Evaluation of Supercapacitor hybrid systems patents and technology trends in energy storage

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Hybrid Systems Background and Objectives

Supercapacitor hybrid systems represent a significant advancement in energy storage technology, combining the high power density of supercapacitors with the high energy density of traditional batteries or other energy storage devices. The evolution of these hybrid systems can be traced back to the early 1990s when researchers began exploring ways to overcome the limitations of individual energy storage technologies. Over the past three decades, this field has witnessed remarkable progress, driven by increasing demands for more efficient, reliable, and sustainable energy storage solutions.

The technological trajectory of supercapacitor hybrid systems has been characterized by continuous improvements in materials science, particularly in electrode materials, electrolytes, and system integration. Early systems primarily focused on simple parallel connections between supercapacitors and batteries, while contemporary designs incorporate sophisticated power management systems and novel architectures that optimize the complementary characteristics of different storage components.

Current trends indicate a growing interest in developing supercapacitor hybrid systems that can address the intermittent nature of renewable energy sources, support rapid charging infrastructure for electric vehicles, and enhance grid stability. The integration of supercapacitors with lithium-ion batteries, fuel cells, and even emerging technologies like solid-state batteries represents the frontier of this technological evolution.

The primary objectives of supercapacitor hybrid system development include increasing energy density while maintaining high power capabilities, extending cycle life beyond traditional battery systems, improving temperature performance range, and reducing overall system costs. Researchers are particularly focused on overcoming the energy density limitations of conventional supercapacitors while preserving their exceptional power handling capabilities and longevity.

Another critical goal is the development of environmentally sustainable systems that reduce reliance on rare or toxic materials. This includes exploration of bio-derived carbon materials, aqueous electrolytes, and designs that facilitate end-of-life recycling. The push toward sustainability aligns with global efforts to transition to cleaner energy technologies and reduce the environmental footprint of energy storage solutions.

From a commercial perspective, the technology aims to achieve cost parity with conventional energy storage systems while delivering superior performance in specific applications. This includes reducing manufacturing complexity, improving scalability, and developing standardized approaches to system integration that can accelerate market adoption across various sectors including transportation, renewable energy, consumer electronics, and industrial applications.

The technological trajectory of supercapacitor hybrid systems has been characterized by continuous improvements in materials science, particularly in electrode materials, electrolytes, and system integration. Early systems primarily focused on simple parallel connections between supercapacitors and batteries, while contemporary designs incorporate sophisticated power management systems and novel architectures that optimize the complementary characteristics of different storage components.

Current trends indicate a growing interest in developing supercapacitor hybrid systems that can address the intermittent nature of renewable energy sources, support rapid charging infrastructure for electric vehicles, and enhance grid stability. The integration of supercapacitors with lithium-ion batteries, fuel cells, and even emerging technologies like solid-state batteries represents the frontier of this technological evolution.

The primary objectives of supercapacitor hybrid system development include increasing energy density while maintaining high power capabilities, extending cycle life beyond traditional battery systems, improving temperature performance range, and reducing overall system costs. Researchers are particularly focused on overcoming the energy density limitations of conventional supercapacitors while preserving their exceptional power handling capabilities and longevity.

Another critical goal is the development of environmentally sustainable systems that reduce reliance on rare or toxic materials. This includes exploration of bio-derived carbon materials, aqueous electrolytes, and designs that facilitate end-of-life recycling. The push toward sustainability aligns with global efforts to transition to cleaner energy technologies and reduce the environmental footprint of energy storage solutions.

From a commercial perspective, the technology aims to achieve cost parity with conventional energy storage systems while delivering superior performance in specific applications. This includes reducing manufacturing complexity, improving scalability, and developing standardized approaches to system integration that can accelerate market adoption across various sectors including transportation, renewable energy, consumer electronics, and industrial applications.

Market Analysis for Hybrid Energy Storage Solutions

The global hybrid energy storage market is experiencing significant growth, driven by increasing demand for reliable and efficient energy storage solutions across various sectors. The market size was valued at approximately $1.95 billion in 2022 and is projected to reach $4.5 billion by 2030, growing at a CAGR of 11.2% during the forecast period. This growth trajectory is primarily fueled by the rising adoption of renewable energy sources and the need for grid stabilization technologies.

Supercapacitor hybrid systems represent a particularly promising segment within this market, combining the high power density of supercapacitors with the high energy density of batteries to create more versatile energy storage solutions. These hybrid systems are gaining traction in automotive applications, renewable energy integration, and industrial power management, where both rapid power delivery and sustained energy supply are critical requirements.

Regional analysis indicates that Asia-Pacific currently dominates the hybrid energy storage market, accounting for approximately 40% of global market share. This dominance is attributed to aggressive renewable energy targets in countries like China, Japan, and South Korea, coupled with substantial investments in energy storage infrastructure. North America follows with roughly 30% market share, driven by grid modernization initiatives and electric vehicle adoption.

