Advances in 3D-printing for Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D-Printing Piezoelectric Sensors: Background and Objectives

The field of 3D-printed piezoelectric sensors represents a convergence of additive manufacturing and advanced sensing technologies. This innovative approach has emerged as a promising solution to address the limitations of traditional piezoelectric sensor fabrication methods. The evolution of this technology can be traced back to the early 2010s when researchers began exploring the potential of 3D printing for creating custom-designed piezoelectric structures.

The primary objective of advancing 3D-printed piezoelectric sensors is to develop highly customizable, cost-effective, and efficient sensing devices for a wide range of applications. These sensors aim to overcome the constraints of conventional manufacturing techniques, such as limited geometries, high production costs, and material waste. By leveraging 3D printing technologies, researchers and engineers seek to create sensors with complex architectures, improved performance, and enhanced functionality.

One of the key drivers behind this technological advancement is the growing demand for sensors in various industries, including healthcare, aerospace, automotive, and consumer electronics. The ability to rapidly prototype and produce piezoelectric sensors with tailored properties opens up new possibilities for real-time monitoring, energy harvesting, and smart device integration.

The development of 3D-printed piezoelectric sensors has been facilitated by advancements in materials science, particularly in the formulation of printable piezoelectric materials. These materials, often in the form of inks or pastes, must possess suitable rheological properties for 3D printing while maintaining their piezoelectric characteristics after deposition and post-processing.

As the technology progresses, researchers are focusing on several critical aspects to enhance the capabilities of 3D-printed piezoelectric sensors. These include improving the resolution and precision of printed structures, expanding the range of compatible materials, and developing novel printing techniques that can produce multi-material and multi-functional devices.

The ultimate goal is to establish 3D printing as a viable and preferred method for manufacturing piezoelectric sensors, enabling rapid customization, reduced production costs, and improved performance across various applications. This technology has the potential to revolutionize sensor design and fabrication, paving the way for next-generation sensing solutions in fields such as structural health monitoring, biomedical devices, and Internet of Things (IoT) applications.

The primary objective of advancing 3D-printed piezoelectric sensors is to develop highly customizable, cost-effective, and efficient sensing devices for a wide range of applications. These sensors aim to overcome the constraints of conventional manufacturing techniques, such as limited geometries, high production costs, and material waste. By leveraging 3D printing technologies, researchers and engineers seek to create sensors with complex architectures, improved performance, and enhanced functionality.

One of the key drivers behind this technological advancement is the growing demand for sensors in various industries, including healthcare, aerospace, automotive, and consumer electronics. The ability to rapidly prototype and produce piezoelectric sensors with tailored properties opens up new possibilities for real-time monitoring, energy harvesting, and smart device integration.

The development of 3D-printed piezoelectric sensors has been facilitated by advancements in materials science, particularly in the formulation of printable piezoelectric materials. These materials, often in the form of inks or pastes, must possess suitable rheological properties for 3D printing while maintaining their piezoelectric characteristics after deposition and post-processing.

As the technology progresses, researchers are focusing on several critical aspects to enhance the capabilities of 3D-printed piezoelectric sensors. These include improving the resolution and precision of printed structures, expanding the range of compatible materials, and developing novel printing techniques that can produce multi-material and multi-functional devices.

The ultimate goal is to establish 3D printing as a viable and preferred method for manufacturing piezoelectric sensors, enabling rapid customization, reduced production costs, and improved performance across various applications. This technology has the potential to revolutionize sensor design and fabrication, paving the way for next-generation sensing solutions in fields such as structural health monitoring, biomedical devices, and Internet of Things (IoT) applications.

Market Analysis for 3D-Printed Piezoelectric Sensors

The market for 3D-printed piezoelectric sensors is experiencing significant growth, driven by advancements in additive manufacturing technologies and increasing demand for customized sensing solutions across various industries. This emerging market segment is poised to disrupt traditional sensor manufacturing processes, offering enhanced design flexibility, reduced production costs, and improved performance characteristics.

The global piezoelectric sensors market, which encompasses both conventional and 3D-printed sensors, is projected to expand steadily over the coming years. Key factors contributing to this growth include the rising adoption of automation and IoT technologies in industrial applications, the growing need for high-precision measurement devices in healthcare and aerospace sectors, and the increasing focus on energy harvesting solutions.

