Analysis of crosslinking reactions in epoxy powder coating systems

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Epoxy Powder Coating Crosslinking Background and Objectives

Epoxy powder coatings have emerged as a significant advancement in surface protection technology since their introduction in the 1960s. These environmentally friendly coating systems have evolved from simple protective layers to sophisticated formulations offering superior performance characteristics across various industrial applications. The evolution of epoxy powder coatings has been driven by increasing environmental regulations restricting volatile organic compounds (VOCs) and the growing demand for durable, cost-effective coating solutions in automotive, appliance, construction, and general industrial sectors.

The crosslinking reaction, which transforms the powder from a free-flowing material to a tough, adherent film, represents the cornerstone of epoxy powder coating technology. Historically, the development path has moved from simple glycidyl epoxy systems crosslinked with dicyandiamide toward more complex formulations incorporating hybrid systems and novel curing agents to enhance specific performance attributes.

Current technological trends in epoxy powder coating crosslinking focus on lowering cure temperatures to accommodate heat-sensitive substrates, accelerating cure rates for improved manufacturing efficiency, and enhancing the durability of the final coating. Additionally, there is significant interest in developing systems with improved weatherability, chemical resistance, and mechanical properties while maintaining the zero-VOC advantage inherent to powder coatings.

The global shift toward sustainable manufacturing processes has further accelerated research into bio-based epoxy resins and environmentally benign crosslinking agents, presenting both challenges and opportunities for innovation in this field. Recent advancements in nanotechnology have also opened new avenues for modifying crosslinking behavior and resultant coating properties.

This technical research aims to comprehensively analyze the fundamental chemistry governing crosslinking reactions in epoxy powder coating systems, with particular emphasis on reaction kinetics, network formation mechanisms, and structure-property relationships. By understanding these fundamental aspects, we seek to identify potential pathways for optimizing cure profiles, enhancing coating performance, and developing next-generation formulations with superior characteristics.

The objectives of this investigation include: mapping the reaction pathways of various epoxy-hardener systems under typical powder coating curing conditions; evaluating the influence of catalysts and accelerators on crosslinking efficiency; assessing the impact of fillers and additives on network formation; and correlating crosslinking density and network architecture with final coating properties. Additionally, we aim to explore novel crosslinking chemistries that could enable lower temperature curing while maintaining or improving coating performance.

Through this analysis, we intend to establish a foundation for future formulation development that addresses current market demands for more energy-efficient, versatile, and high-performance epoxy powder coating systems.

The crosslinking reaction, which transforms the powder from a free-flowing material to a tough, adherent film, represents the cornerstone of epoxy powder coating technology. Historically, the development path has moved from simple glycidyl epoxy systems crosslinked with dicyandiamide toward more complex formulations incorporating hybrid systems and novel curing agents to enhance specific performance attributes.

Current technological trends in epoxy powder coating crosslinking focus on lowering cure temperatures to accommodate heat-sensitive substrates, accelerating cure rates for improved manufacturing efficiency, and enhancing the durability of the final coating. Additionally, there is significant interest in developing systems with improved weatherability, chemical resistance, and mechanical properties while maintaining the zero-VOC advantage inherent to powder coatings.

The global shift toward sustainable manufacturing processes has further accelerated research into bio-based epoxy resins and environmentally benign crosslinking agents, presenting both challenges and opportunities for innovation in this field. Recent advancements in nanotechnology have also opened new avenues for modifying crosslinking behavior and resultant coating properties.

This technical research aims to comprehensively analyze the fundamental chemistry governing crosslinking reactions in epoxy powder coating systems, with particular emphasis on reaction kinetics, network formation mechanisms, and structure-property relationships. By understanding these fundamental aspects, we seek to identify potential pathways for optimizing cure profiles, enhancing coating performance, and developing next-generation formulations with superior characteristics.

The objectives of this investigation include: mapping the reaction pathways of various epoxy-hardener systems under typical powder coating curing conditions; evaluating the influence of catalysts and accelerators on crosslinking efficiency; assessing the impact of fillers and additives on network formation; and correlating crosslinking density and network architecture with final coating properties. Additionally, we aim to explore novel crosslinking chemistries that could enable lower temperature curing while maintaining or improving coating performance.

