Standards for Monitoring Isobutane Emissions

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Emissions Overview and Objectives

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has gained significant attention in recent years due to its widespread use in various industries and its potential environmental impact. As a volatile organic compound (VOC), isobutane emissions have become a growing concern for regulatory bodies, environmental agencies, and industries worldwide. The development of standards for monitoring isobutane emissions is crucial for ensuring environmental protection, worker safety, and regulatory compliance.

The primary objective of establishing standards for monitoring isobutane emissions is to create a comprehensive framework that enables accurate measurement, reporting, and control of these emissions across different sectors. This includes industries such as refrigeration, aerosol propellants, petrochemicals, and foam blowing agents, where isobutane is commonly used. By implementing standardized monitoring practices, stakeholders aim to minimize the environmental footprint of isobutane-related activities and mitigate potential health risks associated with exposure to high concentrations of this gas.

The evolution of isobutane emission monitoring standards has been driven by advancements in detection technologies, increased environmental awareness, and stricter regulatory requirements. Early monitoring efforts primarily focused on workplace safety and leak detection. However, as the understanding of isobutane's environmental impact grew, the scope of monitoring expanded to include ambient air quality, fugitive emissions, and long-term atmospheric concentrations.

Current technological trends in isobutane emission monitoring include the development of real-time monitoring systems, remote sensing technologies, and data analytics platforms for emission prediction and management. These advancements aim to provide more accurate, continuous, and cost-effective monitoring solutions compared to traditional periodic sampling methods.

The establishment of standards for monitoring isobutane emissions faces several challenges, including the need for harmonization across different regions and industries, the development of reliable calibration methods for diverse monitoring equipment, and the integration of emerging technologies into existing regulatory frameworks. Additionally, there is a growing emphasis on addressing the entire lifecycle of isobutane emissions, from production and use to disposal and recycling.

As the global community continues to prioritize environmental sustainability and climate change mitigation, the importance of robust isobutane emission monitoring standards cannot be overstated. These standards will play a crucial role in guiding industry practices, informing policy decisions, and ultimately contributing to the reduction of greenhouse gas emissions and the protection of air quality.

The primary objective of establishing standards for monitoring isobutane emissions is to create a comprehensive framework that enables accurate measurement, reporting, and control of these emissions across different sectors. This includes industries such as refrigeration, aerosol propellants, petrochemicals, and foam blowing agents, where isobutane is commonly used. By implementing standardized monitoring practices, stakeholders aim to minimize the environmental footprint of isobutane-related activities and mitigate potential health risks associated with exposure to high concentrations of this gas.

The evolution of isobutane emission monitoring standards has been driven by advancements in detection technologies, increased environmental awareness, and stricter regulatory requirements. Early monitoring efforts primarily focused on workplace safety and leak detection. However, as the understanding of isobutane's environmental impact grew, the scope of monitoring expanded to include ambient air quality, fugitive emissions, and long-term atmospheric concentrations.

Current technological trends in isobutane emission monitoring include the development of real-time monitoring systems, remote sensing technologies, and data analytics platforms for emission prediction and management. These advancements aim to provide more accurate, continuous, and cost-effective monitoring solutions compared to traditional periodic sampling methods.

The establishment of standards for monitoring isobutane emissions faces several challenges, including the need for harmonization across different regions and industries, the development of reliable calibration methods for diverse monitoring equipment, and the integration of emerging technologies into existing regulatory frameworks. Additionally, there is a growing emphasis on addressing the entire lifecycle of isobutane emissions, from production and use to disposal and recycling.

As the global community continues to prioritize environmental sustainability and climate change mitigation, the importance of robust isobutane emission monitoring standards cannot be overstated. These standards will play a crucial role in guiding industry practices, informing policy decisions, and ultimately contributing to the reduction of greenhouse gas emissions and the protection of air quality.

