Isobutane's Role in Developing Heat Resilient Materials

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane and Heat Resilience: Background and Objectives

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has emerged as a crucial component in the development of heat-resistant materials. This technological advancement is rooted in the growing demand for materials capable of withstanding extreme temperatures across various industries. The evolution of heat-resistant materials has been driven by the need to enhance safety, efficiency, and durability in high-temperature applications.

The journey of isobutane in heat-resistant material development began with its recognition as a potential blowing agent for polymer foams. Its low boiling point and ability to create uniform cell structures in foams made it an attractive option for insulation materials. As research progressed, scientists discovered that isobutane could play a more significant role in enhancing the thermal properties of various materials.

The primary objective of incorporating isobutane into heat-resistant materials is to improve their thermal stability and insulation properties. By leveraging isobutane's unique molecular structure and physical properties, researchers aim to create materials that can maintain their integrity and performance under extreme heat conditions. This goal aligns with the broader industry trend towards developing more resilient and efficient materials for use in challenging environments.

One of the key technological trends in this field is the development of composite materials that incorporate isobutane-based compounds. These composites are designed to combine the heat-resistant properties of traditional materials with the enhanced thermal characteristics provided by isobutane. The synergistic effect of these combinations has opened new possibilities for creating materials with unprecedented heat resistance.

The application of isobutane in heat-resistant materials extends beyond traditional insulation. It has found potential uses in protective coatings, fire-resistant fabrics, and advanced aerospace materials. The versatility of isobutane-enhanced materials has sparked interest across multiple sectors, including construction, automotive, and electronics, where heat management is a critical concern.

As the technology continues to evolve, researchers are exploring novel ways to incorporate isobutane into material structures at the molecular level. This includes investigating methods to create stable isobutane-polymer bonds and developing new synthesis techniques to optimize the distribution of isobutane within materials. The ultimate aim is to create a new generation of heat-resistant materials that offer superior performance and longevity in high-temperature environments.

The development of isobutane-based heat-resistant materials represents a significant step forward in material science. It addresses the growing need for advanced thermal management solutions in an increasingly technology-driven world. As research in this field progresses, it is expected to yield innovative materials that will revolutionize heat-resistant applications across various industries.

The journey of isobutane in heat-resistant material development began with its recognition as a potential blowing agent for polymer foams. Its low boiling point and ability to create uniform cell structures in foams made it an attractive option for insulation materials. As research progressed, scientists discovered that isobutane could play a more significant role in enhancing the thermal properties of various materials.

The primary objective of incorporating isobutane into heat-resistant materials is to improve their thermal stability and insulation properties. By leveraging isobutane's unique molecular structure and physical properties, researchers aim to create materials that can maintain their integrity and performance under extreme heat conditions. This goal aligns with the broader industry trend towards developing more resilient and efficient materials for use in challenging environments.

One of the key technological trends in this field is the development of composite materials that incorporate isobutane-based compounds. These composites are designed to combine the heat-resistant properties of traditional materials with the enhanced thermal characteristics provided by isobutane. The synergistic effect of these combinations has opened new possibilities for creating materials with unprecedented heat resistance.

The application of isobutane in heat-resistant materials extends beyond traditional insulation. It has found potential uses in protective coatings, fire-resistant fabrics, and advanced aerospace materials. The versatility of isobutane-enhanced materials has sparked interest across multiple sectors, including construction, automotive, and electronics, where heat management is a critical concern.

As the technology continues to evolve, researchers are exploring novel ways to incorporate isobutane into material structures at the molecular level. This includes investigating methods to create stable isobutane-polymer bonds and developing new synthesis techniques to optimize the distribution of isobutane within materials. The ultimate aim is to create a new generation of heat-resistant materials that offer superior performance and longevity in high-temperature environments.

The development of isobutane-based heat-resistant materials represents a significant step forward in material science. It addresses the growing need for advanced thermal management solutions in an increasingly technology-driven world. As research in this field progresses, it is expected to yield innovative materials that will revolutionize heat-resistant applications across various industries.

Market Analysis for Heat Resistant Materials

The market for heat resistant materials has been experiencing significant growth due to increasing demand across various industries, including aerospace, automotive, construction, and electronics. This surge is primarily driven by the need for materials that can withstand extreme temperatures and harsh environments while maintaining their structural integrity and performance.

