How curing agents influence thermal stability in epoxy powder coatings

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Curing Agents and Thermal Stability Background

Epoxy powder coatings have emerged as a significant segment in the industrial coatings market due to their exceptional durability, chemical resistance, and environmental benefits. At the heart of these coating systems lies the critical relationship between curing agents and thermal stability, which fundamentally determines product performance and longevity.

The evolution of epoxy powder coating technology dates back to the 1950s, with significant commercial development occurring in the 1960s and 1970s. Initially, these systems faced limitations in thermal stability, restricting their application in high-temperature environments. The technological trajectory has since focused on enhancing thermal resistance through advanced curing agent chemistry.

Curing agents function as cross-linking catalysts that transform liquid or powder epoxy resins into three-dimensional, thermosetting networks. This cross-linking process directly influences the glass transition temperature, heat deflection temperature, and overall thermal degradation resistance of the final coating. Traditional curing agents include amines, anhydrides, phenolics, and carboxylic acids, each imparting distinct thermal properties to the cured system.

The thermal stability of epoxy powder coatings is characterized by their ability to maintain structural integrity, adhesion, and protective properties when exposed to elevated temperatures. This stability is quantified through parameters such as decomposition temperature, char yield, and heat resistance index. Industry standards typically require powder coatings to withstand temperatures ranging from 180°C to 250°C for standard applications, with specialized formulations reaching up to 300°C.

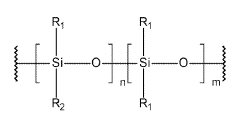

Recent technological advancements have focused on developing novel curing agents that enhance thermal stability while maintaining or improving other coating properties. Silicone-modified curing agents, for instance, have demonstrated superior thermal oxidative stability due to the inherent strength of Si-O bonds. Similarly, phosphorus-containing hardeners have gained attention for their flame-retardant properties and ability to form protective char layers during thermal degradation.

The relationship between curing agent structure and thermal stability follows several established principles. Aromatic structures generally provide better thermal resistance than aliphatic ones due to resonance stabilization. Higher functionality in curing agents typically results in increased cross-link density, enhancing thermal stability. Additionally, the presence of thermally stable chemical bonds, such as aromatic rings or heterocyclic structures, significantly improves heat resistance.

Global research trends indicate growing interest in bio-based curing agents derived from renewable resources, which present both opportunities and challenges for thermal stability engineering. Concurrently, computational modeling approaches are increasingly being employed to predict thermal behavior and optimize curing agent selection without extensive experimental testing.

The evolution of epoxy powder coating technology dates back to the 1950s, with significant commercial development occurring in the 1960s and 1970s. Initially, these systems faced limitations in thermal stability, restricting their application in high-temperature environments. The technological trajectory has since focused on enhancing thermal resistance through advanced curing agent chemistry.

Curing agents function as cross-linking catalysts that transform liquid or powder epoxy resins into three-dimensional, thermosetting networks. This cross-linking process directly influences the glass transition temperature, heat deflection temperature, and overall thermal degradation resistance of the final coating. Traditional curing agents include amines, anhydrides, phenolics, and carboxylic acids, each imparting distinct thermal properties to the cured system.

The thermal stability of epoxy powder coatings is characterized by their ability to maintain structural integrity, adhesion, and protective properties when exposed to elevated temperatures. This stability is quantified through parameters such as decomposition temperature, char yield, and heat resistance index. Industry standards typically require powder coatings to withstand temperatures ranging from 180°C to 250°C for standard applications, with specialized formulations reaching up to 300°C.

Recent technological advancements have focused on developing novel curing agents that enhance thermal stability while maintaining or improving other coating properties. Silicone-modified curing agents, for instance, have demonstrated superior thermal oxidative stability due to the inherent strength of Si-O bonds. Similarly, phosphorus-containing hardeners have gained attention for their flame-retardant properties and ability to form protective char layers during thermal degradation.

The relationship between curing agent structure and thermal stability follows several established principles. Aromatic structures generally provide better thermal resistance than aliphatic ones due to resonance stabilization. Higher functionality in curing agents typically results in increased cross-link density, enhancing thermal stability. Additionally, the presence of thermally stable chemical bonds, such as aromatic rings or heterocyclic structures, significantly improves heat resistance.