Consumer demand patterns reveal a growing preference for energy storage solutions that offer improved cycle life, faster charging capabilities, and reduced environmental impact. Supercapacitor hybrid systems address these preferences by providing up to 1 million charge-discharge cycles compared to 500-1000 cycles for traditional lithium-ion batteries, while also reducing reliance on rare earth materials.

Market segmentation analysis shows that transportation and grid applications currently represent the largest application segments for hybrid energy storage solutions, collectively accounting for over 60% of market demand. However, the consumer electronics segment is expected to witness the fastest growth rate of approximately 14% annually, as manufacturers seek more efficient power management solutions for portable devices.

Key market drivers include increasingly stringent emissions regulations, declining costs of component technologies, and growing energy security concerns. The levelized cost of storage (LCOS) for hybrid systems has decreased by approximately 35% over the past five years, making these solutions increasingly competitive with conventional energy storage technologies.

Supercapacitor hybrid systems represent a particularly promising segment within this market, combining the high power density of supercapacitors with the high energy density of batteries to create more versatile energy storage solutions. These hybrid systems are gaining traction in automotive applications, renewable energy integration, and industrial power management, where both rapid power delivery and sustained energy supply are critical requirements.

Regional analysis indicates that Asia-Pacific currently dominates the hybrid energy storage market, accounting for approximately 40% of global market share. This dominance is attributed to aggressive renewable energy targets in countries like China, Japan, and South Korea, coupled with substantial investments in energy storage infrastructure. North America follows with roughly 30% market share, driven by grid modernization initiatives and electric vehicle adoption.

Consumer demand patterns reveal a growing preference for energy storage solutions that offer improved cycle life, faster charging capabilities, and reduced environmental impact. Supercapacitor hybrid systems address these preferences by providing up to 1 million charge-discharge cycles compared to 500-1000 cycles for traditional lithium-ion batteries, while also reducing reliance on rare earth materials.

Market segmentation analysis shows that transportation and grid applications currently represent the largest application segments for hybrid energy storage solutions, collectively accounting for over 60% of market demand. However, the consumer electronics segment is expected to witness the fastest growth rate of approximately 14% annually, as manufacturers seek more efficient power management solutions for portable devices.

Key market drivers include increasingly stringent emissions regulations, declining costs of component technologies, and growing energy security concerns. The levelized cost of storage (LCOS) for hybrid systems has decreased by approximately 35% over the past five years, making these solutions increasingly competitive with conventional energy storage technologies.

Technical Challenges and Global Development Status

Supercapacitor hybrid systems face significant technical challenges despite their promising potential in energy storage applications. The primary obstacle remains the relatively low energy density compared to conventional batteries, limiting their application in scenarios requiring sustained power delivery. Current commercial supercapacitors typically achieve only 5-10 Wh/kg, substantially below lithium-ion batteries' 150-250 Wh/kg. This fundamental limitation necessitates hybridization with other storage technologies, creating integration complexities.

Material science constraints present another major challenge. Advanced electrode materials like graphene and carbon nanotubes demonstrate impressive theoretical performance but encounter manufacturing scalability issues. The production of these materials with consistent quality at industrial scale remains problematic, creating a gap between laboratory results and commercial implementation. Additionally, the high cost of specialized materials significantly impacts the economic viability of widespread adoption.

System integration challenges are equally critical. Hybrid systems require sophisticated power management electronics to effectively coordinate between supercapacitors and batteries, optimizing the performance characteristics of each component. These control systems add complexity, cost, and potential failure points to the overall solution. Temperature management also presents difficulties, as supercapacitors and batteries often have different optimal operating temperature ranges.

Globally, supercapacitor hybrid technology development shows distinct regional patterns. North America and Europe lead in fundamental research and intellectual property development, with significant patent portfolios held by companies like Maxwell Technologies (now part of Tesla) and academic institutions. Asia, particularly China, Japan, and South Korea, dominates in manufacturing scale and application-specific implementations, leveraging their established battery production infrastructure.

The technology readiness level varies significantly across applications. Transportation applications, especially in regenerative braking systems, have reached commercial deployment. Grid-scale energy storage applications remain predominantly at the demonstration phase, with several pilot projects operational but few full-scale commercial implementations. Consumer electronics applications are emerging but face miniaturization and cost challenges.

Regulatory frameworks and standards for hybrid energy storage systems are still evolving, creating market uncertainty. Different regions have adopted varying approaches to safety certification and performance standards, complicating global commercialization efforts. This regulatory fragmentation represents a significant non-technical barrier to widespread adoption of supercapacitor hybrid systems.

Material science constraints present another major challenge. Advanced electrode materials like graphene and carbon nanotubes demonstrate impressive theoretical performance but encounter manufacturing scalability issues. The production of these materials with consistent quality at industrial scale remains problematic, creating a gap between laboratory results and commercial implementation. Additionally, the high cost of specialized materials significantly impacts the economic viability of widespread adoption.

System integration challenges are equally critical. Hybrid systems require sophisticated power management electronics to effectively coordinate between supercapacitors and batteries, optimizing the performance characteristics of each component. These control systems add complexity, cost, and potential failure points to the overall solution. Temperature management also presents difficulties, as supercapacitors and batteries often have different optimal operating temperature ranges.

