Research on electrostatic deposition efficiency of epoxy powder coatings

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Epoxy Powder Coating Technology Evolution & Objectives

Epoxy powder coating technology has evolved significantly since its inception in the 1950s, transforming from a niche application to a mainstream industrial finishing solution. The journey began with rudimentary thermosetting powders that offered limited performance characteristics and application versatility. Early systems suffered from poor flow properties, limited color options, and inconsistent film formation, restricting their adoption to specialized industrial applications.

The 1970s marked a pivotal turning point with the development of improved resin systems and curing agents that enhanced coating durability and aesthetic qualities. This period saw the introduction of TGIC (triglycidyl isocyanurate) hardeners, which significantly improved weatherability and mechanical properties of epoxy powder coatings, expanding their application scope.

By the 1990s, technological advancements in grinding and particle size control enabled the production of finer powder particles, leading to smoother finishes and better transfer efficiency. Concurrently, electrostatic application techniques evolved from basic corona charging systems to more sophisticated tribo-charging methods, addressing issues related to Faraday cage effect and improving coating uniformity on complex geometries.

The early 2000s witnessed the integration of digital control systems and automation in powder application equipment, allowing for precise parameter control and reproducibility. This era also saw increased focus on environmental considerations, with the development of TGIC-free formulations and low-temperature curing systems that reduced energy consumption and carbon footprint.

Recent developments have centered on enhancing electrostatic deposition efficiency through advanced charging technologies, optimized particle size distributions, and modified powder rheology. Innovations in powder chemistry have led to formulations with improved flow characteristics and self-leveling properties, addressing historical limitations in surface quality and film thickness control.

The primary objectives of current research in epoxy powder coating technology focus on maximizing transfer efficiency while minimizing waste and environmental impact. Specific goals include developing powders with enhanced electrostatic properties that achieve uniform coverage at lower film thicknesses, formulating systems compatible with heat-sensitive substrates through reduced cure temperatures, and creating intelligent application systems that dynamically adjust parameters based on real-time feedback.

Additional research aims include improving the durability and performance characteristics of epoxy powder coatings in extreme environments, developing hybrid systems that combine the benefits of different resin technologies, and creating formulations with enhanced functional properties such as antimicrobial activity, self-healing capabilities, and smart-responsive features.

The 1970s marked a pivotal turning point with the development of improved resin systems and curing agents that enhanced coating durability and aesthetic qualities. This period saw the introduction of TGIC (triglycidyl isocyanurate) hardeners, which significantly improved weatherability and mechanical properties of epoxy powder coatings, expanding their application scope.

By the 1990s, technological advancements in grinding and particle size control enabled the production of finer powder particles, leading to smoother finishes and better transfer efficiency. Concurrently, electrostatic application techniques evolved from basic corona charging systems to more sophisticated tribo-charging methods, addressing issues related to Faraday cage effect and improving coating uniformity on complex geometries.

The early 2000s witnessed the integration of digital control systems and automation in powder application equipment, allowing for precise parameter control and reproducibility. This era also saw increased focus on environmental considerations, with the development of TGIC-free formulations and low-temperature curing systems that reduced energy consumption and carbon footprint.

Recent developments have centered on enhancing electrostatic deposition efficiency through advanced charging technologies, optimized particle size distributions, and modified powder rheology. Innovations in powder chemistry have led to formulations with improved flow characteristics and self-leveling properties, addressing historical limitations in surface quality and film thickness control.

The primary objectives of current research in epoxy powder coating technology focus on maximizing transfer efficiency while minimizing waste and environmental impact. Specific goals include developing powders with enhanced electrostatic properties that achieve uniform coverage at lower film thicknesses, formulating systems compatible with heat-sensitive substrates through reduced cure temperatures, and creating intelligent application systems that dynamically adjust parameters based on real-time feedback.

Additional research aims include improving the durability and performance characteristics of epoxy powder coatings in extreme environments, developing hybrid systems that combine the benefits of different resin technologies, and creating formulations with enhanced functional properties such as antimicrobial activity, self-healing capabilities, and smart-responsive features.

