What role does substrate preparation play in epoxy powder coating adhesion

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Substrate Preparation Technology Background and Objectives

Substrate preparation has evolved significantly over the past decades, transitioning from basic cleaning methods to sophisticated multi-stage processes designed to optimize surface characteristics for coating adhesion. The historical development of substrate preparation technologies parallels advancements in materials science and surface chemistry, with each innovation addressing specific challenges in the powder coating industry. Early approaches focused primarily on removing visible contaminants, while modern techniques aim to create optimal surface profiles at the microscopic level.

The technological trajectory in this field has been driven by increasing performance requirements in industries such as automotive, aerospace, and architectural applications, where coating durability and resistance to environmental factors are paramount. Recent developments have focused on environmentally friendly preparation methods that reduce or eliminate hazardous chemicals while maintaining or improving adhesion performance.

The primary objective of substrate preparation technology is to maximize the adhesion between epoxy powder coatings and the underlying substrate material. This involves creating both mechanical and chemical bonding opportunities at the interface. Mechanical adhesion relies on surface roughness and profile characteristics that allow the coating to physically interlock with the substrate, while chemical adhesion depends on surface energy and reactivity that facilitate molecular-level interactions between the coating and substrate.

Secondary objectives include enhancing coating durability, improving corrosion resistance, and ensuring consistent quality across production batches. These goals are increasingly important as manufacturers face stricter performance standards and warranty requirements. Additionally, modern substrate preparation aims to minimize environmental impact and reduce processing costs through more efficient use of resources and energy.

Current technological trends in substrate preparation include the development of nano-structured surface treatments that can dramatically improve adhesion properties, plasma and laser surface modification techniques that offer precise control over surface characteristics, and smart pretreatment systems that can adapt to different substrate materials and conditions automatically.

The integration of real-time monitoring and quality control systems represents another significant trend, allowing manufacturers to detect and correct preparation deficiencies before coating application. This approach reduces waste and rework while ensuring consistent adhesion performance. Artificial intelligence and machine learning algorithms are beginning to play a role in optimizing preparation parameters based on substrate characteristics and desired coating properties.

Looking forward, the field is moving toward more sustainable and efficient preparation technologies that maintain high performance standards while reducing environmental footprint and processing time. These advancements will be crucial for meeting the growing demand for high-performance coated products across multiple industries.

The technological trajectory in this field has been driven by increasing performance requirements in industries such as automotive, aerospace, and architectural applications, where coating durability and resistance to environmental factors are paramount. Recent developments have focused on environmentally friendly preparation methods that reduce or eliminate hazardous chemicals while maintaining or improving adhesion performance.

The primary objective of substrate preparation technology is to maximize the adhesion between epoxy powder coatings and the underlying substrate material. This involves creating both mechanical and chemical bonding opportunities at the interface. Mechanical adhesion relies on surface roughness and profile characteristics that allow the coating to physically interlock with the substrate, while chemical adhesion depends on surface energy and reactivity that facilitate molecular-level interactions between the coating and substrate.

Secondary objectives include enhancing coating durability, improving corrosion resistance, and ensuring consistent quality across production batches. These goals are increasingly important as manufacturers face stricter performance standards and warranty requirements. Additionally, modern substrate preparation aims to minimize environmental impact and reduce processing costs through more efficient use of resources and energy.

Current technological trends in substrate preparation include the development of nano-structured surface treatments that can dramatically improve adhesion properties, plasma and laser surface modification techniques that offer precise control over surface characteristics, and smart pretreatment systems that can adapt to different substrate materials and conditions automatically.

The integration of real-time monitoring and quality control systems represents another significant trend, allowing manufacturers to detect and correct preparation deficiencies before coating application. This approach reduces waste and rework while ensuring consistent adhesion performance. Artificial intelligence and machine learning algorithms are beginning to play a role in optimizing preparation parameters based on substrate characteristics and desired coating properties.