Globally, supercapacitor hybrid technology development shows distinct regional patterns. North America and Europe lead in fundamental research and intellectual property development, with significant patent portfolios held by companies like Maxwell Technologies (now part of Tesla) and academic institutions. Asia, particularly China, Japan, and South Korea, dominates in manufacturing scale and application-specific implementations, leveraging their established battery production infrastructure.

The technology readiness level varies significantly across applications. Transportation applications, especially in regenerative braking systems, have reached commercial deployment. Grid-scale energy storage applications remain predominantly at the demonstration phase, with several pilot projects operational but few full-scale commercial implementations. Consumer electronics applications are emerging but face miniaturization and cost challenges.

Regulatory frameworks and standards for hybrid energy storage systems are still evolving, creating market uncertainty. Different regions have adopted varying approaches to safety certification and performance standards, complicating global commercialization efforts. This regulatory fragmentation represents a significant non-technical barrier to widespread adoption of supercapacitor hybrid systems.

Current Technical Solutions for Hybrid Energy Storage

01 Hybrid energy storage systems combining supercapacitors with batteries

Hybrid energy storage systems that integrate supercapacitors with traditional batteries to leverage the high power density of supercapacitors and the high energy density of batteries. These systems optimize energy management by using supercapacitors for rapid charge/discharge cycles while batteries handle sustained power needs. This combination improves overall system efficiency, extends battery life, and provides better performance for applications requiring both power bursts and long-term energy supply.- Hybrid energy storage systems combining supercapacitors with batteries: Hybrid energy storage systems that integrate supercapacitors with traditional batteries to leverage the high power density of supercapacitors and the high energy density of batteries. These systems optimize energy management by using supercapacitors for rapid charge/discharge cycles while batteries handle sustained energy needs. This combination improves overall system efficiency, extends battery life, and provides better performance for applications requiring both power bursts and long-term energy supply.

- Supercapacitor materials and electrode innovations: Advanced materials and electrode designs for supercapacitors that enhance energy density, power density, and cycle life. These innovations include novel carbon-based materials, metal oxides, conducting polymers, and composite structures that increase surface area and improve charge storage mechanisms. Electrode architecture improvements focus on optimizing ion transport pathways, reducing internal resistance, and enhancing electrochemical stability for better overall performance in hybrid energy storage applications.

- Control systems and energy management for supercapacitor hybrids: Intelligent control systems and energy management algorithms designed specifically for supercapacitor hybrid systems. These technologies optimize power distribution between supercapacitors and other energy sources, manage charging/discharging cycles, and implement predictive control strategies based on load demands. Advanced management systems include real-time monitoring, adaptive control mechanisms, and machine learning algorithms that maximize efficiency, extend component lifetimes, and ensure reliable operation under varying conditions.

- Supercapacitor integration in renewable energy systems: Integration of supercapacitor hybrid systems with renewable energy sources such as solar and wind power. These configurations use supercapacitors to buffer the intermittent nature of renewable generation, providing grid stability and power quality improvement. The hybrid systems enable efficient energy harvesting by capturing surplus energy during peak production periods and delivering it during high demand or low production periods, thereby enhancing the reliability and effectiveness of renewable energy installations.

- Automotive and transportation applications of supercapacitor hybrids: Specialized supercapacitor hybrid systems designed for automotive and transportation applications, including electric vehicles, hybrid electric vehicles, and regenerative braking systems. These configurations utilize supercapacitors to handle high-power demands during acceleration and to capture energy during braking events. The integration improves vehicle efficiency, extends driving range, reduces battery stress, and enhances overall performance while supporting rapid charging capabilities for transportation applications.

02 Supercapacitor materials and electrode innovations

Advanced materials and electrode designs for enhancing supercapacitor performance in hybrid systems. These innovations include novel carbon-based materials, metal oxides, and composite structures that increase surface area and improve charge storage capabilities. Electrode modifications focus on optimizing ion transport pathways and enhancing electrical conductivity, resulting in higher energy density, improved power delivery, and longer cycle life for supercapacitor components in hybrid energy systems.Expand Specific Solutions03 Control systems and energy management for supercapacitor hybrids

Intelligent control systems and energy management algorithms designed specifically for supercapacitor hybrid configurations. These technologies enable dynamic power distribution between supercapacitors and other energy sources based on real-time demand, state of charge, and operating conditions. Advanced control strategies optimize energy flow, reduce power losses, and extend system lifetime by intelligently managing charge/discharge cycles and preventing component degradation under various load conditions.Expand Specific Solutions04 Automotive and transportation applications of supercapacitor hybrids

Implementation of supercapacitor hybrid systems in vehicles and transportation infrastructure to improve energy efficiency and performance. These applications include regenerative braking systems that capture and store energy during deceleration, start-stop systems that reduce fuel consumption, and power boosting for acceleration. Supercapacitor hybrids in transportation provide rapid energy storage and release capabilities, reducing strain on primary batteries and extending the range and lifetime of electric and hybrid vehicles.Expand Specific Solutions05 Grid-scale and renewable energy integration with supercapacitor hybrids

