What interface engineering strategies enhance Supercapacitor hybrid systems electrochemical performance

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Interface Engineering Background and Objectives

Supercapacitors have emerged as pivotal energy storage devices over the past three decades, offering exceptional power density, rapid charge-discharge capabilities, and extended cycle life compared to conventional batteries. The evolution of supercapacitor technology has progressed from traditional carbon-based electric double-layer capacitors (EDLCs) to more advanced pseudocapacitors and hybrid systems that combine both mechanisms to maximize energy and power densities.

Interface engineering represents a critical frontier in supercapacitor development, as the electrode-electrolyte interface fundamentally determines charge storage efficiency, rate capability, and long-term stability. Historical developments in this field have moved from simple carbon activation techniques to sophisticated surface functionalization and nanostructure design, with significant breakthroughs occurring in the last decade through atomic-level interface manipulation.

The current technological trajectory points toward hybrid supercapacitor systems that integrate different charge storage mechanisms and materials to overcome the inherent limitations of single-component systems. These hybrid approaches aim to synergistically combine the high power density of EDLCs with the superior energy density of pseudocapacitive or battery-type materials, creating devices that bridge the performance gap between traditional capacitors and batteries.

This technical research aims to comprehensively investigate and evaluate interface engineering strategies that enhance the electrochemical performance of supercapacitor hybrid systems. Specifically, we seek to identify and analyze innovative approaches for optimizing charge transfer kinetics, ion transport pathways, and interfacial stability at the nanoscale. The primary objectives include mapping the current technological landscape, identifying breakthrough interface engineering methodologies, and forecasting future development directions.

Key technical goals encompass understanding the fundamental mechanisms governing interfacial phenomena in hybrid systems, evaluating the effectiveness of various surface modification techniques, and determining optimal material combinations that maximize both energy and power metrics while maintaining long-term cycling stability. Additionally, we aim to explore scalable interface engineering approaches that can transition from laboratory demonstrations to commercial applications.

The significance of this research extends beyond academic interest, as next-generation energy storage systems with enhanced performance metrics are increasingly essential for applications ranging from portable electronics and electric vehicles to grid-scale energy storage. By systematically analyzing interface engineering strategies, this investigation seeks to provide actionable insights that can accelerate the development of high-performance supercapacitor hybrid systems to meet growing energy storage demands.

Interface engineering represents a critical frontier in supercapacitor development, as the electrode-electrolyte interface fundamentally determines charge storage efficiency, rate capability, and long-term stability. Historical developments in this field have moved from simple carbon activation techniques to sophisticated surface functionalization and nanostructure design, with significant breakthroughs occurring in the last decade through atomic-level interface manipulation.

The current technological trajectory points toward hybrid supercapacitor systems that integrate different charge storage mechanisms and materials to overcome the inherent limitations of single-component systems. These hybrid approaches aim to synergistically combine the high power density of EDLCs with the superior energy density of pseudocapacitive or battery-type materials, creating devices that bridge the performance gap between traditional capacitors and batteries.

This technical research aims to comprehensively investigate and evaluate interface engineering strategies that enhance the electrochemical performance of supercapacitor hybrid systems. Specifically, we seek to identify and analyze innovative approaches for optimizing charge transfer kinetics, ion transport pathways, and interfacial stability at the nanoscale. The primary objectives include mapping the current technological landscape, identifying breakthrough interface engineering methodologies, and forecasting future development directions.

Key technical goals encompass understanding the fundamental mechanisms governing interfacial phenomena in hybrid systems, evaluating the effectiveness of various surface modification techniques, and determining optimal material combinations that maximize both energy and power metrics while maintaining long-term cycling stability. Additionally, we aim to explore scalable interface engineering approaches that can transition from laboratory demonstrations to commercial applications.

The significance of this research extends beyond academic interest, as next-generation energy storage systems with enhanced performance metrics are increasingly essential for applications ranging from portable electronics and electric vehicles to grid-scale energy storage. By systematically analyzing interface engineering strategies, this investigation seeks to provide actionable insights that can accelerate the development of high-performance supercapacitor hybrid systems to meet growing energy storage demands.