Market Analysis of Electrostatic Powder Coating Applications

The global market for electrostatic powder coating applications has experienced significant growth over the past decade, driven by increasing demand across multiple industries. The automotive sector remains the largest consumer of epoxy powder coatings, accounting for approximately 30% of the total market share. This dominance stems from the automotive industry's stringent requirements for corrosion resistance, durability, and aesthetic appeal in vehicle components.

Construction and architectural applications represent the second-largest market segment, with substantial growth observed in regions undergoing rapid urbanization and infrastructure development. The building materials sector has increasingly adopted powder coating technologies for metal facades, window frames, and structural elements due to their superior weathering properties and environmental benefits.

Consumer goods manufacturing has emerged as a rapidly expanding application area, particularly for household appliances, furniture, and electronic enclosures. This growth is attributed to manufacturers seeking cost-effective finishing solutions that meet increasingly stringent environmental regulations while providing excellent surface properties.

Regional analysis reveals that Asia-Pacific currently dominates the global powder coating market, with China and India serving as manufacturing hubs and showing the highest growth rates. North America and Europe maintain significant market shares, primarily driven by technological innovations and stringent environmental regulations that favor powder coatings over traditional liquid systems.

Market dynamics are increasingly influenced by sustainability factors, with powder coatings gaining preference due to their near-zero VOC emissions, reduced waste generation, and energy efficiency advantages. The recyclability of overspray material presents a compelling economic and environmental case for manufacturers seeking to reduce their carbon footprint and operational costs.

Technological advancements in application equipment have significantly expanded the potential market for powder coatings. Improvements in electrostatic spray guns, powder delivery systems, and curing technologies have enabled more efficient deposition on complex geometries and temperature-sensitive substrates, opening new application possibilities.

Economic analysis indicates that the total cost of ownership for powder coating systems continues to decrease as application efficiencies improve. Enhanced transfer efficiency rates, now reaching 65-70% in optimized systems, represent a critical factor driving market adoption across price-sensitive industries.

Market forecasts project continued growth at a compound annual rate of 6-7% through 2028, with particularly strong expansion in emerging economies. This growth trajectory is supported by increasing industrial production, rising environmental awareness, and continuous improvements in powder formulations that enhance performance characteristics.

Construction and architectural applications represent the second-largest market segment, with substantial growth observed in regions undergoing rapid urbanization and infrastructure development. The building materials sector has increasingly adopted powder coating technologies for metal facades, window frames, and structural elements due to their superior weathering properties and environmental benefits.

Consumer goods manufacturing has emerged as a rapidly expanding application area, particularly for household appliances, furniture, and electronic enclosures. This growth is attributed to manufacturers seeking cost-effective finishing solutions that meet increasingly stringent environmental regulations while providing excellent surface properties.

Regional analysis reveals that Asia-Pacific currently dominates the global powder coating market, with China and India serving as manufacturing hubs and showing the highest growth rates. North America and Europe maintain significant market shares, primarily driven by technological innovations and stringent environmental regulations that favor powder coatings over traditional liquid systems.

Market dynamics are increasingly influenced by sustainability factors, with powder coatings gaining preference due to their near-zero VOC emissions, reduced waste generation, and energy efficiency advantages. The recyclability of overspray material presents a compelling economic and environmental case for manufacturers seeking to reduce their carbon footprint and operational costs.

Technological advancements in application equipment have significantly expanded the potential market for powder coatings. Improvements in electrostatic spray guns, powder delivery systems, and curing technologies have enabled more efficient deposition on complex geometries and temperature-sensitive substrates, opening new application possibilities.

Economic analysis indicates that the total cost of ownership for powder coating systems continues to decrease as application efficiencies improve. Enhanced transfer efficiency rates, now reaching 65-70% in optimized systems, represent a critical factor driving market adoption across price-sensitive industries.