Global research trends indicate growing interest in bio-based curing agents derived from renewable resources, which present both opportunities and challenges for thermal stability engineering. Concurrently, computational modeling approaches are increasingly being employed to predict thermal behavior and optimize curing agent selection without extensive experimental testing.

Market Analysis of High-Temperature Epoxy Coatings

The high-temperature epoxy coatings market has experienced substantial growth in recent years, driven primarily by increasing demand from industries requiring protective solutions for extreme operating environments. The global market value for high-temperature epoxy coatings reached approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2028.

The aerospace and automotive sectors represent the largest application segments, collectively accounting for over 40% of market consumption. This dominance stems from the critical need for thermal stability in components exposed to extreme temperature variations and mechanical stress. The oil and gas industry follows closely, with growing implementation in pipeline coatings, offshore platforms, and refinery equipment protection systems.

Regionally, North America and Europe currently lead market consumption, benefiting from established industrial bases and stringent regulatory frameworks promoting high-performance coating solutions. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India emerging as manufacturing powerhouses requiring advanced thermal protection technologies.

Consumer demand patterns reveal increasing preference for epoxy powder coatings with enhanced thermal stability properties, particularly those capable of withstanding temperatures exceeding 200°C without degradation. This trend correlates directly with the influence of curing agents on thermal performance, as manufacturers seek formulations offering extended service life under extreme conditions.

Market research indicates price sensitivity varies significantly by application segment. While industrial maintenance applications demonstrate high price elasticity, specialized sectors like aerospace and electronics exhibit willingness to pay premium prices for coatings with superior thermal stability profiles, especially those achieved through advanced curing agent technologies.

The competitive landscape features both established multinational corporations and specialized coating manufacturers. Major players have increasingly focused R&D investments on developing proprietary curing agent systems that enhance thermal stability while maintaining other critical performance parameters like adhesion and impact resistance.

Future market growth appears closely tied to innovations in curing agent chemistry, with particular emphasis on systems capable of withstanding higher temperature thresholds while meeting increasingly stringent environmental regulations. Manufacturers developing curing agents that enable thermal stability without compromising application properties or introducing hazardous components are positioned to capture significant market share in the coming years.

The aerospace and automotive sectors represent the largest application segments, collectively accounting for over 40% of market consumption. This dominance stems from the critical need for thermal stability in components exposed to extreme temperature variations and mechanical stress. The oil and gas industry follows closely, with growing implementation in pipeline coatings, offshore platforms, and refinery equipment protection systems.

Regionally, North America and Europe currently lead market consumption, benefiting from established industrial bases and stringent regulatory frameworks promoting high-performance coating solutions. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India emerging as manufacturing powerhouses requiring advanced thermal protection technologies.

Consumer demand patterns reveal increasing preference for epoxy powder coatings with enhanced thermal stability properties, particularly those capable of withstanding temperatures exceeding 200°C without degradation. This trend correlates directly with the influence of curing agents on thermal performance, as manufacturers seek formulations offering extended service life under extreme conditions.

Market research indicates price sensitivity varies significantly by application segment. While industrial maintenance applications demonstrate high price elasticity, specialized sectors like aerospace and electronics exhibit willingness to pay premium prices for coatings with superior thermal stability profiles, especially those achieved through advanced curing agent technologies.

The competitive landscape features both established multinational corporations and specialized coating manufacturers. Major players have increasingly focused R&D investments on developing proprietary curing agent systems that enhance thermal stability while maintaining other critical performance parameters like adhesion and impact resistance.

Future market growth appears closely tied to innovations in curing agent chemistry, with particular emphasis on systems capable of withstanding higher temperature thresholds while meeting increasingly stringent environmental regulations. Manufacturers developing curing agents that enable thermal stability without compromising application properties or introducing hazardous components are positioned to capture significant market share in the coming years.

Current Challenges in Epoxy Powder Coating Stability

Despite significant advancements in epoxy powder coating technology, several persistent challenges continue to impede optimal thermal stability performance. The primary challenge lies in balancing curing efficiency with thermal resistance properties. Conventional curing agents such as dicyandiamide (DICY) and phenolic hardeners provide adequate crosslinking but often compromise long-term thermal stability at elevated temperatures, resulting in discoloration and mechanical property degradation after prolonged exposure.