Large-scale supercapacitor hybrid systems designed for power grid stabilization and renewable energy integration. These systems address the intermittency challenges of renewable sources like solar and wind by providing rapid response energy storage. Supercapacitor hybrids help manage grid frequency regulation, smooth power output fluctuations, and provide backup power during short-term outages. The technology enables more efficient energy harvesting from renewable sources while maintaining grid stability and power quality.Expand Specific Solutions

Leading Companies and Competitive Landscape

The supercapacitor hybrid systems market for energy storage is currently in a growth phase, with increasing adoption across various sectors. The market size is expanding rapidly due to rising demand for efficient energy storage solutions, particularly in renewable energy integration and electric vehicle applications. Technologically, the field shows varying maturity levels, with academic institutions like Huazhong University of Science & Technology and Tsinghua University driving fundamental research, while companies like Maxwell Technologies and Shanghai Aowei Technology have commercialized products. Major industrial players including State Grid Corp. of China, Hon Hai Precision, and NEC Corp. are investing heavily in application development. Automotive manufacturers such as SAIC Motor and Peugeot SA are exploring hybrid supercapacitor systems for vehicle electrification, indicating cross-industry adoption potential.

Institute of Electrical Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Electrical Engineering at the Chinese Academy of Sciences has developed innovative hybrid supercapacitor technologies that combine the advantages of both pseudocapacitors and electric double-layer capacitors. Their patented composite electrode materials incorporate transition metal oxides (including MnO2, NiO, and Co3O4) with graphene and carbon nanotubes to achieve energy densities of 30-40 Wh/kg while maintaining power densities above 10 kW/kg[6]. Their research has pioneered hierarchical porous carbon structures that optimize ion transport pathways, reducing internal resistance and enhancing rate capability. The Institute has also developed novel electrolyte formulations that extend the voltage window of aqueous supercapacitors to 2.2V, significantly increasing energy density without compromising safety[7]. Their hybrid energy management systems incorporate advanced algorithms that dynamically adjust charge-discharge profiles based on real-time monitoring of cell parameters, extending operational lifetime by up to 40% compared to conventional control strategies. Recent patents include innovative manufacturing techniques for mass production of their advanced electrode materials, reducing production costs by approximately 30%[8].

Strengths: Cutting-edge materials science expertise, particularly in composite electrode development and electrolyte formulations. Strong research capabilities with extensive laboratory testing facilities and comprehensive performance validation. Weaknesses: Less commercial deployment experience compared to industry players, with some technologies still in transition from laboratory to commercial scale. Intellectual property focused more on materials and components rather than complete system integration.

Ningbo CRRC New Energy Technology Co., Ltd.

Technical Solution: Ningbo CRRC has developed an integrated supercapacitor-battery hybrid energy storage system specifically optimized for rail transit applications. Their technology combines lithium titanate batteries with high-power supercapacitors in a modular architecture that can be scaled from 50kW to multi-MW installations[3]. The system features advanced power electronics that intelligently distribute load demands between supercapacitors (handling peak power) and batteries (providing base energy), extending battery life by up to 300%[4]. Their patented thermal management system maintains optimal operating temperatures across varied environmental conditions, enabling deployment in diverse climatic zones. CRRC's energy management system incorporates predictive algorithms that analyze route profiles and energy demands to optimize power distribution, achieving energy recovery rates of up to 98% during braking events in urban rail applications[5]. The company has successfully deployed these systems in over 20 cities globally, demonstrating field-proven reliability with MTBF (Mean Time Between Failures) exceeding 50,000 hours.

Strengths: Specialized expertise in transportation applications, particularly rail transit, with proven large-scale deployments. Their systems demonstrate exceptional energy recovery efficiency and are designed for extreme durability in transportation environments. Weaknesses: Technology is highly specialized for transportation sector, limiting crossover potential to stationary storage markets. Higher initial capital costs compared to conventional solutions, though lifetime cost benefits are substantial.

Key Patent Analysis and Technical Innovations

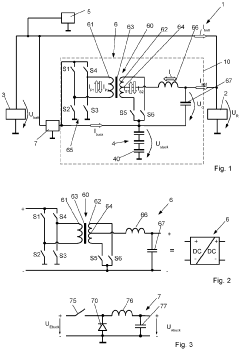

Hybrid electrical energy storage system

PatentPendingEP4116136A1

Innovation

- A hybrid electrical energy storage system incorporating a capacitive energy storage stack with a full-bridge circuit and a push-pull forward converter using a transmission transformer, where the supercapacitor stack is connected in series and the push-pull converter efficiently manages current peaks by directing excess current to the supercapacitor stack, allowing for full utilization of stored energy.