Market forecasts project continued growth at a compound annual rate of 6-7% through 2028, with particularly strong expansion in emerging economies. This growth trajectory is supported by increasing industrial production, rising environmental awareness, and continuous improvements in powder formulations that enhance performance characteristics.

Current Challenges in Electrostatic Deposition Efficiency

Despite significant advancements in electrostatic powder coating technology, the industry continues to face several critical challenges in achieving optimal deposition efficiency for epoxy powder coatings. The primary obstacle remains the inconsistent transfer efficiency, which typically ranges between 60-70% in industrial applications, resulting in substantial material waste and increased production costs. This inefficiency is particularly pronounced when coating complex geometries with deep recesses or sharp edges due to the Faraday cage effect, where electric field lines concentrate at protruding areas while leaving recessed areas with insufficient coating.

Environmental factors present another significant challenge, as fluctuations in ambient humidity and temperature can dramatically alter powder charging characteristics and flow properties. High humidity environments (above 65% RH) can cause powder particles to absorb moisture, leading to agglomeration and reduced charging capacity, while excessively dry conditions may intensify static buildup and trigger powder clumping or back-ionization phenomena.

The particle size distribution of epoxy powders continues to pose technical difficulties. While finer particles (10-25 μm) offer superior surface finish and film uniformity, they demonstrate poorer fluidization properties and are more susceptible to premature curing during application. Conversely, larger particles (50-100 μm) exhibit better transfer efficiency but compromise the final coating quality and appearance.

Equipment limitations further compound these challenges. Current gun designs struggle to maintain consistent charge-to-mass ratios across varying application conditions, and many systems lack real-time feedback mechanisms to adjust parameters during operation. The industry has yet to develop fully adaptive systems capable of responding to changing substrate geometries or environmental conditions without manual intervention.

Material formulation issues also persist, particularly in balancing the competing requirements of charge acceptance, flow characteristics, and final coating performance. Additives that enhance electrostatic properties often negatively impact mechanical or chemical resistance properties of the cured film. Furthermore, the development of low-temperature curing epoxy formulations with adequate electrostatic properties remains elusive, limiting energy efficiency improvements in the overall process.

Measurement and control systems present additional hurdles. Current technologies for real-time monitoring of charge distribution, particle trajectory, and deposition patterns lack the precision needed for truly optimized processes. The industry still relies heavily on empirical testing and operator experience rather than predictive models or AI-assisted parameter optimization.

Environmental factors present another significant challenge, as fluctuations in ambient humidity and temperature can dramatically alter powder charging characteristics and flow properties. High humidity environments (above 65% RH) can cause powder particles to absorb moisture, leading to agglomeration and reduced charging capacity, while excessively dry conditions may intensify static buildup and trigger powder clumping or back-ionization phenomena.

The particle size distribution of epoxy powders continues to pose technical difficulties. While finer particles (10-25 μm) offer superior surface finish and film uniformity, they demonstrate poorer fluidization properties and are more susceptible to premature curing during application. Conversely, larger particles (50-100 μm) exhibit better transfer efficiency but compromise the final coating quality and appearance.

Equipment limitations further compound these challenges. Current gun designs struggle to maintain consistent charge-to-mass ratios across varying application conditions, and many systems lack real-time feedback mechanisms to adjust parameters during operation. The industry has yet to develop fully adaptive systems capable of responding to changing substrate geometries or environmental conditions without manual intervention.

Material formulation issues also persist, particularly in balancing the competing requirements of charge acceptance, flow characteristics, and final coating performance. Additives that enhance electrostatic properties often negatively impact mechanical or chemical resistance properties of the cured film. Furthermore, the development of low-temperature curing epoxy formulations with adequate electrostatic properties remains elusive, limiting energy efficiency improvements in the overall process.

Measurement and control systems present additional hurdles. Current technologies for real-time monitoring of charge distribution, particle trajectory, and deposition patterns lack the precision needed for truly optimized processes. The industry still relies heavily on empirical testing and operator experience rather than predictive models or AI-assisted parameter optimization.