The degradation mechanisms present another significant challenge, as they involve complex chemical reactions that are difficult to predict and control. When exposed to thermal stress, epoxy networks can undergo oxidative degradation, chain scission, and depolymerization. The presence of certain curing agents can accelerate these processes by introducing thermally vulnerable linkages or reactive groups that become initiation sites for degradation pathways.

Compatibility issues between curing agents and other formulation components further complicate thermal stability optimization. Many high-performance curing agents that enhance thermal resistance exhibit poor compatibility with common epoxy resins or additives, leading to phase separation, reduced shelf stability, or inconsistent curing profiles. This incompatibility often necessitates the use of additional compatibilizers or coupling agents, increasing formulation complexity and cost.

The processing window constraints represent another technical hurdle. Curing agents that provide superior thermal stability often require higher curing temperatures or longer curing times, which conflicts with industry demands for energy-efficient and rapid processing. This creates a difficult trade-off between production efficiency and end-product performance that manufacturers struggle to resolve.

Environmental and regulatory pressures add another layer of complexity. Traditional curing agents with excellent thermal stability properties, such as certain aromatic amines, face increasing restrictions due to toxicity concerns. The industry is being forced to transition to more environmentally friendly alternatives that often deliver inferior thermal performance, creating a significant technical gap that requires innovative solutions.

Measurement and prediction methodologies also remain problematic. Current accelerated aging tests do not always accurately predict real-world thermal stability performance, making it difficult to evaluate new curing agent technologies effectively. The lack of standardized, reliable testing protocols that correlate with actual service conditions hampers development efforts and creates uncertainty in material selection decisions.

Finally, cost considerations present a persistent barrier to implementation. High-performance curing agents that deliver superior thermal stability typically come at premium prices, limiting their adoption in cost-sensitive applications. The challenge of developing economically viable solutions that do not compromise thermal performance remains a significant obstacle for the industry.

The degradation mechanisms present another significant challenge, as they involve complex chemical reactions that are difficult to predict and control. When exposed to thermal stress, epoxy networks can undergo oxidative degradation, chain scission, and depolymerization. The presence of certain curing agents can accelerate these processes by introducing thermally vulnerable linkages or reactive groups that become initiation sites for degradation pathways.

Compatibility issues between curing agents and other formulation components further complicate thermal stability optimization. Many high-performance curing agents that enhance thermal resistance exhibit poor compatibility with common epoxy resins or additives, leading to phase separation, reduced shelf stability, or inconsistent curing profiles. This incompatibility often necessitates the use of additional compatibilizers or coupling agents, increasing formulation complexity and cost.

The processing window constraints represent another technical hurdle. Curing agents that provide superior thermal stability often require higher curing temperatures or longer curing times, which conflicts with industry demands for energy-efficient and rapid processing. This creates a difficult trade-off between production efficiency and end-product performance that manufacturers struggle to resolve.

Environmental and regulatory pressures add another layer of complexity. Traditional curing agents with excellent thermal stability properties, such as certain aromatic amines, face increasing restrictions due to toxicity concerns. The industry is being forced to transition to more environmentally friendly alternatives that often deliver inferior thermal performance, creating a significant technical gap that requires innovative solutions.

Measurement and prediction methodologies also remain problematic. Current accelerated aging tests do not always accurately predict real-world thermal stability performance, making it difficult to evaluate new curing agent technologies effectively. The lack of standardized, reliable testing protocols that correlate with actual service conditions hampers development efforts and creates uncertainty in material selection decisions.

Finally, cost considerations present a persistent barrier to implementation. High-performance curing agents that deliver superior thermal stability typically come at premium prices, limiting their adoption in cost-sensitive applications. The challenge of developing economically viable solutions that do not compromise thermal performance remains a significant obstacle for the industry.