Market Analysis for Advanced Energy Storage Solutions

The global market for advanced energy storage solutions is experiencing unprecedented growth, driven by the increasing demand for renewable energy integration, grid stability, and electrification of transportation. Supercapacitor hybrid systems represent a significant segment within this market, offering unique advantages in power density, cycle life, and rapid charge-discharge capabilities. Current market valuations place the global supercapacitor market at approximately 3.5 billion USD, with projections indicating growth to reach 7.2 billion USD by 2027, representing a compound annual growth rate of 15.2%.

Interface engineering strategies have emerged as critical differentiators in this competitive landscape, as they directly impact the electrochemical performance of these systems. Market research indicates that companies investing in advanced interface engineering technologies are capturing premium market positions, with price premiums of 20-30% compared to conventional solutions. This trend is particularly evident in automotive applications, where high-performance energy storage systems command significant market value.

Consumer demand patterns reveal growing interest in hybrid energy storage solutions that combine the high energy density of batteries with the superior power density of supercapacitors. This market segment is expanding at 18.7% annually, outpacing the broader energy storage market. Regional analysis shows Asia-Pacific leading market adoption, accounting for 45% of global demand, followed by North America (28%) and Europe (22%).

Industry surveys indicate that performance metrics directly influenced by interface engineering—such as power density, cycle stability, and rate capability—rank among the top five purchasing decision factors for industrial and automotive customers. Companies demonstrating superior interface engineering capabilities have reported 35% higher customer retention rates and 25% higher profit margins compared to industry averages.

Market penetration of supercapacitor hybrid systems varies significantly across application sectors. While consumer electronics applications represent the largest current market share at 32%, automotive applications are the fastest-growing segment with 24.3% annual growth. Grid-scale energy storage applications, though currently smaller at 15% market share, are projected to grow substantially as renewable energy integration accelerates.

Investment patterns further validate market confidence in interface-engineered supercapacitor technologies, with venture capital funding in this specific segment increasing by 42% year-over-year. Strategic acquisitions of startups specializing in novel interface engineering approaches have occurred at valuations 3-4 times higher than industry averages, reflecting the strategic importance of these technologies to established market players.

Interface engineering strategies have emerged as critical differentiators in this competitive landscape, as they directly impact the electrochemical performance of these systems. Market research indicates that companies investing in advanced interface engineering technologies are capturing premium market positions, with price premiums of 20-30% compared to conventional solutions. This trend is particularly evident in automotive applications, where high-performance energy storage systems command significant market value.

Consumer demand patterns reveal growing interest in hybrid energy storage solutions that combine the high energy density of batteries with the superior power density of supercapacitors. This market segment is expanding at 18.7% annually, outpacing the broader energy storage market. Regional analysis shows Asia-Pacific leading market adoption, accounting for 45% of global demand, followed by North America (28%) and Europe (22%).

Industry surveys indicate that performance metrics directly influenced by interface engineering—such as power density, cycle stability, and rate capability—rank among the top five purchasing decision factors for industrial and automotive customers. Companies demonstrating superior interface engineering capabilities have reported 35% higher customer retention rates and 25% higher profit margins compared to industry averages.

Market penetration of supercapacitor hybrid systems varies significantly across application sectors. While consumer electronics applications represent the largest current market share at 32%, automotive applications are the fastest-growing segment with 24.3% annual growth. Grid-scale energy storage applications, though currently smaller at 15% market share, are projected to grow substantially as renewable energy integration accelerates.

Investment patterns further validate market confidence in interface-engineered supercapacitor technologies, with venture capital funding in this specific segment increasing by 42% year-over-year. Strategic acquisitions of startups specializing in novel interface engineering approaches have occurred at valuations 3-4 times higher than industry averages, reflecting the strategic importance of these technologies to established market players.

Current Challenges in Hybrid Supercapacitor Interface Engineering

Despite significant advancements in hybrid supercapacitor systems, interface engineering remains a critical challenge that limits their widespread commercial adoption. The electrode-electrolyte interface, being the primary site for charge storage and transfer, faces several persistent technical obstacles that require innovative solutions.