Electrostatic Deposition Methodologies and Parameters

01 Particle size and distribution control for improved deposition efficiency

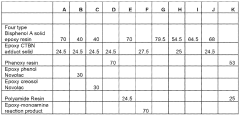

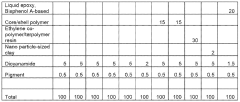

Controlling the particle size and distribution of epoxy powder coatings can significantly improve deposition efficiency. Optimized particle sizes, typically in the range of 10-100 microns, ensure better electrostatic attraction to the substrate and reduce overspray. Narrow particle size distribution helps achieve uniform coating thickness and better transfer efficiency during application, resulting in less waste and more economical use of coating materials.- Formulation of epoxy powder coatings for improved deposition: Specific formulations of epoxy powder coatings can significantly improve deposition efficiency. These formulations typically include carefully selected resins, hardeners, and additives that enhance the electrostatic properties of the powder. By optimizing the particle size distribution and incorporating flow modifiers, these formulations ensure better attraction to the substrate and more uniform coverage, resulting in higher transfer efficiency and reduced waste during application.

- Electrostatic application techniques for epoxy powder coatings: Advanced electrostatic application methods can enhance the deposition efficiency of epoxy powder coatings. These techniques involve optimizing the charging parameters, gun-to-substrate distance, and spray patterns to maximize the transfer of powder particles to the substrate. By controlling the electrostatic field strength and ensuring proper grounding of the substrate, these methods improve the attraction between the charged powder particles and the target surface, resulting in higher deposition rates and more uniform coating thickness.

- Particle size and morphology control for enhanced deposition: The control of particle size and morphology plays a crucial role in the deposition efficiency of epoxy powder coatings. Optimized particle size distribution, typically in the range of 10-100 microns, ensures better electrostatic charging and transfer to the substrate. Spherical particles with smooth surfaces tend to flow better and create more uniform films. By engineering particles with specific shapes and surface characteristics, manufacturers can achieve higher deposition rates and reduce overspray, leading to more efficient coating processes.

- Additives and modifiers for improved transfer efficiency: Various additives and modifiers can be incorporated into epoxy powder coating formulations to enhance deposition efficiency. These include flow agents, charge control additives, and surface modifiers that improve the electrostatic properties and flow characteristics of the powder. By incorporating these specialized additives, manufacturers can achieve better powder attraction to the substrate, reduced back-ionization, and improved edge coverage. These modifications result in higher transfer efficiency, reduced material consumption, and more consistent coating quality.

- Equipment and process optimization for maximum deposition: Optimizing equipment settings and process parameters is essential for maximizing the deposition efficiency of epoxy powder coatings. This includes adjusting spray gun voltage, air pressure, feed rate, and booth conditions such as temperature and humidity. Advanced application equipment with precise control systems can significantly improve transfer efficiency. Additionally, proper maintenance of equipment, including regular cleaning of spray guns and recovery systems, ensures consistent performance and high deposition rates throughout the coating operation.

02 Electrostatic charging enhancement techniques

Various techniques can be employed to enhance the electrostatic charging of epoxy powder particles, thereby improving deposition efficiency. These include incorporating charge control agents, optimizing the triboelectric properties of the powder, and modifying the powder formulation to increase electrical resistivity. Enhanced electrostatic charging ensures better attraction between the powder particles and the substrate, resulting in higher transfer efficiency and reduced material waste during application.Expand Specific Solutions03 Flow additives and surface modifiers

Incorporating flow additives and surface modifiers into epoxy powder coating formulations can significantly improve deposition efficiency. These additives, such as silica, aluminum oxide, or specific polymeric materials, enhance the flowability of the powder and reduce agglomeration during application. Improved flow characteristics lead to more uniform coating distribution, better substrate coverage, and increased transfer efficiency in both corona and tribo-charging application methods.Expand Specific Solutions04 Equipment and application technique optimization

