How Isobutane Refines Enhanced Oil Recovery Techniques

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane EOR Background

Enhanced Oil Recovery (EOR) techniques have been a cornerstone of the petroleum industry for decades, aiming to increase the amount of crude oil extracted from oil fields. Among these techniques, the use of isobutane has emerged as a promising method to refine and improve EOR processes. Isobutane, a hydrocarbon with the molecular formula C4H10, has unique properties that make it particularly suitable for enhancing oil recovery.

The background of isobutane in EOR can be traced back to the 1970s when researchers began exploring the potential of various gases for improving oil extraction. Isobutane, being a light hydrocarbon gas, was found to have several advantageous characteristics for EOR applications. Its low molecular weight and high volatility allow it to easily penetrate reservoir rock formations, while its ability to dissolve in oil helps reduce viscosity and improve flow properties.

Initially, isobutane was primarily used in gas injection EOR methods, where it was injected into oil reservoirs to increase pressure and displace oil towards production wells. As technology advanced, researchers discovered that isobutane could be effectively combined with other substances, such as carbon dioxide or nitrogen, to create more efficient EOR solutions.

The evolution of isobutane EOR techniques has been driven by the need to address the limitations of conventional recovery methods, which typically leave a significant portion of oil trapped in reservoirs. By leveraging isobutane's unique properties, engineers have developed innovative approaches to mobilize residual oil and improve overall recovery rates.

One of the key advantages of isobutane in EOR is its miscibility with crude oil under reservoir conditions. This miscibility allows for the formation of a single-phase fluid, which can more effectively sweep through the reservoir and displace oil that would otherwise remain trapped. Additionally, isobutane's low minimum miscibility pressure (MMP) compared to other gases makes it suitable for a wider range of reservoir conditions.

Over the years, isobutane EOR techniques have been refined and optimized through extensive research and field trials. Scientists have focused on understanding the complex interactions between isobutane, reservoir fluids, and rock formations to develop more effective injection strategies and recovery processes. This has led to the development of advanced simulation models and monitoring techniques to optimize isobutane EOR operations.

The adoption of isobutane in EOR has also been influenced by environmental considerations. As a naturally occurring hydrocarbon, isobutane is generally considered more environmentally friendly compared to some chemical EOR methods. Furthermore, its potential for recycling and reuse in closed-loop systems has made it an attractive option for sustainable oil recovery operations.

The background of isobutane in EOR can be traced back to the 1970s when researchers began exploring the potential of various gases for improving oil extraction. Isobutane, being a light hydrocarbon gas, was found to have several advantageous characteristics for EOR applications. Its low molecular weight and high volatility allow it to easily penetrate reservoir rock formations, while its ability to dissolve in oil helps reduce viscosity and improve flow properties.

Initially, isobutane was primarily used in gas injection EOR methods, where it was injected into oil reservoirs to increase pressure and displace oil towards production wells. As technology advanced, researchers discovered that isobutane could be effectively combined with other substances, such as carbon dioxide or nitrogen, to create more efficient EOR solutions.

The evolution of isobutane EOR techniques has been driven by the need to address the limitations of conventional recovery methods, which typically leave a significant portion of oil trapped in reservoirs. By leveraging isobutane's unique properties, engineers have developed innovative approaches to mobilize residual oil and improve overall recovery rates.

One of the key advantages of isobutane in EOR is its miscibility with crude oil under reservoir conditions. This miscibility allows for the formation of a single-phase fluid, which can more effectively sweep through the reservoir and displace oil that would otherwise remain trapped. Additionally, isobutane's low minimum miscibility pressure (MMP) compared to other gases makes it suitable for a wider range of reservoir conditions.

Over the years, isobutane EOR techniques have been refined and optimized through extensive research and field trials. Scientists have focused on understanding the complex interactions between isobutane, reservoir fluids, and rock formations to develop more effective injection strategies and recovery processes. This has led to the development of advanced simulation models and monitoring techniques to optimize isobutane EOR operations.

The adoption of isobutane in EOR has also been influenced by environmental considerations. As a naturally occurring hydrocarbon, isobutane is generally considered more environmentally friendly compared to some chemical EOR methods. Furthermore, its potential for recycling and reuse in closed-loop systems has made it an attractive option for sustainable oil recovery operations.

Market Demand Analysis

The market demand for enhanced oil recovery (EOR) techniques utilizing isobutane has been steadily growing in recent years. This growth is primarily driven by the increasing global energy demand and the need to maximize oil production from existing reservoirs. As conventional oil reserves become depleted, the industry is turning to EOR methods to extract additional oil from mature fields.