Market Drivers for Isobutane Emissions Monitoring

The market for isobutane emissions monitoring is driven by a combination of regulatory pressures, environmental concerns, and industry-specific needs. As global awareness of climate change and air quality issues grows, governments and international bodies have implemented increasingly stringent regulations on greenhouse gas emissions, including volatile organic compounds (VOCs) like isobutane. This regulatory landscape has created a significant demand for accurate and reliable monitoring solutions.

In the industrial sector, particularly in petrochemical plants, refineries, and manufacturing facilities that use isobutane as a refrigerant or propellant, there is a pressing need to comply with emission standards. These industries are investing in advanced monitoring technologies to avoid penalties, maintain operational licenses, and demonstrate corporate responsibility. The potential for substantial fines and reputational damage associated with non-compliance has become a major market driver.

Environmental sustainability initiatives and corporate social responsibility programs have also emerged as key factors influencing the market. Companies are increasingly adopting voluntary emission reduction targets, which require sophisticated monitoring systems to track progress and validate results. This trend is particularly evident in industries that are under public scrutiny for their environmental impact.

The insurance industry has begun to recognize the financial risks associated with undetected or uncontrolled emissions. As a result, there is growing pressure on businesses to implement comprehensive monitoring systems as a risk mitigation strategy. This has created a new market segment for emissions monitoring equipment and services.

Technological advancements in sensor technology, data analytics, and Internet of Things (IoT) connectivity have expanded the capabilities of isobutane emissions monitoring systems. These innovations have improved accuracy, reduced costs, and enabled real-time monitoring, making it more feasible for a wider range of businesses to adopt such solutions. The integration of artificial intelligence and machine learning algorithms for predictive maintenance and emission forecasting has further enhanced the value proposition of these systems.

Public health concerns have also played a significant role in driving market growth. As research continues to link air pollution to various health issues, there is increasing public demand for transparency and action regarding industrial emissions. This has led to community-driven initiatives and local government policies that require more comprehensive monitoring and reporting of emissions, including isobutane.

The global push towards a circular economy and sustainable manufacturing practices has created additional market opportunities. Companies are seeking ways to minimize waste and maximize resource efficiency, which includes reducing and recapturing volatile organic compound emissions. This has spurred interest in monitoring systems that can not only detect leaks but also quantify emissions for potential recovery and reuse.

In the industrial sector, particularly in petrochemical plants, refineries, and manufacturing facilities that use isobutane as a refrigerant or propellant, there is a pressing need to comply with emission standards. These industries are investing in advanced monitoring technologies to avoid penalties, maintain operational licenses, and demonstrate corporate responsibility. The potential for substantial fines and reputational damage associated with non-compliance has become a major market driver.

Environmental sustainability initiatives and corporate social responsibility programs have also emerged as key factors influencing the market. Companies are increasingly adopting voluntary emission reduction targets, which require sophisticated monitoring systems to track progress and validate results. This trend is particularly evident in industries that are under public scrutiny for their environmental impact.

The insurance industry has begun to recognize the financial risks associated with undetected or uncontrolled emissions. As a result, there is growing pressure on businesses to implement comprehensive monitoring systems as a risk mitigation strategy. This has created a new market segment for emissions monitoring equipment and services.

Technological advancements in sensor technology, data analytics, and Internet of Things (IoT) connectivity have expanded the capabilities of isobutane emissions monitoring systems. These innovations have improved accuracy, reduced costs, and enabled real-time monitoring, making it more feasible for a wider range of businesses to adopt such solutions. The integration of artificial intelligence and machine learning algorithms for predictive maintenance and emission forecasting has further enhanced the value proposition of these systems.

Public health concerns have also played a significant role in driving market growth. As research continues to link air pollution to various health issues, there is increasing public demand for transparency and action regarding industrial emissions. This has led to community-driven initiatives and local government policies that require more comprehensive monitoring and reporting of emissions, including isobutane.