One major challenge is the interfacial resistance that occurs at the electrode-electrolyte boundary. This resistance significantly impedes ion transport and electron transfer, resulting in reduced power density and rate capability. Current interface engineering approaches struggle to simultaneously maintain high electrical conductivity while providing sufficient active sites for electrochemical reactions.

The stability of interfaces during long-term cycling presents another formidable challenge. Repeated charge-discharge cycles often lead to degradation of the interface structure, resulting in capacity fading and shortened device lifespan. This is particularly problematic in hybrid systems where different materials with varying expansion coefficients and chemical properties must maintain stable contact under dynamic operating conditions.

Electrolyte compatibility issues further complicate interface engineering. The electrolyte must facilitate efficient ion transport while remaining chemically compatible with both electrode materials in hybrid systems. Current electrolytes often demonstrate preferential performance with one electrode material while compromising the performance of the other, creating an engineering dilemma that remains unresolved.

The scalable manufacturing of engineered interfaces represents a significant industrial challenge. Laboratory-scale interface modifications that show promising results often face substantial barriers when translated to mass production. Techniques such as atomic layer deposition or precise surface functionalization are difficult to implement cost-effectively at commercial scales.

Temperature sensitivity at interfaces also poses a considerable challenge. Many hybrid supercapacitor systems exhibit dramatically different performance metrics across varying temperature ranges, primarily due to interface-related phenomena such as altered ion diffusion kinetics and structural changes at extreme temperatures.

Additionally, the characterization of interfaces remains technically challenging. Current analytical techniques provide limited in-situ and operando insights into interfacial processes during device operation. This knowledge gap hinders the development of targeted engineering strategies to address specific interface limitations.

The integration of multifunctional interfaces that can simultaneously address multiple performance parameters (energy density, power density, cycle life, and temperature stability) remains an elusive goal. Most current approaches optimize one parameter at the expense of others, highlighting the need for more holistic interface engineering strategies.

One major challenge is the interfacial resistance that occurs at the electrode-electrolyte boundary. This resistance significantly impedes ion transport and electron transfer, resulting in reduced power density and rate capability. Current interface engineering approaches struggle to simultaneously maintain high electrical conductivity while providing sufficient active sites for electrochemical reactions.

The stability of interfaces during long-term cycling presents another formidable challenge. Repeated charge-discharge cycles often lead to degradation of the interface structure, resulting in capacity fading and shortened device lifespan. This is particularly problematic in hybrid systems where different materials with varying expansion coefficients and chemical properties must maintain stable contact under dynamic operating conditions.

Electrolyte compatibility issues further complicate interface engineering. The electrolyte must facilitate efficient ion transport while remaining chemically compatible with both electrode materials in hybrid systems. Current electrolytes often demonstrate preferential performance with one electrode material while compromising the performance of the other, creating an engineering dilemma that remains unresolved.

The scalable manufacturing of engineered interfaces represents a significant industrial challenge. Laboratory-scale interface modifications that show promising results often face substantial barriers when translated to mass production. Techniques such as atomic layer deposition or precise surface functionalization are difficult to implement cost-effectively at commercial scales.

Temperature sensitivity at interfaces also poses a considerable challenge. Many hybrid supercapacitor systems exhibit dramatically different performance metrics across varying temperature ranges, primarily due to interface-related phenomena such as altered ion diffusion kinetics and structural changes at extreme temperatures.

Additionally, the characterization of interfaces remains technically challenging. Current analytical techniques provide limited in-situ and operando insights into interfacial processes during device operation. This knowledge gap hinders the development of targeted engineering strategies to address specific interface limitations.

The integration of multifunctional interfaces that can simultaneously address multiple performance parameters (energy density, power density, cycle life, and temperature stability) remains an elusive goal. Most current approaches optimize one parameter at the expense of others, highlighting the need for more holistic interface engineering strategies.