Mainstream Curing Agent Solutions

01 Stabilizers and additives for thermal stability

Various stabilizers and additives can be incorporated into epoxy powder coatings to enhance their thermal stability. These include antioxidants, hindered amine light stabilizers (HALS), UV absorbers, and metal deactivators. These additives work by preventing oxidation reactions, scavenging free radicals, or blocking UV radiation that can lead to degradation at high temperatures. The proper selection and combination of these stabilizers can significantly improve the coating's resistance to thermal degradation during both processing and service life.- Stabilizers and additives for thermal stability: Various stabilizers and additives can be incorporated into epoxy powder coatings to enhance their thermal stability. These include antioxidants, hindered amine light stabilizers (HALS), UV absorbers, and metal deactivators. These additives work by preventing oxidation reactions, scavenging free radicals, or blocking UV radiation that can lead to degradation at high temperatures. The proper selection and combination of these stabilizers can significantly improve the coating's resistance to thermal degradation during both processing and service life.

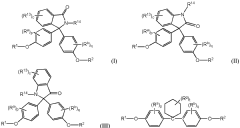

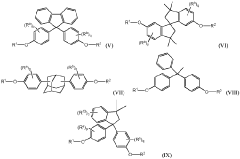

- Modified epoxy resin structures: Structural modifications to epoxy resins can enhance thermal stability of powder coatings. These modifications include incorporating aromatic or cycloaliphatic structures, increasing crosslinking density, and introducing thermally stable chemical bonds. Hybrid systems combining epoxy with other thermally stable resins like silicones or fluoropolymers can also improve heat resistance. These structural modifications create more rigid molecular networks that resist deformation and degradation at elevated temperatures.

- Curing agent selection for heat resistance: The choice of curing agent significantly impacts the thermal stability of epoxy powder coatings. Aromatic amines, anhydrides, and phenolic hardeners typically provide better heat resistance compared to aliphatic amines. Dicyandiamide and its derivatives are commonly used for applications requiring high thermal stability. Some formulations employ latent curing agents that allow for controlled curing reactions at elevated temperatures, resulting in more thermally stable crosslinked networks with fewer weak points susceptible to thermal degradation.

- Inorganic fillers and reinforcements: Incorporating inorganic fillers and reinforcements into epoxy powder coating formulations can substantially improve thermal stability. Materials such as silica, alumina, clay minerals, metal oxides, and ceramic particles act as heat shields and thermal barriers. These fillers can absorb and dissipate heat, reduce thermal expansion, and create tortuous paths that slow down degradation processes. Nano-sized fillers are particularly effective due to their high surface area and ability to interact with the polymer matrix at the molecular level.

- Processing techniques for enhanced thermal properties: Advanced processing techniques can improve the thermal stability of epoxy powder coatings. These include optimized curing cycles with controlled temperature ramps, post-curing treatments, and specialized mixing methods that ensure homogeneous distribution of stabilizers and fillers. Some processes involve pre-reaction steps to create partially cured intermediates with enhanced thermal properties. Careful control of particle size distribution during powder manufacturing also contributes to consistent thermal performance by ensuring uniform melting and flow during application.

02 Modified epoxy resin structures

Structural modifications to epoxy resins can enhance their thermal stability properties. These modifications include the incorporation of aromatic groups, cycloaliphatic structures, or silicon-containing segments into the resin backbone. Additionally, increasing crosslinking density through specific curing agents or introducing thermally stable bonds can improve resistance to degradation at elevated temperatures. These modified structures typically exhibit higher glass transition temperatures and better retention of mechanical properties when exposed to heat.Expand Specific Solutions03 Novel curing agents and hardeners

The selection of appropriate curing agents and hardeners plays a crucial role in determining the thermal stability of epoxy powder coatings. Novel curing agents such as modified anhydrides, aromatic amines, and phenolic compounds can provide enhanced crosslinking and thermal resistance. Some formulations incorporate latent curing agents that allow for better processing while maintaining excellent thermal properties in the cured state. The reaction mechanism and curing kinetics significantly influence the final coating's ability to withstand high temperatures.Expand Specific Solutions04 Nanocomposite and hybrid systems

Incorporating nanomaterials and creating hybrid systems can significantly enhance the thermal stability of epoxy powder coatings. Nanomaterials such as silica, clay, carbon nanotubes, and metal oxides create reinforced structures that resist thermal degradation. Hybrid systems combining epoxy with other thermally stable polymers like silicones or phenolics can also improve performance. These composite structures create physical barriers that limit molecular mobility and inhibit degradation pathways when exposed to elevated temperatures.Expand Specific Solutions05 Processing techniques for improved thermal stability

