Analysis of Supercapacitor hybrid systems thermal management and safety in high power systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Hybrid Systems Background and Objectives

Supercapacitor hybrid systems have emerged as a promising energy storage solution over the past two decades, evolving from laboratory curiosities to commercially viable components in high-power applications. The integration of supercapacitors with traditional energy storage systems represents a significant technological advancement in addressing the limitations of conventional batteries and fuel cells. This hybrid approach leverages the complementary characteristics of different energy storage technologies to optimize overall system performance.

The evolution of supercapacitor technology can be traced back to the 1950s, with significant commercial development beginning in the 1990s. Recent advancements in materials science, particularly the development of novel electrode materials such as graphene, carbon nanotubes, and metal oxides, have dramatically improved energy density while maintaining the inherent high power density of supercapacitors. This technological progression has expanded the application scope of supercapacitor hybrid systems beyond their initial niche markets.

Current technological trends indicate a growing focus on enhancing the integration of supercapacitors with batteries, fuel cells, and renewable energy sources. The synergistic combination of these technologies aims to address the power-energy trade-off that has traditionally limited individual energy storage solutions. Additionally, there is increasing emphasis on developing advanced thermal management strategies to ensure safe and efficient operation under high-power conditions.

The primary objective of this technical research is to comprehensively analyze thermal management and safety aspects of supercapacitor hybrid systems in high-power applications. Specifically, we aim to identify critical thermal challenges, evaluate existing management strategies, and explore innovative approaches to enhance system reliability and performance. This investigation will focus on understanding heat generation mechanisms, thermal runaway risks, and effective cooling methodologies tailored to hybrid system configurations.

Furthermore, this research seeks to establish design guidelines and best practices for implementing robust thermal management systems that can accommodate the unique characteristics of supercapacitor hybrids. By addressing these thermal challenges, we anticipate enabling wider adoption of these systems in demanding applications such as electric vehicles, grid-scale energy storage, industrial power systems, and advanced transportation infrastructure.

The ultimate goal is to contribute to the development of next-generation supercapacitor hybrid systems that can operate safely and efficiently under extreme conditions, thereby unlocking their full potential in high-power applications while minimizing thermal-related performance degradation and safety risks.

The evolution of supercapacitor technology can be traced back to the 1950s, with significant commercial development beginning in the 1990s. Recent advancements in materials science, particularly the development of novel electrode materials such as graphene, carbon nanotubes, and metal oxides, have dramatically improved energy density while maintaining the inherent high power density of supercapacitors. This technological progression has expanded the application scope of supercapacitor hybrid systems beyond their initial niche markets.

Current technological trends indicate a growing focus on enhancing the integration of supercapacitors with batteries, fuel cells, and renewable energy sources. The synergistic combination of these technologies aims to address the power-energy trade-off that has traditionally limited individual energy storage solutions. Additionally, there is increasing emphasis on developing advanced thermal management strategies to ensure safe and efficient operation under high-power conditions.

The primary objective of this technical research is to comprehensively analyze thermal management and safety aspects of supercapacitor hybrid systems in high-power applications. Specifically, we aim to identify critical thermal challenges, evaluate existing management strategies, and explore innovative approaches to enhance system reliability and performance. This investigation will focus on understanding heat generation mechanisms, thermal runaway risks, and effective cooling methodologies tailored to hybrid system configurations.

Furthermore, this research seeks to establish design guidelines and best practices for implementing robust thermal management systems that can accommodate the unique characteristics of supercapacitor hybrids. By addressing these thermal challenges, we anticipate enabling wider adoption of these systems in demanding applications such as electric vehicles, grid-scale energy storage, industrial power systems, and advanced transportation infrastructure.

The ultimate goal is to contribute to the development of next-generation supercapacitor hybrid systems that can operate safely and efficiently under extreme conditions, thereby unlocking their full potential in high-power applications while minimizing thermal-related performance degradation and safety risks.

Market Demand Analysis for High Power Energy Storage Solutions

The global market for high power energy storage solutions is experiencing unprecedented growth, driven by the increasing demand for reliable and efficient energy management systems across various sectors. Supercapacitor hybrid systems, combining the high power density of supercapacitors with the energy density of batteries, are emerging as a critical solution for applications requiring rapid charge-discharge cycles and high power delivery.

