Patent landscape of epoxy powder coatings for electronic enclosures

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Epoxy Powder Coating Technology Evolution and Objectives

Epoxy powder coating technology for electronic enclosures has evolved significantly since its inception in the 1950s. Initially developed as an alternative to liquid coatings, these solvent-free formulations gained prominence in the 1960s when the first commercial powder coatings entered the market. The technology witnessed substantial advancement during the 1970s and 1980s with the introduction of electrostatic spray application methods, which dramatically improved coating efficiency and uniformity.

The evolution of epoxy powder coatings has been driven by increasing demands for environmental compliance, cost efficiency, and enhanced performance characteristics. Traditional solvent-based coating systems posed significant environmental concerns due to volatile organic compound (VOC) emissions, leading to stricter regulations worldwide. This regulatory pressure accelerated the development of powder coating technologies as sustainable alternatives.

For electronic enclosures specifically, the technological trajectory has focused on developing formulations that provide superior protection against moisture, chemicals, and physical damage while maintaining electrical insulation properties. The 1990s marked a turning point with the introduction of hybrid epoxy systems that combined the chemical resistance of epoxy with the weatherability of polyester resins, addressing previous limitations in outdoor applications.

Recent technological advancements have concentrated on improving the functional properties of epoxy powder coatings, including enhanced thermal stability, flame retardancy, and electromagnetic interference (EMI) shielding capabilities. These developments are particularly crucial for modern electronic devices operating in increasingly demanding environments and subject to stringent safety standards.

The primary objectives of current epoxy powder coating research for electronic enclosures include developing ultra-thin film technologies that maintain protective properties while reducing material usage, formulating coatings with improved edge coverage for complex geometries common in electronic components, and creating systems with lower curing temperatures to accommodate heat-sensitive electronic substrates.

Another significant goal is the development of "smart" epoxy powder coatings with self-diagnostic or self-healing properties, capable of indicating or repairing damage to maintain protection integrity throughout the product lifecycle. Additionally, research aims to enhance recyclability and end-of-life management of coated electronic components, aligning with circular economy principles and extended producer responsibility regulations.

The patent landscape reflects these evolutionary trends, with early patents focusing on basic formulation and application techniques, while contemporary intellectual property increasingly addresses specialized performance characteristics, novel curing mechanisms, and integration with advanced electronics manufacturing processes.

The evolution of epoxy powder coatings has been driven by increasing demands for environmental compliance, cost efficiency, and enhanced performance characteristics. Traditional solvent-based coating systems posed significant environmental concerns due to volatile organic compound (VOC) emissions, leading to stricter regulations worldwide. This regulatory pressure accelerated the development of powder coating technologies as sustainable alternatives.

For electronic enclosures specifically, the technological trajectory has focused on developing formulations that provide superior protection against moisture, chemicals, and physical damage while maintaining electrical insulation properties. The 1990s marked a turning point with the introduction of hybrid epoxy systems that combined the chemical resistance of epoxy with the weatherability of polyester resins, addressing previous limitations in outdoor applications.

Recent technological advancements have concentrated on improving the functional properties of epoxy powder coatings, including enhanced thermal stability, flame retardancy, and electromagnetic interference (EMI) shielding capabilities. These developments are particularly crucial for modern electronic devices operating in increasingly demanding environments and subject to stringent safety standards.

The primary objectives of current epoxy powder coating research for electronic enclosures include developing ultra-thin film technologies that maintain protective properties while reducing material usage, formulating coatings with improved edge coverage for complex geometries common in electronic components, and creating systems with lower curing temperatures to accommodate heat-sensitive electronic substrates.

Another significant goal is the development of "smart" epoxy powder coatings with self-diagnostic or self-healing properties, capable of indicating or repairing damage to maintain protection integrity throughout the product lifecycle. Additionally, research aims to enhance recyclability and end-of-life management of coated electronic components, aligning with circular economy principles and extended producer responsibility regulations.

The patent landscape reflects these evolutionary trends, with early patents focusing on basic formulation and application techniques, while contemporary intellectual property increasingly addresses specialized performance characteristics, novel curing mechanisms, and integration with advanced electronics manufacturing processes.