Advanced processing techniques can enhance the thermal stability of epoxy powder coatings. These include controlled curing profiles, multi-stage curing processes, and specialized extrusion methods that minimize thermal stress during manufacturing. Post-curing treatments at elevated temperatures can also improve thermal stability by completing crosslinking reactions and removing volatile components. Additionally, particle size control and distribution optimization during powder production can lead to more uniform curing and better thermal resistance in the final coating.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The epoxy powder coating market is currently in a mature growth phase, with increasing demand for thermally stable coatings across industrial applications. The global market size is estimated to exceed $4 billion, driven by automotive, appliance, and construction sectors. Technical competition centers on developing curing agents that enhance thermal stability without compromising performance. Industry leaders like Evonik Operations and Akzo Nobel Coatings have established strong market positions through proprietary curing agent technologies, while KCC Corp. and Jotun AS focus on specialized applications. Research institutions such as Zhejiang University collaborate with companies like Sika Technology AG to advance thermal resistance properties. Japanese manufacturers including Asahi Kasei and Sumitomo Bakelite are gaining market share through innovative hybrid curing systems that significantly improve heat resistance in high-temperature environments.

Evonik Operations GmbH

Technical Solution: Evonik has developed proprietary VESTAGON® curing agents specifically designed to enhance thermal stability in epoxy powder coatings. Their technology utilizes modified dicyandiamide (DICY) curing agents combined with accelerators that create a highly crosslinked network structure. This approach enables controlled curing kinetics with activation temperatures around 180°C, resulting in powder coatings with glass transition temperatures exceeding 100°C. Evonik's research demonstrates that incorporating specialized phenolic hardeners with their DICY systems significantly improves heat resistance by forming thermally stable bonds that resist degradation at elevated temperatures. Their formulations also include proprietary stabilizers that prevent oxidative degradation during thermal cycling, extending coating lifespan by up to 30% compared to conventional systems.

Strengths: Superior thermal stability with service temperatures up to 200°C; excellent chemical resistance against aggressive substances; controlled curing profile allowing for optimized application parameters. Weaknesses: Higher cost compared to conventional curing agents; requires precise processing conditions; may have limited flexibility in some high-temperature applications.

Sika Technology AG

Technical Solution: Sika Technology has developed innovative epoxy powder coating systems utilizing advanced phenolic and anhydride-based curing agents specifically engineered for high-temperature applications. Their proprietary SikaPower® technology incorporates modified cyclic anhydrides that create thermally resistant crosslink networks with activation energies carefully calibrated to provide controlled curing profiles. These systems achieve glass transition temperatures exceeding 140°C while maintaining excellent adhesion properties. Sika's research has demonstrated that incorporating nano-silica particles (5-20 nm) into their curing agent formulations creates additional thermal stability through reinforcement of the polymer network and improved heat dissipation. Their technology also utilizes specialized phosphorus-containing co-curing agents that impart flame retardancy while simultaneously enhancing thermal stability through the formation of a protective char layer during heat exposure. This multi-functional approach allows their coatings to maintain structural integrity at temperatures up to 250°C for extended periods.

Strengths: Exceptional thermal resistance suitable for industrial applications; excellent chemical resistance against acids and solvents; superior adhesion to difficult substrates even after thermal cycling. Weaknesses: Higher cost compared to conventional systems; requires specialized application equipment; limited color options in ultra-high temperature formulations.

Key Patents in Thermal-Resistant Epoxy Formulations

Powder paint composition

PatentWO2024111928A1

Innovation

- A powder coating composition combining epoxy resin, silicone-modified toughening agents, and a curing agent, along with fillers and additives, to enhance flexibility, appearance, and corrosion resistance without lowering the glass transition temperature, ensuring excellent adhesion and thermal stability.

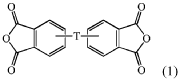

Thermosetting epoxy composition for powder coating

PatentWO2020180979A1

Innovation

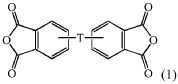

- A thermosetting epoxy powder coating composition comprising 100 parts by weight of an epoxy resin, 30 to 200 parts by weight of an aromatic dianhydride curing agent, and optionally a curing catalyst or promoter, with a stoichiometric ratio of 0.1:1 to 1.6:1, providing a glass transition temperature of 120 to 320°C and impact resistance greater than 2 Newton meters after curing.