3D-printed piezoelectric sensors are finding applications in diverse fields, including automotive, aerospace, healthcare, consumer electronics, and industrial monitoring. In the automotive sector, these sensors are being integrated into advanced driver assistance systems (ADAS) and structural health monitoring systems. The aerospace industry is leveraging 3D-printed piezoelectric sensors for vibration monitoring and structural integrity assessment of aircraft components.

In healthcare, 3D-printed piezoelectric sensors are enabling the development of novel wearable devices for continuous health monitoring and personalized medicine. The consumer electronics market is exploring the potential of these sensors in haptic feedback systems and energy harvesting applications for smart devices. Industrial monitoring applications include predictive maintenance systems and process control in manufacturing environments.

The market for 3D-printed piezoelectric sensors is characterized by a high degree of innovation and rapid technological advancements. Key trends shaping the market include the development of multi-material 3D printing techniques for enhanced sensor performance, the integration of artificial intelligence and machine learning algorithms for improved data analysis, and the exploration of novel piezoelectric materials with superior properties.

Challenges facing the market include the need for standardization and quality control in 3D-printed sensor production, concerns regarding long-term reliability and durability of printed sensors, and the relatively high initial investment required for adopting 3D printing technologies. However, ongoing research and development efforts are addressing these challenges, paving the way for wider adoption of 3D-printed piezoelectric sensors across industries.

As the technology matures and production costs decrease, the market for 3D-printed piezoelectric sensors is expected to witness accelerated growth. The ability to create complex geometries and customize sensor designs for specific applications will likely drive increased adoption in niche markets and specialized industries. Furthermore, the potential for on-demand, localized production of sensors could disrupt traditional supply chains and lead to more agile and responsive manufacturing processes.

The global piezoelectric sensors market, which encompasses both conventional and 3D-printed sensors, is projected to expand steadily over the coming years. Key factors contributing to this growth include the rising adoption of automation and IoT technologies in industrial applications, the growing need for high-precision measurement devices in healthcare and aerospace sectors, and the increasing focus on energy harvesting solutions.

3D-printed piezoelectric sensors are finding applications in diverse fields, including automotive, aerospace, healthcare, consumer electronics, and industrial monitoring. In the automotive sector, these sensors are being integrated into advanced driver assistance systems (ADAS) and structural health monitoring systems. The aerospace industry is leveraging 3D-printed piezoelectric sensors for vibration monitoring and structural integrity assessment of aircraft components.

In healthcare, 3D-printed piezoelectric sensors are enabling the development of novel wearable devices for continuous health monitoring and personalized medicine. The consumer electronics market is exploring the potential of these sensors in haptic feedback systems and energy harvesting applications for smart devices. Industrial monitoring applications include predictive maintenance systems and process control in manufacturing environments.

The market for 3D-printed piezoelectric sensors is characterized by a high degree of innovation and rapid technological advancements. Key trends shaping the market include the development of multi-material 3D printing techniques for enhanced sensor performance, the integration of artificial intelligence and machine learning algorithms for improved data analysis, and the exploration of novel piezoelectric materials with superior properties.

Challenges facing the market include the need for standardization and quality control in 3D-printed sensor production, concerns regarding long-term reliability and durability of printed sensors, and the relatively high initial investment required for adopting 3D printing technologies. However, ongoing research and development efforts are addressing these challenges, paving the way for wider adoption of 3D-printed piezoelectric sensors across industries.

As the technology matures and production costs decrease, the market for 3D-printed piezoelectric sensors is expected to witness accelerated growth. The ability to create complex geometries and customize sensor designs for specific applications will likely drive increased adoption in niche markets and specialized industries. Furthermore, the potential for on-demand, localized production of sensors could disrupt traditional supply chains and lead to more agile and responsive manufacturing processes.

Current Challenges in 3D-Printing Piezoelectric Materials

Despite significant advancements in 3D-printing technology for piezoelectric sensors, several challenges persist in the fabrication process of piezoelectric materials. One of the primary obstacles is achieving precise control over the microstructure and composition of the printed materials. The piezoelectric properties of these sensors are highly dependent on the crystalline structure and orientation of the piezoelectric elements, which can be difficult to maintain during the 3D-printing process.

Another major challenge lies in the limited range of printable piezoelectric materials. While some common piezoelectric materials like polyvinylidene fluoride (PVDF) and lead zirconate titanate (PZT) have been successfully 3D-printed, many other high-performance piezoelectric materials remain challenging to adapt to additive manufacturing techniques. This limitation restricts the potential applications and performance of 3D-printed piezoelectric sensors.