The global push towards a circular economy and sustainable manufacturing practices has created additional market opportunities. Companies are seeking ways to minimize waste and maximize resource efficiency, which includes reducing and recapturing volatile organic compound emissions. This has spurred interest in monitoring systems that can not only detect leaks but also quantify emissions for potential recovery and reuse.

Current Monitoring Technologies and Challenges

The current landscape of isobutane emissions monitoring technologies presents a mix of established methods and emerging solutions, each with its own set of challenges. Traditional methods include gas chromatography (GC) and flame ionization detection (FID), which have been industry standards for decades. These techniques offer high accuracy and specificity but are often limited by their need for complex equipment and trained personnel, making them less suitable for continuous, on-site monitoring.

Infrared (IR) spectroscopy has gained traction as a more versatile option, allowing for real-time, non-invasive detection of isobutane emissions. However, IR-based systems can be affected by interference from other gases and environmental factors, necessitating careful calibration and data interpretation. Photoionization detectors (PIDs) offer another portable solution, prized for their sensitivity to volatile organic compounds (VOCs) like isobutane, but they lack specificity and may produce false positives in complex gas mixtures.

Recent advancements in sensor technology have led to the development of miniaturized, low-cost semiconductor sensors capable of detecting isobutane. While these sensors offer the potential for widespread deployment in industrial settings, they often struggle with long-term stability and cross-sensitivity to other gases, limiting their reliability for regulatory compliance monitoring.

One of the primary challenges in isobutane emissions monitoring is achieving a balance between accuracy, cost-effectiveness, and ease of use. Many current technologies excel in one or two of these areas but fall short in others. For instance, while laser-based detection methods offer exceptional sensitivity and specificity, their high cost and complexity make them impractical for widespread adoption in smaller facilities or for continuous monitoring applications.

Another significant challenge is the need for robust, weather-resistant monitoring solutions capable of operating reliably in diverse industrial environments. Many existing technologies are sensitive to temperature fluctuations, humidity, and dust, which can compromise measurement accuracy and long-term performance. This is particularly problematic for outdoor monitoring stations or in harsh industrial settings where isobutane emissions are likely to occur.

Data integration and analysis present additional hurdles. As monitoring networks grow more complex, there is an increasing need for sophisticated data management systems capable of processing and interpreting large volumes of real-time emissions data. This includes the ability to distinguish between normal operational emissions and potentially hazardous leaks or releases, as well as to provide actionable insights for emissions reduction strategies.

Regulatory compliance adds another layer of complexity to the monitoring landscape. As environmental regulations become more stringent, there is a growing demand for monitoring technologies that not only meet current standards but are also adaptable to future regulatory changes. This requires ongoing innovation in both hardware and software components of monitoring systems to ensure they remain compliant and effective over time.

Infrared (IR) spectroscopy has gained traction as a more versatile option, allowing for real-time, non-invasive detection of isobutane emissions. However, IR-based systems can be affected by interference from other gases and environmental factors, necessitating careful calibration and data interpretation. Photoionization detectors (PIDs) offer another portable solution, prized for their sensitivity to volatile organic compounds (VOCs) like isobutane, but they lack specificity and may produce false positives in complex gas mixtures.

Recent advancements in sensor technology have led to the development of miniaturized, low-cost semiconductor sensors capable of detecting isobutane. While these sensors offer the potential for widespread deployment in industrial settings, they often struggle with long-term stability and cross-sensitivity to other gases, limiting their reliability for regulatory compliance monitoring.

One of the primary challenges in isobutane emissions monitoring is achieving a balance between accuracy, cost-effectiveness, and ease of use. Many current technologies excel in one or two of these areas but fall short in others. For instance, while laser-based detection methods offer exceptional sensitivity and specificity, their high cost and complexity make them impractical for widespread adoption in smaller facilities or for continuous monitoring applications.

Another significant challenge is the need for robust, weather-resistant monitoring solutions capable of operating reliably in diverse industrial environments. Many existing technologies are sensitive to temperature fluctuations, humidity, and dust, which can compromise measurement accuracy and long-term performance. This is particularly problematic for outdoor monitoring stations or in harsh industrial settings where isobutane emissions are likely to occur.