Environmental Impact of Curing Agent Selection

The selection of curing agents in epoxy powder coatings carries significant environmental implications throughout the product lifecycle. Traditional curing agents, particularly those containing TGIC (triglycidyl isocyanurate), have raised considerable environmental concerns due to their mutagenic properties and potential ecological harm. Regulatory bodies worldwide, including the European Union through REACH regulations, have imposed strict limitations on such substances, driving the industry toward more environmentally benign alternatives.

Amine-based curing agents, while effective for thermal stability, often release volatile organic compounds (VOCs) during the curing process, contributing to air pollution and potential health hazards for workers in manufacturing facilities. The environmental footprint extends beyond emissions to include energy consumption during the curing process, where different agents require varying temperature profiles and curing times, directly impacting carbon emissions associated with coating application.

Newer generation curing agents, such as carboxyl-functional polyesters and phenolic hardeners, demonstrate improved environmental profiles with reduced toxicity and lower curing temperatures. These advancements contribute to decreased energy consumption and carbon footprint during the application process while maintaining or enhancing thermal stability properties of the final coating.

Waste management considerations also factor significantly into environmental impact assessment. Curing agents that enable longer pot life and storage stability reduce material waste, while those facilitating more efficient application processes minimize overspray and associated disposal challenges. Additionally, some modern curing agents are designed to improve coating durability, extending service life and reducing the frequency of reapplication, thereby decreasing overall material consumption and waste generation.

The biodegradability and end-of-life characteristics of cured epoxy systems vary substantially depending on the curing agent employed. Research indicates that certain bio-based curing agents derived from renewable resources not only offer comparable thermal stability but also demonstrate improved biodegradability compared to petroleum-based counterparts. This characteristic becomes increasingly important as circular economy principles gain traction in industrial applications.

Water-based alternatives to traditional solvent-borne systems represent another environmental advancement, with specialized curing agents enabling effective crosslinking in aqueous environments. These systems significantly reduce VOC emissions while maintaining thermal performance parameters critical for industrial applications, though challenges remain in achieving equivalent heat resistance to conventional powder coating systems.

Amine-based curing agents, while effective for thermal stability, often release volatile organic compounds (VOCs) during the curing process, contributing to air pollution and potential health hazards for workers in manufacturing facilities. The environmental footprint extends beyond emissions to include energy consumption during the curing process, where different agents require varying temperature profiles and curing times, directly impacting carbon emissions associated with coating application.

Newer generation curing agents, such as carboxyl-functional polyesters and phenolic hardeners, demonstrate improved environmental profiles with reduced toxicity and lower curing temperatures. These advancements contribute to decreased energy consumption and carbon footprint during the application process while maintaining or enhancing thermal stability properties of the final coating.

Waste management considerations also factor significantly into environmental impact assessment. Curing agents that enable longer pot life and storage stability reduce material waste, while those facilitating more efficient application processes minimize overspray and associated disposal challenges. Additionally, some modern curing agents are designed to improve coating durability, extending service life and reducing the frequency of reapplication, thereby decreasing overall material consumption and waste generation.

The biodegradability and end-of-life characteristics of cured epoxy systems vary substantially depending on the curing agent employed. Research indicates that certain bio-based curing agents derived from renewable resources not only offer comparable thermal stability but also demonstrate improved biodegradability compared to petroleum-based counterparts. This characteristic becomes increasingly important as circular economy principles gain traction in industrial applications.

Water-based alternatives to traditional solvent-borne systems represent another environmental advancement, with specialized curing agents enabling effective crosslinking in aqueous environments. These systems significantly reduce VOC emissions while maintaining thermal performance parameters critical for industrial applications, though challenges remain in achieving equivalent heat resistance to conventional powder coating systems.

Accelerated Aging Test Methodologies

Accelerated aging test methodologies are essential for evaluating the long-term thermal stability of epoxy powder coatings under compressed timeframes. These methodologies simulate extended environmental exposure conditions to predict coating performance over years of service life within weeks or months of testing. The selection of appropriate accelerated aging protocols is critical when investigating how different curing agents influence thermal stability in epoxy systems.