Isobutane-based EOR techniques have gained traction due to their effectiveness in improving oil recovery rates. These methods are particularly valuable for heavy oil reservoirs and tight formations where traditional recovery methods are less efficient. The market for isobutane in EOR is closely tied to the overall oil and gas industry, which is projected to maintain steady growth in the coming years.

The demand for isobutane in EOR is influenced by several factors. Firstly, the fluctuating oil prices play a crucial role in determining the economic viability of EOR projects. When oil prices are high, there is greater incentive for companies to invest in advanced recovery techniques. Conversely, low oil prices may lead to reduced investment in EOR technologies.

Geographically, North America, particularly the United States and Canada, represents a significant market for isobutane-based EOR techniques. This is due to the presence of numerous mature oil fields and the advanced technological infrastructure in these regions. The Middle East and Asia-Pacific are also emerging as key markets, driven by the need to enhance oil recovery from aging reservoirs.

The environmental benefits associated with isobutane-based EOR techniques are contributing to their increased adoption. These methods often result in lower carbon emissions compared to other EOR techniques, aligning with the industry's growing focus on sustainability and environmental responsibility.

Market analysts predict a compound annual growth rate for the EOR market, including isobutane-based techniques, in the mid-single digits over the next five years. This growth is expected to be fueled by technological advancements, increasing energy demand, and the need to maximize recovery from existing oil fields.

The market demand is also influenced by regulatory factors. Governments in various countries are implementing policies to promote the use of advanced oil recovery techniques to ensure energy security and maximize domestic oil production. These policies often include incentives for companies investing in EOR technologies, further driving market growth.

In conclusion, the market demand for isobutane-refined EOR techniques is robust and expected to continue growing. The combination of technological advancements, environmental benefits, and the need for increased oil recovery from mature fields positions isobutane-based EOR as a critical component of the oil and gas industry's future strategy.

Isobutane-based EOR techniques have gained traction due to their effectiveness in improving oil recovery rates. These methods are particularly valuable for heavy oil reservoirs and tight formations where traditional recovery methods are less efficient. The market for isobutane in EOR is closely tied to the overall oil and gas industry, which is projected to maintain steady growth in the coming years.

The demand for isobutane in EOR is influenced by several factors. Firstly, the fluctuating oil prices play a crucial role in determining the economic viability of EOR projects. When oil prices are high, there is greater incentive for companies to invest in advanced recovery techniques. Conversely, low oil prices may lead to reduced investment in EOR technologies.

Geographically, North America, particularly the United States and Canada, represents a significant market for isobutane-based EOR techniques. This is due to the presence of numerous mature oil fields and the advanced technological infrastructure in these regions. The Middle East and Asia-Pacific are also emerging as key markets, driven by the need to enhance oil recovery from aging reservoirs.

The environmental benefits associated with isobutane-based EOR techniques are contributing to their increased adoption. These methods often result in lower carbon emissions compared to other EOR techniques, aligning with the industry's growing focus on sustainability and environmental responsibility.

Market analysts predict a compound annual growth rate for the EOR market, including isobutane-based techniques, in the mid-single digits over the next five years. This growth is expected to be fueled by technological advancements, increasing energy demand, and the need to maximize recovery from existing oil fields.

The market demand is also influenced by regulatory factors. Governments in various countries are implementing policies to promote the use of advanced oil recovery techniques to ensure energy security and maximize domestic oil production. These policies often include incentives for companies investing in EOR technologies, further driving market growth.

In conclusion, the market demand for isobutane-refined EOR techniques is robust and expected to continue growing. The combination of technological advancements, environmental benefits, and the need for increased oil recovery from mature fields positions isobutane-based EOR as a critical component of the oil and gas industry's future strategy.

Technical Challenges

The use of isobutane in enhanced oil recovery (EOR) techniques presents several technical challenges that require careful consideration and innovative solutions. One of the primary obstacles is the management of isobutane's high volatility and low boiling point. This characteristic makes it difficult to maintain the desired pressure and concentration within the reservoir, potentially leading to reduced effectiveness of the EOR process.

Another significant challenge lies in the design and implementation of injection systems capable of handling isobutane's unique properties. The equipment must be able to withstand high pressures and prevent leakage, which is crucial for both safety and efficiency. Additionally, the corrosive nature of isobutane when mixed with certain reservoir fluids necessitates the use of specialized materials and coatings to protect the infrastructure.

The interaction between isobutane and reservoir rock poses further complications. The adsorption of isobutane onto rock surfaces can alter the wettability of the formation, potentially impacting oil recovery rates. Understanding and controlling these interactions requires advanced modeling and simulation techniques, as well as extensive laboratory testing to accurately predict behavior under reservoir conditions.