Data integration and analysis present additional hurdles. As monitoring networks grow more complex, there is an increasing need for sophisticated data management systems capable of processing and interpreting large volumes of real-time emissions data. This includes the ability to distinguish between normal operational emissions and potentially hazardous leaks or releases, as well as to provide actionable insights for emissions reduction strategies.

Regulatory compliance adds another layer of complexity to the monitoring landscape. As environmental regulations become more stringent, there is a growing demand for monitoring technologies that not only meet current standards but are also adaptable to future regulatory changes. This requires ongoing innovation in both hardware and software components of monitoring systems to ensure they remain compliant and effective over time.

Existing Standards and Monitoring Solutions

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described, including catalytic processes, distillation techniques, and separation methods. These processes aim to improve the efficiency of isobutane production while minimizing emissions and impurities.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described, including catalytic processes, distillation techniques, and separation methods. These processes aim to improve the efficiency of isobutane production while minimizing emissions and impurities.

- Isobutane as a refrigerant and propellant: Isobutane is used as a refrigerant and propellant in various applications. Research focuses on improving its performance, reducing emissions, and developing more environmentally friendly formulations for these purposes.

- Catalytic conversion processes involving isobutane: Catalytic processes for converting isobutane to other valuable chemicals are explored. These processes aim to optimize yield, selectivity, and reduce emissions through the use of novel catalysts and reaction conditions.

- Emission control and reduction techniques: Various methods and systems for controlling and reducing isobutane emissions are developed. These include adsorption technologies, membrane separation, and process optimization to minimize the release of isobutane into the environment.

- Isobutane in chemical synthesis and industrial processes: Isobutane is used as a feedstock or intermediate in various chemical synthesis and industrial processes. Research focuses on developing more efficient and environmentally friendly methods for utilizing isobutane while minimizing emissions and waste.

02 Isobutane as a refrigerant and propellant

Isobutane is used as a refrigerant and propellant in various applications. Research focuses on optimizing its use in these areas while addressing emission concerns through improved containment and recovery systems.Expand Specific Solutions03 Catalytic conversion processes involving isobutane

Catalytic processes for converting isobutane to other valuable products are explored, with an emphasis on reducing emissions during these reactions. This includes the development of novel catalysts and reaction conditions to improve selectivity and yield.Expand Specific Solutions04 Emission control in isobutane-related industrial processes

Technologies and methods for controlling and reducing isobutane emissions in industrial processes are developed. This includes improved capture and recycling systems, as well as process modifications to minimize fugitive emissions.Expand Specific Solutions05 Isobutane in fuel blends and combustion processes

Research on the use of isobutane in fuel blends and combustion processes, focusing on optimizing performance while minimizing emissions. This includes studies on engine modifications, fuel formulations, and exhaust treatment systems to reduce environmental impact.Expand Specific Solutions

Key Industry Players in Emissions Monitoring

The standards for monitoring isobutane emissions are in a developing stage, with the market showing significant growth potential due to increasing environmental regulations. The technology's maturity varies among key players, with established companies like China Petroleum & Chemical Corp. and Scania CV AB leading in advanced monitoring solutions. Emerging firms such as Beijing Yingshi Ruida Technology and Shanghai LEEG Instruments are rapidly innovating in this space. Academic institutions like Peking University and Tsinghua University contribute valuable research, while government-affiliated entities like Shandong Ecological Environment Monitoring Center play crucial roles in standardization efforts. The competitive landscape is diverse, with a mix of global corporations, specialized environmental technology firms, and research institutions driving progress in isobutane emission monitoring standards.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced monitoring systems for isobutane emissions in their petrochemical facilities. Their approach combines real-time gas chromatography with mass spectrometry (GC-MS) for precise detection and quantification of isobutane[1]. The system employs a network of sensors strategically placed throughout the facility, connected to a central control unit for continuous monitoring. Sinopec has also implemented machine learning algorithms to predict potential leaks based on historical data and operational parameters[3]. Additionally, they have developed portable detection devices for field inspections, utilizing infrared spectroscopy for rapid on-site analysis[5].