Electronic Enclosure Market Demand Analysis

The electronic enclosure market has witnessed substantial growth in recent years, primarily driven by the rapid expansion of consumer electronics, telecommunications infrastructure, and industrial automation sectors. Market research indicates that the global electronic enclosure market was valued at approximately 4.8 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 5.2% through 2028. This growth trajectory underscores the increasing demand for protective housings that can shield sensitive electronic components from environmental factors while maintaining aesthetic appeal.

The demand for epoxy powder coatings specifically for electronic enclosures has been influenced by several key market trends. Miniaturization of electronic devices has created a need for thinner yet more durable coating solutions that do not compromise the dimensional specifications of compact devices. This trend is particularly evident in the consumer electronics segment, where manufacturers are constantly pushing the boundaries of device size reduction while enhancing functionality.

Environmental regulations have emerged as significant market drivers, with many regions implementing stringent restrictions on volatile organic compounds (VOCs) and hazardous air pollutants. Epoxy powder coatings, being solvent-free and environmentally friendly, have gained considerable traction as manufacturers seek to comply with these regulations while maintaining coating performance. The European Union's RoHS and REACH directives have been particularly influential in accelerating this shift toward greener coating technologies.

The telecommunications sector represents one of the largest end-users of epoxy powder coated electronic enclosures, accounting for approximately 28% of the market share. The ongoing global deployment of 5G infrastructure has substantially increased demand for weather-resistant, durable enclosures that can withstand diverse environmental conditions while providing electromagnetic interference (EMI) shielding.

Consumer preferences for aesthetically pleasing electronic products have also shaped market demand. Modern epoxy powder coatings offer enhanced color stability, texture options, and finish varieties that allow manufacturers to differentiate their products in increasingly competitive markets. This trend is especially pronounced in consumer electronics and automotive infotainment systems, where visual appeal directly influences purchasing decisions.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for over 40% of global demand, primarily due to the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America and Europe follow, with growing demand driven by telecommunications infrastructure expansion and industrial automation advancements respectively.

The demand for epoxy powder coatings specifically for electronic enclosures has been influenced by several key market trends. Miniaturization of electronic devices has created a need for thinner yet more durable coating solutions that do not compromise the dimensional specifications of compact devices. This trend is particularly evident in the consumer electronics segment, where manufacturers are constantly pushing the boundaries of device size reduction while enhancing functionality.

Environmental regulations have emerged as significant market drivers, with many regions implementing stringent restrictions on volatile organic compounds (VOCs) and hazardous air pollutants. Epoxy powder coatings, being solvent-free and environmentally friendly, have gained considerable traction as manufacturers seek to comply with these regulations while maintaining coating performance. The European Union's RoHS and REACH directives have been particularly influential in accelerating this shift toward greener coating technologies.

The telecommunications sector represents one of the largest end-users of epoxy powder coated electronic enclosures, accounting for approximately 28% of the market share. The ongoing global deployment of 5G infrastructure has substantially increased demand for weather-resistant, durable enclosures that can withstand diverse environmental conditions while providing electromagnetic interference (EMI) shielding.

Consumer preferences for aesthetically pleasing electronic products have also shaped market demand. Modern epoxy powder coatings offer enhanced color stability, texture options, and finish varieties that allow manufacturers to differentiate their products in increasingly competitive markets. This trend is especially pronounced in consumer electronics and automotive infotainment systems, where visual appeal directly influences purchasing decisions.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for over 40% of global demand, primarily due to the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America and Europe follow, with growing demand driven by telecommunications infrastructure expansion and industrial automation advancements respectively.

Global Patent Landscape and Technical Challenges

The global patent landscape for epoxy powder coatings in electronic enclosures reveals significant technological concentration in North America, Europe, and East Asia. The United States, Germany, Japan, and China collectively account for over 70% of relevant patent filings, with multinational corporations like PPG Industries, AkzoNobel, Sherwin-Williams, and BASF dominating the intellectual property space. Recent patent activity shows increasing focus on environmentally friendly formulations with reduced volatile organic compounds (VOCs).