Through this analysis, we intend to establish a foundation for future formulation development that addresses current market demands for more energy-efficient, versatile, and high-performance epoxy powder coating systems.

Market Analysis of Epoxy Powder Coating Systems

The global epoxy powder coating market has demonstrated robust growth, valued at approximately $3.2 billion in 2022 and projected to reach $4.8 billion by 2028, with a compound annual growth rate (CAGR) of 6.9%. This growth is primarily driven by increasing demand across automotive, construction, appliance, and general industrial sectors, where performance requirements continue to elevate.

The automotive industry represents the largest application segment, accounting for nearly 28% of the market share. This dominance stems from the superior corrosion resistance, durability, and aesthetic finish that epoxy powder coatings provide to automotive components. The construction sector follows closely at 24%, with growing adoption in architectural applications, particularly in regions experiencing rapid infrastructure development.

Geographically, Asia-Pacific leads the market with 42% share, fueled by China's massive manufacturing base and infrastructure investments. North America and Europe collectively represent 45% of the market, with their demand driven by stringent environmental regulations favoring powder coatings over solvent-based alternatives.

Environmental sustainability has emerged as a critical market driver, with VOC-free formulations experiencing 15% faster growth than conventional alternatives. This trend aligns with increasingly stringent regulations in Europe and North America, where environmental compliance has become a competitive necessity rather than an option.

Technical performance requirements continue to evolve, with end-users demanding enhanced weatherability, chemical resistance, and cure efficiency. This has created a premium segment within the market, growing at 9.2% annually, focused on high-performance crosslinking systems that deliver superior mechanical properties and durability.

The competitive landscape features both global chemical conglomerates and specialized coating manufacturers. Key players include AkzoNobel, PPG Industries, Sherwin-Williams, and Axalta, collectively controlling approximately 52% of the global market. Regional manufacturers, particularly in Asia, are gaining market share through cost advantages and localized formulation expertise.

Supply chain considerations have gained prominence following recent global disruptions, with manufacturers increasingly focused on raw material security and regional production capabilities. The price volatility of key epoxy resins and crosslinking agents has prompted strategic shifts toward alternative formulation approaches and vertical integration strategies.

Customer preferences are increasingly favoring one-coat solutions that reduce application costs while maintaining performance standards. This has accelerated innovation in crosslinking chemistry to achieve faster cure rates and improved flow characteristics without compromising durability or appearance.

The automotive industry represents the largest application segment, accounting for nearly 28% of the market share. This dominance stems from the superior corrosion resistance, durability, and aesthetic finish that epoxy powder coatings provide to automotive components. The construction sector follows closely at 24%, with growing adoption in architectural applications, particularly in regions experiencing rapid infrastructure development.

Geographically, Asia-Pacific leads the market with 42% share, fueled by China's massive manufacturing base and infrastructure investments. North America and Europe collectively represent 45% of the market, with their demand driven by stringent environmental regulations favoring powder coatings over solvent-based alternatives.

Environmental sustainability has emerged as a critical market driver, with VOC-free formulations experiencing 15% faster growth than conventional alternatives. This trend aligns with increasingly stringent regulations in Europe and North America, where environmental compliance has become a competitive necessity rather than an option.

Technical performance requirements continue to evolve, with end-users demanding enhanced weatherability, chemical resistance, and cure efficiency. This has created a premium segment within the market, growing at 9.2% annually, focused on high-performance crosslinking systems that deliver superior mechanical properties and durability.

The competitive landscape features both global chemical conglomerates and specialized coating manufacturers. Key players include AkzoNobel, PPG Industries, Sherwin-Williams, and Axalta, collectively controlling approximately 52% of the global market. Regional manufacturers, particularly in Asia, are gaining market share through cost advantages and localized formulation expertise.

Supply chain considerations have gained prominence following recent global disruptions, with manufacturers increasingly focused on raw material security and regional production capabilities. The price volatility of key epoxy resins and crosslinking agents has prompted strategic shifts toward alternative formulation approaches and vertical integration strategies.

Customer preferences are increasingly favoring one-coat solutions that reduce application costs while maintaining performance standards. This has accelerated innovation in crosslinking chemistry to achieve faster cure rates and improved flow characteristics without compromising durability or appearance.