In the aerospace sector, the demand for heat resistant materials is particularly strong, as these materials are crucial for developing components that can withstand the high temperatures experienced during flight and re-entry. The automotive industry is another major consumer of heat resistant materials, especially in the manufacturing of engine components and exhaust systems.

The construction industry is also contributing to the market growth, with a rising demand for fire-resistant building materials. As urban areas expand and building codes become more stringent, the need for heat resistant materials in construction is expected to increase further.

In the electronics sector, the miniaturization of devices and the increasing power density of electronic components have led to a growing demand for materials that can efficiently dissipate heat and maintain performance under high-temperature conditions.

The global market for heat resistant materials is projected to continue its upward trajectory in the coming years. Factors such as technological advancements, increasing safety regulations, and the growing focus on energy efficiency are expected to drive this growth further.

Isobutane's potential role in developing heat resilient materials is gaining attention in the market. As a compound with unique properties, isobutane could potentially be used to enhance the heat resistance of various materials or as a precursor in the synthesis of new heat resistant compounds.

The market for isobutane-based heat resistant materials is still in its early stages, but it shows promise for future growth. Research and development efforts are focusing on exploring isobutane's capabilities in improving the thermal properties of existing materials and creating novel heat resistant composites.

As industries continue to push the boundaries of material performance under extreme conditions, the demand for innovative heat resistant solutions is expected to rise. This presents an opportunity for isobutane-based materials to carve out a niche in the market, particularly if they can offer superior heat resistance or other advantageous properties compared to existing solutions.

However, the success of isobutane in the heat resistant materials market will depend on factors such as cost-effectiveness, scalability of production, and performance advantages over current materials. As research progresses and potential applications are identified, a clearer picture of isobutane's market potential in this sector will emerge.

In the aerospace sector, the demand for heat resistant materials is particularly strong, as these materials are crucial for developing components that can withstand the high temperatures experienced during flight and re-entry. The automotive industry is another major consumer of heat resistant materials, especially in the manufacturing of engine components and exhaust systems.

The construction industry is also contributing to the market growth, with a rising demand for fire-resistant building materials. As urban areas expand and building codes become more stringent, the need for heat resistant materials in construction is expected to increase further.

In the electronics sector, the miniaturization of devices and the increasing power density of electronic components have led to a growing demand for materials that can efficiently dissipate heat and maintain performance under high-temperature conditions.

The global market for heat resistant materials is projected to continue its upward trajectory in the coming years. Factors such as technological advancements, increasing safety regulations, and the growing focus on energy efficiency are expected to drive this growth further.

Isobutane's potential role in developing heat resilient materials is gaining attention in the market. As a compound with unique properties, isobutane could potentially be used to enhance the heat resistance of various materials or as a precursor in the synthesis of new heat resistant compounds.

The market for isobutane-based heat resistant materials is still in its early stages, but it shows promise for future growth. Research and development efforts are focusing on exploring isobutane's capabilities in improving the thermal properties of existing materials and creating novel heat resistant composites.

As industries continue to push the boundaries of material performance under extreme conditions, the demand for innovative heat resistant solutions is expected to rise. This presents an opportunity for isobutane-based materials to carve out a niche in the market, particularly if they can offer superior heat resistance or other advantageous properties compared to existing solutions.

However, the success of isobutane in the heat resistant materials market will depend on factors such as cost-effectiveness, scalability of production, and performance advantages over current materials. As research progresses and potential applications are identified, a clearer picture of isobutane's market potential in this sector will emerge.

Current Challenges in Isobutane-Based Heat Resilient Materials

The development of heat resilient materials using isobutane faces several significant challenges. One of the primary obstacles is achieving a balance between thermal stability and mechanical properties. While isobutane-based materials can offer excellent heat resistance, they often struggle to maintain structural integrity under extreme temperatures.

Another challenge lies in the processing and manufacturing of these materials. Isobutane's high volatility and flammability pose safety risks during production, requiring specialized equipment and stringent safety protocols. This complexity in manufacturing processes can lead to increased production costs and limited scalability.

The environmental impact of isobutane-based materials is also a growing concern. As global regulations on greenhouse gas emissions become more stringent, the use of isobutane, a hydrocarbon with a high global warming potential, faces scrutiny. Developing eco-friendly alternatives or improving the environmental profile of isobutane-based materials without compromising their heat-resistant properties remains a significant challenge.