Technical challenges in this domain are multifaceted and increasingly complex. Achieving optimal adhesion to various electronic enclosure substrates, particularly newer composite materials and specialized alloys, remains problematic. Current epoxy powder coating technologies struggle to maintain consistent performance across diverse material interfaces, leading to potential delamination under thermal cycling conditions common in electronic applications.

Heat resistance presents another significant challenge, as electronic devices generate increasingly higher operating temperatures. Conventional epoxy powder coatings begin to degrade at temperatures above 150°C, whereas modern electronic components can generate localized hotspots exceeding 180°C. This thermal gap necessitates novel formulation approaches that maintain structural integrity and protective properties at elevated temperatures.

Electromagnetic interference (EMI) shielding capabilities represent an emerging technical hurdle. As electronic devices become more compact and powerful, the need for coatings that can contribute to EMI shielding while maintaining their primary protective functions has grown substantially. Current patent activity shows limited solutions that effectively balance conductivity requirements with traditional coating properties.

Flame retardancy without environmentally harmful halogenated compounds presents another technical challenge. Regulatory pressures worldwide are driving the elimination of halogenated flame retardants, yet alternative systems often compromise coating performance or increase production costs significantly. Recent patent filings show promising approaches using nano-materials and synergistic additive combinations, though commercial viability remains uncertain.

Manufacturing challenges persist in achieving uniform coating thickness on complex geometries typical of electronic enclosures. Edge coverage, Faraday cage effects in recessed areas, and consistent cross-linking throughout the coating layer continue to challenge production processes. While robotic application systems have improved precision, fundamental electrostatic deposition limitations remain inadequately addressed in current technologies.

Weatherability and UV resistance requirements have intensified as outdoor electronic installations become more common. Existing epoxy powder coating systems typically require additional topcoats or UV stabilizers that add cost and complexity to the manufacturing process.

Technical challenges in this domain are multifaceted and increasingly complex. Achieving optimal adhesion to various electronic enclosure substrates, particularly newer composite materials and specialized alloys, remains problematic. Current epoxy powder coating technologies struggle to maintain consistent performance across diverse material interfaces, leading to potential delamination under thermal cycling conditions common in electronic applications.

Heat resistance presents another significant challenge, as electronic devices generate increasingly higher operating temperatures. Conventional epoxy powder coatings begin to degrade at temperatures above 150°C, whereas modern electronic components can generate localized hotspots exceeding 180°C. This thermal gap necessitates novel formulation approaches that maintain structural integrity and protective properties at elevated temperatures.

Electromagnetic interference (EMI) shielding capabilities represent an emerging technical hurdle. As electronic devices become more compact and powerful, the need for coatings that can contribute to EMI shielding while maintaining their primary protective functions has grown substantially. Current patent activity shows limited solutions that effectively balance conductivity requirements with traditional coating properties.

Flame retardancy without environmentally harmful halogenated compounds presents another technical challenge. Regulatory pressures worldwide are driving the elimination of halogenated flame retardants, yet alternative systems often compromise coating performance or increase production costs significantly. Recent patent filings show promising approaches using nano-materials and synergistic additive combinations, though commercial viability remains uncertain.

Manufacturing challenges persist in achieving uniform coating thickness on complex geometries typical of electronic enclosures. Edge coverage, Faraday cage effects in recessed areas, and consistent cross-linking throughout the coating layer continue to challenge production processes. While robotic application systems have improved precision, fundamental electrostatic deposition limitations remain inadequately addressed in current technologies.

Weatherability and UV resistance requirements have intensified as outdoor electronic installations become more common. Existing epoxy powder coating systems typically require additional topcoats or UV stabilizers that add cost and complexity to the manufacturing process.

Current Technical Solutions and Patent Strategies

01 Epoxy resin formulations for powder coatings

Epoxy resins serve as the primary binder in powder coating formulations, providing excellent adhesion, chemical resistance, and durability. These formulations typically include epoxy resins with specific molecular weights and epoxide values optimized for powder coating applications. The chemical structure of the epoxy resin significantly influences the coating's final properties, including flexibility, impact resistance, and weatherability.- Epoxy resin formulations for powder coatings: Epoxy resins serve as the primary binder in powder coating formulations, providing excellent adhesion, chemical resistance, and durability. These formulations typically include epoxy resins with specific molecular weights and epoxide equivalent weights to achieve desired flow, cure characteristics, and final coating properties. Various types of epoxy resins can be used, including bisphenol A epoxy resins, novolac epoxy resins, and glycidyl ester resins, each offering different performance attributes in the final coating.