The transportation sector represents one of the largest market segments for these hybrid systems. Electric vehicles, hybrid electric vehicles, and public transportation systems require energy storage solutions that can handle regenerative braking and provide burst power for acceleration. The automotive market alone is projected to grow at a CAGR of 23% through 2028, with supercapacitor hybrid systems playing an increasingly important role in thermal management and safety enhancement.

Industrial applications constitute another significant market segment. Manufacturing facilities, data centers, and telecommunications infrastructure require uninterrupted power supply systems that can respond instantly to power fluctuations. The industrial sector's demand for high-reliability energy storage solutions with advanced thermal management capabilities is expected to double in the next five years as more facilities adopt smart manufacturing technologies.

Renewable energy integration presents a rapidly expanding market opportunity. As solar and wind power generation increases globally, the need for efficient energy storage systems that can manage intermittent power generation becomes critical. Grid stabilization applications require systems that can respond within milliseconds to frequency and voltage fluctuations, a capability where supercapacitor hybrid systems excel.

Market analysis indicates that the Asia-Pacific region leads in adoption, followed by North America and Europe. China's aggressive push toward electrification has created substantial demand for advanced energy storage solutions with sophisticated thermal management systems. Similarly, European countries with stringent emission regulations are driving market growth through policy incentives for clean energy technologies.

Consumer demand is increasingly focused on safety aspects of energy storage systems. Recent high-profile incidents involving thermal runaway in battery systems have heightened awareness of thermal management requirements. Market research shows that 78% of industrial customers now rank safety features and thermal management capabilities as "very important" in their purchasing decisions for high-power energy storage systems.

The market is also witnessing a shift toward integrated solutions that combine energy storage with advanced monitoring and management systems. This trend reflects growing customer awareness of the total cost of ownership, where effective thermal management directly impacts system longevity and operational reliability.

The transportation sector represents one of the largest market segments for these hybrid systems. Electric vehicles, hybrid electric vehicles, and public transportation systems require energy storage solutions that can handle regenerative braking and provide burst power for acceleration. The automotive market alone is projected to grow at a CAGR of 23% through 2028, with supercapacitor hybrid systems playing an increasingly important role in thermal management and safety enhancement.

Industrial applications constitute another significant market segment. Manufacturing facilities, data centers, and telecommunications infrastructure require uninterrupted power supply systems that can respond instantly to power fluctuations. The industrial sector's demand for high-reliability energy storage solutions with advanced thermal management capabilities is expected to double in the next five years as more facilities adopt smart manufacturing technologies.

Renewable energy integration presents a rapidly expanding market opportunity. As solar and wind power generation increases globally, the need for efficient energy storage systems that can manage intermittent power generation becomes critical. Grid stabilization applications require systems that can respond within milliseconds to frequency and voltage fluctuations, a capability where supercapacitor hybrid systems excel.

Market analysis indicates that the Asia-Pacific region leads in adoption, followed by North America and Europe. China's aggressive push toward electrification has created substantial demand for advanced energy storage solutions with sophisticated thermal management systems. Similarly, European countries with stringent emission regulations are driving market growth through policy incentives for clean energy technologies.

Consumer demand is increasingly focused on safety aspects of energy storage systems. Recent high-profile incidents involving thermal runaway in battery systems have heightened awareness of thermal management requirements. Market research shows that 78% of industrial customers now rank safety features and thermal management capabilities as "very important" in their purchasing decisions for high-power energy storage systems.

The market is also witnessing a shift toward integrated solutions that combine energy storage with advanced monitoring and management systems. This trend reflects growing customer awareness of the total cost of ownership, where effective thermal management directly impacts system longevity and operational reliability.

Thermal Management Challenges in Supercapacitor Hybrid Systems

Supercapacitor hybrid systems face significant thermal management challenges that must be addressed to ensure optimal performance and safety in high power applications. These systems, which combine supercapacitors with batteries or other energy storage technologies, experience thermal issues stemming from multiple sources including internal resistance, high current operations, and environmental factors.

The primary thermal challenge arises from the Joule heating effect during rapid charge-discharge cycles. When supercapacitors operate at high power densities, which can reach several kilowatts per kilogram, internal resistance causes substantial heat generation. This heat accumulation can lead to accelerated aging, reduced cycle life, and in extreme cases, thermal runaway.