Optimizing application equipment and techniques plays a crucial role in improving the deposition efficiency of epoxy powder coatings. This includes adjusting gun voltage, distance from substrate, spray patterns, and air flow parameters. Advanced application systems with precise control over electrostatic charge and powder flow can significantly enhance transfer efficiency. Proper maintenance of equipment and training of operators also contribute to consistent high-efficiency deposition.Expand Specific Solutions05 Resin and hardener system modifications

Modifications to the epoxy resin and hardener systems can lead to improved deposition efficiency in powder coatings. These modifications include adjusting the molecular weight distribution of the resin, incorporating functional additives that enhance charge retention, and developing hybrid systems that combine the benefits of different resin types. Specially engineered resin systems can provide better electrostatic properties and improved flow characteristics during application, resulting in higher transfer efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrostatic deposition efficiency of epoxy powder coatings market is currently in a growth phase, with increasing adoption across automotive, consumer goods, and industrial applications. The global market size is estimated to exceed $4 billion, driven by demand for environmentally friendly coating solutions. Leading players include established chemical corporations like Henkel AG, PPG Industries, and 3M Innovative Properties, who possess advanced R&D capabilities and extensive patent portfolios. Asian manufacturers such as Zhejiang Lvhuan and Contemporary Amperex Technology are rapidly gaining market share through cost-effective solutions. Technical innovation focuses on improving transfer efficiency, reducing waste, and enhancing coating performance, with research institutions like South China University of Technology and Rutgers University collaborating with industry to advance electrostatic deposition technologies.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed an innovative approach to epoxy powder coating deposition through their BONDERITE® and AQUENCE® technology platforms. Their system employs modified epoxy resins with engineered surface functionality that enhances electrostatic charging capability. The company's technology incorporates nano-additives (typically 0.5-2% by weight) that create more uniform charge distribution across powder particles, resulting in deposition efficiencies exceeding 90% in optimized systems. Henkel's approach includes specialized pretreatment solutions that create controlled surface conductivity profiles on substrates, enhancing the electrostatic attraction between charged particles and the workpiece. Their formulations feature proprietary flow modifiers that allow for lower curing temperatures (reducing from typical 180-200°C to 160-170°C) while maintaining excellent surface finish and adhesion properties. Henkel has also pioneered hybrid charging systems that combine the benefits of corona and triboelectric charging methods to maximize deposition efficiency across varying part geometries.

Strengths: Excellent integration with substrate pretreatment systems creating comprehensive coating solutions; lower curing temperature requirements reducing energy consumption; superior performance on complex geometries with mixed material substrates. Weaknesses: More complex formulation requiring precise quality control; higher sensitivity to environmental humidity variations; requires specialized application equipment for optimal performance.

Nippon Paint Co., Ltd. /Shinagawa-ku/

Technical Solution: Nippon Paint has developed the E-CUBE technology platform specifically addressing electrostatic deposition efficiency challenges in epoxy powder coatings. Their approach utilizes modified epoxy resins with carefully engineered particle morphology and size distribution (typically centered around 40 microns with narrow distribution) to optimize charge acceptance and transfer efficiency. The company's formulations incorporate proprietary surface-active agents that enhance triboelectric charging capability, achieving charge-to-mass ratios up to 2.5 μC/g compared to industry standard 1.5-2.0 μC/g. Nippon's technology includes specialized additives that reduce the influence of ambient humidity on charging performance, maintaining consistent deposition efficiency across relative humidity ranges from 30-70%. Their system employs advanced corona charging equipment with precisely controlled ion generation zones and electric field patterns that maximize particle charging while minimizing free ion effects that can lead to back-ionization and reduced transfer efficiency. Nippon Paint has also developed specialized pretreatment processes that create optimal surface conductivity profiles on various substrate materials.

Strengths: Exceptional humidity resistance maintaining consistent performance across varying environmental conditions; superior edge coverage and penetration into recessed areas; excellent film build uniformity even on complex geometries. Weaknesses: Requires specialized application equipment for optimal performance; higher material costs compared to conventional formulations; more sensitive to variations in application parameters requiring precise process control.