Durability and long-term performance of isobutane-based heat resilient materials present another hurdle. While these materials may exhibit excellent heat resistance initially, maintaining this performance over extended periods, especially under cyclic thermal loading, proves challenging. Degradation of properties over time can limit their applicability in long-term, high-temperature applications.

The compatibility of isobutane-based materials with other substances in complex systems is also a critical issue. In many applications, heat-resistant materials must interact with various chemicals, lubricants, or other materials without degradation or adverse reactions. Ensuring this compatibility while maintaining heat resistance is a complex balancing act.

Furthermore, the cost-effectiveness of isobutane-based heat resilient materials compared to traditional alternatives remains a challenge. While they offer superior heat resistance in many cases, the higher production costs and specialized handling requirements can make them less economically viable for widespread adoption in certain industries.

Lastly, there is a continuous need for improving the thermal conductivity of these materials. Many applications require not only heat resistance but also efficient heat dissipation. Enhancing the thermal conductivity of isobutane-based materials without compromising their insulating properties or heat resistance is an ongoing challenge in material science and engineering.

Another challenge lies in the processing and manufacturing of these materials. Isobutane's high volatility and flammability pose safety risks during production, requiring specialized equipment and stringent safety protocols. This complexity in manufacturing processes can lead to increased production costs and limited scalability.

The environmental impact of isobutane-based materials is also a growing concern. As global regulations on greenhouse gas emissions become more stringent, the use of isobutane, a hydrocarbon with a high global warming potential, faces scrutiny. Developing eco-friendly alternatives or improving the environmental profile of isobutane-based materials without compromising their heat-resistant properties remains a significant challenge.

Durability and long-term performance of isobutane-based heat resilient materials present another hurdle. While these materials may exhibit excellent heat resistance initially, maintaining this performance over extended periods, especially under cyclic thermal loading, proves challenging. Degradation of properties over time can limit their applicability in long-term, high-temperature applications.

The compatibility of isobutane-based materials with other substances in complex systems is also a critical issue. In many applications, heat-resistant materials must interact with various chemicals, lubricants, or other materials without degradation or adverse reactions. Ensuring this compatibility while maintaining heat resistance is a complex balancing act.

Furthermore, the cost-effectiveness of isobutane-based heat resilient materials compared to traditional alternatives remains a challenge. While they offer superior heat resistance in many cases, the higher production costs and specialized handling requirements can make them less economically viable for widespread adoption in certain industries.

Lastly, there is a continuous need for improving the thermal conductivity of these materials. Many applications require not only heat resistance but also efficient heat dissipation. Enhancing the thermal conductivity of isobutane-based materials without compromising their insulating properties or heat resistance is an ongoing challenge in material science and engineering.

Existing Isobutane-Based Heat Resistant Material Solutions

01 Isobutane as a heat-resistant refrigerant

Isobutane is utilized as a refrigerant in various cooling systems due to its excellent heat resilience properties. It offers improved energy efficiency and environmental friendliness compared to traditional refrigerants. The use of isobutane in refrigeration systems contributes to better thermal management and overall system performance.- Isobutane as a heat-resistant refrigerant: Isobutane is utilized as a refrigerant in various cooling systems due to its excellent heat resilience properties. It offers improved energy efficiency and environmental friendliness compared to traditional refrigerants. The use of isobutane in refrigeration systems contributes to better thermal management and overall system performance.

- Heat-resistant isobutane-based polymer compositions: Polymer compositions incorporating isobutane demonstrate enhanced heat resistance. These compositions are used in various applications where thermal stability is crucial. The addition of isobutane to polymer formulations improves their ability to withstand high temperatures without degradation, making them suitable for use in demanding environments.

- Isobutane in heat-resistant coatings and materials: Isobutane is utilized in the development of heat-resistant coatings and materials. These coatings provide thermal protection to various surfaces and substrates, enhancing their durability and longevity when exposed to high temperatures. The incorporation of isobutane in these materials contributes to their ability to maintain structural integrity under thermal stress.

- Isobutane in heat-resistant chemical processes: Isobutane plays a role in various chemical processes that require heat resistance. It is used as a reactant or intermediate in the production of heat-stable compounds and materials. The thermal stability of isobutane makes it valuable in high-temperature chemical reactions and industrial processes where heat resilience is essential.

- Heat-resistant isobutane storage and transportation: Specialized systems and methods are developed for the storage and transportation of isobutane under high-temperature conditions. These systems ensure the safe handling and containment of isobutane while maintaining its thermal stability. Heat-resistant materials and designs are employed to prevent degradation or loss of isobutane during storage and transport in high-temperature environments.