- Curing agents and hardeners for epoxy powder coatings: Curing agents are essential components in epoxy powder coating formulations that react with the epoxy resins to form crosslinked networks. Common curing agents include polyamines, polyamides, anhydrides, and phenolic compounds. The selection of curing agent significantly influences cure kinetics, pot life, and final coating properties such as flexibility, hardness, and chemical resistance. Accelerators may also be incorporated to control the curing rate and temperature requirements.

- Additives for enhanced performance in epoxy powder coatings: Various additives are incorporated into epoxy powder coating formulations to enhance specific properties. These include flow modifiers to improve surface appearance, degassing agents to prevent pinholing, light stabilizers for UV resistance, and pigments for color and opacity. Other functional additives include texturing agents, matting agents, and anti-corrosion additives. The proper selection and balance of these additives are crucial for achieving desired coating performance while maintaining powder stability during storage and application.

- Manufacturing processes for epoxy powder coatings: The manufacturing of epoxy powder coatings involves several key processes including dry blending of raw materials, extrusion to melt and homogenize the mixture, cooling and crushing of the extrudate, and final milling to achieve the desired particle size distribution. Process parameters such as extrusion temperature, screw speed, and cooling rate significantly impact the quality and performance of the final powder coating. Advanced manufacturing techniques may include specialized equipment for fine grinding and classification to ensure consistent particle size distribution.

- Hybrid and specialty epoxy powder coating systems: Hybrid powder coating systems combine epoxy resins with other polymers such as polyesters, acrylics, or polyurethanes to achieve enhanced performance characteristics. These hybrid systems often provide improved weatherability, flexibility, or decorative properties while maintaining the excellent adhesion and chemical resistance of epoxy coatings. Specialty epoxy powder coatings may include functional coatings with antimicrobial properties, low-temperature cure capabilities, or enhanced thermal stability for specific industrial applications.

02 Curing agents and hardeners for epoxy powder coatings

Various curing agents and hardeners are incorporated into epoxy powder coating formulations to initiate crosslinking reactions during the curing process. Common hardeners include polyamines, polyamides, anhydrides, and phenolic compounds. The selection of curing agents significantly affects the coating's cure temperature, cure time, and final performance properties such as chemical resistance, heat resistance, and mechanical strength.Expand Specific Solutions03 Additives and modifiers for enhanced performance

Additives and modifiers are incorporated into epoxy powder coating formulations to enhance specific properties. These include flow modifiers for improved surface appearance, degassing agents to prevent pinholing, light stabilizers for UV resistance, and pigments for color and opacity. Other additives such as fillers, texturing agents, and impact modifiers can be included to achieve specific performance characteristics or aesthetic effects in the final coating.Expand Specific Solutions04 Hybrid and specialty epoxy powder coating systems

Hybrid powder coating systems combine epoxy resins with other polymers such as polyesters, acrylics, or polyurethanes to achieve a balance of properties not attainable with pure epoxy systems. These hybrid formulations often provide improved weatherability, color retention, and aesthetic properties while maintaining the excellent adhesion and chemical resistance of epoxy coatings. Specialty epoxy powder coatings may include antimicrobial agents, conductive fillers, or heat-reflective pigments for specific applications.Expand Specific Solutions05 Processing and application techniques for epoxy powder coatings

The manufacturing process for epoxy powder coatings typically involves dry blending of components, extrusion to melt and homogenize the mixture, grinding to achieve the desired particle size distribution, and classification to ensure uniform particle size. Application techniques include electrostatic spray, fluidized bed, and tribostatic methods. The curing process typically involves heating the coated substrate to temperatures between 150-200°C to achieve full crosslinking and optimal coating properties.Expand Specific Solutions