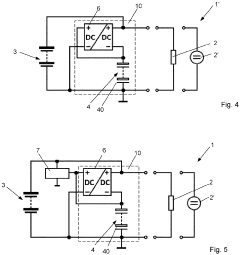

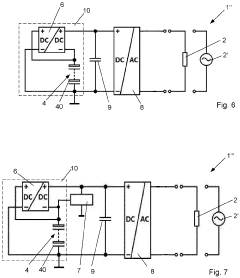

Hybrid energy storage system

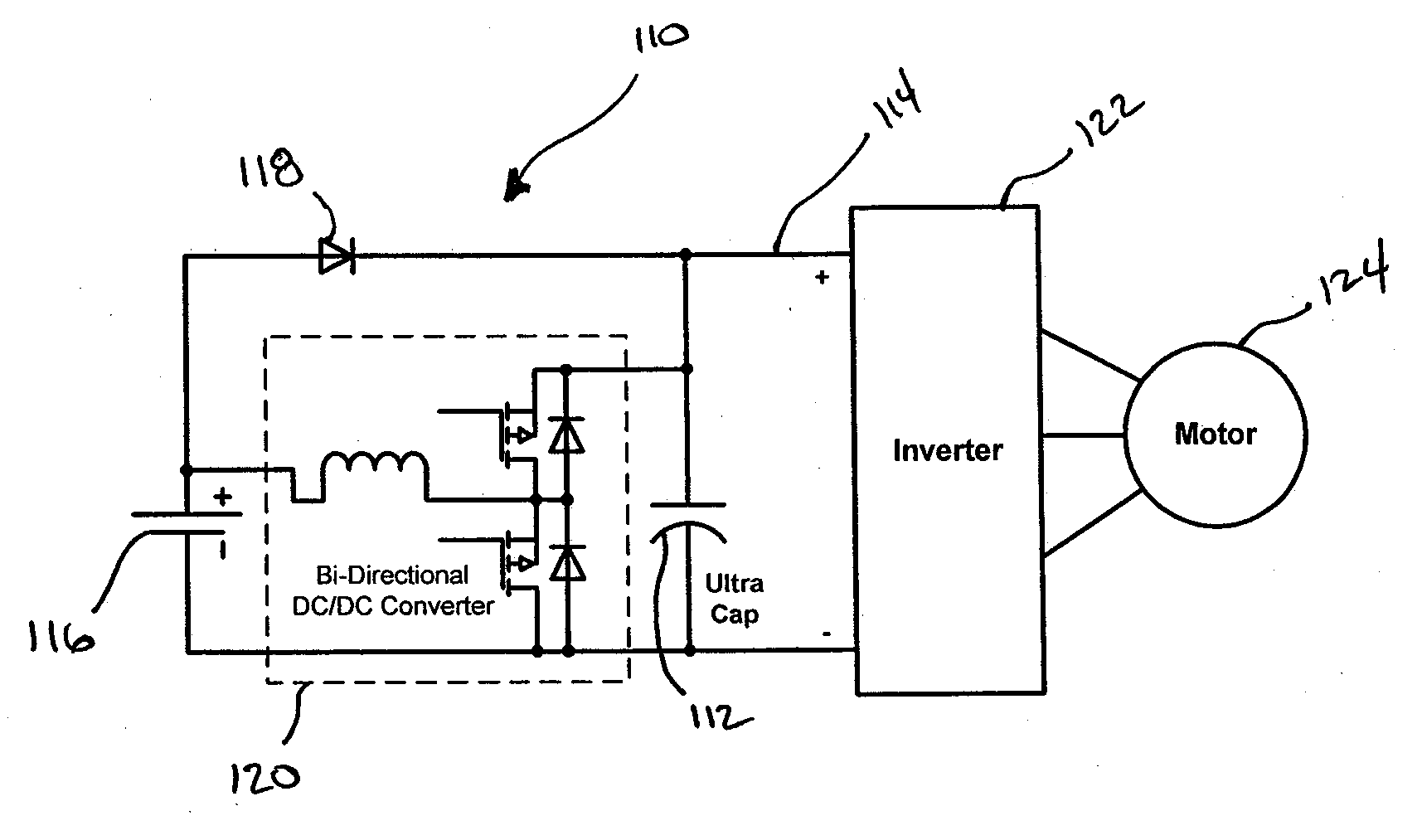

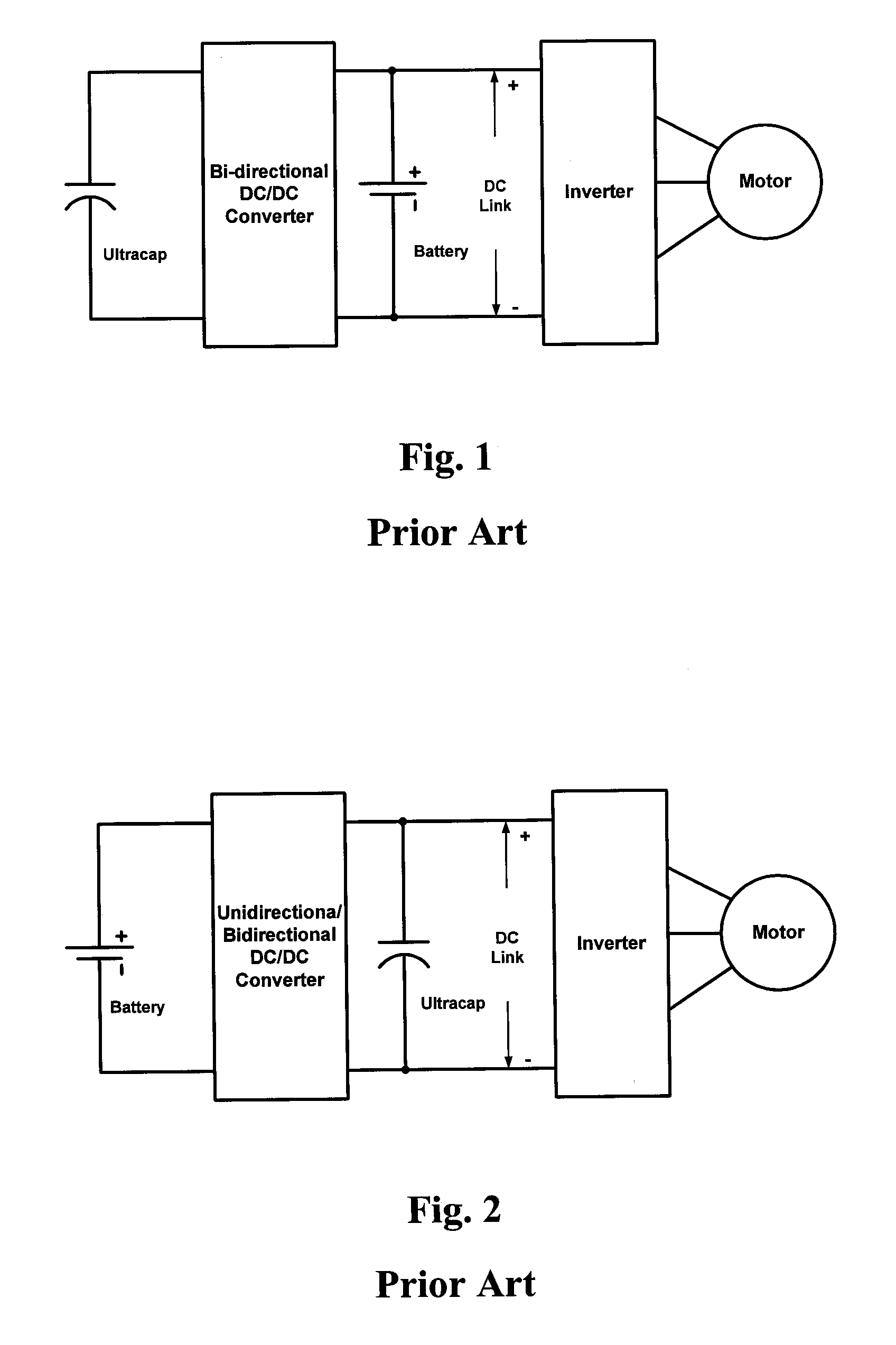

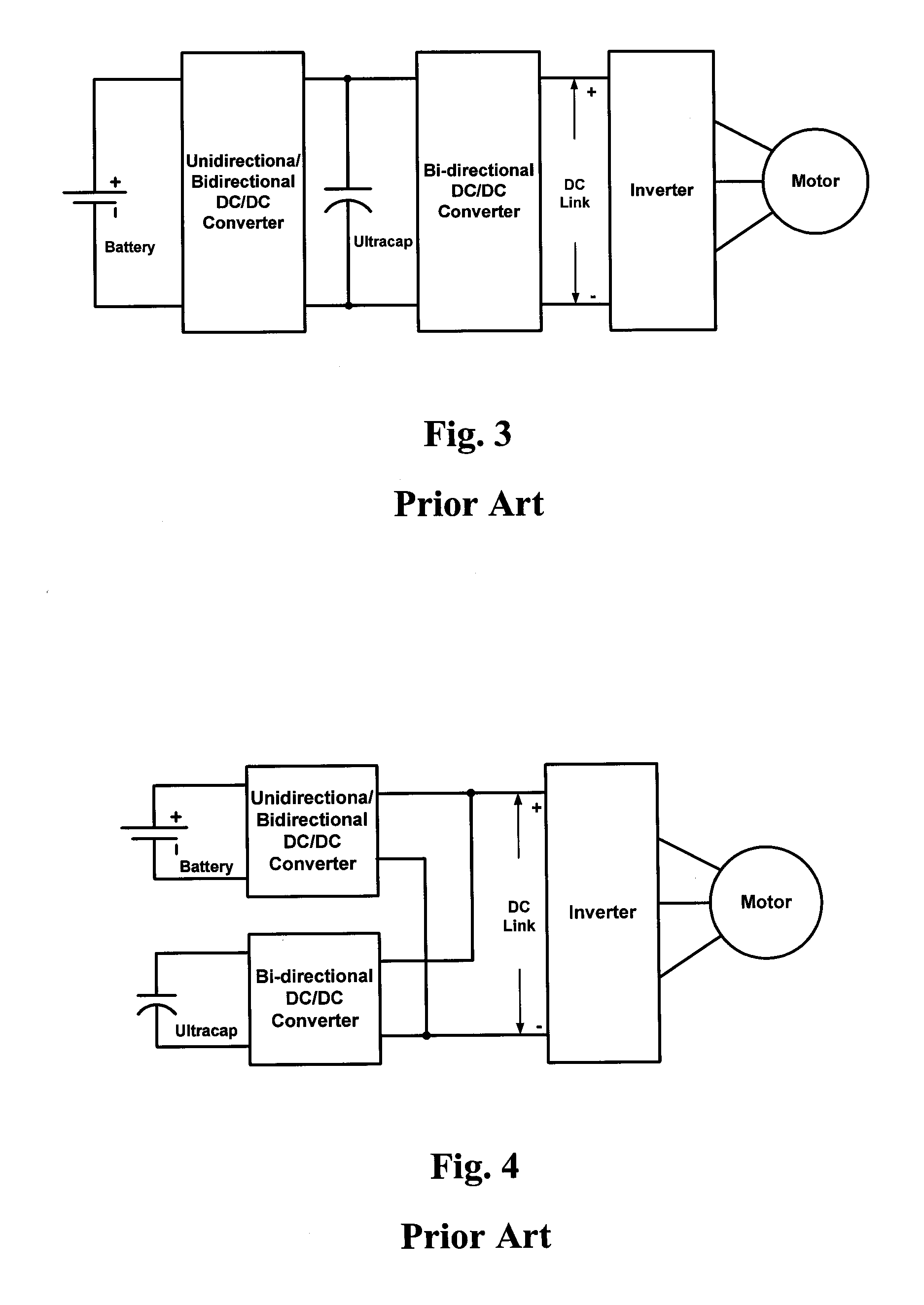

PatentActiveUS20110084648A1

Innovation

- A hybrid energy storage system with an ultra-capacitor connected to a DC bus via a DC/DC converter, where the converter boosts the power source voltage to charge the ultra-capacitor, allowing for multiple operational modes to manage power demand and extend battery life by directing regenerative energy to the ultra-capacitor.

Environmental Impact and Sustainability Assessment

Supercapacitor hybrid systems represent a significant advancement in sustainable energy storage technologies, offering reduced environmental footprints compared to conventional battery systems. The life cycle assessment of these hybrid systems reveals substantially lower greenhouse gas emissions during manufacturing processes, with estimates suggesting 30-45% reduction compared to lithium-ion batteries of equivalent capacity. This environmental advantage stems primarily from the reduced dependency on rare earth metals and toxic materials typically required in traditional battery production.