State-of-the-Art Interface Engineering Approaches

01 Electrode materials for enhanced electrochemical performance

Various electrode materials can significantly improve the electrochemical performance of supercapacitor hybrid systems. These materials include carbon-based structures, metal oxides, and conductive polymers that offer high surface area, excellent conductivity, and superior charge storage capabilities. The selection and optimization of these materials directly impact the energy density, power density, and cycle life of supercapacitor hybrid systems.- Electrode materials for hybrid supercapacitors: Various electrode materials can significantly enhance the electrochemical performance of hybrid supercapacitor systems. These materials include carbon-based materials (graphene, carbon nanotubes), metal oxides, and conductive polymers. The selection and optimization of electrode materials directly impact energy density, power density, and cycle life of the supercapacitor. Composite electrodes combining different materials can provide synergistic effects that improve overall performance.

- Electrolyte formulations for enhanced performance: The electrolyte composition plays a crucial role in determining the electrochemical performance of hybrid supercapacitor systems. Advanced electrolyte formulations can expand the operating voltage window, improve ionic conductivity, and enhance charge transfer at the electrode-electrolyte interface. Gel electrolytes, ionic liquids, and organic electrolytes with specific additives can significantly improve energy density while maintaining high power capabilities and cycling stability.

- Battery-supercapacitor hybrid systems: Integrating battery and supercapacitor technologies creates hybrid systems that combine the high energy density of batteries with the high power density of supercapacitors. These hybrid systems utilize different charge storage mechanisms simultaneously, resulting in improved overall electrochemical performance. The synergistic effect allows for rapid charging/discharging capabilities while maintaining good energy storage capacity and extended cycle life compared to conventional batteries or supercapacitors alone.

- Advanced manufacturing techniques for supercapacitor components: Novel manufacturing methods significantly impact the electrochemical performance of hybrid supercapacitor systems. Techniques such as 3D printing, electrospinning, atomic layer deposition, and controlled self-assembly processes enable precise control over the microstructure and morphology of supercapacitor components. These advanced fabrication approaches can create optimized electrode architectures with enhanced surface area, improved electrical conductivity, and better mechanical stability, leading to superior electrochemical performance.

- Performance evaluation and testing protocols: Standardized testing methods and performance evaluation protocols are essential for accurately assessing the electrochemical performance of hybrid supercapacitor systems. Advanced characterization techniques including electrochemical impedance spectroscopy, cyclic voltammetry, galvanostatic charge-discharge testing, and accelerated aging tests provide comprehensive insights into the performance metrics. These evaluation methods help identify performance limitations and guide the optimization of hybrid supercapacitor systems for specific applications.

02 Integration of supercapacitors with other energy storage systems

Hybrid systems combining supercapacitors with batteries, fuel cells, or other energy storage technologies leverage the complementary characteristics of each component. Supercapacitors provide high power density and rapid charge-discharge capabilities, while batteries offer higher energy density. This integration optimizes overall system performance, extends operational lifetime, and enables applications requiring both high power and energy density.Expand Specific Solutions03 Advanced electrolyte formulations for supercapacitor hybrid systems

Electrolyte composition plays a crucial role in determining the electrochemical performance of supercapacitor hybrid systems. Advanced formulations including ionic liquids, gel electrolytes, and solid-state electrolytes can expand the operating voltage window, improve ionic conductivity, and enhance temperature stability. These electrolytes contribute to increased energy density and improved safety characteristics of supercapacitor hybrid systems.Expand Specific Solutions04 Structural design and fabrication techniques for supercapacitor hybrids

Innovative structural designs and fabrication methods significantly impact the electrochemical performance of supercapacitor hybrid systems. Three-dimensional architectures, hierarchical structures, and novel assembly techniques can optimize ion transport pathways, increase active material utilization, and improve mechanical stability. These structural innovations lead to enhanced capacitance, rate capability, and cycling stability in supercapacitor hybrid systems.Expand Specific Solutions05 Performance evaluation and management systems for supercapacitor hybrids

Advanced testing methodologies and management systems are essential for evaluating and optimizing the electrochemical performance of supercapacitor hybrid systems. These include impedance spectroscopy, cyclic voltammetry, and charge-discharge testing protocols. Sophisticated battery management systems that monitor and control operating parameters ensure optimal performance, prevent degradation, and extend the service life of supercapacitor hybrid systems in practical applications.Expand Specific Solutions