Key Patents in Efficiency Enhancement Technologies

Method and apparatus for adhesive deposition

PatentWO2014022182A2

Innovation

- A method involving electrostatic delivery of precursor particles forming a latent curing polymeric material, which are transformed into a tack-free, dry precursor layer film that can be cross-linked upon activation, allowing for controlled bonding of substrates with precise thickness and adhesion properties, using electromagnetic brush printing and specific particle sizes and compositions.

Environmental Impact and Sustainability Considerations

Electrostatic powder coating technology has emerged as a more environmentally friendly alternative to traditional liquid coating systems. The absence of volatile organic compounds (VOCs) in powder coatings significantly reduces air pollution and associated health risks for workers and surrounding communities. Traditional solvent-based coatings release substantial amounts of VOCs during application and curing, contributing to smog formation and respiratory issues, whereas powder coatings eliminate these emissions entirely.

The energy efficiency of electrostatic powder coating processes further enhances their sustainability profile. Modern powder application systems have been optimized to reduce energy consumption during both application and curing phases. Advanced recovery systems can reclaim up to 98% of overspray powder for reuse, dramatically reducing waste compared to liquid coating systems where overspray typically becomes hazardous waste requiring special disposal procedures.

From a lifecycle perspective, epoxy powder coatings demonstrate superior durability and longevity compared to many conventional coating alternatives. This extended service life translates to reduced maintenance requirements and less frequent reapplication, consequently lowering the overall environmental footprint of coated products throughout their usable life. The enhanced corrosion resistance of properly applied epoxy powder coatings is particularly valuable in extending the lifespan of metal infrastructure and equipment.

Waste management considerations also favor powder coating technologies. Unused or reclaimed powder can be stored for future use without degradation, unlike liquid coatings that have limited shelf life once mixed. Additionally, cured powder coating waste is generally classified as non-hazardous, simplifying disposal processes and reducing associated environmental risks and costs.

Recent innovations in epoxy powder formulations have further improved their environmental credentials. Low-temperature cure systems reduce energy requirements during the curing process by 30-40% compared to conventional systems. Water-based powder coating technologies are also emerging, potentially offering even greater environmental benefits by eliminating the need for organic solvents in the manufacturing process of the powder itself.

Regulatory frameworks worldwide increasingly favor powder coating technologies. The European Union's VOC Solvents Emissions Directive and similar regulations in North America have accelerated the transition from liquid to powder coating systems across multiple industries. Companies adopting efficient electrostatic powder coating processes can often qualify for environmental certifications and sustainability credits, providing additional market advantages beyond the direct operational benefits.

The energy efficiency of electrostatic powder coating processes further enhances their sustainability profile. Modern powder application systems have been optimized to reduce energy consumption during both application and curing phases. Advanced recovery systems can reclaim up to 98% of overspray powder for reuse, dramatically reducing waste compared to liquid coating systems where overspray typically becomes hazardous waste requiring special disposal procedures.

From a lifecycle perspective, epoxy powder coatings demonstrate superior durability and longevity compared to many conventional coating alternatives. This extended service life translates to reduced maintenance requirements and less frequent reapplication, consequently lowering the overall environmental footprint of coated products throughout their usable life. The enhanced corrosion resistance of properly applied epoxy powder coatings is particularly valuable in extending the lifespan of metal infrastructure and equipment.

Waste management considerations also favor powder coating technologies. Unused or reclaimed powder can be stored for future use without degradation, unlike liquid coatings that have limited shelf life once mixed. Additionally, cured powder coating waste is generally classified as non-hazardous, simplifying disposal processes and reducing associated environmental risks and costs.

Recent innovations in epoxy powder formulations have further improved their environmental credentials. Low-temperature cure systems reduce energy requirements during the curing process by 30-40% compared to conventional systems. Water-based powder coating technologies are also emerging, potentially offering even greater environmental benefits by eliminating the need for organic solvents in the manufacturing process of the powder itself.