Strengths: Comprehensive monitoring system, high accuracy in detection, predictive capabilities. Weaknesses: High initial implementation cost, requires regular calibration and maintenance.

Anhui Institute of Optics and Fine Mechanics, Chinese Academy of Sciences

Technical Solution: The Anhui Institute of Optics and Fine Mechanics has pioneered the use of laser-based spectroscopic techniques for monitoring isobutane emissions. Their system employs tunable diode laser absorption spectroscopy (TDLAS) for real-time, in-situ measurements of isobutane concentrations[2]. The institute has developed a multi-path cell design that enhances sensitivity, allowing for detection of isobutane at parts-per-billion levels. They have also integrated their system with advanced data processing algorithms to compensate for interference from other gases and environmental factors[4]. The institute's technology has been successfully deployed in various industrial settings, including petrochemical plants and refrigeration facilities[6].

Strengths: High sensitivity and selectivity, real-time monitoring capability, minimal calibration required. Weaknesses: Potentially affected by harsh environmental conditions, higher cost compared to traditional methods.

Innovative Approaches in Isobutane Detection

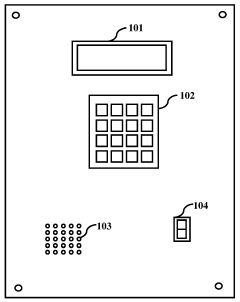

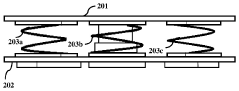

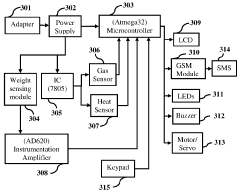

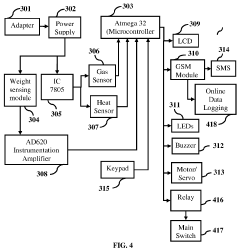

Automatic continuous monitoring and control system for liquefied petroleum gas (LPG) cylinders

PatentInactiveIN3343MUM2014A

Innovation

- A device with a weight measurement module using a load cell, gas leakage detection module, temperature measurement module, and alert/notification system that sends SMS alerts to both users and service providers, automatically ordering refills and shutting off gas supplies in case of leaks.

Volatile organic compound pollutant standard exceeding early warning air bag sampling and sample reserving system

PatentPendingCN111323541A

Innovation

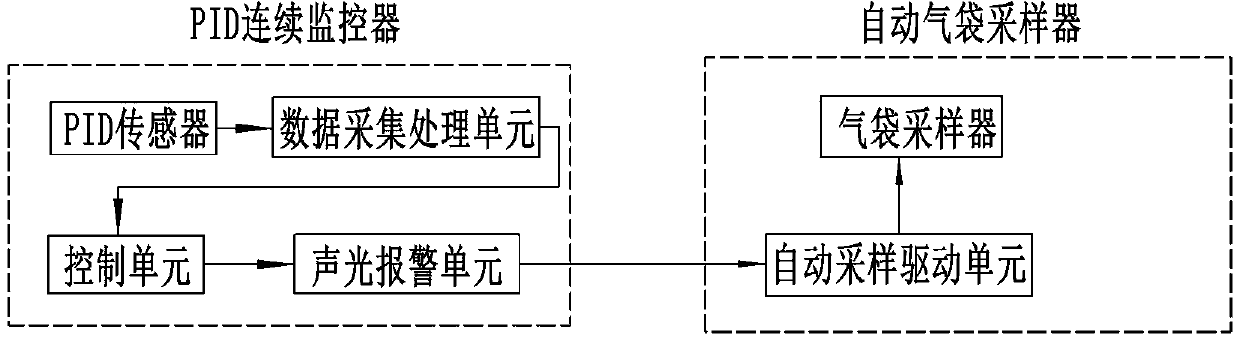

- A combined system of PID continuous monitor and automatic air bag sampler is used to detect volatile organic compounds through the PID sensor, the data acquisition and processing unit filters the signal, the control unit sets the alarm value, the sound and light alarm unit issues an alarm signal, and the automatic air bag sampler Collect samples to achieve continuous monitoring and early warning sampling.