Looking forward, the field is moving toward more sustainable and efficient preparation technologies that maintain high performance standards while reducing environmental footprint and processing time. These advancements will be crucial for meeting the growing demand for high-performance coated products across multiple industries.

Market Analysis of Epoxy Powder Coating Applications

The global epoxy powder coating market has demonstrated robust growth, valued at approximately $12.1 billion in 2022 and projected to reach $16.8 billion by 2028, with a compound annual growth rate of 5.6%. This growth is primarily driven by increasing demand across automotive, appliance, construction, and general industrial sectors, where superior adhesion properties are critical performance factors.

The automotive industry represents the largest application segment, accounting for nearly 28% of the market share. In this sector, proper substrate preparation is essential for meeting stringent quality and durability standards, particularly for underbody components and chassis parts exposed to harsh environmental conditions. The construction industry follows closely at 24%, where architectural applications demand coatings with exceptional weathering resistance and adhesion to various substrates.

Consumer appliances constitute approximately 19% of the market, with manufacturers increasingly adopting powder coatings for white goods due to their superior adhesion properties and environmental benefits. The general industrial segment represents 17% of applications, spanning from shelving to machinery, where adhesion to metal substrates directly impacts product longevity.

Regional analysis reveals Asia-Pacific as the dominant market with 42% share, driven by rapid industrialization in China and India where manufacturing sectors are expanding. However, these regions also face challenges related to inconsistent substrate preparation standards, affecting overall coating performance. North America and Europe together account for 48% of the market, with stricter environmental regulations accelerating the shift from liquid coatings to powder alternatives.

Market trends indicate growing demand for single-coat systems that reduce processing time while maintaining adhesion quality. This has intensified focus on advanced substrate preparation technologies, with the market for preparation chemicals and equipment growing at 6.3% annually. Manufacturers are increasingly investing in automated preparation systems that ensure consistent surface treatment quality.

Consumer preferences are shifting toward more durable and environmentally sustainable coating solutions, with 76% of industrial buyers citing adhesion performance as a critical selection criterion. This has created a premium segment for high-performance powder coatings with enhanced substrate compatibility, growing at twice the rate of standard formulations.

The competitive landscape shows consolidation among major suppliers, with emphasis on developing integrated solutions that address both substrate preparation and coating application as a unified system rather than separate processes.

The automotive industry represents the largest application segment, accounting for nearly 28% of the market share. In this sector, proper substrate preparation is essential for meeting stringent quality and durability standards, particularly for underbody components and chassis parts exposed to harsh environmental conditions. The construction industry follows closely at 24%, where architectural applications demand coatings with exceptional weathering resistance and adhesion to various substrates.

Consumer appliances constitute approximately 19% of the market, with manufacturers increasingly adopting powder coatings for white goods due to their superior adhesion properties and environmental benefits. The general industrial segment represents 17% of applications, spanning from shelving to machinery, where adhesion to metal substrates directly impacts product longevity.

Regional analysis reveals Asia-Pacific as the dominant market with 42% share, driven by rapid industrialization in China and India where manufacturing sectors are expanding. However, these regions also face challenges related to inconsistent substrate preparation standards, affecting overall coating performance. North America and Europe together account for 48% of the market, with stricter environmental regulations accelerating the shift from liquid coatings to powder alternatives.

Market trends indicate growing demand for single-coat systems that reduce processing time while maintaining adhesion quality. This has intensified focus on advanced substrate preparation technologies, with the market for preparation chemicals and equipment growing at 6.3% annually. Manufacturers are increasingly investing in automated preparation systems that ensure consistent surface treatment quality.

Consumer preferences are shifting toward more durable and environmentally sustainable coating solutions, with 76% of industrial buyers citing adhesion performance as a critical selection criterion. This has created a premium segment for high-performance powder coatings with enhanced substrate compatibility, growing at twice the rate of standard formulations.

The competitive landscape shows consolidation among major suppliers, with emphasis on developing integrated solutions that address both substrate preparation and coating application as a unified system rather than separate processes.