Current Challenges in Crosslinking Technology

Despite significant advancements in epoxy powder coating technology, several critical challenges persist in crosslinking reactions that limit performance optimization and broader industrial adoption. The primary challenge involves achieving precise control over curing kinetics, as current systems often exhibit inconsistent reaction rates across different temperature zones, leading to defects such as orange peel, pinholes, and uneven surface finish. This variability significantly impacts coating quality and performance reliability in demanding applications.

Temperature sensitivity remains a major obstacle, with most epoxy powder systems requiring relatively high curing temperatures (180-200°C), which restricts their application on heat-sensitive substrates like wood, plastic, and certain composite materials. The energy consumption associated with these high-temperature curing processes also raises sustainability concerns and increases production costs.

Catalyst efficiency presents another significant challenge. Current catalysts often demonstrate limited selectivity, promoting side reactions that can compromise the final coating properties. These side reactions may lead to discoloration, reduced gloss retention, and diminished weathering resistance. Additionally, many catalysts contain heavy metals or environmentally problematic compounds, creating regulatory compliance issues in various markets.

The shelf life stability of reactive components in powder formulations continues to be problematic. Premature crosslinking during storage or transportation results in increased viscosity, reduced flow properties, and ultimately compromised coating quality. This necessitates special storage conditions and limits distribution logistics, particularly in regions with hot climates.

Compatibility issues between crosslinking agents and other formulation components frequently arise, causing phase separation, agglomeration, or inconsistent particle size distribution. These phenomena negatively affect powder application uniformity and final film properties. The challenge is particularly pronounced when incorporating novel additives or attempting to achieve specialized performance characteristics.

Measurement and characterization of crosslinking reactions in real-time during industrial processing remains technically difficult. Current analytical methods often provide only post-cure information, limiting the ability to optimize processes dynamically. The lack of reliable in-situ monitoring techniques hampers both quality control and the development of more sophisticated curing profiles.

Finally, the industry faces increasing pressure to develop low-temperature curing systems that maintain high performance while reducing energy consumption. This challenge is compounded by the need to simultaneously address VOC emissions, REACH compliance, and other environmental regulations that restrict the use of certain crosslinking chemistries traditionally employed in epoxy powder coatings.

Temperature sensitivity remains a major obstacle, with most epoxy powder systems requiring relatively high curing temperatures (180-200°C), which restricts their application on heat-sensitive substrates like wood, plastic, and certain composite materials. The energy consumption associated with these high-temperature curing processes also raises sustainability concerns and increases production costs.

Catalyst efficiency presents another significant challenge. Current catalysts often demonstrate limited selectivity, promoting side reactions that can compromise the final coating properties. These side reactions may lead to discoloration, reduced gloss retention, and diminished weathering resistance. Additionally, many catalysts contain heavy metals or environmentally problematic compounds, creating regulatory compliance issues in various markets.

The shelf life stability of reactive components in powder formulations continues to be problematic. Premature crosslinking during storage or transportation results in increased viscosity, reduced flow properties, and ultimately compromised coating quality. This necessitates special storage conditions and limits distribution logistics, particularly in regions with hot climates.

Compatibility issues between crosslinking agents and other formulation components frequently arise, causing phase separation, agglomeration, or inconsistent particle size distribution. These phenomena negatively affect powder application uniformity and final film properties. The challenge is particularly pronounced when incorporating novel additives or attempting to achieve specialized performance characteristics.

Measurement and characterization of crosslinking reactions in real-time during industrial processing remains technically difficult. Current analytical methods often provide only post-cure information, limiting the ability to optimize processes dynamically. The lack of reliable in-situ monitoring techniques hampers both quality control and the development of more sophisticated curing profiles.

Finally, the industry faces increasing pressure to develop low-temperature curing systems that maintain high performance while reducing energy consumption. This challenge is compounded by the need to simultaneously address VOC emissions, REACH compliance, and other environmental regulations that restrict the use of certain crosslinking chemistries traditionally employed in epoxy powder coatings.