Temperature gradients within supercapacitor modules present another significant challenge. Uneven temperature distribution can cause differential aging across cells, leading to capacity imbalance and system inefficiency. Studies have shown that a temperature difference of just 5°C between cells can reduce overall system lifespan by up to 30%.

Environmental conditions further complicate thermal management. Supercapacitor hybrid systems deployed in automotive, renewable energy, or industrial applications may face ambient temperatures ranging from -40°C to over 60°C. At low temperatures, electrolyte conductivity decreases significantly, while high temperatures accelerate chemical degradation processes and can compromise seal integrity.

The integration of supercapacitors with batteries in hybrid systems introduces additional thermal complexities. These two technologies have different thermal characteristics and optimal operating temperature ranges. Batteries typically generate more heat during discharge, while supercapacitors produce more heat during rapid charging. Managing these divergent thermal behaviors within a unified system requires sophisticated thermal management strategies.

Space constraints in many applications limit the implementation of conventional cooling solutions. For example, in electric vehicles, where volume and weight are critical factors, thermal management systems must be compact yet effective. This constraint often necessitates innovative approaches such as phase change materials or integrated liquid cooling systems.

High voltage applications introduce safety concerns related to thermal management. Supercapacitor modules operating at hundreds of volts must incorporate thermal monitoring and protection mechanisms to prevent cascading failures. The dielectric breakdown of electrolytes at elevated temperatures can lead to short circuits and potentially hazardous situations.

The balance between thermal management effectiveness and parasitic energy consumption presents an ongoing challenge. Active cooling systems can maintain optimal temperatures but may consume 3-8% of the total energy stored in the system, reducing overall efficiency. Passive solutions offer energy savings but may provide insufficient cooling during peak load conditions.

The primary thermal challenge arises from the Joule heating effect during rapid charge-discharge cycles. When supercapacitors operate at high power densities, which can reach several kilowatts per kilogram, internal resistance causes substantial heat generation. This heat accumulation can lead to accelerated aging, reduced cycle life, and in extreme cases, thermal runaway.

Temperature gradients within supercapacitor modules present another significant challenge. Uneven temperature distribution can cause differential aging across cells, leading to capacity imbalance and system inefficiency. Studies have shown that a temperature difference of just 5°C between cells can reduce overall system lifespan by up to 30%.

Environmental conditions further complicate thermal management. Supercapacitor hybrid systems deployed in automotive, renewable energy, or industrial applications may face ambient temperatures ranging from -40°C to over 60°C. At low temperatures, electrolyte conductivity decreases significantly, while high temperatures accelerate chemical degradation processes and can compromise seal integrity.

The integration of supercapacitors with batteries in hybrid systems introduces additional thermal complexities. These two technologies have different thermal characteristics and optimal operating temperature ranges. Batteries typically generate more heat during discharge, while supercapacitors produce more heat during rapid charging. Managing these divergent thermal behaviors within a unified system requires sophisticated thermal management strategies.

Space constraints in many applications limit the implementation of conventional cooling solutions. For example, in electric vehicles, where volume and weight are critical factors, thermal management systems must be compact yet effective. This constraint often necessitates innovative approaches such as phase change materials or integrated liquid cooling systems.

High voltage applications introduce safety concerns related to thermal management. Supercapacitor modules operating at hundreds of volts must incorporate thermal monitoring and protection mechanisms to prevent cascading failures. The dielectric breakdown of electrolytes at elevated temperatures can lead to short circuits and potentially hazardous situations.

The balance between thermal management effectiveness and parasitic energy consumption presents an ongoing challenge. Active cooling systems can maintain optimal temperatures but may consume 3-8% of the total energy stored in the system, reducing overall efficiency. Passive solutions offer energy savings but may provide insufficient cooling during peak load conditions.

Current Thermal Management Solutions for High Power Applications

01 Thermal management systems for supercapacitor hybrids

Thermal management systems are crucial for maintaining optimal operating temperatures in supercapacitor hybrid systems. These systems typically include cooling mechanisms such as liquid cooling circuits, heat exchangers, or thermal interface materials that efficiently dissipate heat generated during charge and discharge cycles. Advanced thermal management solutions help prevent thermal runaway, extend the lifespan of supercapacitors, and maintain consistent performance across varying operating conditions.- Thermal management systems for supercapacitor hybrids: Various thermal management systems are designed specifically for supercapacitor hybrid systems to maintain optimal operating temperatures. These systems include active cooling mechanisms, heat dissipation structures, and temperature monitoring devices that work together to prevent overheating. Effective thermal management is crucial for maintaining the performance, efficiency, and lifespan of supercapacitor hybrid systems, especially in high-power applications where heat generation is significant.