The resolution and accuracy of 3D-printing technologies also present significant hurdles. Many piezoelectric applications require fine-scale structures or precise geometries that push the boundaries of current 3D-printing capabilities. Achieving the necessary precision while maintaining the piezoelectric properties of the materials is a complex balancing act that researchers are still working to optimize.

Scalability and production speed remain concerns for the widespread adoption of 3D-printed piezoelectric sensors in industrial applications. Current printing processes for piezoelectric materials are often slow and limited in scale, making it challenging to produce large quantities of sensors efficiently. This limitation hinders the technology's potential for mass production and commercial viability.

The integration of electrodes and other functional components into 3D-printed piezoelectric structures poses another significant challenge. Ensuring proper electrical connections and maintaining the integrity of the piezoelectric material during the integration process is crucial for sensor performance but can be difficult to achieve consistently in a 3D-printing environment.

Lastly, the long-term stability and reliability of 3D-printed piezoelectric sensors remain areas of concern. The layered nature of 3D-printed structures can lead to potential weak points or inconsistencies in the material properties over time. Ensuring that these sensors maintain their piezoelectric performance and structural integrity under various environmental conditions and over extended periods is critical for their practical application in real-world scenarios.

Another major challenge lies in the limited range of printable piezoelectric materials. While some common piezoelectric materials like polyvinylidene fluoride (PVDF) and lead zirconate titanate (PZT) have been successfully 3D-printed, many other high-performance piezoelectric materials remain challenging to adapt to additive manufacturing techniques. This limitation restricts the potential applications and performance of 3D-printed piezoelectric sensors.

The resolution and accuracy of 3D-printing technologies also present significant hurdles. Many piezoelectric applications require fine-scale structures or precise geometries that push the boundaries of current 3D-printing capabilities. Achieving the necessary precision while maintaining the piezoelectric properties of the materials is a complex balancing act that researchers are still working to optimize.

Scalability and production speed remain concerns for the widespread adoption of 3D-printed piezoelectric sensors in industrial applications. Current printing processes for piezoelectric materials are often slow and limited in scale, making it challenging to produce large quantities of sensors efficiently. This limitation hinders the technology's potential for mass production and commercial viability.

The integration of electrodes and other functional components into 3D-printed piezoelectric structures poses another significant challenge. Ensuring proper electrical connections and maintaining the integrity of the piezoelectric material during the integration process is crucial for sensor performance but can be difficult to achieve consistently in a 3D-printing environment.

Lastly, the long-term stability and reliability of 3D-printed piezoelectric sensors remain areas of concern. The layered nature of 3D-printed structures can lead to potential weak points or inconsistencies in the material properties over time. Ensuring that these sensors maintain their piezoelectric performance and structural integrity under various environmental conditions and over extended periods is critical for their practical application in real-world scenarios.

State-of-the-Art 3D-Printing Methods for Piezoelectric Sensors

01 3D printing of piezoelectric materials

Utilizing 3D printing techniques to fabricate piezoelectric materials for sensor applications. This method allows for the creation of complex geometries and customized designs, enabling the production of sensors with improved performance and functionality.- 3D printing of piezoelectric materials: Utilizing 3D printing techniques to fabricate piezoelectric materials for sensor applications. This method allows for the creation of complex geometries and customized structures, enhancing the performance and functionality of piezoelectric sensors.

- Integration of piezoelectric sensors in 3D printed structures: Embedding piezoelectric sensors within 3D printed objects or structures. This approach enables the creation of smart objects with integrated sensing capabilities, suitable for various applications such as structural health monitoring or wearable devices.

- 3D printed flexible piezoelectric sensors: Development of flexible piezoelectric sensors using 3D printing technologies. These sensors can conform to curved surfaces and are suitable for applications in soft robotics, wearable electronics, and biomedical devices.

- Multi-material 3D printing for piezoelectric sensors: Utilizing multi-material 3D printing techniques to create piezoelectric sensors with enhanced properties. This approach allows for the combination of different materials within a single print, enabling the fabrication of sensors with tailored mechanical and electrical characteristics.

- 3D printed piezoelectric nanocomposites: Developing piezoelectric nanocomposites using 3D printing techniques. These nanocomposites combine piezoelectric materials with other nanoparticles or polymers to enhance sensitivity, durability, or other properties of the resulting sensors.