Current Challenges in Substrate-Coating Interface

Despite significant advancements in epoxy powder coating technology, the substrate-coating interface remains a critical challenge area that directly impacts coating performance and longevity. One persistent issue is achieving consistent surface cleanliness across different substrate materials. Contaminants such as oils, greases, and processing residues create an invisible barrier between the substrate and coating, leading to adhesion failures that may not manifest until the product is in service. Current cleaning methods often struggle to remove all contaminants uniformly, especially on complex geometries or porous surfaces.

Surface profile optimization presents another significant challenge. While roughening techniques like grit blasting improve mechanical adhesion, controlling the precise profile depth and pattern consistency across large or irregularly shaped components remains difficult. Too aggressive profiling can create stress concentration points, while insufficient roughening fails to provide adequate mechanical keying for the powder coating. The industry lacks standardized, quantifiable metrics for optimal surface profiles across different substrate materials and coating systems.

Chemical pretreatment compatibility issues continue to plague many coating operations. The transition toward more environmentally friendly pretreatments has introduced new variables affecting adhesion performance. Chromate-free conversion coatings, while better for the environment, often demonstrate less consistent adhesion promotion compared to traditional chromate treatments. Additionally, these newer pretreatments frequently exhibit narrower process windows, making them more sensitive to bath chemistry fluctuations and application parameters.

Edge coverage deficiencies represent a persistent technical challenge at the substrate-coating interface. Sharp edges and corners experience thinner coating buildup due to electrostatic field effects, creating vulnerable points for corrosion initiation. Current edge rounding recommendations are often impractical for complex fabricated parts, and alternative solutions like edge-specific primers add cost and complexity to the coating process.

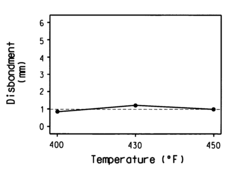

Temperature-related interface stresses continue to challenge coating durability. The significant difference in thermal expansion coefficients between metal substrates and epoxy powder coatings creates cyclical stress at the interface during temperature fluctuations. This thermal cycling can gradually weaken the adhesive bond, particularly in outdoor applications or thermally dynamic environments. Current coating formulations have not fully resolved this fundamental mismatch in material properties.

Moisture management at the substrate-coating interface remains problematic, particularly for ferrous substrates. Microscopic moisture trapped in surface irregularities can vaporize during the curing process, creating outgassing defects that compromise adhesion. Even properly prepared surfaces can absorb atmospheric moisture between preparation and coating application, especially in humid environments. Current process controls often fail to adequately address this time-sensitive variable.

Surface profile optimization presents another significant challenge. While roughening techniques like grit blasting improve mechanical adhesion, controlling the precise profile depth and pattern consistency across large or irregularly shaped components remains difficult. Too aggressive profiling can create stress concentration points, while insufficient roughening fails to provide adequate mechanical keying for the powder coating. The industry lacks standardized, quantifiable metrics for optimal surface profiles across different substrate materials and coating systems.

Chemical pretreatment compatibility issues continue to plague many coating operations. The transition toward more environmentally friendly pretreatments has introduced new variables affecting adhesion performance. Chromate-free conversion coatings, while better for the environment, often demonstrate less consistent adhesion promotion compared to traditional chromate treatments. Additionally, these newer pretreatments frequently exhibit narrower process windows, making them more sensitive to bath chemistry fluctuations and application parameters.

Edge coverage deficiencies represent a persistent technical challenge at the substrate-coating interface. Sharp edges and corners experience thinner coating buildup due to electrostatic field effects, creating vulnerable points for corrosion initiation. Current edge rounding recommendations are often impractical for complex fabricated parts, and alternative solutions like edge-specific primers add cost and complexity to the coating process.

Temperature-related interface stresses continue to challenge coating durability. The significant difference in thermal expansion coefficients between metal substrates and epoxy powder coatings creates cyclical stress at the interface during temperature fluctuations. This thermal cycling can gradually weaken the adhesive bond, particularly in outdoor applications or thermally dynamic environments. Current coating formulations have not fully resolved this fundamental mismatch in material properties.

