOx). These compounds can have detrimental effects on air quality and human health. Carbon monoxide is a toxic gas that can cause severe health issues when inhaled in high concentrations, while nitrogen oxides contribute to the formation of smog and acid rain.

The incomplete combustion of isobutane may result in the release of unburned hydrocarbons and particulate matter. These emissions can have adverse effects on both human health and the environment, contributing to respiratory problems and the formation of ground-level ozone.

The environmental impact of isobutane combustion processes extends beyond air pollution. The production and transportation of isobutane for use in combustion applications can also have environmental consequences, including energy consumption and potential leaks or spills during handling and storage.

To mitigate the environmental impact of isobutane combustion, various strategies have been developed and implemented. These include improving combustion efficiency to reduce emissions, implementing emission control technologies such as catalytic converters, and exploring alternative fuels or energy sources with lower environmental impacts.

Regulatory frameworks and environmental standards play a crucial role in managing the environmental impact of isobutane combustion processes. Many countries have established emission limits and monitoring requirements for industrial facilities that utilize isobutane combustion, aiming to minimize the release of harmful pollutants into the environment.

Research and development efforts continue to focus on optimizing isobutane combustion processes to reduce their environmental footprint. This includes exploring advanced combustion technologies, developing more efficient catalysts, and investigating the potential for carbon capture and storage systems to mitigate CO2 emissions from isobutane combustion.

Safety Regulations for Isobutane Handling and Combustion

Safety regulations for isobutane handling and combustion are critical in controlled environments due to the flammable and potentially explosive nature of this hydrocarbon. These regulations are designed to protect workers, facilities, and the environment from potential hazards associated with isobutane use in industrial and research settings.

One of the primary safety considerations is proper storage and handling of isobutane. Regulations typically require that isobutane be stored in approved pressure vessels or cylinders, away from sources of heat, ignition, and oxidizing agents. Storage areas must be well-ventilated and equipped with appropriate fire suppression systems. Strict inventory control and regular inspections of storage containers are mandated to prevent leaks and ensure structural integrity.

Personal protective equipment (PPE) requirements are another crucial aspect of isobutane safety regulations. Workers handling isobutane must wear appropriate PPE, including flame-resistant clothing, safety goggles, and gloves. In areas where high concentrations of isobutane may be present, self-contained breathing apparatus (SCBA) may be required.

Ventilation systems play a vital role in maintaining safe working environments. Regulations often specify minimum air exchange rates and the use of explosion-proof ventilation equipment in areas where isobutane is handled or used. Continuous monitoring of isobutane concentrations in the air is typically required, with automatic alarms and shutdown systems activated when levels approach the lower explosive limit (LEL).

Electrical safety is paramount in isobutane-handling areas. Regulations mandate the use of explosion-proof electrical equipment and proper grounding to prevent static electricity buildup, which could potentially ignite isobutane vapors. Regular maintenance and inspection of electrical systems are essential to ensure compliance and safety.

Emergency response planning is a critical component of isobutane safety regulations. Facilities must have detailed emergency procedures in place, including evacuation plans, spill response protocols, and firefighting strategies specific to isobutane fires. Regular drills and training sessions are typically required to ensure all personnel are familiar with emergency procedures.

Combustion processes involving isobutane are subject to strict controls. Regulations often specify maximum allowable concentrations of isobutane in combustion mixtures, as well as requirements for flame arrestors, pressure relief devices, and automatic shutdown systems. Continuous monitoring of combustion parameters, such as temperature, pressure, and exhaust gas composition, is typically mandated to ensure safe and efficient operation.

Transportation of isobutane is governed by specific regulations, including requirements for proper labeling, packaging, and vehicle specifications. Drivers transporting isobutane must receive specialized training and adhere to strict routing and scheduling guidelines to minimize risks during transit.

One of the primary safety considerations is proper storage and handling of isobutane. Regulations typically require that isobutane be stored in approved pressure vessels or cylinders, away from sources of heat, ignition, and oxidizing agents. Storage areas must be well-ventilated and equipped with appropriate fire suppression systems. Strict inventory control and regular inspections of storage containers are mandated to prevent leaks and ensure structural integrity.

Personal protective equipment (PPE) requirements are another crucial aspect of isobutane safety regulations. Workers handling isobutane must wear appropriate PPE, including flame-resistant clothing, safety goggles, and gloves. In areas where high concentrations of isobutane may be present, self-contained breathing apparatus (SCBA) may be required.

Ventilation systems play a vital role in maintaining safe working environments. Regulations often specify minimum air exchange rates and the use of explosion-proof ventilation equipment in areas where isobutane is handled or used. Continuous monitoring of isobutane concentrations in the air is typically required, with automatic alarms and shutdown systems activated when levels approach the lower explosive limit (LEL).

Electrical safety is paramount in isobutane-handling areas. Regulations mandate the use of explosion-proof electrical equipment and proper grounding to prevent static electricity buildup, which could potentially ignite isobutane vapors. Regular maintenance and inspection of electrical systems are essential to ensure compliance and safety.

Emergency response planning is a critical component of isobutane safety regulations. Facilities must have detailed emergency procedures in place, including evacuation plans, spill response protocols, and firefighting strategies specific to isobutane fires. Regular drills and training sessions are typically required to ensure all personnel are familiar with emergency procedures.

Combustion processes involving isobutane are subject to strict controls. Regulations often specify maximum allowable concentrations of isobutane in combustion mixtures, as well as requirements for flame arrestors, pressure relief devices, and automatic shutdown systems. Continuous monitoring of combustion parameters, such as temperature, pressure, and exhaust gas composition, is typically mandated to ensure safe and efficient operation.

Transportation of isobutane is governed by specific regulations, including requirements for proper labeling, packaging, and vehicle specifications. Drivers transporting isobutane must receive specialized training and adhere to strict routing and scheduling guidelines to minimize risks during transit.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!