Current Crosslinking Solutions and Methodologies

01 Epoxy-polyester hybrid systems for powder coatings

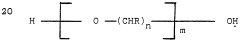

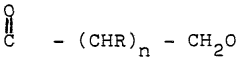

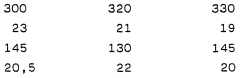

Hybrid systems combining epoxy resins with polyesters are widely used in powder coating formulations. These systems typically involve the reaction between epoxy functional groups and carboxyl-terminated polyesters. The crosslinking reaction occurs when the carboxyl groups of the polyester react with the epoxy groups under heat, forming a three-dimensional network. This hybrid approach offers a balance of properties including good flow, mechanical resistance, and chemical resistance while maintaining cost-effectiveness.- Epoxy-polyester hybrid systems for powder coatings: Hybrid systems combining epoxy resins with polyesters are widely used in powder coating formulations. These systems typically involve the reaction between epoxy functional groups and carboxyl-terminated polyesters, resulting in crosslinked networks with enhanced properties. The crosslinking reaction occurs during the curing process at elevated temperatures, forming ester linkages between the epoxy and polyester components. These hybrid systems offer a balance of properties including good adhesion, mechanical strength, and chemical resistance.

- Curing agents and catalysts for epoxy powder coatings: Various curing agents and catalysts are employed to facilitate crosslinking reactions in epoxy powder coating systems. Common curing agents include amines, anhydrides, and phenolic compounds that react with epoxy groups to form a three-dimensional network. Catalysts such as imidazoles, quaternary ammonium salts, and metal complexes accelerate these reactions by lowering the activation energy. The selection of appropriate curing agents and catalysts significantly influences the curing kinetics, reaction temperature, and final properties of the coating.

- Novel epoxy resin modifications for improved performance: Modifications to conventional epoxy resins have been developed to enhance specific properties of powder coatings. These modifications include the incorporation of silicone, fluorine, or other functional groups into the epoxy backbone, resulting in improved weather resistance, chemical resistance, or flexibility. Additionally, the use of epoxy resins with varying molecular weights, functionalities, and structures allows for tailored crosslinking densities and performance characteristics. These modified epoxy systems undergo controlled crosslinking reactions to achieve the desired coating properties.

- Environmentally friendly epoxy powder coating systems: Recent developments in epoxy powder coating technology have focused on environmentally friendly formulations with reduced environmental impact. These systems include low-temperature curing epoxies that require less energy during application, formulations free from toxic compounds such as bisphenol A, and systems with reduced volatile organic compound (VOC) emissions. The crosslinking chemistry in these eco-friendly systems is designed to maintain performance while addressing environmental and health concerns, often utilizing bio-based raw materials or alternative crosslinking mechanisms.

- Kinetics and mechanisms of epoxy crosslinking reactions: The study of reaction kinetics and mechanisms in epoxy powder coating systems provides insights for optimizing curing processes and final coating properties. Research has elucidated the step-growth polymerization mechanisms involved in epoxy crosslinking, including the effects of temperature, catalyst concentration, and competing reactions on cure rates. Advanced analytical techniques such as differential scanning calorimetry (DSC) and Fourier-transform infrared spectroscopy (FTIR) are employed to monitor reaction progress and determine activation energies. Understanding these fundamental aspects enables the development of more efficient curing cycles and improved coating performance.

02 Epoxy-amine crosslinking mechanisms

Amine hardeners are commonly used as crosslinking agents in epoxy powder coating systems. The reaction involves the opening of the epoxy ring by the amine groups, forming a hydroxyl group and creating a covalent bond between the epoxy resin and the hardener. Primary amines can react with two epoxy groups, while secondary amines react with one, leading to a highly crosslinked structure. This mechanism provides excellent chemical resistance, adhesion properties, and thermal stability to the cured coating.Expand Specific Solutions03 Accelerators and catalysts for epoxy crosslinking

Various catalysts and accelerators are employed to enhance the rate and efficiency of crosslinking reactions in epoxy powder coating systems. These include tertiary amines, imidazoles, and metal complexes that facilitate the opening of the epoxy ring and subsequent crosslinking reactions. Catalysts can significantly reduce curing temperatures and times while improving the degree of crosslinking. The selection of appropriate catalysts depends on the specific epoxy system and desired curing conditions, affecting the final coating properties.Expand Specific Solutions04 Novel crosslinkers for improved coating performance