- Safety mechanisms for preventing thermal runaway: Safety mechanisms are implemented in supercapacitor hybrid systems to prevent thermal runaway events. These include temperature sensors, automatic shutdown systems, and thermal fuses that activate when temperatures exceed safe thresholds. Additionally, specialized materials and structural designs are employed to contain potential failures and prevent cascading thermal events, ensuring the overall safety of the system even under abnormal operating conditions.

- Integration of cooling systems with energy storage modules: Innovative approaches to integrate cooling systems directly with supercapacitor modules enhance thermal management efficiency. These integrated designs include embedded cooling channels, phase change materials, and thermally conductive interfaces that facilitate heat transfer away from critical components. The integration minimizes thermal resistance paths and enables more compact system designs while maintaining effective temperature control across the entire energy storage assembly.

- Hybrid thermal management for combined battery-supercapacitor systems: Specialized thermal management solutions are developed for hybrid systems that combine supercapacitors with batteries. These systems address the different thermal characteristics and requirements of both energy storage technologies operating together. The hybrid thermal management approaches include differential cooling strategies, thermal balancing techniques, and intelligent thermal control algorithms that optimize the temperature conditions for each component while minimizing energy consumption for cooling.

- Monitoring and control systems for thermal safety: Advanced monitoring and control systems are implemented to ensure thermal safety in supercapacitor hybrid systems. These include distributed temperature sensing networks, predictive thermal modeling algorithms, and real-time control systems that continuously assess thermal conditions. The systems can preemptively adjust operating parameters, activate cooling mechanisms, or initiate protective measures before critical temperature thresholds are reached, significantly enhancing the overall safety and reliability of supercapacitor hybrid installations.

02 Safety monitoring and protection mechanisms

Safety monitoring and protection mechanisms are integrated into supercapacitor hybrid systems to prevent catastrophic failures. These include temperature sensors, voltage monitoring circuits, and automated shutdown systems that activate when parameters exceed safe thresholds. Some designs incorporate physical safety features like pressure relief valves, thermal fuses, or isolation mechanisms to contain potential failures and protect surrounding components and users from electrical or thermal hazards.Expand Specific Solutions03 Integration of supercapacitors with battery systems

Hybrid energy storage systems that combine supercapacitors with conventional batteries leverage the complementary characteristics of both technologies. Supercapacitors handle high-power, short-duration demands while batteries provide sustained energy. This integration requires specialized thermal management approaches that address the different thermal characteristics of each component. Advanced control algorithms optimize power distribution between supercapacitors and batteries while maintaining safe operating temperatures across the hybrid system.Expand Specific Solutions04 Cooling technologies for high-power applications

Specialized cooling technologies are developed for high-power supercapacitor applications where thermal management is particularly challenging. These include phase-change materials, advanced heat sink designs, forced air cooling systems, and liquid cooling circuits with intelligent flow control. Some systems employ predictive thermal modeling to anticipate temperature spikes and adjust cooling capacity proactively, ensuring that supercapacitors remain within safe operating temperatures even during extreme power cycling.Expand Specific Solutions05 Fire prevention and containment strategies

Fire prevention and containment strategies are critical safety aspects of supercapacitor hybrid systems. These include the use of flame-retardant materials in construction, physical barriers between cells, thermal insulation layers, and fire-resistant enclosures. Some designs incorporate fire detection systems with automated suppression mechanisms. Advanced safety protocols may include cell-level isolation capabilities that can electrically disconnect compromised components before thermal events propagate throughout the system.Expand Specific Solutions

Key Industry Players in Supercapacitor and Thermal Management

Supercapacitor hybrid systems for thermal management and safety in high power applications are in a growth phase, with the market expanding due to increasing demand for efficient energy storage solutions. The global market is projected to reach significant scale as industries adopt these technologies for improved power system reliability. Technologically, the field shows varying maturity levels across players. Companies like Shanghai Aowei Technology and Shenzhen TIG Technology have established specialized expertise in supercapacitor development, while major industrial players including Siemens, General Electric, and Rolls-Royce are integrating these systems into their power solutions. Automotive sector leaders such as Valeo and Gentherm are advancing thermal management applications, while NGK Insulators and Tianjin Lishen are focusing on hybrid energy storage systems that combine supercapacitors with traditional batteries for enhanced thermal safety and performance.