Environmental concerns also present technical hurdles in the application of isobutane for EOR. The potential for greenhouse gas emissions and the risk of groundwater contamination demand the development of robust monitoring systems and containment strategies. Engineers must design methods to capture and recycle isobutane effectively, minimizing its release into the atmosphere.

The miscibility of isobutane with reservoir fluids is a critical factor that influences the success of EOR operations. Achieving and maintaining the optimal miscibility conditions across the entire reservoir is technically challenging, especially in heterogeneous formations. This requires precise control over injection parameters and a thorough understanding of phase behavior under varying pressure and temperature conditions.

Furthermore, the economic viability of isobutane-based EOR techniques hinges on efficient recovery and recycling of the injected isobutane. Developing cost-effective separation and purification processes to extract isobutane from produced fluids is a significant technical challenge that impacts the overall feasibility of the method.

Lastly, the scale-up from laboratory experiments to field-scale applications introduces additional complexities. Factors such as reservoir heterogeneity, fluid distribution, and geological uncertainties can significantly affect the performance of isobutane-based EOR techniques. Overcoming these challenges requires advanced reservoir characterization methods and adaptive injection strategies to optimize recovery under real-world conditions.

Another significant challenge lies in the design and implementation of injection systems capable of handling isobutane's unique properties. The equipment must be able to withstand high pressures and prevent leakage, which is crucial for both safety and efficiency. Additionally, the corrosive nature of isobutane when mixed with certain reservoir fluids necessitates the use of specialized materials and coatings to protect the infrastructure.

The interaction between isobutane and reservoir rock poses further complications. The adsorption of isobutane onto rock surfaces can alter the wettability of the formation, potentially impacting oil recovery rates. Understanding and controlling these interactions requires advanced modeling and simulation techniques, as well as extensive laboratory testing to accurately predict behavior under reservoir conditions.

Environmental concerns also present technical hurdles in the application of isobutane for EOR. The potential for greenhouse gas emissions and the risk of groundwater contamination demand the development of robust monitoring systems and containment strategies. Engineers must design methods to capture and recycle isobutane effectively, minimizing its release into the atmosphere.

The miscibility of isobutane with reservoir fluids is a critical factor that influences the success of EOR operations. Achieving and maintaining the optimal miscibility conditions across the entire reservoir is technically challenging, especially in heterogeneous formations. This requires precise control over injection parameters and a thorough understanding of phase behavior under varying pressure and temperature conditions.

Furthermore, the economic viability of isobutane-based EOR techniques hinges on efficient recovery and recycling of the injected isobutane. Developing cost-effective separation and purification processes to extract isobutane from produced fluids is a significant technical challenge that impacts the overall feasibility of the method.

Lastly, the scale-up from laboratory experiments to field-scale applications introduces additional complexities. Factors such as reservoir heterogeneity, fluid distribution, and geological uncertainties can significantly affect the performance of isobutane-based EOR techniques. Overcoming these challenges requires advanced reservoir characterization methods and adaptive injection strategies to optimize recovery under real-world conditions.

Current Isobutane EOR

01 Separation and recovery of isobutane from oil mixtures

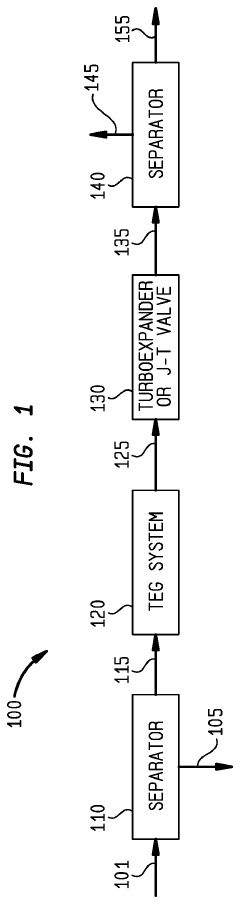

Various methods are employed to separate and recover isobutane from oil mixtures. These techniques may involve distillation, adsorption, or membrane separation processes. The goal is to efficiently isolate isobutane from other hydrocarbons present in the oil, allowing for its recovery and potential reuse in industrial applications.- Separation and recovery of isobutane from oil mixtures: Various methods are employed to separate and recover isobutane from oil mixtures. These techniques may involve distillation, absorption, or membrane separation processes. The goal is to efficiently isolate isobutane from other hydrocarbons present in the oil, allowing for its recovery and potential reuse in industrial applications.