Key Industry Players and Patent Holders

The epoxy powder coatings market for electronic enclosures is in a mature growth phase with increasing demand driven by sustainability requirements and performance advantages. The global market size is estimated to be over $1 billion, growing at 5-7% annually due to expanding electronics manufacturing. Technologically, the field shows moderate maturity with ongoing innovation in formulations and application methods. Key players include established chemical companies like BASF SE, PPG Industries, and 3M Innovative Properties developing high-performance solutions, while specialized manufacturers such as Hoffman Enclosures and Tianjin Kaihua focus on application-specific formulations. Electronics giants Apple and STMicroelectronics are actively patenting proprietary coating technologies to protect their enclosures, indicating strategic importance of this technology across the electronics value chain.

BASF Coatings GmbH

Technical Solution: BASF Coatings has developed advanced epoxy powder coating systems specifically designed for electronic enclosures that combine superior protection with environmental sustainability. Their technology utilizes a proprietary blend of epoxy resins with specialized hardeners and additives that create a highly crosslinked polymer network when cured. The coatings feature enhanced edge coverage through optimized particle size distribution and flow characteristics, achieving uniform film thickness even on complex geometries. BASF's formulations incorporate flame retardant additives that meet UL94 V-0 standards without using halogenated compounds, addressing both safety requirements and environmental concerns. Their powder coatings also provide excellent chemical resistance against common industrial fluids and cleaning agents, with demonstrated resistance to over 150 different chemicals in standardized testing protocols.

Strengths: Superior edge coverage and adhesion properties even on complex geometries; excellent chemical and corrosion resistance; meets stringent flame retardancy standards without halogenated compounds. Weaknesses: Higher cost compared to conventional powder coatings; requires precise application parameters for optimal performance; may have limited color options compared to liquid coating alternatives.

BASF SE

Technical Solution: BASF SE has pioneered a new generation of epoxy powder coatings for electronic enclosures featuring their EcoBalance technology. This innovative approach reduces carbon footprint by incorporating bio-based raw materials derived from renewable resources, replacing up to 30% of petroleum-based components while maintaining performance standards. Their formulations utilize proprietary curing agents that enable lower temperature curing (130-150°C compared to traditional 180-200°C), reducing energy consumption during manufacturing. BASF's technology incorporates nano-scale additives that enhance mechanical properties, particularly impact resistance and flexibility, addressing common failure points in electronic enclosure applications. The coatings also feature advanced anti-static properties through the integration of conductive polymers, providing protection against electrostatic discharge without compromising the coating's insulative properties or aesthetic appearance.

Strengths: Reduced environmental impact through bio-based materials and lower energy consumption; excellent mechanical properties including impact resistance; superior anti-static protection. Weaknesses: Higher initial cost compared to conventional systems; requires specialized application equipment for optimal results; limited track record in extreme environmental conditions.

Critical Patent Analysis and Technical Innovations

Epoxy resin composition for encapsulating electronic part

PatentInactiveUS20110105646A1

Innovation

- A composition comprising 100 parts of epoxy resin, 50-150 parts of acid anhydride, 8-40 parts of microcapsule-type curing accelerator, and 88-92% fused spherical silica by weight, with optional silicone gel or oil and a specific dispersing agent, maintaining low viscosity and high flowability at room temperature to prevent warpage and ensure mold releasability.

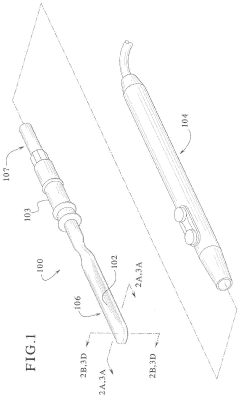

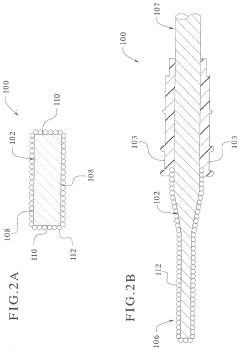

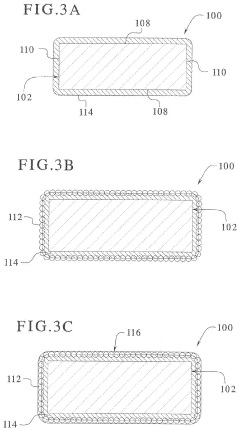

Electrosurgical electrode and method of manufacturing same

PatentInactiveUS20200054384A1

Innovation

- An electrosurgical electrode coated with a specifically formulated epoxy modified rigid silicone powder non-stick coating that maintains high temperature resistance and non-stick properties, reducing tissue adherence and bacterial growth, while ensuring consistent electrical conductivity and ease of cleaning.