Moisture management at the substrate-coating interface remains problematic, particularly for ferrous substrates. Microscopic moisture trapped in surface irregularities can vaporize during the curing process, creating outgassing defects that compromise adhesion. Even properly prepared surfaces can absorb atmospheric moisture between preparation and coating application, especially in humid environments. Current process controls often fail to adequately address this time-sensitive variable.

Established Substrate Preparation Methodologies

01 Surface treatment methods for improved adhesion

Various surface treatment methods can be employed to enhance the adhesion of epoxy powder coatings to substrates. These methods include chemical treatments, plasma treatment, corona discharge, and mechanical abrasion. Surface preparation removes contaminants, creates surface roughness, and activates the substrate surface, providing better mechanical interlocking and chemical bonding with the epoxy powder coating.- Surface treatment methods for improved adhesion: Various surface treatment methods can be employed to enhance the adhesion of epoxy powder coatings to substrates. These methods include chemical pretreatments, plasma treatment, corona discharge, and mechanical abrasion. Surface preparation removes contaminants, creates surface roughness, and activates the substrate surface, providing better mechanical interlocking and chemical bonding with the epoxy coating, resulting in improved adhesion strength and durability.

- Adhesion promoters and coupling agents: Specific additives such as silane coupling agents, titanates, and other adhesion promoters can be incorporated into epoxy powder coating formulations to enhance bonding to various substrates. These compounds create chemical bridges between the epoxy resin and the substrate surface, particularly for challenging surfaces like metals, plastics, and composites. The adhesion promoters typically contain functional groups that can react with both the substrate and the epoxy matrix, forming strong chemical bonds across the interface.

- Modified epoxy resin formulations: Specially modified epoxy resins can be formulated to enhance adhesion properties in powder coatings. These modifications include incorporating flexible segments, functional groups, or hybrid systems combining epoxy with other polymers like polyesters or acrylics. The modified resins offer improved wetting characteristics, better compatibility with difficult substrates, and enhanced mechanical properties, resulting in superior adhesion performance even under challenging environmental conditions.

- Curing agent selection for adhesion optimization: The choice of curing agent significantly impacts the adhesion properties of epoxy powder coatings. Different hardeners such as amines, anhydrides, polyamides, and phenolics create varied crosslinking networks with distinct adhesion characteristics. Some curing agents promote better substrate wetting during the melting phase, while others create stronger chemical bonds with specific substrate materials. Optimizing the curing agent system can enhance both initial adhesion and long-term durability of the coating.

- Filler and reinforcement technologies: Incorporating specific fillers and reinforcement materials into epoxy powder coatings can significantly improve adhesion properties. Nano-fillers, functionalized particles, and certain mineral additives can enhance the mechanical interlocking at the coating-substrate interface. These materials can also modify the thermal expansion properties of the coating to better match the substrate, reducing internal stresses that might compromise adhesion. Additionally, some fillers can improve the flow characteristics during curing, enabling better surface wetting and contact.

02 Adhesion promoters and coupling agents

Specific additives such as silane coupling agents, titanates, and other adhesion promoters can be incorporated into epoxy powder coating formulations to enhance bonding to various substrates. These agents create chemical bridges between the substrate and the coating, improving interfacial adhesion. The selection of appropriate adhesion promoters depends on the substrate material and the specific epoxy resin system used.Expand Specific Solutions03 Modified epoxy resin formulations

Epoxy resin systems can be modified with various polymers and additives to enhance adhesion properties. Hybrid systems combining epoxy with polyester, acrylic, or polyurethane components can provide improved adhesion to difficult substrates. Additionally, the incorporation of elastomeric components or functional monomers can enhance flexibility and adhesion, particularly on substrates that undergo thermal expansion or contraction.Expand Specific Solutions04 Curing agent selection for adhesion optimization