- Enhanced oil recovery using isobutane: Isobutane is utilized in enhanced oil recovery techniques to improve the extraction of oil from reservoirs. This process involves injecting isobutane into oil wells to increase pressure and reduce oil viscosity, facilitating easier flow and recovery of oil. The method can significantly improve oil production rates from existing wells.

- Isobutane recovery in natural gas processing: In natural gas processing, isobutane is often recovered as a valuable byproduct. This involves separating isobutane from other components of natural gas streams using techniques such as cryogenic distillation or absorption. The recovered isobutane can then be used in various industrial applications or as a fuel.

- Catalytic processes for isobutane production and recovery: Catalytic processes are employed to produce and recover isobutane from various hydrocarbon feedstocks. These methods often involve the use of specialized catalysts to promote specific reactions that yield isobutane. The resulting isobutane can then be separated and recovered from the reaction mixture using appropriate separation techniques.

- Isobutane recovery in refinery operations: Refineries implement various processes to recover isobutane as part of their operations. This may include the recovery of isobutane from refinery off-gases or as a byproduct of other refining processes. The recovered isobutane can be used as a feedstock for other refinery processes or sold as a valuable product.

02 Enhanced oil recovery using isobutane

Isobutane is utilized in enhanced oil recovery techniques to improve the extraction of oil from reservoirs. This process involves injecting isobutane into oil wells to increase pressure and reduce oil viscosity, facilitating easier flow and recovery of oil. The method can significantly improve oil production rates from mature or depleted oil fields.Expand Specific Solutions03 Isobutane recovery in natural gas processing

In natural gas processing, isobutane is often recovered as a valuable byproduct. The process typically involves cryogenic separation or fractionation of natural gas liquids. Recovered isobutane can be used in various applications, including as a refrigerant or as a feedstock for petrochemical processes.Expand Specific Solutions04 Catalytic processes for isobutane production and recovery

Catalytic processes are employed to produce and recover isobutane from various hydrocarbon sources. These methods may involve isomerization of n-butane, dehydrogenation of isobutane, or other catalytic reactions. The use of specific catalysts and reaction conditions allows for selective production and efficient recovery of isobutane.Expand Specific Solutions05 Isobutane recovery in refinery operations

Refineries implement specialized processes to recover isobutane from various streams. This may include recovery from refinery off-gases, light ends fractionation, or alkylation unit effluents. The recovered isobutane can be recycled within the refinery or sold as a valuable product, improving overall process efficiency and economics.Expand Specific Solutions

Key Industry Players

The enhanced oil recovery (EOR) techniques utilizing isobutane are in a mature stage of development, with a growing market size driven by increasing global energy demands. The technology's maturity is evident from the involvement of major players like China Petroleum & Chemical Corp. and UOP LLC, who have extensive experience in refining processes. The competitive landscape is characterized by a mix of established oil and gas companies, specialized chemical firms, and research institutions. Companies such as Halliburton Energy Services and Schlumberger Technologies are leveraging their expertise in oilfield services to advance isobutane-based EOR methods. Research entities like SINOPEC Beijing Research Institute of Chemical Industry and IFP Energies Nouvelles are contributing to technological advancements, indicating ongoing innovation in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to enhanced oil recovery (EOR) using isobutane. Their technique involves injecting a mixture of isobutane and other light hydrocarbons into oil reservoirs to reduce oil viscosity and improve flow characteristics. This method has shown to increase oil recovery rates by up to 20% in some fields [1]. Sinopec's process also incorporates advanced reservoir modeling and real-time monitoring systems to optimize the injection process and maximize recovery efficiency. The company has successfully implemented this technology in several of its mature oilfields, demonstrating its effectiveness in various geological conditions [3].

Strengths: Proven technology with significant recovery rate improvements; adaptable to various reservoir types. Weaknesses: High initial investment costs; potential environmental concerns related to hydrocarbon injection.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a proprietary isobutane-based EOR technique called "IsoBoost". This method combines isobutane injection with their patented surfactant formulations to create a highly effective oil displacement mechanism. The IsoBoost process involves cyclic injection of isobutane followed by water, creating a pulsating effect that helps mobilize trapped oil. Halliburton's approach also incorporates advanced reservoir characterization and simulation tools to optimize the injection strategy for each specific field. Field trials have shown oil recovery improvements of up to 15-25% over conventional methods [2]. Additionally, Halliburton has integrated this technology with their digital oilfield solutions, allowing for real-time monitoring and adjustment of the EOR process [5].

Strengths: Comprehensive solution combining chemical and digital technologies; proven effectiveness in field trials. Weaknesses: May require significant modifications to existing infrastructure; potential scalability issues for smaller operators.