Regulatory Framework for Isobutane Emissions

The regulatory framework for isobutane emissions is a complex and evolving landscape that encompasses various levels of governance, from international agreements to local regulations. At the global level, the United Nations Framework Convention on Climate Change (UNFCCC) and the Paris Agreement provide overarching guidelines for reducing greenhouse gas emissions, including volatile organic compounds (VOCs) like isobutane. These international accords set the stage for national and regional policies aimed at mitigating climate change and improving air quality.

In the United States, the Environmental Protection Agency (EPA) plays a central role in regulating isobutane emissions under the Clean Air Act. The EPA has established National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) that apply to various industries and processes involving isobutane. These standards often require the implementation of Maximum Achievable Control Technology (MACT) to minimize emissions.

The European Union has its own comprehensive regulatory framework, including the Industrial Emissions Directive (IED) and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. These directives set emission limits and require companies to implement best available techniques (BAT) for controlling isobutane releases.

At the state and local levels, additional regulations may be in place to address specific regional air quality concerns. For instance, California's Air Resources Board (CARB) has implemented stringent VOC emission standards that often exceed federal requirements. Similarly, other states and municipalities may have their own regulations tailored to local environmental priorities and industrial activities.

Industry-specific regulations also play a crucial role in controlling isobutane emissions. For example, the refrigeration and air conditioning sector faces specific guidelines under the Montreal Protocol and its amendments, which address the use of hydrocarbon refrigerants like isobutane. These regulations often focus on leak detection, repair protocols, and proper disposal methods.

Compliance with these regulatory frameworks typically involves a combination of emission monitoring, reporting, and control measures. Companies are often required to conduct regular emissions inventories, implement leak detection and repair (LDAR) programs, and utilize appropriate control technologies such as vapor recovery systems or thermal oxidizers. The specific requirements can vary depending on the industry, facility size, and location.

In the United States, the Environmental Protection Agency (EPA) plays a central role in regulating isobutane emissions under the Clean Air Act. The EPA has established National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) that apply to various industries and processes involving isobutane. These standards often require the implementation of Maximum Achievable Control Technology (MACT) to minimize emissions.

The European Union has its own comprehensive regulatory framework, including the Industrial Emissions Directive (IED) and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. These directives set emission limits and require companies to implement best available techniques (BAT) for controlling isobutane releases.

At the state and local levels, additional regulations may be in place to address specific regional air quality concerns. For instance, California's Air Resources Board (CARB) has implemented stringent VOC emission standards that often exceed federal requirements. Similarly, other states and municipalities may have their own regulations tailored to local environmental priorities and industrial activities.

Industry-specific regulations also play a crucial role in controlling isobutane emissions. For example, the refrigeration and air conditioning sector faces specific guidelines under the Montreal Protocol and its amendments, which address the use of hydrocarbon refrigerants like isobutane. These regulations often focus on leak detection, repair protocols, and proper disposal methods.

Compliance with these regulatory frameworks typically involves a combination of emission monitoring, reporting, and control measures. Companies are often required to conduct regular emissions inventories, implement leak detection and repair (LDAR) programs, and utilize appropriate control technologies such as vapor recovery systems or thermal oxidizers. The specific requirements can vary depending on the industry, facility size, and location.

Environmental Impact Assessment

The environmental impact assessment of isobutane emissions monitoring standards is crucial for understanding the potential effects on ecosystems and human health. Isobutane, a volatile organic compound (VOC), can contribute to air pollution and climate change when released into the atmosphere. Implementing robust monitoring standards helps in quantifying and controlling these emissions effectively.