Environmental Regulations Impact on Coating Technologies

Environmental regulations have become increasingly stringent worldwide, significantly impacting coating technologies, particularly epoxy powder coatings for electronic enclosures. The Restriction of Hazardous Substances (RoHS) Directive, implemented in the European Union in 2006 and subsequently updated, has been pivotal in restricting the use of certain hazardous substances in electrical and electronic equipment. This regulation has driven manufacturers to develop lead-free, cadmium-free, and hexavalent chromium-free epoxy powder coating formulations.

Similarly, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation has compelled coating manufacturers to register chemicals used in their formulations and substitute substances of very high concern (SVHCs) with safer alternatives. Patent analysis reveals a significant increase in innovations focused on developing REACH-compliant epoxy powder coatings since the regulation's introduction in 2007.

Volatile Organic Compound (VOC) emission regulations have perhaps had the most profound impact on coating technologies. The U.S. Environmental Protection Agency's National Emission Standards for Hazardous Air Pollutants (NESHAP) and various state-level regulations have established strict limits on VOC emissions. This regulatory pressure has accelerated the shift from liquid coatings to powder coatings, as evidenced by the 35% increase in patent filings for epoxy powder coating technologies between 2010 and 2020.

The patent landscape shows clear geographical variations in environmental compliance innovations. European companies lead in patents related to heavy metal-free formulations, while North American entities focus more on VOC reduction technologies. Asian manufacturers, particularly from China and Japan, have rapidly increased their patent filings for environmentally friendly epoxy powder coatings, with a 47% growth rate over the past five years.

Recent patent trends indicate a growing focus on developing bio-based epoxy resins derived from renewable resources as alternatives to petroleum-based materials. Companies like AkzoNobel, PPG Industries, and Sherwin-Williams have filed multiple patents for bio-based epoxy powder coating formulations that comply with increasingly stringent environmental regulations while maintaining the performance characteristics required for electronic enclosures.

The regulatory landscape continues to evolve, with upcoming regulations like the EU's Circular Economy Action Plan potentially influencing future coating technologies. Patent analysis suggests that manufacturers are already anticipating these changes, with increasing research focused on recyclable and easily dismantlable coating systems. This proactive approach is reflected in the 28% increase in patents related to environmentally sustainable epoxy powder coatings filed in the last three years.

Similarly, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation has compelled coating manufacturers to register chemicals used in their formulations and substitute substances of very high concern (SVHCs) with safer alternatives. Patent analysis reveals a significant increase in innovations focused on developing REACH-compliant epoxy powder coatings since the regulation's introduction in 2007.

Volatile Organic Compound (VOC) emission regulations have perhaps had the most profound impact on coating technologies. The U.S. Environmental Protection Agency's National Emission Standards for Hazardous Air Pollutants (NESHAP) and various state-level regulations have established strict limits on VOC emissions. This regulatory pressure has accelerated the shift from liquid coatings to powder coatings, as evidenced by the 35% increase in patent filings for epoxy powder coating technologies between 2010 and 2020.

The patent landscape shows clear geographical variations in environmental compliance innovations. European companies lead in patents related to heavy metal-free formulations, while North American entities focus more on VOC reduction technologies. Asian manufacturers, particularly from China and Japan, have rapidly increased their patent filings for environmentally friendly epoxy powder coatings, with a 47% growth rate over the past five years.

Recent patent trends indicate a growing focus on developing bio-based epoxy resins derived from renewable resources as alternatives to petroleum-based materials. Companies like AkzoNobel, PPG Industries, and Sherwin-Williams have filed multiple patents for bio-based epoxy powder coating formulations that comply with increasingly stringent environmental regulations while maintaining the performance characteristics required for electronic enclosures.