02 Heat-resistant isobutane-based polymer compositions

Polymer compositions incorporating isobutane demonstrate enhanced heat resistance. These compositions are used in various applications where thermal stability is crucial. The addition of isobutane to polymer formulations improves their ability to withstand high temperatures without degradation, making them suitable for use in demanding environments.Expand Specific Solutions03 Isobutane in heat-resistant coatings and materials

Isobutane is utilized in the development of heat-resistant coatings and materials. These coatings provide thermal protection to various surfaces and substrates, enhancing their ability to withstand high temperatures. The incorporation of isobutane in these materials contributes to improved insulation properties and overall heat resilience.Expand Specific Solutions04 Isobutane in heat-resistant catalytic processes

Isobutane plays a role in heat-resistant catalytic processes, particularly in the petrochemical industry. It is used as a feedstock or intermediate in various high-temperature reactions, demonstrating its ability to withstand elevated temperatures during chemical transformations. The heat resilience of isobutane contributes to the efficiency and stability of these catalytic processes.Expand Specific Solutions05 Heat-resistant isobutane storage and transportation

Specialized storage and transportation systems are developed to handle isobutane under high-temperature conditions. These systems are designed to maintain the stability and safety of isobutane during storage and transport, even in environments with elevated temperatures. The heat resilience of isobutane is considered in the design and operation of these systems to prevent accidents and ensure efficient handling.Expand Specific Solutions

Key Players in Isobutane and Heat Resistant Material Industry

The development of heat resilient materials using isobutane is in a nascent stage, with significant potential for growth. The market is characterized by intense competition among major petrochemical and chemical companies, including China Petroleum & Chemical Corp., BASF Corp., and ExxonMobil Chemical Patents, Inc. These industry leaders are investing heavily in research and development to advance the technology. The market size is expected to expand rapidly as demand for heat-resistant materials increases across various industries. While the technology is still evolving, several companies have made notable progress, with UOP LLC and Covestro Deutschland AG emerging as key players in developing innovative solutions. The competitive landscape is dynamic, with both established corporations and research institutions like Beijing Institute of Petrochemical Technology contributing to technological advancements in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative heat-resistant materials using isobutane as a key component. Their approach involves incorporating isobutane into polymer matrices to enhance thermal stability and mechanical properties. The company has created a novel foam insulation material that utilizes isobutane as a blowing agent, resulting in a product with superior heat resistance and low thermal conductivity[1]. This material can withstand temperatures up to 200°C while maintaining its structural integrity. Additionally, Sinopec has developed a heat-resistant coating that incorporates isobutane-derived compounds, providing excellent protection for industrial equipment exposed to high temperatures[3].

Strengths: Extensive petrochemical expertise, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Potential environmental concerns associated with isobutane production and use.

BASF Corp.

Technical Solution: BASF Corp. has leveraged isobutane in developing advanced heat-resilient materials for various applications. Their innovative approach involves using isobutane as a precursor for synthesizing high-performance polymers with exceptional thermal stability. BASF has created a series of isobutane-based polyurethanes that exhibit remarkable heat resistance, maintaining their properties at temperatures exceeding 150°C[2]. These materials find applications in automotive and aerospace industries. Furthermore, BASF has developed a novel process for producing heat-resistant foams using isobutane as a blowing agent, resulting in lightweight materials with excellent insulation properties and fire resistance[4]. The company has also incorporated isobutane-derived additives into their thermoplastic formulations to enhance heat deflection temperatures and long-term thermal stability.

Strengths: Diverse product portfolio, strong global presence, and extensive R&D capabilities. Weaknesses: Reliance on petrochemical feedstocks and potential regulatory challenges related to chemical production.

Core Innovations in Isobutane for Heat Resilience

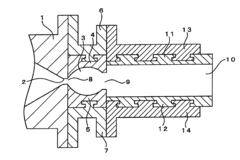

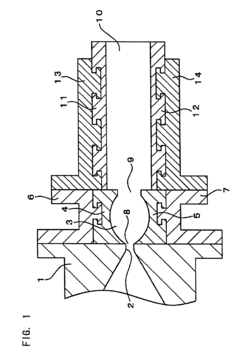

Method for production of extruded, polystyrene-based resin foam plate and extruded foam plate obtained thereby

PatentInactiveUS7008578B2

Innovation

- A method for producing extruded polystyrene-based resin foam plates using a blowing agent composition comprising 25-65% isobutane, 5-70% dimethyl ether, and 5-55% carbon dioxide, along with a flame retardant and nucleating agent, to create a foam with low thermal conductivity and excellent flame retardancy, while minimizing environmental impact.