The choice of curing agent significantly impacts the adhesion properties of epoxy powder coatings. Different hardeners such as polyamines, polyamides, anhydrides, and phenolic compounds provide varying degrees of adhesion to different substrates. Some curing agents can react with substrate surfaces to form chemical bonds, while others influence the coating's flexibility and stress distribution at the interface, thereby affecting adhesion performance.Expand Specific Solutions05 Testing and evaluation methods for adhesion

Various standardized and specialized methods are used to evaluate the adhesion of epoxy powder coatings to substrates. These include cross-cut tests, pull-off adhesion tests, impact tests, and thermal cycling tests. Advanced analytical techniques such as scanning electron microscopy and spectroscopic methods can be employed to understand adhesion mechanisms and failure modes, helping to optimize coating formulations and application processes.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Substrate preparation plays a critical role in epoxy powder coating adhesion, with the market currently in a growth phase driven by increasing demand for durable, corrosion-resistant finishes across multiple industries. The global powder coating market is expanding at approximately 6-7% annually, reaching over $15 billion. Leading companies like DuPont, Axalta, Jotun, and Henkel are advancing surface preparation technologies through innovations in chemical pretreatments, mechanical abrasion techniques, and environmentally friendly solutions. Research from companies such as BASF Coatings and 3M Innovative Properties focuses on developing specialized primers and surface modifiers that enhance adhesion on challenging substrates. The competitive landscape shows established players investing in R&D while regional manufacturers like Nantong Meiyicai and Zhang Jia Gang Jiang Nan Powder Coating emerge with specialized solutions for local markets.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced substrate preparation technologies for epoxy powder coating applications that focus on multi-stage pretreatment processes. Their approach includes chemical cleaning to remove oils and contaminants, followed by conversion coating applications (typically zinc or iron phosphate) that create a microrough surface profile. DuPont's proprietary surface modification techniques enhance mechanical interlocking between the substrate and coating by creating controlled surface topography at the microscale level. Their research has shown that optimized substrate preparation can increase adhesion strength by up to 40% compared to conventional methods. DuPont also employs plasma treatment technologies that modify surface energy characteristics of difficult-to-coat substrates, enabling better wetting and chemical bonding with epoxy powder coatings.

Strengths: Comprehensive multi-stage approach addresses both mechanical and chemical adhesion factors; proprietary plasma treatment technologies enable coating of difficult substrates. Weaknesses: Complex pretreatment processes may increase production costs and time; some techniques require specialized equipment that limits implementation in smaller manufacturing operations.

Axalta Coating Systems IP Co. LLC

Technical Solution: Axalta has pioneered substrate preparation technologies specifically engineered for epoxy powder coating applications across automotive, industrial, and architectural markets. Their approach centers on a three-phase substrate preparation system: First, an alkaline cleaning process removes organic contaminants and provides initial etching. Second, a proprietary conversion coating creates a nanoporous interface layer that significantly increases surface area for mechanical bonding. Third, a final rinse containing adhesion promoters introduces chemical functionalities that form covalent bonds with epoxy resins during curing. Axalta's research demonstrates that this integrated approach can improve coating adhesion by up to 35% while reducing pretreatment chemical consumption by approximately 20%. Their system also incorporates environmentally-friendly pretreatment chemicals that eliminate heavy metals like chromium while maintaining superior adhesion performance.

Strengths: Comprehensive system addressing both mechanical and chemical adhesion mechanisms; environmentally-friendly formulations reduce regulatory concerns; proven performance across diverse substrate materials. Weaknesses: Requires precise process control parameters that may be challenging to maintain in variable manufacturing environments; initial implementation costs can be significant for smaller operations.

Critical Patents in Surface Treatment Technologies

Primer-less coated substrates

PatentWO2017059404A1

Innovation

- A substrate is coated with an epoxy coating composition comprising a non-aromatic epoxy resin, an amine curing agent, and a corrosion inhibitor, applied directly without a prior organic primer, utilizing a pretreatment or conversion coating to enhance adhesion and corrosion resistance.