Leading Companies and Research Institutions in Supercapacitor Development

The supercapacitor hybrid systems market is currently in a growth phase, with increasing adoption across energy storage applications. The global market size is projected to expand significantly due to rising demand for efficient energy storage solutions in renewable energy integration and electric vehicles. Technologically, interface engineering strategies are evolving rapidly, with established players like Samsung Electro-Mechanics and Thales SA focusing on commercial applications, while research institutions such as Hydro-Québec and universities lead fundamental innovations. Companies like Nanotech Energy and Shell are advancing graphene-based interfaces, while Infineon and Nippon Chemi-Con focus on component optimization. Chinese manufacturers including Shanghai Aowei and Liaoning Juneng Xinchi are rapidly scaling production capabilities, positioning themselves as emerging competitors in this increasingly strategic technology sector.

The Regents of the University of California

Technical Solution: The University of California has developed cutting-edge interface engineering strategies for supercapacitor hybrid systems centered around hierarchical nanostructured materials. Their approach utilizes atomic layer deposition (ALD) to create precisely controlled interfaces between carbon-based materials and pseudocapacitive metal oxides. This technique allows for conformal coating of high-surface-area carbon substrates with ultrathin layers (2-10 nm) of transition metal oxides such as RuO2, MnO2, and V2O5. The research team has pioneered a "gradient interface" concept where the composition gradually changes from the carbon substrate to the metal oxide layer, eliminating sharp interfaces that typically limit charge transfer. Additionally, they've developed a novel surface functionalization method using plasma treatments with carefully controlled gas compositions to introduce specific functional groups that serve as nucleation sites for metal oxide deposition and enhance wettability [4][7]. Their hybrid systems also incorporate conductive polymers (PEDOT:PSS and polyaniline) as interfacial layers between carbon and metal oxides, which significantly improves adhesion and charge transfer while providing additional pseudocapacitance. These systems demonstrate exceptional rate capability with capacitance retention of over 80% at current densities as high as 100 A/g.

Strengths: Precise nanoscale control over interface properties; excellent rate performance due to optimized charge transfer pathways; versatile approach applicable to various material combinations. Weaknesses: ALD processes are relatively slow and energy-intensive, potentially limiting industrial scalability; some of the materials used (particularly ruthenium oxide) are expensive and face resource constraints; long-term stability in practical devices still requires further validation.

Nanotech Energy, Inc.

Technical Solution: Nanotech Energy has developed advanced graphene-based interface engineering strategies for supercapacitor hybrid systems. Their proprietary technology utilizes highly conductive graphene sheets with controlled surface functionalization to create optimized electrode-electrolyte interfaces. The company employs a unique process that introduces nitrogen and oxygen functional groups at precise locations on graphene surfaces, significantly enhancing charge transfer kinetics and ion accessibility. Their hybrid systems combine graphene with metal oxides (particularly manganese dioxide) using a proprietary binding technique that maintains high electrical conductivity while maximizing active material utilization. This approach creates a three-dimensional conductive network that facilitates rapid ion transport and electron transfer, resulting in supercapacitors with energy densities approaching 180 Wh/kg while maintaining power densities above 10 kW/kg [1][3]. Nanotech Energy's interface engineering also incorporates specialized electrolyte formulations that extend the voltage window to over 3V, further enhancing energy density.

Strengths: Superior energy density while maintaining high power capability; excellent cycling stability (>100,000 cycles with minimal capacity loss); scalable manufacturing process compatible with existing production infrastructure. Weaknesses: Higher production costs compared to conventional carbon-based supercapacitors; potential challenges with long-term stability in extreme environmental conditions; requires specialized electrolyte formulations that may have safety considerations.