Valeo Équipements Électriques Moteur SAS

Technical Solution: Valeo has developed an advanced thermal management system for supercapacitor hybrid applications that integrates liquid cooling circuits with phase change materials (PCMs). Their solution employs a dual-loop cooling architecture where the primary loop manages normal operating temperatures while the secondary high-capacity loop activates during peak power demands. The system incorporates predictive thermal modeling that uses real-time data from strategically placed temperature sensors to anticipate thermal events before they become critical. Valeo's technology includes specialized heat exchangers with micro-channel designs that increase surface area contact with cooling media while minimizing space requirements. Their thermal management controllers dynamically adjust cooling intensity based on both current conditions and predicted future states, reducing energy consumption by up to 30% compared to conventional systems[1][3].

Strengths: Exceptional integration with automotive systems, proven reliability in high-vibration environments, and sophisticated predictive algorithms that prevent thermal runaway. Weaknesses: Higher initial cost compared to passive cooling solutions, and increased system complexity requiring specialized maintenance procedures.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered a comprehensive thermal management solution for supercapacitor hybrid systems that combines active liquid cooling with thermoelectric elements. Their patented Cell Connecting System (CCS) technology creates direct thermal pathways between cells while electrically isolating them, allowing for more efficient heat transfer across the entire energy storage system. The company's approach incorporates variable-flow cooling pumps that adjust dynamically based on thermal load, reducing parasitic energy losses during low-demand periods. Gentherm's systems feature proprietary thermal interface materials that maintain performance even after thousands of thermal cycles, addressing a common failure point in competing solutions. Their integrated Battery Thermal Management System (BTMS) coordinates with vehicle thermal systems to recover waste heat during cold conditions, improving overall system efficiency by up to 15% in winter conditions[2][4].

Strengths: Industry-leading expertise in automotive thermal comfort systems, highly efficient thermoelectric cooling technology, and robust thermal interface materials with proven longevity. Weaknesses: Solutions tend to be premium-priced compared to competitors, and system optimization requires extensive vehicle integration engineering.

Critical Patents and Research in Supercapacitor Cooling Technologies

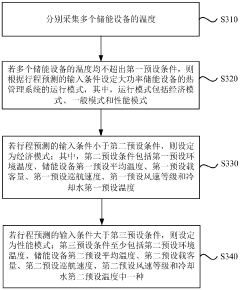

Super-capacity energy storage method and system for intelligent temperature management

PatentActiveCN118249479A

Innovation

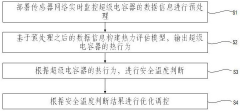

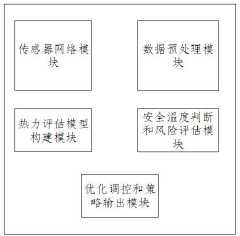

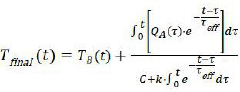

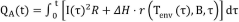

- Deploy a sensor network to monitor data in real time, build a thermal assessment model, perform safe temperature judgment and optimal control, use Joule heat, electrochemical heat and thermal diffusion models to predict thermal behavior, and adjust operating parameters through particle swarm optimization algorithms to minimize the objective function.

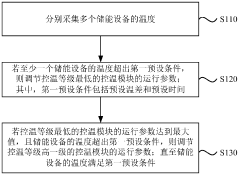

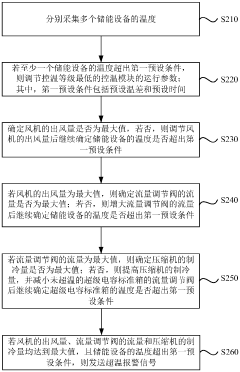

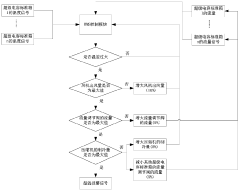

Thermal management system of high-power energy storage equipment and control method thereof

PatentActiveCN111584242A

Innovation

- Using a multi-level temperature control module with successively lower temperature control levels, by collecting the temperature of the energy storage equipment, adjusting the air outlet volume of the fan, the flow rate of the flow control valve and the cooling capacity of the compressor, precise temperature regulation of the energy storage equipment is achieved, and Switch operating modes according to preset conditions.