02 Integration of piezoelectric sensors in 3D printed structures

Embedding piezoelectric sensors within 3D printed structures or components. This approach enables the creation of smart objects with built-in sensing capabilities, suitable for various applications such as structural health monitoring or wearable devices.Expand Specific Solutions03 3D printed flexible piezoelectric sensors

Developing flexible piezoelectric sensors using 3D printing technologies. These sensors can conform to curved surfaces and are suitable for applications in wearable electronics, soft robotics, and biomedical devices.Expand Specific Solutions04 Multi-material 3D printing for piezoelectric sensors

Employing multi-material 3D printing techniques to fabricate piezoelectric sensors with enhanced functionality. This method allows for the integration of different materials within a single printing process, enabling the creation of sensors with tailored properties and improved performance.Expand Specific Solutions05 Post-processing of 3D printed piezoelectric sensors

Implementing post-processing techniques to enhance the properties and performance of 3D printed piezoelectric sensors. This may include treatments such as poling, annealing, or surface modifications to optimize the piezoelectric response and overall sensor functionality.Expand Specific Solutions

Key Players in 3D-Printed Piezoelectric Sensor Industry

The field of 3D-printing for piezoelectric sensors is in a growth phase, with increasing market size and technological advancements. The global market for piezoelectric devices is projected to expand significantly, driven by demand in various industries. While the technology is maturing, there is still room for innovation and improvement. Key players like Huazhong University of Science & Technology, Virginia Tech, and Shandong University are contributing to research and development. Companies such as NGK Insulators and Saint-Gobain Ceramics & Plastics are likely leveraging this technology for commercial applications. The involvement of research institutions and established manufacturers indicates a competitive landscape with potential for further growth and technological refinement.

The Board of Regents of The University of Texas System

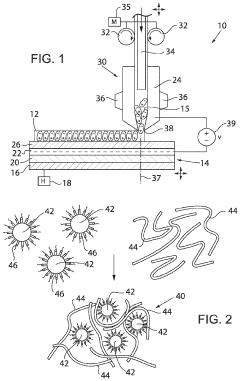

Technical Solution: The University of Texas has developed a 3D-printing technique for piezoelectric sensors using a combination of fused deposition modeling (FDM) and electrospinning. This hybrid approach allows for the creation of flexible, stretchable sensors with enhanced piezoelectric properties[7]. The process involves 3D printing a flexible polymer substrate using FDM, followed by the deposition of aligned piezoelectric nanofibers through electrospinning. The nanofibers, typically made of polyvinylidene fluoride (PVDF) or its copolymers, are precisely positioned on the substrate to create the sensing elements[8]. This method enables the fabrication of sensors with complex 3D geometries and improved sensitivity due to the aligned nanofiber structure[9].

Strengths: Produces flexible and stretchable sensors, combines benefits of 3D printing and nanofiber technology, potential for wearable and conformal sensing applications. Weaknesses: May require specialized equipment for electrospinning, and the integration of two fabrication processes could increase production complexity.

Purdue Research Foundation

Technical Solution: Purdue University researchers have developed a 3D-printing method for piezoelectric sensors using a ferroelectric ceramic/polymer composite. Their approach utilizes a direct ink writing (DIW) technique with a specially formulated ink containing lead zirconate titanate (PZT) particles suspended in a photocurable resin[4]. This method allows for the fabrication of sensors with complex geometries and controlled porosity, which can enhance sensitivity. The printed structures undergo a post-processing step involving debinding and sintering to achieve the final piezoelectric properties[5]. The team has demonstrated the ability to print sensors with varying PZT concentrations, enabling tunable piezoelectric responses suitable for different applications[6].

Strengths: High degree of geometric freedom, ability to control material composition and porosity, potential for scalable manufacturing. Weaknesses: Requires post-processing steps, which may limit some applications, and the use of lead-based materials may pose environmental concerns.

Innovative Materials for 3D-Printed Piezoelectric Sensors

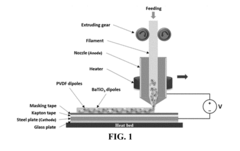

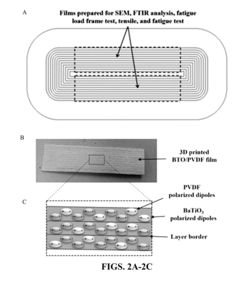

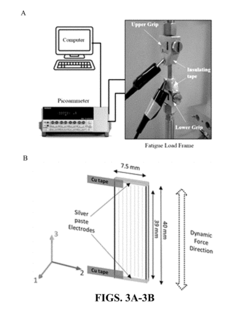

3D printing of piezoelectric ceramic particle/fluoropolymer nanocomposites with in-situ poling for sensor applications

PatentActiveUS20190054659A1

Innovation

- A composite filament comprising barium titanate (BTO) particles and poly(vinylidene fluoride) (PVDF) with optional multiwall carbon nanotubes (MWCNTs) is developed, using a solvent-casting process to create a uniform distribution of BTO in PVDF, followed by extrusion into a printable form, enabling multi-layer fabrication and enhanced piezoelectric properties through in-situ electric poling during the 3D printing process.