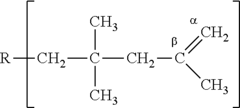

PIB as high viscosity lubricant base stock

PatentInactiveUS20180066200A1

Innovation

- A lubricant composition incorporating a highly reactive polyisobutene polymer with a high number of terminal double bonds, combined with a low viscosity ester and optionally a base oil, which functions as a viscosity index improving component without the need for additional thickening agents like polyisobutenes, oligomeric copolymers, or high viscosity esters.

Environmental Impact of Isobutane in Material Development

The environmental impact of isobutane in material development, particularly in the context of heat-resistant materials, is a complex issue that requires careful consideration. Isobutane, a hydrocarbon compound, plays a significant role in the production of various materials, including those designed to withstand high temperatures. However, its use comes with both benefits and drawbacks from an environmental perspective.

One of the primary environmental concerns associated with isobutane is its potential as a greenhouse gas. When released into the atmosphere, isobutane contributes to global warming, albeit to a lesser extent than some other hydrocarbons. The production and use of isobutane in material development processes can lead to emissions, either through direct release or as a byproduct of manufacturing.

On the other hand, the development of heat-resistant materials using isobutane can have positive environmental implications. These materials often contribute to improved energy efficiency in various applications, such as in building insulation or industrial equipment. By enhancing thermal performance, they can reduce overall energy consumption and, consequently, decrease greenhouse gas emissions from energy production.

The lifecycle assessment of isobutane-based heat-resistant materials is crucial in understanding their net environmental impact. While the production phase may have negative effects, the use phase often demonstrates environmental benefits through improved energy efficiency and extended product lifespans. This balance must be carefully evaluated to determine the overall sustainability of these materials.

In terms of waste management, the disposal or recycling of heat-resistant materials containing isobutane presents challenges. Some of these materials may not be easily biodegradable or recyclable, potentially contributing to long-term environmental issues if not properly managed at the end of their lifecycle.

Efforts to mitigate the environmental impact of isobutane in material development are ongoing. These include improving production processes to minimize emissions, developing more efficient recycling methods, and exploring alternative compounds that could provide similar heat-resistant properties with reduced environmental impact.

Regulatory frameworks also play a crucial role in managing the environmental aspects of isobutane use. Many countries have implemented strict regulations on the production, use, and disposal of materials containing volatile organic compounds like isobutane, aiming to minimize their environmental footprint.

As research in this field progresses, there is a growing focus on developing bio-based alternatives that could potentially replace isobutane in certain applications. These alternatives aim to provide similar heat-resistant properties while offering improved environmental profiles, though their widespread adoption remains a challenge due to cost and performance considerations.

One of the primary environmental concerns associated with isobutane is its potential as a greenhouse gas. When released into the atmosphere, isobutane contributes to global warming, albeit to a lesser extent than some other hydrocarbons. The production and use of isobutane in material development processes can lead to emissions, either through direct release or as a byproduct of manufacturing.

On the other hand, the development of heat-resistant materials using isobutane can have positive environmental implications. These materials often contribute to improved energy efficiency in various applications, such as in building insulation or industrial equipment. By enhancing thermal performance, they can reduce overall energy consumption and, consequently, decrease greenhouse gas emissions from energy production.

The lifecycle assessment of isobutane-based heat-resistant materials is crucial in understanding their net environmental impact. While the production phase may have negative effects, the use phase often demonstrates environmental benefits through improved energy efficiency and extended product lifespans. This balance must be carefully evaluated to determine the overall sustainability of these materials.

In terms of waste management, the disposal or recycling of heat-resistant materials containing isobutane presents challenges. Some of these materials may not be easily biodegradable or recyclable, potentially contributing to long-term environmental issues if not properly managed at the end of their lifecycle.

Efforts to mitigate the environmental impact of isobutane in material development are ongoing. These include improving production processes to minimize emissions, developing more efficient recycling methods, and exploring alternative compounds that could provide similar heat-resistant properties with reduced environmental impact.