The most widely implemented methodology is the heat aging test, where coated specimens are exposed to elevated temperatures (typically 60-200°C) for predetermined periods. This test directly correlates with the thermal stability imparted by various curing agents, as different crosslinking chemistries exhibit distinct degradation patterns when subjected to thermal stress. For epoxy powder coatings, standard protocols often follow ASTM D2485 or ISO 16474-1 guidelines, with modifications specific to powder coating formulations.

Cyclic thermal shock testing represents another valuable methodology, alternating between extreme temperature conditions (-40°C to 180°C) to evaluate coating integrity under thermal expansion and contraction stresses. This approach is particularly revealing for epoxy systems with different curing agents, as the crosslink density and network flexibility significantly impact resistance to thermal cycling damage.

Weathering chambers incorporating UV exposure alongside thermal cycling (following ASTM G154 or ISO 16474-3) provide comprehensive assessment of both thermal and photochemical stability. This combined approach is crucial since certain curing agents may enhance thermal resistance while simultaneously reducing UV stability, or vice versa, requiring balanced formulation strategies.

Humidity-thermal cycling tests (following ISO 6270-2 or ASTM D2247) evaluate moisture resistance under fluctuating temperature conditions, revealing how different curing agent chemistries respond to hydrolytic degradation mechanisms. Amine-cured systems often demonstrate different moisture sensitivity profiles compared to anhydride or catalytic curing systems when subjected to these conditions.

Corrosion-accelerated testing methodologies, such as salt spray exposure combined with thermal cycling (ASTM B117 modified with thermal elements), assess how curing agent selection influences barrier properties and substrate protection under aggressive conditions. The crosslinking density and network hydrophobicity imparted by different curing agents directly correlate with performance in these tests.

Data collection protocols typically include regular intervals for gloss retention measurement, color stability assessment, adhesion testing, and mechanical property evaluation. Advanced analytical techniques such as DSC, TGA, and FTIR spectroscopy performed on aged specimens provide deeper insights into degradation mechanisms specific to each curing agent chemistry, enabling more accurate prediction of long-term thermal stability performance.

The most widely implemented methodology is the heat aging test, where coated specimens are exposed to elevated temperatures (typically 60-200°C) for predetermined periods. This test directly correlates with the thermal stability imparted by various curing agents, as different crosslinking chemistries exhibit distinct degradation patterns when subjected to thermal stress. For epoxy powder coatings, standard protocols often follow ASTM D2485 or ISO 16474-1 guidelines, with modifications specific to powder coating formulations.

Cyclic thermal shock testing represents another valuable methodology, alternating between extreme temperature conditions (-40°C to 180°C) to evaluate coating integrity under thermal expansion and contraction stresses. This approach is particularly revealing for epoxy systems with different curing agents, as the crosslink density and network flexibility significantly impact resistance to thermal cycling damage.

Weathering chambers incorporating UV exposure alongside thermal cycling (following ASTM G154 or ISO 16474-3) provide comprehensive assessment of both thermal and photochemical stability. This combined approach is crucial since certain curing agents may enhance thermal resistance while simultaneously reducing UV stability, or vice versa, requiring balanced formulation strategies.

Humidity-thermal cycling tests (following ISO 6270-2 or ASTM D2247) evaluate moisture resistance under fluctuating temperature conditions, revealing how different curing agent chemistries respond to hydrolytic degradation mechanisms. Amine-cured systems often demonstrate different moisture sensitivity profiles compared to anhydride or catalytic curing systems when subjected to these conditions.

Corrosion-accelerated testing methodologies, such as salt spray exposure combined with thermal cycling (ASTM B117 modified with thermal elements), assess how curing agent selection influences barrier properties and substrate protection under aggressive conditions. The crosslinking density and network hydrophobicity imparted by different curing agents directly correlate with performance in these tests.

Data collection protocols typically include regular intervals for gloss retention measurement, color stability assessment, adhesion testing, and mechanical property evaluation. Advanced analytical techniques such as DSC, TGA, and FTIR spectroscopy performed on aged specimens provide deeper insights into degradation mechanisms specific to each curing agent chemistry, enabling more accurate prediction of long-term thermal stability performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!