Curable alkanolamine containing epoxy powder coating composition

PatentInactiveUS20050075430A1

Innovation

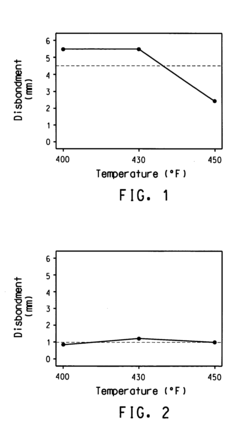

- A curable epoxy powder coating composition comprising an intimate mixture of epoxy resin, low levels of alkanolamine, and an epoxy curing agent, with optional addition of zinc borate, where these components are not pre-reacted, providing improved adhesion and resistance to cathodic disbondment at lower application temperatures.

Environmental Impact of Preparation Processes

The environmental impact of substrate preparation processes in epoxy powder coating applications has become increasingly significant as industries face stricter regulations and growing sustainability concerns. Traditional preparation methods often involve chemical treatments that generate hazardous waste streams. Solvent-based cleaning processes emit volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to workers. These emissions are subject to increasingly stringent regulations worldwide, with many regions implementing caps on allowable VOC emissions from industrial facilities.

Mechanical preparation techniques, while reducing chemical waste, often generate particulate matter that requires proper collection and disposal systems. Abrasive blasting, for instance, creates substantial amounts of spent media contaminated with substrate materials, potentially including heavy metals or other hazardous substances. The energy consumption associated with these processes also contributes significantly to their environmental footprint, particularly for large-scale industrial applications.

Water-based preparation systems present their own environmental challenges. These processes typically generate contaminated wastewater containing oils, greases, and removed surface contaminants that require treatment before discharge. Advanced filtration and treatment systems can mitigate these impacts but add complexity and cost to the overall process. The water consumption itself can be substantial, raising concerns in regions facing water scarcity issues.

Recent innovations have focused on developing more environmentally friendly preparation alternatives. Plasma treatment and CO2 blasting represent emerging technologies that significantly reduce waste generation and resource consumption. Biological cleaning agents derived from renewable resources are also gaining traction as replacements for traditional chemical cleaners, offering biodegradability and reduced toxicity profiles.

Life cycle assessment (LCA) studies comparing different preparation methods have revealed that environmental impacts extend beyond the immediate process emissions. The production and transportation of preparation chemicals, energy requirements, waste management, and potential environmental remediation all contribute to the overall environmental footprint. These assessments increasingly influence industrial decision-making as companies seek to reduce their environmental impact while maintaining coating performance.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in other regions are progressively limiting the use of hazardous substances in surface preparation. This regulatory landscape is driving innovation toward greener technologies and processes that maintain effective substrate preparation while minimizing environmental harm.

Mechanical preparation techniques, while reducing chemical waste, often generate particulate matter that requires proper collection and disposal systems. Abrasive blasting, for instance, creates substantial amounts of spent media contaminated with substrate materials, potentially including heavy metals or other hazardous substances. The energy consumption associated with these processes also contributes significantly to their environmental footprint, particularly for large-scale industrial applications.

Water-based preparation systems present their own environmental challenges. These processes typically generate contaminated wastewater containing oils, greases, and removed surface contaminants that require treatment before discharge. Advanced filtration and treatment systems can mitigate these impacts but add complexity and cost to the overall process. The water consumption itself can be substantial, raising concerns in regions facing water scarcity issues.

Recent innovations have focused on developing more environmentally friendly preparation alternatives. Plasma treatment and CO2 blasting represent emerging technologies that significantly reduce waste generation and resource consumption. Biological cleaning agents derived from renewable resources are also gaining traction as replacements for traditional chemical cleaners, offering biodegradability and reduced toxicity profiles.

Life cycle assessment (LCA) studies comparing different preparation methods have revealed that environmental impacts extend beyond the immediate process emissions. The production and transportation of preparation chemicals, energy requirements, waste management, and potential environmental remediation all contribute to the overall environmental footprint. These assessments increasingly influence industrial decision-making as companies seek to reduce their environmental impact while maintaining coating performance.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in other regions are progressively limiting the use of hazardous substances in surface preparation. This regulatory landscape is driving innovation toward greener technologies and processes that maintain effective substrate preparation while minimizing environmental harm.