The raw material acquisition phase for supercapacitor components demonstrates improved sustainability metrics, particularly through the increasing utilization of carbon-based materials derived from renewable or waste sources. Recent patent filings indicate a growing trend toward incorporating biomass-derived activated carbons and graphene produced through environmentally conscious methods, significantly reducing the ecological impact of material sourcing.

During operational lifespans, supercapacitor hybrid systems exhibit exceptional durability, with cycle lives often exceeding 500,000 cycles compared to 1,000-3,000 cycles for conventional batteries. This extended operational period translates to reduced waste generation and resource consumption over time. Energy efficiency analyses documented in recent technical literature demonstrate that advanced hybrid configurations achieve round-trip efficiencies of 90-95%, minimizing energy losses and associated environmental impacts during charge-discharge cycles.

End-of-life considerations represent another area where supercapacitor hybrid systems demonstrate environmental advantages. The recyclability rate of these systems reaches approximately 80-90%, significantly higher than the 50-60% typically achieved with lithium-ion technologies. Patent trends reveal increasing focus on designing systems with modular components that facilitate disassembly and material recovery, addressing previous limitations in recycling infrastructure.

Water consumption metrics associated with supercapacitor production show promising reductions, with manufacturing processes requiring 40-60% less water compared to conventional battery technologies. This aspect becomes increasingly critical as water scarcity concerns intensify globally. Additionally, the reduced reliance on mining activities for material acquisition translates to decreased habitat disruption and biodiversity impacts.

Carbon footprint analyses across the complete product lifecycle indicate that supercapacitor hybrid systems can achieve carbon payback periods approximately 30% shorter than comparable energy storage alternatives. This advantage becomes particularly pronounced when these systems are deployed in conjunction with renewable energy sources, creating truly sustainable energy storage solutions that minimize environmental impacts while maximizing grid stability and energy security.

The raw material acquisition phase for supercapacitor components demonstrates improved sustainability metrics, particularly through the increasing utilization of carbon-based materials derived from renewable or waste sources. Recent patent filings indicate a growing trend toward incorporating biomass-derived activated carbons and graphene produced through environmentally conscious methods, significantly reducing the ecological impact of material sourcing.