Core Isobutane Innovations

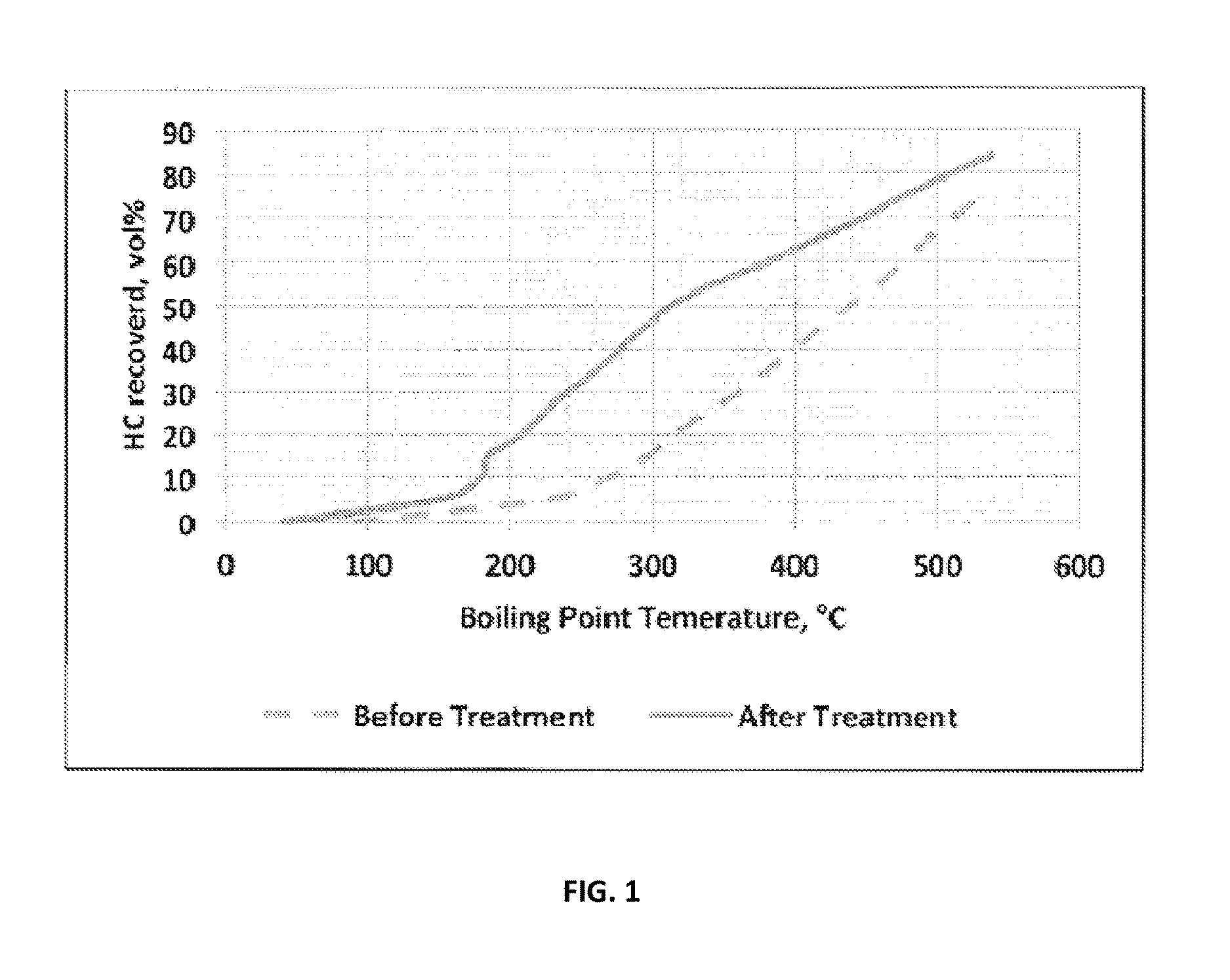

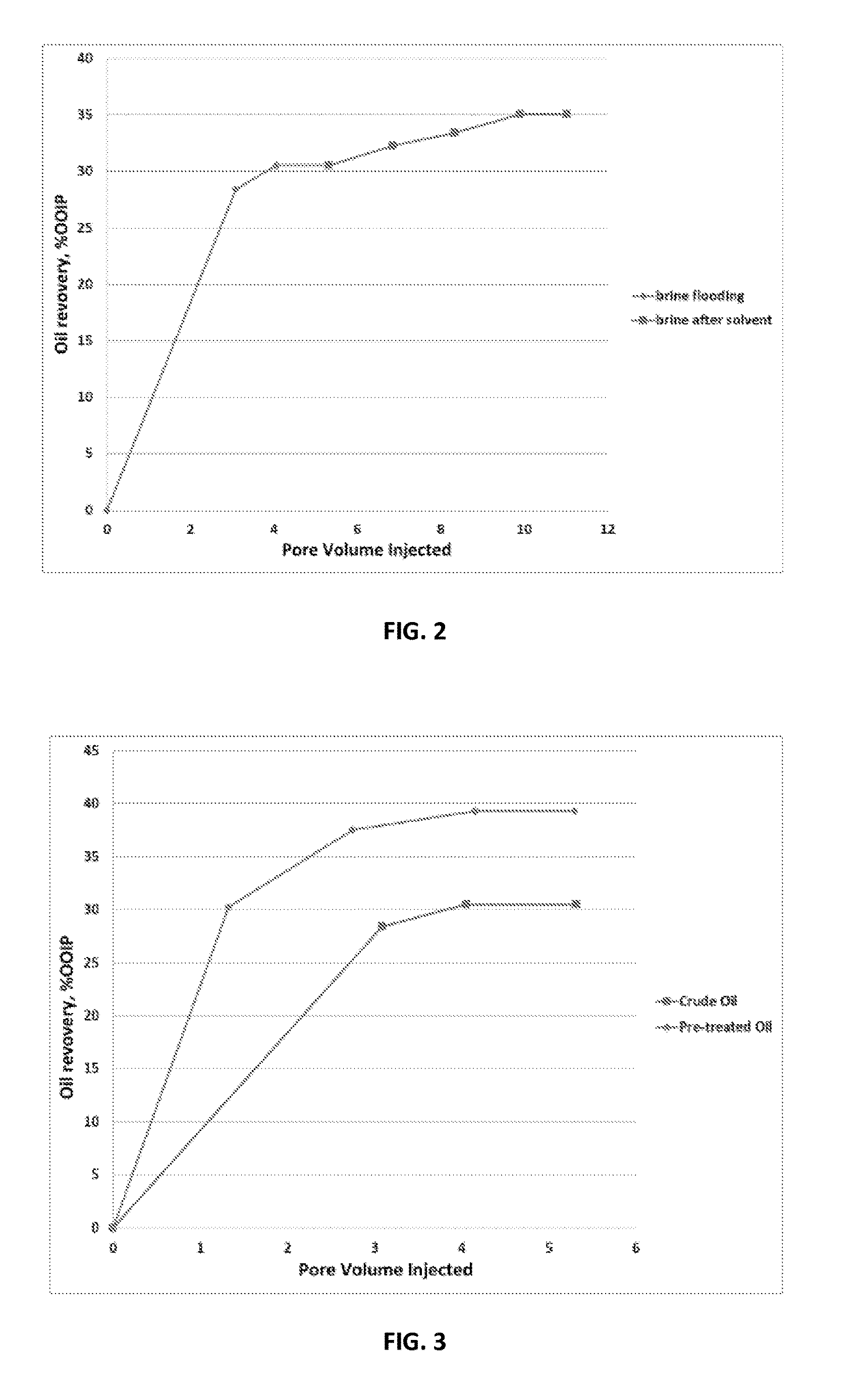

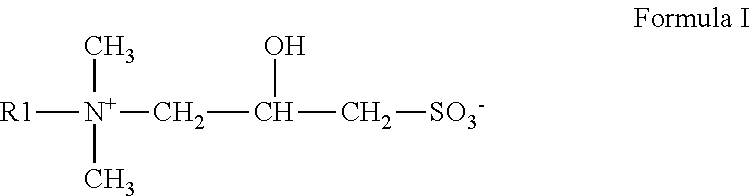

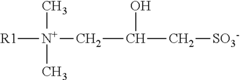

Enhanced oil recovery method for producing light crude oil from heavy oil fields

PatentInactiveUS20170058187A1

Innovation

- A nano-fluid composition comprising sultaines as wetting agents, hydrocarbon solvents, and nanoparticles like Magnesia, Alumina, and Zinc Oxide is injected into heavy oil formations to reduce viscosity and transform heavy crude oil into lighter, more easily recoverable oil, utilizing a solvent mix and nanoparticles that act as room temperature catalysts.