Regulatory frameworks worldwide increasingly favor powder coating technologies. The European Union's VOC Solvents Emissions Directive and similar regulations in North America have accelerated the transition from liquid to powder coating systems across multiple industries. Companies adopting efficient electrostatic powder coating processes can often qualify for environmental certifications and sustainability credits, providing additional market advantages beyond the direct operational benefits.

Cost-Benefit Analysis of Advanced Deposition Technologies

When evaluating the implementation of electrostatic powder coating technologies, a comprehensive cost-benefit analysis reveals significant economic advantages over traditional liquid coating methods. Initial capital investment for electrostatic powder coating equipment typically ranges from $50,000 to $200,000 depending on system complexity and automation level, representing a substantial upfront cost. However, this investment is offset by operational savings within 2-3 years for most manufacturing operations.

Material efficiency stands as one of the most compelling economic benefits. Electrostatic powder coating systems achieve transfer efficiencies of 95-98% compared to 60-70% for conventional spray methods. This translates to approximately 30% reduction in coating material consumption, generating substantial cost savings for high-volume operations. Additionally, overspray powder can be reclaimed and reused, further enhancing material utilization rates.

Energy consumption analysis demonstrates that powder coating curing processes require 30-40% less energy than solvent-based coating systems. Modern infrared and combination curing technologies have further reduced energy requirements by 15-20% compared to conventional convection ovens, with corresponding reductions in utility costs. These energy efficiencies contribute significantly to lowering operational expenses.

Labor costs also decrease with advanced electrostatic systems. Automated powder coating lines require 25-35% less labor than manual liquid coating operations. The simplified application process and reduced need for touch-ups contribute to higher productivity rates, with some manufacturers reporting throughput increases of 40-50% after transitioning to electrostatic powder technologies.

Regulatory compliance represents another area of cost advantage. The elimination of VOCs and hazardous air pollutants reduces environmental compliance costs by an average of $15,000-$30,000 annually for medium-sized operations. Insurance premiums typically decrease by 10-15% due to reduced fire hazards and improved workplace safety conditions.

Maintenance requirements for electrostatic powder coating systems are generally lower than liquid systems, with annual maintenance costs averaging 3-5% of initial equipment investment versus 7-10% for conventional spray systems. The absence of solvent-based cleaning processes further reduces maintenance downtime and associated costs. When factoring in these operational advantages alongside quality improvements and extended coating durability, the total cost of ownership analysis strongly favors electrostatic powder coating technologies for most industrial applications.

Material efficiency stands as one of the most compelling economic benefits. Electrostatic powder coating systems achieve transfer efficiencies of 95-98% compared to 60-70% for conventional spray methods. This translates to approximately 30% reduction in coating material consumption, generating substantial cost savings for high-volume operations. Additionally, overspray powder can be reclaimed and reused, further enhancing material utilization rates.

Energy consumption analysis demonstrates that powder coating curing processes require 30-40% less energy than solvent-based coating systems. Modern infrared and combination curing technologies have further reduced energy requirements by 15-20% compared to conventional convection ovens, with corresponding reductions in utility costs. These energy efficiencies contribute significantly to lowering operational expenses.

Labor costs also decrease with advanced electrostatic systems. Automated powder coating lines require 25-35% less labor than manual liquid coating operations. The simplified application process and reduced need for touch-ups contribute to higher productivity rates, with some manufacturers reporting throughput increases of 40-50% after transitioning to electrostatic powder technologies.

Regulatory compliance represents another area of cost advantage. The elimination of VOCs and hazardous air pollutants reduces environmental compliance costs by an average of $15,000-$30,000 annually for medium-sized operations. Insurance premiums typically decrease by 10-15% due to reduced fire hazards and improved workplace safety conditions.

Maintenance requirements for electrostatic powder coating systems are generally lower than liquid systems, with annual maintenance costs averaging 3-5% of initial equipment investment versus 7-10% for conventional spray systems. The absence of solvent-based cleaning processes further reduces maintenance downtime and associated costs. When factoring in these operational advantages alongside quality improvements and extended coating durability, the total cost of ownership analysis strongly favors electrostatic powder coating technologies for most industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!