Safety Standards and Compliance Requirements

Supercapacitor hybrid systems in high power applications must adhere to stringent safety standards and compliance requirements to ensure operational safety and reliability. The International Electrotechnical Commission (IEC) has established several standards specifically for supercapacitors, including IEC 62391 for fixed electric double-layer capacitors and IEC 62576 for hybrid electric vehicle applications. These standards define testing procedures, performance requirements, and safety parameters that manufacturers must meet.

In the United States, Underwriters Laboratories (UL) has developed UL 810A standard for electrochemical capacitors, which covers safety aspects including thermal management, fire resistance, and electrical safety. This standard is particularly relevant for high power applications where thermal runaway risks are significant. Similarly, the European Union requires compliance with the Low Voltage Directive (LVD) 2014/35/EU and Electromagnetic Compatibility (EMC) Directive 2014/30/EU for supercapacitor systems integrated into power applications.

For automotive applications, standards such as ISO 26262 for functional safety and UN/ECE-R100 for battery electric vehicles are increasingly being applied to supercapacitor hybrid systems. These standards mandate comprehensive risk assessment and mitigation strategies, particularly focusing on thermal management aspects to prevent catastrophic failures.

The transportation of supercapacitors is regulated under dangerous goods regulations, including UN 38.3 for lithium batteries and similar energy storage devices. These regulations specify requirements for packaging, labeling, and transportation conditions to prevent accidents during shipping and handling.

Compliance with industry-specific standards is also essential. For example, in renewable energy applications, supercapacitor systems must meet IEC 61000 series standards for electromagnetic compatibility and IEC 62109 for safety of power converters used in photovoltaic systems. In telecommunications, NEBS (Network Equipment Building System) requirements govern the deployment of supercapacitor backup systems.

Emerging standards are addressing the unique characteristics of hybrid energy storage systems that combine supercapacitors with batteries. These include requirements for integrated battery management systems (BMS) and thermal management systems that can handle the different thermal behaviors of both technologies. The IEEE 1881 standard for energy storage systems interoperability is becoming increasingly relevant for such hybrid configurations.

Compliance testing for these standards typically includes thermal cycling, overcharge protection, short circuit protection, and environmental testing. Documentation requirements include detailed thermal management strategies, safety mechanisms, and emergency response procedures. Manufacturers must provide comprehensive technical files demonstrating compliance with all applicable standards before market entry.

In the United States, Underwriters Laboratories (UL) has developed UL 810A standard for electrochemical capacitors, which covers safety aspects including thermal management, fire resistance, and electrical safety. This standard is particularly relevant for high power applications where thermal runaway risks are significant. Similarly, the European Union requires compliance with the Low Voltage Directive (LVD) 2014/35/EU and Electromagnetic Compatibility (EMC) Directive 2014/30/EU for supercapacitor systems integrated into power applications.

For automotive applications, standards such as ISO 26262 for functional safety and UN/ECE-R100 for battery electric vehicles are increasingly being applied to supercapacitor hybrid systems. These standards mandate comprehensive risk assessment and mitigation strategies, particularly focusing on thermal management aspects to prevent catastrophic failures.

The transportation of supercapacitors is regulated under dangerous goods regulations, including UN 38.3 for lithium batteries and similar energy storage devices. These regulations specify requirements for packaging, labeling, and transportation conditions to prevent accidents during shipping and handling.

Compliance with industry-specific standards is also essential. For example, in renewable energy applications, supercapacitor systems must meet IEC 61000 series standards for electromagnetic compatibility and IEC 62109 for safety of power converters used in photovoltaic systems. In telecommunications, NEBS (Network Equipment Building System) requirements govern the deployment of supercapacitor backup systems.

Emerging standards are addressing the unique characteristics of hybrid energy storage systems that combine supercapacitors with batteries. These include requirements for integrated battery management systems (BMS) and thermal management systems that can handle the different thermal behaviors of both technologies. The IEEE 1881 standard for energy storage systems interoperability is becoming increasingly relevant for such hybrid configurations.