Systems and methods of optimizing Y-grade NGL enhanced oil recovery fluids

PatentActiveUS10724351B2

Innovation

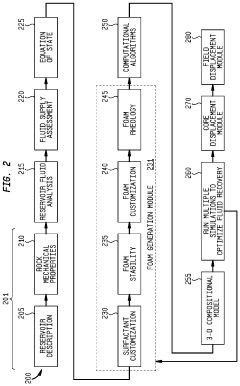

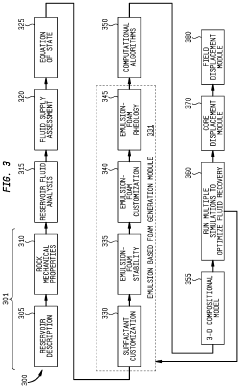

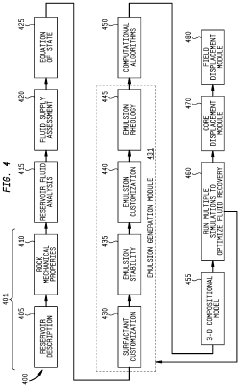

- The method involves generating optimized hydrocarbon foams, emulsions, or gelled fluids using Y-Grade NGL, customized surfactants, and geostatic data to reduce interfacial tension and improve sweep efficiency, utilizing 3-D compositional reservoir simulation models to determine the most effective fluid composition for enhanced oil recovery.

Environmental Impact

The use of isobutane in enhanced oil recovery (EOR) techniques has significant environmental implications that must be carefully considered. While isobutane can improve oil recovery efficiency, its application also poses potential risks to ecosystems and contributes to greenhouse gas emissions.

One of the primary environmental concerns is the potential for isobutane leakage during the EOR process. Isobutane is a volatile organic compound (VOC) that can escape into the atmosphere, contributing to air pollution and potentially affecting local air quality. These emissions can lead to the formation of ground-level ozone, which has adverse effects on human health and vegetation.

Furthermore, the injection of isobutane into oil reservoirs may alter the subsurface environment, potentially impacting groundwater quality. There is a risk of contamination if isobutane or other associated chemicals migrate into aquifers, potentially affecting drinking water sources and aquatic ecosystems.

The production and transportation of isobutane for EOR purposes also contribute to the overall carbon footprint of the oil recovery process. The energy-intensive nature of isobutane production and its transportation to oil fields results in additional greenhouse gas emissions, exacerbating climate change concerns.

However, it is important to note that the use of isobutane in EOR can also have some positive environmental impacts. By increasing oil recovery from existing wells, it reduces the need for new drilling operations, which can help minimize land disturbance and habitat fragmentation associated with conventional oil extraction methods.

To mitigate the environmental risks associated with isobutane-based EOR, stringent monitoring and control measures are essential. This includes implementing advanced leak detection systems, employing proper well integrity management practices, and utilizing closed-loop systems to minimize emissions.

Additionally, research into more environmentally friendly alternatives to isobutane is ongoing. Some promising options include the use of carbon dioxide or nitrogen as injection gases, which could potentially reduce the environmental impact while still improving oil recovery rates.

As the oil and gas industry continues to evolve, balancing the economic benefits of enhanced oil recovery with environmental protection remains a critical challenge. Regulatory frameworks and industry best practices must adapt to ensure that isobutane-based EOR techniques are implemented responsibly, with a focus on minimizing environmental harm and promoting sustainable resource extraction.

One of the primary environmental concerns is the potential for isobutane leakage during the EOR process. Isobutane is a volatile organic compound (VOC) that can escape into the atmosphere, contributing to air pollution and potentially affecting local air quality. These emissions can lead to the formation of ground-level ozone, which has adverse effects on human health and vegetation.

Furthermore, the injection of isobutane into oil reservoirs may alter the subsurface environment, potentially impacting groundwater quality. There is a risk of contamination if isobutane or other associated chemicals migrate into aquifers, potentially affecting drinking water sources and aquatic ecosystems.

The production and transportation of isobutane for EOR purposes also contribute to the overall carbon footprint of the oil recovery process. The energy-intensive nature of isobutane production and its transportation to oil fields results in additional greenhouse gas emissions, exacerbating climate change concerns.

However, it is important to note that the use of isobutane in EOR can also have some positive environmental impacts. By increasing oil recovery from existing wells, it reduces the need for new drilling operations, which can help minimize land disturbance and habitat fragmentation associated with conventional oil extraction methods.

To mitigate the environmental risks associated with isobutane-based EOR, stringent monitoring and control measures are essential. This includes implementing advanced leak detection systems, employing proper well integrity management practices, and utilizing closed-loop systems to minimize emissions.

Additionally, research into more environmentally friendly alternatives to isobutane is ongoing. Some promising options include the use of carbon dioxide or nitrogen as injection gases, which could potentially reduce the environmental impact while still improving oil recovery rates.

As the oil and gas industry continues to evolve, balancing the economic benefits of enhanced oil recovery with environmental protection remains a critical challenge. Regulatory frameworks and industry best practices must adapt to ensure that isobutane-based EOR techniques are implemented responsibly, with a focus on minimizing environmental harm and promoting sustainable resource extraction.