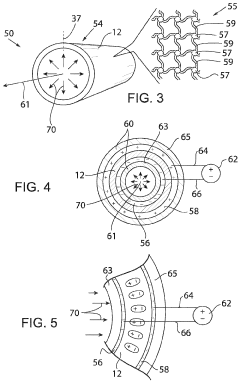

3D printed and in-situ poled flexible piezoelectric pressure sensor

PatentActiveUS11849642B2

Innovation

- 3D printed artificial blood vessels using ferroelectric materials with piezoelectric responses, specifically a composite of ferroelectric potassium sodium niobate (KNN) particles embedded in a polyvinylidene fluoride (PVDF) polymer matrix, allowing for real-time pressure and motion sensing through electric field-assisted additive manufacturing.

Environmental Impact of 3D-Printed Sensor Production

The environmental impact of 3D-printed sensor production is a critical consideration as this technology advances. The process of 3D printing piezoelectric sensors offers several environmental benefits compared to traditional manufacturing methods. Firstly, it significantly reduces material waste, as additive manufacturing allows for precise material deposition, minimizing excess material usage and reducing the need for post-processing.

However, the environmental implications extend beyond waste reduction. The energy consumption during the 3D printing process is an important factor to consider. While 3D printing can be more energy-efficient for small-scale production, large-scale manufacturing may require substantial energy inputs, potentially offsetting some of the environmental gains. The type of 3D printing technology used also influences energy consumption, with some methods being more energy-intensive than others.

The materials used in 3D-printed piezoelectric sensors also play a crucial role in their environmental impact. Many piezoelectric materials, such as lead zirconate titanate (PZT), contain toxic elements that can pose environmental risks if not properly managed. However, the development of lead-free piezoelectric materials for 3D printing is an active area of research, which could significantly reduce the environmental footprint of these sensors.

The lifecycle of 3D-printed sensors is another important aspect to consider. These sensors may have improved durability and longer lifespans compared to traditionally manufactured counterparts, potentially reducing the need for frequent replacements and thus decreasing overall resource consumption and waste generation.

Additionally, the localized nature of 3D printing can reduce transportation-related emissions associated with traditional global supply chains. By enabling on-demand, on-site production, 3D printing can minimize the need for long-distance shipping of components or finished products.

However, the environmental impact of 3D-printed sensor production also includes considerations such as the disposal or recycling of used printing materials and failed prints. The development of effective recycling methods for these materials is crucial to further improve the environmental profile of this manufacturing approach.

In conclusion, while 3D printing of piezoelectric sensors offers several environmental advantages, a comprehensive life cycle assessment is necessary to fully understand and optimize its environmental impact. Ongoing research and development in materials, processes, and recycling technologies will be key to maximizing the environmental benefits of this emerging manufacturing technique.

However, the environmental implications extend beyond waste reduction. The energy consumption during the 3D printing process is an important factor to consider. While 3D printing can be more energy-efficient for small-scale production, large-scale manufacturing may require substantial energy inputs, potentially offsetting some of the environmental gains. The type of 3D printing technology used also influences energy consumption, with some methods being more energy-intensive than others.

The materials used in 3D-printed piezoelectric sensors also play a crucial role in their environmental impact. Many piezoelectric materials, such as lead zirconate titanate (PZT), contain toxic elements that can pose environmental risks if not properly managed. However, the development of lead-free piezoelectric materials for 3D printing is an active area of research, which could significantly reduce the environmental footprint of these sensors.

The lifecycle of 3D-printed sensors is another important aspect to consider. These sensors may have improved durability and longer lifespans compared to traditionally manufactured counterparts, potentially reducing the need for frequent replacements and thus decreasing overall resource consumption and waste generation.

Additionally, the localized nature of 3D printing can reduce transportation-related emissions associated with traditional global supply chains. By enabling on-demand, on-site production, 3D printing can minimize the need for long-distance shipping of components or finished products.

However, the environmental impact of 3D-printed sensor production also includes considerations such as the disposal or recycling of used printing materials and failed prints. The development of effective recycling methods for these materials is crucial to further improve the environmental profile of this manufacturing approach.