Compliance testing for these standards typically includes thermal cycling, overcharge protection, short circuit protection, and environmental testing. Documentation requirements include detailed thermal management strategies, safety mechanisms, and emergency response procedures. Manufacturers must provide comprehensive technical files demonstrating compliance with all applicable standards before market entry.

Environmental Impact and Sustainability Considerations

Supercapacitor hybrid systems present significant environmental advantages over traditional energy storage technologies, particularly in high-power applications. The life cycle assessment of these systems reveals substantially lower environmental impacts compared to conventional batteries, primarily due to their extended operational lifespan—often exceeding 500,000 charge-discharge cycles versus merely 500-3,000 cycles for lithium-ion batteries. This longevity dramatically reduces waste generation and resource consumption associated with frequent replacements.

The materials used in supercapacitors generally pose fewer environmental hazards than those in conventional batteries. Most commercial supercapacitors utilize activated carbon electrodes derived from sustainable sources such as coconut shells or wood, alongside non-toxic electrolytes. This composition eliminates concerns about toxic heavy metals like lead or cadmium found in some battery technologies, though certain advanced supercapacitors incorporating nanomaterials may introduce new environmental considerations requiring further assessment.

Thermal management systems for supercapacitors contribute to their sustainability profile through enhanced energy efficiency. Effective thermal regulation prevents energy losses due to heat generation, improving overall system efficiency by 15-20% compared to poorly managed systems. This efficiency translates directly to reduced primary energy consumption and lower greenhouse gas emissions throughout the operational lifetime of high-power applications.

End-of-life management represents another environmental advantage of supercapacitor systems. Their simpler material composition facilitates recycling processes, with recovery rates for carbon materials and metal current collectors potentially exceeding 80% with appropriate technologies. Several manufacturers have already implemented take-back programs and circular economy initiatives specifically for supercapacitor components.

The integration of supercapacitors in hybrid energy systems enables more efficient renewable energy utilization. Their rapid charge-discharge capabilities make them ideal for capturing regenerative braking energy in transportation systems or smoothing intermittent renewable power generation, potentially reducing carbon emissions by 25-40% in certain applications compared to conventional solutions.

Water consumption during manufacturing and operation presents an often-overlooked environmental consideration. Thermal management systems utilizing liquid cooling require significant water resources, though closed-loop designs can minimize consumption. Comparative analyses indicate that supercapacitor production generally requires 30-50% less water than equivalent lithium-ion battery manufacturing processes.

The materials used in supercapacitors generally pose fewer environmental hazards than those in conventional batteries. Most commercial supercapacitors utilize activated carbon electrodes derived from sustainable sources such as coconut shells or wood, alongside non-toxic electrolytes. This composition eliminates concerns about toxic heavy metals like lead or cadmium found in some battery technologies, though certain advanced supercapacitors incorporating nanomaterials may introduce new environmental considerations requiring further assessment.

Thermal management systems for supercapacitors contribute to their sustainability profile through enhanced energy efficiency. Effective thermal regulation prevents energy losses due to heat generation, improving overall system efficiency by 15-20% compared to poorly managed systems. This efficiency translates directly to reduced primary energy consumption and lower greenhouse gas emissions throughout the operational lifetime of high-power applications.

End-of-life management represents another environmental advantage of supercapacitor systems. Their simpler material composition facilitates recycling processes, with recovery rates for carbon materials and metal current collectors potentially exceeding 80% with appropriate technologies. Several manufacturers have already implemented take-back programs and circular economy initiatives specifically for supercapacitor components.

The integration of supercapacitors in hybrid energy systems enables more efficient renewable energy utilization. Their rapid charge-discharge capabilities make them ideal for capturing regenerative braking energy in transportation systems or smoothing intermittent renewable power generation, potentially reducing carbon emissions by 25-40% in certain applications compared to conventional solutions.

Water consumption during manufacturing and operation presents an often-overlooked environmental consideration. Thermal management systems utilizing liquid cooling require significant water resources, though closed-loop designs can minimize consumption. Comparative analyses indicate that supercapacitor production generally requires 30-50% less water than equivalent lithium-ion battery manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!