Research has led to the development of novel crosslinking agents for epoxy powder coatings with enhanced performance characteristics. These include modified anhydrides, blocked isocyanates, and specialized carboxylic acid functional compounds. These innovative crosslinkers can provide benefits such as lower curing temperatures, improved weatherability, enhanced mechanical properties, and reduced environmental impact. The chemical structure of these crosslinkers is designed to optimize reactivity with epoxy groups while maintaining storage stability of the powder coating formulation.Expand Specific Solutions05 Environmental and regulatory considerations in crosslinking chemistry

Environmental regulations have driven the development of more sustainable crosslinking chemistries for epoxy powder coatings. This includes the reduction or elimination of volatile organic compounds (VOCs), hazardous air pollutants, and toxic heavy metals from formulations. Alternative crosslinking mechanisms that operate at lower temperatures to reduce energy consumption are also being explored. These environmentally friendly approaches focus on maintaining or improving coating performance while meeting increasingly stringent regulatory requirements worldwide.Expand Specific Solutions

Key Industry Players in Epoxy Powder Coatings

The epoxy powder coating crosslinking reactions market is currently in a growth phase, with an estimated global market size of $4-5 billion and projected annual growth of 5-7%. Major players include BASF, PPG Industries, and Covestro, who lead technological innovation through extensive R&D investments. The competitive landscape features both established chemical conglomerates (Henkel, Bayer) and specialized coating manufacturers (Allnex, SWIMC). Technical maturity varies across applications, with automotive and industrial sectors showing high maturity while emerging applications in electronics and aerospace remain in development. Recent advancements by BASF and PPG in low-temperature curing systems and Covestro's bio-based hardeners represent significant technological breakthroughs driving market evolution.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed innovative epoxy powder coating systems featuring proprietary crosslinking technology that enables rapid curing at reduced temperatures. Their approach utilizes specially engineered hardeners with multiple reactive sites that form three-dimensional networks with epoxy resins. PPG's formulations incorporate phase-separated catalyst systems that remain dormant during storage but activate precisely at predetermined temperatures, enabling controlled reaction initiation and progression. Their technology employs modified polyester co-reactants that participate in the crosslinking process, creating hybrid networks with enhanced flexibility and impact resistance while maintaining excellent chemical resistance. PPG has also developed specialized surface additives that migrate during the curing process to optimize surface properties without disrupting the underlying crosslinking reactions.

Strengths: Rapid cure response at lower temperatures reducing energy consumption; excellent balance of flexibility and chemical resistance; superior edge coverage on complex geometries. Weaknesses: More sensitive to application thickness variations; higher raw material costs; some formulations may show color instability under extreme UV exposure conditions.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered advanced epoxy powder coating systems utilizing innovative crosslinking chemistry based on blocked polyisocyanates and specialized epoxy resins. Their technology employs thermally-activated blocking agents that release reactive isocyanate groups at specific temperature thresholds (170-190°C), enabling precise control over reaction initiation. Covestro's systems incorporate proprietary catalysts that selectively accelerate the reaction between hydroxyl groups in the epoxy resin and the deblocked isocyanates, creating urethane linkages alongside traditional epoxy crosslinks. This dual-cure approach results in networks with enhanced flexibility and impact resistance. Their formulations also feature specialized flow additives that maintain optimal surface tension during the curing process, ensuring excellent leveling and appearance without compromising crosslinking efficiency.

Strengths: Exceptional balance of hardness and flexibility through hybrid crosslinking networks; excellent weatherability and UV resistance; superior adhesion to difficult substrates. Weaknesses: Narrower processing window compared to conventional systems; potential for isocyanate emissions during curing requiring appropriate ventilation; higher formulation complexity increasing production costs.

Critical Patents and Research in Crosslinking Chemistry

Process for producing cathodically precipitatable dispersions of binders with crosslinking agents based on polyisocyanates blocked by amino groups.

PatentWO1989004352A1

Innovation

- A process for producing aqueous binder/crosslinker dispersions using polyepoxides, compounds with hydroxyl groups, and secondary amines, where epoxide-containing intermediates are formed at higher temperatures, then reacted with amines and crosslinking agents, allowing for crosslinking at lower temperatures of 95°C to 120°C, resulting in reproducible surfaces with good mechanical properties.