Economic Feasibility

The economic feasibility of using isobutane to refine enhanced oil recovery (EOR) techniques is a critical consideration for oil and gas companies. This approach offers potential benefits in terms of increased oil recovery rates and improved operational efficiency, but it also comes with significant costs and risks that must be carefully evaluated.

From a cost perspective, implementing isobutane-based EOR techniques requires substantial upfront investment. This includes the expenses associated with modifying existing infrastructure, purchasing specialized equipment, and training personnel to handle the new processes. Additionally, there are ongoing operational costs related to the procurement and handling of isobutane, as well as potential increases in energy consumption during the recovery process.

However, these costs must be weighed against the potential economic benefits. Isobutane-enhanced EOR techniques have shown promising results in increasing oil recovery rates, particularly in mature oil fields where conventional methods have reached their limits. By improving the efficiency of oil extraction, companies can potentially extend the productive life of their assets and increase overall oil recovery, leading to higher revenues over time.

The economic viability of this approach is also influenced by market conditions, particularly oil prices. In periods of high oil prices, the increased recovery rates offered by isobutane-based techniques can significantly boost profitability, making the initial investments more justifiable. Conversely, during periods of low oil prices, the high costs associated with these advanced techniques may be harder to recoup, potentially impacting their economic feasibility.

Environmental regulations and carbon pricing mechanisms also play a crucial role in the economic equation. While isobutane-based EOR techniques can potentially reduce the environmental footprint of oil recovery operations compared to some other methods, they still involve the use of hydrocarbons and energy-intensive processes. As such, companies must factor in potential regulatory compliance costs and carbon taxes when assessing the long-term economic viability of these techniques.

The scalability of isobutane-based EOR techniques is another important economic consideration. The ability to apply these methods across multiple oil fields or to scale up operations within a single field can significantly impact their cost-effectiveness. Economies of scale can help reduce per-unit costs and improve overall economic feasibility, making this approach more attractive for larger operations or companies with diverse asset portfolios.

Ultimately, the economic feasibility of using isobutane to refine EOR techniques will vary depending on specific field characteristics, operational conditions, and broader market factors. Companies must conduct thorough economic analyses, including detailed cost-benefit assessments and sensitivity analyses, to determine whether this approach is financially viable for their particular circumstances. As the technology continues to evolve and mature, its economic profile may improve, potentially making it a more attractive option for a wider range of oil and gas operations in the future.

From a cost perspective, implementing isobutane-based EOR techniques requires substantial upfront investment. This includes the expenses associated with modifying existing infrastructure, purchasing specialized equipment, and training personnel to handle the new processes. Additionally, there are ongoing operational costs related to the procurement and handling of isobutane, as well as potential increases in energy consumption during the recovery process.

However, these costs must be weighed against the potential economic benefits. Isobutane-enhanced EOR techniques have shown promising results in increasing oil recovery rates, particularly in mature oil fields where conventional methods have reached their limits. By improving the efficiency of oil extraction, companies can potentially extend the productive life of their assets and increase overall oil recovery, leading to higher revenues over time.

The economic viability of this approach is also influenced by market conditions, particularly oil prices. In periods of high oil prices, the increased recovery rates offered by isobutane-based techniques can significantly boost profitability, making the initial investments more justifiable. Conversely, during periods of low oil prices, the high costs associated with these advanced techniques may be harder to recoup, potentially impacting their economic feasibility.

Environmental regulations and carbon pricing mechanisms also play a crucial role in the economic equation. While isobutane-based EOR techniques can potentially reduce the environmental footprint of oil recovery operations compared to some other methods, they still involve the use of hydrocarbons and energy-intensive processes. As such, companies must factor in potential regulatory compliance costs and carbon taxes when assessing the long-term economic viability of these techniques.

The scalability of isobutane-based EOR techniques is another important economic consideration. The ability to apply these methods across multiple oil fields or to scale up operations within a single field can significantly impact their cost-effectiveness. Economies of scale can help reduce per-unit costs and improve overall economic feasibility, making this approach more attractive for larger operations or companies with diverse asset portfolios.

Ultimately, the economic feasibility of using isobutane to refine EOR techniques will vary depending on specific field characteristics, operational conditions, and broader market factors. Companies must conduct thorough economic analyses, including detailed cost-benefit assessments and sensitivity analyses, to determine whether this approach is financially viable for their particular circumstances. As the technology continues to evolve and mature, its economic profile may improve, potentially making it a more attractive option for a wider range of oil and gas operations in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!