Regulatory frameworks also play a crucial role in managing the environmental aspects of isobutane use. Many countries have implemented strict regulations on the production, use, and disposal of materials containing volatile organic compounds like isobutane, aiming to minimize their environmental footprint.

As research in this field progresses, there is a growing focus on developing bio-based alternatives that could potentially replace isobutane in certain applications. These alternatives aim to provide similar heat-resistant properties while offering improved environmental profiles, though their widespread adoption remains a challenge due to cost and performance considerations.

Safety Regulations for Isobutane in Material Manufacturing

The development of heat-resistant materials using isobutane necessitates stringent safety regulations in the manufacturing process. These regulations are crucial to mitigate potential risks associated with the flammable and explosive nature of isobutane. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established comprehensive guidelines for handling isobutane in industrial settings.

One of the primary safety concerns is the prevention of isobutane leaks. Manufacturers are required to implement robust leak detection systems and regular equipment inspections to ensure the integrity of storage tanks, pipelines, and processing units. These systems often include gas sensors strategically placed throughout the facility to detect even minute concentrations of isobutane in the air.

Ventilation requirements form another critical aspect of safety regulations. Manufacturing facilities must maintain adequate airflow to prevent the accumulation of isobutane vapors. This typically involves the installation of powerful exhaust systems and the strategic placement of air intake and outlet points to create a safe working environment.

Personal protective equipment (PPE) regulations are also stringent in isobutane-related manufacturing processes. Workers are required to wear appropriate protective gear, including flame-resistant clothing, safety goggles, and in some cases, respiratory protection. Regular training on the proper use of PPE and emergency procedures is mandated to ensure worker safety.

Fire safety measures are paramount in facilities handling isobutane. Regulations often require the installation of advanced fire suppression systems, including foam-based extinguishers specifically designed for flammable gas fires. Additionally, facilities must have clearly marked emergency exits and evacuation routes, with regular drills conducted to prepare workers for potential incidents.

Storage regulations for isobutane are particularly strict. Manufacturers must adhere to specific guidelines regarding the design and location of storage tanks, including pressure relief systems and temperature control mechanisms. These tanks are often required to be located in designated areas away from main production lines and populated areas of the facility.

Electrical safety is another crucial aspect of isobutane-related regulations. All electrical equipment in areas where isobutane is present must be explosion-proof and properly grounded to prevent spark-induced ignition. This includes lighting fixtures, motors, switches, and any other electrical components that could potentially generate sparks.

Transportation of isobutane to and from manufacturing facilities is also subject to rigorous safety protocols. These include specific requirements for tanker trucks, loading and unloading procedures, and emergency response plans in case of accidents during transit.

One of the primary safety concerns is the prevention of isobutane leaks. Manufacturers are required to implement robust leak detection systems and regular equipment inspections to ensure the integrity of storage tanks, pipelines, and processing units. These systems often include gas sensors strategically placed throughout the facility to detect even minute concentrations of isobutane in the air.

Ventilation requirements form another critical aspect of safety regulations. Manufacturing facilities must maintain adequate airflow to prevent the accumulation of isobutane vapors. This typically involves the installation of powerful exhaust systems and the strategic placement of air intake and outlet points to create a safe working environment.

Personal protective equipment (PPE) regulations are also stringent in isobutane-related manufacturing processes. Workers are required to wear appropriate protective gear, including flame-resistant clothing, safety goggles, and in some cases, respiratory protection. Regular training on the proper use of PPE and emergency procedures is mandated to ensure worker safety.

Fire safety measures are paramount in facilities handling isobutane. Regulations often require the installation of advanced fire suppression systems, including foam-based extinguishers specifically designed for flammable gas fires. Additionally, facilities must have clearly marked emergency exits and evacuation routes, with regular drills conducted to prepare workers for potential incidents.

Storage regulations for isobutane are particularly strict. Manufacturers must adhere to specific guidelines regarding the design and location of storage tanks, including pressure relief systems and temperature control mechanisms. These tanks are often required to be located in designated areas away from main production lines and populated areas of the facility.

Electrical safety is another crucial aspect of isobutane-related regulations. All electrical equipment in areas where isobutane is present must be explosion-proof and properly grounded to prevent spark-induced ignition. This includes lighting fixtures, motors, switches, and any other electrical components that could potentially generate sparks.

Transportation of isobutane to and from manufacturing facilities is also subject to rigorous safety protocols. These include specific requirements for tanker trucks, loading and unloading procedures, and emergency response plans in case of accidents during transit.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!