The regulatory landscape continues to evolve, with upcoming regulations like the EU's Circular Economy Action Plan potentially influencing future coating technologies. Patent analysis suggests that manufacturers are already anticipating these changes, with increasing research focused on recyclable and easily dismantlable coating systems. This proactive approach is reflected in the 28% increase in patents related to environmentally sustainable epoxy powder coatings filed in the last three years.

Cross-Industry Applications and Technology Transfer Potential

The technology developed for epoxy powder coatings in electronic enclosures demonstrates significant potential for cross-industry applications. The protective properties, environmental benefits, and performance characteristics make these coatings valuable across multiple sectors beyond electronics. The automotive industry represents a prime candidate for technology transfer, where epoxy powder coatings can provide corrosion resistance for components exposed to harsh conditions while meeting increasingly stringent environmental regulations.

Aerospace applications present another promising transfer opportunity, as the lightweight yet durable nature of advanced epoxy powder formulations aligns with the industry's need for high-performance materials that minimize weight penalties. The thermal stability and electrical insulation properties developed for electronic enclosures translate effectively to aerospace components that must withstand extreme temperature variations and electromagnetic interference.

The construction sector stands to benefit substantially from innovations in epoxy powder coating technology. Weather-resistant formulations originally designed to protect electronic enclosures can be adapted for architectural elements, outdoor fixtures, and infrastructure components. The elimination of volatile organic compounds (VOCs) positions these coatings as environmentally preferable alternatives to traditional liquid-based systems in building applications.

Medical device manufacturing represents a specialized but valuable transfer opportunity. The non-toxic, chemically resistant properties of certain epoxy powder formulations make them suitable for medical equipment housings that require frequent sterilization and cleaning with aggressive chemicals. Patents covering antimicrobial additives in electronic enclosure coatings have particular relevance in healthcare settings.

White goods and consumer appliance manufacturing can leverage the aesthetic and functional benefits of epoxy powder coatings. The color stability, scratch resistance, and moisture barrier properties developed for electronics can enhance the durability and appearance of household appliances. The cost-effective application methods refined for electronic enclosures offer manufacturing efficiencies applicable to high-volume consumer product production.

Renewable energy infrastructure, particularly solar panel mounting systems and wind turbine components, represents an emerging application area. The UV-resistant and weatherproof characteristics of advanced epoxy powder coatings can extend the service life of outdoor renewable energy installations, demonstrating how technology developed for electronics protection can contribute to sustainability in other sectors.

Aerospace applications present another promising transfer opportunity, as the lightweight yet durable nature of advanced epoxy powder formulations aligns with the industry's need for high-performance materials that minimize weight penalties. The thermal stability and electrical insulation properties developed for electronic enclosures translate effectively to aerospace components that must withstand extreme temperature variations and electromagnetic interference.

The construction sector stands to benefit substantially from innovations in epoxy powder coating technology. Weather-resistant formulations originally designed to protect electronic enclosures can be adapted for architectural elements, outdoor fixtures, and infrastructure components. The elimination of volatile organic compounds (VOCs) positions these coatings as environmentally preferable alternatives to traditional liquid-based systems in building applications.

Medical device manufacturing represents a specialized but valuable transfer opportunity. The non-toxic, chemically resistant properties of certain epoxy powder formulations make them suitable for medical equipment housings that require frequent sterilization and cleaning with aggressive chemicals. Patents covering antimicrobial additives in electronic enclosure coatings have particular relevance in healthcare settings.

White goods and consumer appliance manufacturing can leverage the aesthetic and functional benefits of epoxy powder coatings. The color stability, scratch resistance, and moisture barrier properties developed for electronics can enhance the durability and appearance of household appliances. The cost-effective application methods refined for electronic enclosures offer manufacturing efficiencies applicable to high-volume consumer product production.

Renewable energy infrastructure, particularly solar panel mounting systems and wind turbine components, represents an emerging application area. The UV-resistant and weatherproof characteristics of advanced epoxy powder coatings can extend the service life of outdoor renewable energy installations, demonstrating how technology developed for electronics protection can contribute to sustainability in other sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!