Process for producing dispersions of cathodically precipitated binders with crosslinking agents based on polyisocyanates blocked by hydroxyl groups

PatentInactiveEP0389527A1

Innovation

- A process involving the preparation of aqueous binder/crosslinker dispersions using polyepoxides, hydroxyl-blocked polyisocyanates, and specific catalysts at elevated temperatures, followed by cooling and refluxing with solvents, allows for the formation of crosslinked binder systems that react at reduced temperatures, ensuring reproducible and mechanically robust surfaces.

Environmental Impact and Sustainability Considerations

The environmental impact of epoxy powder coating systems has gained significant attention as industries increasingly prioritize sustainable manufacturing processes. Traditional liquid coating systems typically contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air pollution and pose health risks. In contrast, powder coating systems offer substantial environmental advantages due to their solvent-free formulation, eliminating VOC emissions during application and curing processes.

The crosslinking reactions in epoxy powder coating systems present unique sustainability benefits. These systems typically achieve near 100% material utilization rates, as overspray can be collected and reused, significantly reducing waste compared to liquid systems where overspray becomes hazardous waste. This high transfer efficiency translates to reduced raw material consumption and minimized disposal requirements, creating both environmental and economic benefits.

Energy consumption during the curing process represents a significant environmental consideration. The crosslinking reactions in epoxy powder coatings typically require elevated temperatures (160-200°C), contributing to the carbon footprint of the coating process. Recent innovations focus on developing low-temperature cure systems that maintain performance while reducing energy requirements. Catalysts that enable efficient crosslinking at lower temperatures show promising results in decreasing the overall energy intensity of powder coating operations.

Life cycle assessment (LCA) studies comparing epoxy powder coatings with traditional solvent-based systems demonstrate significant reductions in environmental impact categories including global warming potential, acidification, and photochemical ozone creation. The durability of properly crosslinked epoxy powder coatings further enhances their sustainability profile by extending service life and reducing maintenance frequency and associated environmental impacts.

Regulatory frameworks worldwide increasingly favor powder coating technologies. The European Union's VOC Solvents Emissions Directive and similar regulations in North America have accelerated the adoption of powder coating systems. Understanding crosslinking chemistry enables manufacturers to develop compliant formulations that meet both environmental regulations and performance requirements without compromising coating quality.

Emerging bio-based epoxy resins derived from renewable resources represent the frontier of sustainable powder coating development. These systems utilize epoxidized vegetable oils and other plant-derived materials to partially replace petroleum-based components. Research indicates that optimizing crosslinking reactions for these bio-based systems can maintain performance characteristics while further reducing environmental footprint through decreased reliance on fossil resources.

The crosslinking reactions in epoxy powder coating systems present unique sustainability benefits. These systems typically achieve near 100% material utilization rates, as overspray can be collected and reused, significantly reducing waste compared to liquid systems where overspray becomes hazardous waste. This high transfer efficiency translates to reduced raw material consumption and minimized disposal requirements, creating both environmental and economic benefits.

Energy consumption during the curing process represents a significant environmental consideration. The crosslinking reactions in epoxy powder coatings typically require elevated temperatures (160-200°C), contributing to the carbon footprint of the coating process. Recent innovations focus on developing low-temperature cure systems that maintain performance while reducing energy requirements. Catalysts that enable efficient crosslinking at lower temperatures show promising results in decreasing the overall energy intensity of powder coating operations.

Life cycle assessment (LCA) studies comparing epoxy powder coatings with traditional solvent-based systems demonstrate significant reductions in environmental impact categories including global warming potential, acidification, and photochemical ozone creation. The durability of properly crosslinked epoxy powder coatings further enhances their sustainability profile by extending service life and reducing maintenance frequency and associated environmental impacts.

Regulatory frameworks worldwide increasingly favor powder coating technologies. The European Union's VOC Solvents Emissions Directive and similar regulations in North America have accelerated the adoption of powder coating systems. Understanding crosslinking chemistry enables manufacturers to develop compliant formulations that meet both environmental regulations and performance requirements without compromising coating quality.