During operational lifespans, supercapacitor hybrid systems exhibit exceptional durability, with cycle lives often exceeding 500,000 cycles compared to 1,000-3,000 cycles for conventional batteries. This extended operational period translates to reduced waste generation and resource consumption over time. Energy efficiency analyses documented in recent technical literature demonstrate that advanced hybrid configurations achieve round-trip efficiencies of 90-95%, minimizing energy losses and associated environmental impacts during charge-discharge cycles.

End-of-life considerations represent another area where supercapacitor hybrid systems demonstrate environmental advantages. The recyclability rate of these systems reaches approximately 80-90%, significantly higher than the 50-60% typically achieved with lithium-ion technologies. Patent trends reveal increasing focus on designing systems with modular components that facilitate disassembly and material recovery, addressing previous limitations in recycling infrastructure.

Water consumption metrics associated with supercapacitor production show promising reductions, with manufacturing processes requiring 40-60% less water compared to conventional battery technologies. This aspect becomes increasingly critical as water scarcity concerns intensify globally. Additionally, the reduced reliance on mining activities for material acquisition translates to decreased habitat disruption and biodiversity impacts.

Carbon footprint analyses across the complete product lifecycle indicate that supercapacitor hybrid systems can achieve carbon payback periods approximately 30% shorter than comparable energy storage alternatives. This advantage becomes particularly pronounced when these systems are deployed in conjunction with renewable energy sources, creating truly sustainable energy storage solutions that minimize environmental impacts while maximizing grid stability and energy security.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of supercapacitor hybrid systems represents a critical factor in their commercial viability and widespread adoption. Current manufacturing processes face significant challenges in scaling production while maintaining consistent quality and performance. The primary bottleneck exists in electrode material production, where achieving uniform porosity and surface area characteristics at industrial scales remains difficult. Additionally, the assembly of hybrid systems requires precise integration of supercapacitor and battery components, creating complexity that traditional battery manufacturing lines are not optimized to handle.

Cost analysis reveals that material expenses constitute approximately 40-60% of total manufacturing costs for supercapacitor hybrid systems. High-purity activated carbon, specialized electrolytes, and separator materials contribute significantly to this cost structure. The production of advanced electrode materials such as graphene and carbon nanotubes, which show promising performance improvements, currently involves expensive processes that limit cost-effective mass production. Industry data indicates that economies of scale have reduced costs by approximately 15-20% annually over the past five years, but further reductions are necessary to achieve price parity with conventional energy storage solutions.

Automation represents a promising avenue for improving manufacturing efficiency and reducing labor costs, which currently account for 15-25% of production expenses. Companies implementing semi-automated assembly lines have reported productivity increases of 30-40% compared to manual processes. However, the capital investment required for fully automated production lines remains prohibitively high for many manufacturers, creating barriers to entry for smaller companies and limiting industry expansion.

Regional manufacturing cost disparities significantly impact production strategies. Asian manufacturers, particularly in China and South Korea, maintain a 20-30% cost advantage over North American and European counterparts due to lower labor costs, government subsidies, and established supply chains. This regional advantage has concentrated approximately 70% of global supercapacitor hybrid system manufacturing capacity in Asia, creating potential supply chain vulnerabilities for Western markets.

Energy consumption during manufacturing represents another significant cost factor, accounting for 10-15% of production expenses. The energy-intensive processes required for electrode material preparation and thermal treatments contribute to both environmental impact and operational costs. Recent innovations in low-temperature synthesis methods and energy-efficient drying techniques demonstrate potential for reducing energy requirements by 25-35%, simultaneously lowering costs and improving sustainability metrics.

Cost analysis reveals that material expenses constitute approximately 40-60% of total manufacturing costs for supercapacitor hybrid systems. High-purity activated carbon, specialized electrolytes, and separator materials contribute significantly to this cost structure. The production of advanced electrode materials such as graphene and carbon nanotubes, which show promising performance improvements, currently involves expensive processes that limit cost-effective mass production. Industry data indicates that economies of scale have reduced costs by approximately 15-20% annually over the past five years, but further reductions are necessary to achieve price parity with conventional energy storage solutions.

Automation represents a promising avenue for improving manufacturing efficiency and reducing labor costs, which currently account for 15-25% of production expenses. Companies implementing semi-automated assembly lines have reported productivity increases of 30-40% compared to manual processes. However, the capital investment required for fully automated production lines remains prohibitively high for many manufacturers, creating barriers to entry for smaller companies and limiting industry expansion.

Regional manufacturing cost disparities significantly impact production strategies. Asian manufacturers, particularly in China and South Korea, maintain a 20-30% cost advantage over North American and European counterparts due to lower labor costs, government subsidies, and established supply chains. This regional advantage has concentrated approximately 70% of global supercapacitor hybrid system manufacturing capacity in Asia, creating potential supply chain vulnerabilities for Western markets.

Energy consumption during manufacturing represents another significant cost factor, accounting for 10-15% of production expenses. The energy-intensive processes required for electrode material preparation and thermal treatments contribute to both environmental impact and operational costs. Recent innovations in low-temperature synthesis methods and energy-efficient drying techniques demonstrate potential for reducing energy requirements by 25-35%, simultaneously lowering costs and improving sustainability metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!