In conclusion, while 3D printing of piezoelectric sensors offers several environmental advantages, a comprehensive life cycle assessment is necessary to fully understand and optimize its environmental impact. Ongoing research and development in materials, processes, and recycling technologies will be key to maximizing the environmental benefits of this emerging manufacturing technique.

Standardization and Quality Control in 3D-Printed Sensors

Standardization and quality control are critical aspects in the advancement of 3D-printed piezoelectric sensors. As this technology continues to evolve, establishing consistent manufacturing processes and ensuring reliable sensor performance become paramount. The variability inherent in 3D printing processes poses unique challenges for maintaining uniform sensor characteristics across production batches.

To address these challenges, researchers and industry leaders are developing standardized protocols for material selection, printing parameters, and post-processing techniques. These protocols aim to minimize variations in sensor properties such as sensitivity, frequency response, and durability. Implementing rigorous quality control measures throughout the manufacturing process is essential to achieve consistent results.

One key area of focus is the standardization of piezoelectric materials used in 3D printing. This includes establishing specifications for particle size distribution, purity, and rheological properties of printable piezoelectric inks. By defining these parameters, manufacturers can ensure consistent material behavior during the printing process and in the final sensor products.

Printing parameters such as extrusion temperature, print speed, and layer height also play a crucial role in sensor quality. Developing standardized printing profiles for different sensor designs helps maintain consistency across production runs. Additionally, calibration procedures for 3D printers used in sensor fabrication are being refined to ensure accurate deposition of piezoelectric materials.

Post-processing techniques, including poling and electrode deposition, require standardization to optimize sensor performance. Establishing uniform poling protocols ensures consistent piezoelectric properties across printed sensors. Standardized electrode deposition methods are crucial for achieving reliable electrical connections and sensor response.

Quality control measures are being implemented at various stages of the manufacturing process. In-line monitoring systems are being developed to assess print quality in real-time, allowing for immediate adjustments to printing parameters. Non-destructive testing methods, such as impedance analysis and laser vibrometry, are being adapted for rapid assessment of sensor performance.

Statistical process control techniques are being applied to track and analyze key performance indicators throughout the production cycle. This data-driven approach enables manufacturers to identify and address sources of variability, leading to continuous improvement in sensor quality and consistency.

As the field of 3D-printed piezoelectric sensors matures, industry collaborations and standards organizations are working towards establishing widely accepted quality benchmarks and testing protocols. These efforts aim to facilitate broader adoption of 3D-printed sensors in critical applications, where reliability and reproducibility are essential.

To address these challenges, researchers and industry leaders are developing standardized protocols for material selection, printing parameters, and post-processing techniques. These protocols aim to minimize variations in sensor properties such as sensitivity, frequency response, and durability. Implementing rigorous quality control measures throughout the manufacturing process is essential to achieve consistent results.

One key area of focus is the standardization of piezoelectric materials used in 3D printing. This includes establishing specifications for particle size distribution, purity, and rheological properties of printable piezoelectric inks. By defining these parameters, manufacturers can ensure consistent material behavior during the printing process and in the final sensor products.

Printing parameters such as extrusion temperature, print speed, and layer height also play a crucial role in sensor quality. Developing standardized printing profiles for different sensor designs helps maintain consistency across production runs. Additionally, calibration procedures for 3D printers used in sensor fabrication are being refined to ensure accurate deposition of piezoelectric materials.

Post-processing techniques, including poling and electrode deposition, require standardization to optimize sensor performance. Establishing uniform poling protocols ensures consistent piezoelectric properties across printed sensors. Standardized electrode deposition methods are crucial for achieving reliable electrical connections and sensor response.

Quality control measures are being implemented at various stages of the manufacturing process. In-line monitoring systems are being developed to assess print quality in real-time, allowing for immediate adjustments to printing parameters. Non-destructive testing methods, such as impedance analysis and laser vibrometry, are being adapted for rapid assessment of sensor performance.

Statistical process control techniques are being applied to track and analyze key performance indicators throughout the production cycle. This data-driven approach enables manufacturers to identify and address sources of variability, leading to continuous improvement in sensor quality and consistency.

As the field of 3D-printed piezoelectric sensors matures, industry collaborations and standards organizations are working towards establishing widely accepted quality benchmarks and testing protocols. These efforts aim to facilitate broader adoption of 3D-printed sensors in critical applications, where reliability and reproducibility are essential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!