Quality Control Standards for Substrate Preparation

Quality control standards for substrate preparation in epoxy powder coating processes are essential to ensure optimal adhesion and long-term performance. These standards typically align with international frameworks such as ISO 8501, ASTM D2200, and SSPC-SP standards, which provide comprehensive guidelines for surface cleanliness, profile measurements, and preparation methodologies.

The primary quality control parameters monitored during substrate preparation include surface cleanliness levels, which must achieve a minimum of SA 2.5 (near-white metal) according to ISO 8501-1 for most industrial applications. Surface profile measurements, typically ranging between 1.5-3.0 mils (38-75 μm), must be regularly verified using comparators or digital profile gauges to ensure proper mechanical anchoring for the powder coating.

Environmental condition monitoring represents another critical aspect of quality control standards. Temperature must be maintained at least 3°C above the dew point to prevent flash rusting, while relative humidity should not exceed 85% during preparation processes. Documentation of these parameters at regular intervals ensures compliance with quality standards and provides traceability for warranty purposes.

Testing protocols form the backbone of quality assurance in substrate preparation. Pull-off adhesion testing (ASTM D4541) should yield minimum values of 5-7 MPa for properly prepared substrates. Cross-cut adhesion tests (ASTM D3359) must achieve ratings of 4B or 5B to indicate acceptable preparation quality. Salt spray resistance testing (ASTM B117) should demonstrate resistance for a minimum of 1,000 hours without significant coating deterioration when substrate preparation meets quality standards.

Implementation of statistical process control (SPC) methodologies enables continuous monitoring of preparation quality. Key performance indicators such as surface profile consistency, cleanliness levels, and environmental compliance should be tracked using control charts with clearly defined upper and lower control limits. This approach allows for early detection of process drift before it impacts coating adhesion.

Regular calibration of measurement instruments is mandated by quality control standards, with verification of profile gauges, moisture meters, and surface contamination detection equipment required at intervals not exceeding six months. This ensures measurement accuracy and consistency across production batches, supporting reliable quality assessment throughout the manufacturing process.

The primary quality control parameters monitored during substrate preparation include surface cleanliness levels, which must achieve a minimum of SA 2.5 (near-white metal) according to ISO 8501-1 for most industrial applications. Surface profile measurements, typically ranging between 1.5-3.0 mils (38-75 μm), must be regularly verified using comparators or digital profile gauges to ensure proper mechanical anchoring for the powder coating.

Environmental condition monitoring represents another critical aspect of quality control standards. Temperature must be maintained at least 3°C above the dew point to prevent flash rusting, while relative humidity should not exceed 85% during preparation processes. Documentation of these parameters at regular intervals ensures compliance with quality standards and provides traceability for warranty purposes.

Testing protocols form the backbone of quality assurance in substrate preparation. Pull-off adhesion testing (ASTM D4541) should yield minimum values of 5-7 MPa for properly prepared substrates. Cross-cut adhesion tests (ASTM D3359) must achieve ratings of 4B or 5B to indicate acceptable preparation quality. Salt spray resistance testing (ASTM B117) should demonstrate resistance for a minimum of 1,000 hours without significant coating deterioration when substrate preparation meets quality standards.

Implementation of statistical process control (SPC) methodologies enables continuous monitoring of preparation quality. Key performance indicators such as surface profile consistency, cleanliness levels, and environmental compliance should be tracked using control charts with clearly defined upper and lower control limits. This approach allows for early detection of process drift before it impacts coating adhesion.

Regular calibration of measurement instruments is mandated by quality control standards, with verification of profile gauges, moisture meters, and surface contamination detection equipment required at intervals not exceeding six months. This ensures measurement accuracy and consistency across production batches, supporting reliable quality assessment throughout the manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!