Emerging bio-based epoxy resins derived from renewable resources represent the frontier of sustainable powder coating development. These systems utilize epoxidized vegetable oils and other plant-derived materials to partially replace petroleum-based components. Research indicates that optimizing crosslinking reactions for these bio-based systems can maintain performance characteristics while further reducing environmental footprint through decreased reliance on fossil resources.

Regulatory Framework for Powder Coating Systems

The regulatory landscape for powder coating systems, particularly those involving epoxy crosslinking reactions, has evolved significantly in response to environmental concerns and occupational health considerations. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation represents one of the most comprehensive frameworks governing chemical substances used in powder coatings. Under REACH, manufacturers must register substances produced or imported in quantities exceeding one ton annually, with specific attention to crosslinking agents like triglycidyl isocyanurate (TGIC) which has been classified as mutagenic.

In the United States, the Environmental Protection Agency (EPA) regulates powder coatings primarily through the Toxic Substances Control Act (TSCA) and the Clean Air Act. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses surface coating operations, setting limits on volatile organic compound (VOC) emissions. While powder coatings generally emit fewer VOCs than liquid alternatives, the curing process of epoxy systems can still release compounds requiring regulatory compliance.

Occupational safety regulations administered by OSHA (Occupational Safety and Health Administration) mandate specific handling procedures for powder coating materials. These include requirements for personal protective equipment, ventilation systems, and explosion prevention measures, particularly relevant for fine epoxy powder particles which can form explosive dust clouds under certain conditions.

Global harmonization efforts have led to the implementation of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), standardizing hazard communication for coating materials. This system requires detailed Safety Data Sheets (SDS) documenting the chemical composition, hazards, and safe handling procedures for epoxy powder coating formulations.

Recent regulatory trends show increasing scrutiny of bisphenol A (BPA) and its derivatives commonly used in epoxy resins. Several jurisdictions have implemented restrictions on BPA in consumer products, potentially affecting future formulations of epoxy powder coatings. The industry has responded by developing BPA-free alternatives, though these often present different crosslinking kinetics requiring adjusted curing parameters.

Waste management regulations also impact powder coating operations, with the EU's Waste Framework Directive and similar legislation in other regions governing the disposal of unused powder and filter dust. Recovery and recycling requirements are becoming more stringent, encouraging manufacturers to implement closed-loop systems for powder reclamation.

Compliance certification systems like ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) have become de facto regulatory requirements for many powder coating operations, particularly those supplying to automotive and aerospace industries where stringent quality and environmental standards apply.

In the United States, the Environmental Protection Agency (EPA) regulates powder coatings primarily through the Toxic Substances Control Act (TSCA) and the Clean Air Act. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses surface coating operations, setting limits on volatile organic compound (VOC) emissions. While powder coatings generally emit fewer VOCs than liquid alternatives, the curing process of epoxy systems can still release compounds requiring regulatory compliance.

Occupational safety regulations administered by OSHA (Occupational Safety and Health Administration) mandate specific handling procedures for powder coating materials. These include requirements for personal protective equipment, ventilation systems, and explosion prevention measures, particularly relevant for fine epoxy powder particles which can form explosive dust clouds under certain conditions.

Global harmonization efforts have led to the implementation of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), standardizing hazard communication for coating materials. This system requires detailed Safety Data Sheets (SDS) documenting the chemical composition, hazards, and safe handling procedures for epoxy powder coating formulations.

Recent regulatory trends show increasing scrutiny of bisphenol A (BPA) and its derivatives commonly used in epoxy resins. Several jurisdictions have implemented restrictions on BPA in consumer products, potentially affecting future formulations of epoxy powder coatings. The industry has responded by developing BPA-free alternatives, though these often present different crosslinking kinetics requiring adjusted curing parameters.

Waste management regulations also impact powder coating operations, with the EU's Waste Framework Directive and similar legislation in other regions governing the disposal of unused powder and filter dust. Recovery and recycling requirements are becoming more stringent, encouraging manufacturers to implement closed-loop systems for powder reclamation.

Compliance certification systems like ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) have become de facto regulatory requirements for many powder coating operations, particularly those supplying to automotive and aerospace industries where stringent quality and environmental standards apply.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!