Atmospheric dispersion modeling plays a significant role in assessing the environmental impact of isobutane emissions. These models simulate the transport and dilution of pollutants in the air, considering factors such as wind patterns, temperature, and topography. By utilizing these models, researchers and environmental agencies can predict the concentration of isobutane in different areas and evaluate potential risks to sensitive receptors.

The impact of isobutane emissions on air quality is a primary concern. When released, isobutane can react with other pollutants in the presence of sunlight, contributing to the formation of ground-level ozone. This secondary pollutant can have detrimental effects on human health, causing respiratory issues and exacerbating existing conditions such as asthma. Additionally, prolonged exposure to elevated levels of isobutane may lead to various health problems, including headaches, dizziness, and in extreme cases, asphyxiation.

Ecosystem effects are another critical aspect of the environmental impact assessment. Isobutane emissions can potentially harm vegetation by interfering with photosynthesis and altering plant growth patterns. Aquatic ecosystems may also be affected if isobutane dissolves in water bodies, potentially impacting aquatic organisms and disrupting food chains.

Climate change implications are an essential consideration in the assessment. Isobutane is a greenhouse gas with a global warming potential significantly higher than carbon dioxide. While its atmospheric lifetime is relatively short, the cumulative effect of continuous emissions can contribute to global warming and associated climate change impacts.

The assessment should also consider the potential for accidental releases and their environmental consequences. Large-scale isobutane leaks can lead to localized air quality issues and pose fire and explosion risks. Evaluating the probability and potential impact of such events is crucial for developing appropriate mitigation strategies and emergency response plans.

Monitoring standards for isobutane emissions play a vital role in mitigating these environmental impacts. By establishing accurate and reliable measurement techniques, industries and regulatory bodies can better quantify emissions, identify sources, and implement effective control measures. This, in turn, helps in reducing the overall environmental footprint of isobutane-related activities and supports sustainable development goals.

Atmospheric dispersion modeling plays a significant role in assessing the environmental impact of isobutane emissions. These models simulate the transport and dilution of pollutants in the air, considering factors such as wind patterns, temperature, and topography. By utilizing these models, researchers and environmental agencies can predict the concentration of isobutane in different areas and evaluate potential risks to sensitive receptors.

The impact of isobutane emissions on air quality is a primary concern. When released, isobutane can react with other pollutants in the presence of sunlight, contributing to the formation of ground-level ozone. This secondary pollutant can have detrimental effects on human health, causing respiratory issues and exacerbating existing conditions such as asthma. Additionally, prolonged exposure to elevated levels of isobutane may lead to various health problems, including headaches, dizziness, and in extreme cases, asphyxiation.

Ecosystem effects are another critical aspect of the environmental impact assessment. Isobutane emissions can potentially harm vegetation by interfering with photosynthesis and altering plant growth patterns. Aquatic ecosystems may also be affected if isobutane dissolves in water bodies, potentially impacting aquatic organisms and disrupting food chains.

Climate change implications are an essential consideration in the assessment. Isobutane is a greenhouse gas with a global warming potential significantly higher than carbon dioxide. While its atmospheric lifetime is relatively short, the cumulative effect of continuous emissions can contribute to global warming and associated climate change impacts.

The assessment should also consider the potential for accidental releases and their environmental consequences. Large-scale isobutane leaks can lead to localized air quality issues and pose fire and explosion risks. Evaluating the probability and potential impact of such events is crucial for developing appropriate mitigation strategies and emergency response plans.

Monitoring standards for isobutane emissions play a vital role in mitigating these environmental impacts. By establishing accurate and reliable measurement techniques, industries and regulatory bodies can better quantify emissions, identify sources, and implement effective control measures. This, in turn, helps in reducing the overall environmental footprint of isobutane-related activities and supports sustainable development goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!