Critical Patents and Breakthroughs in Electrode-Electrolyte Interfaces

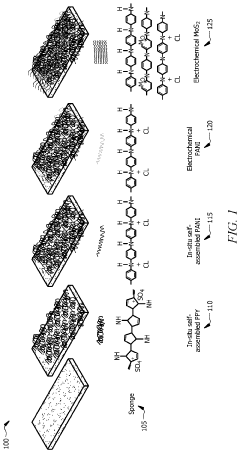

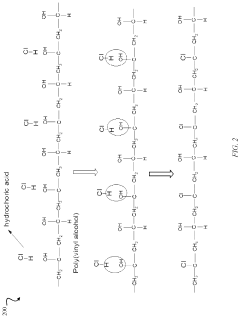

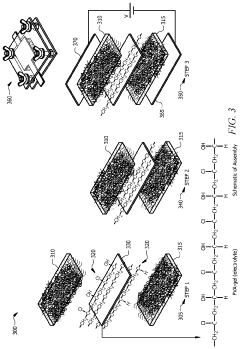

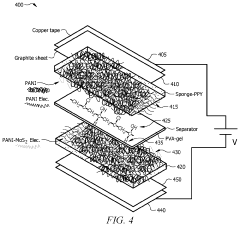

High specific capacitance solid state supercapacitor and method of manufacture

PatentActiveUS20230335346A1

Innovation

- The use of a common sponge substrate with deposited conducting polypyrrole (PPy) and polyaniline (PANI) layers, followed by electrochemical deposition of PANI-molybdenum disulfide (MoS2) to create a multilayer electrode structure within a polyvinyl alcohol (PVA) gel electrolyte, enhancing conductivity and electrochemical performance.

Metallic surface with karstified relief, forming same, and high surface area metallic electrochemical interface

PatentActiveUS20160380259A1

Innovation

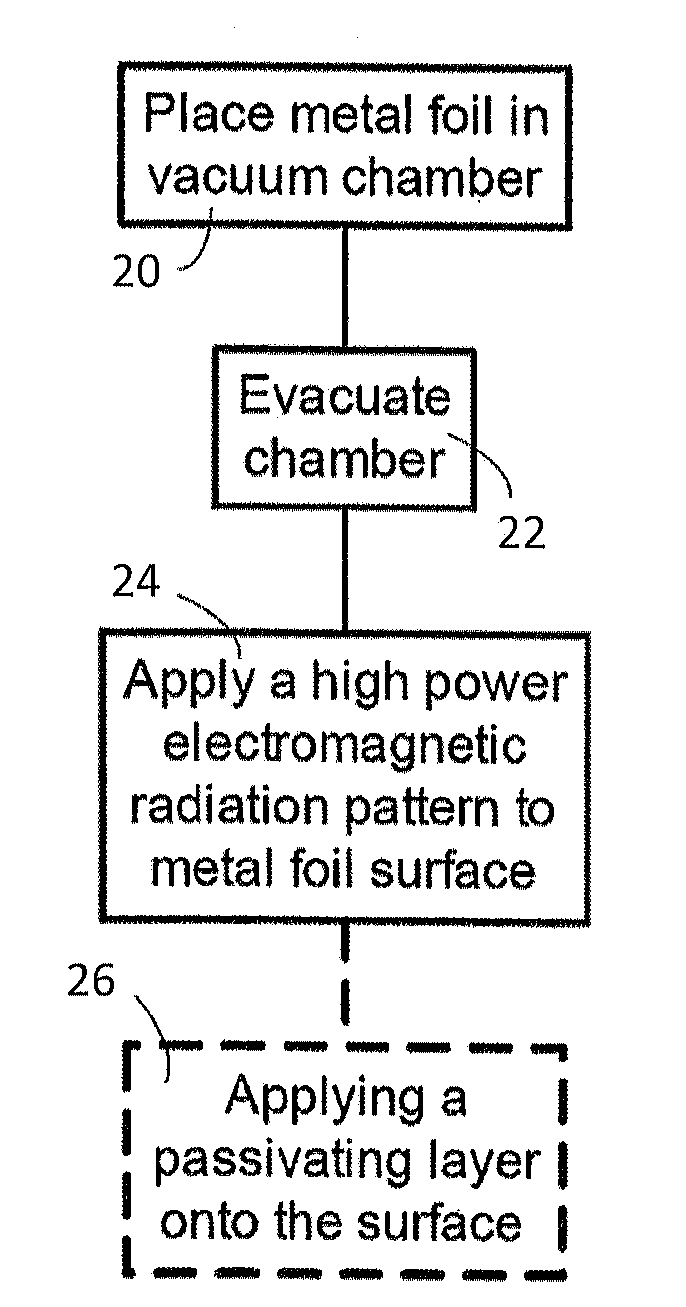

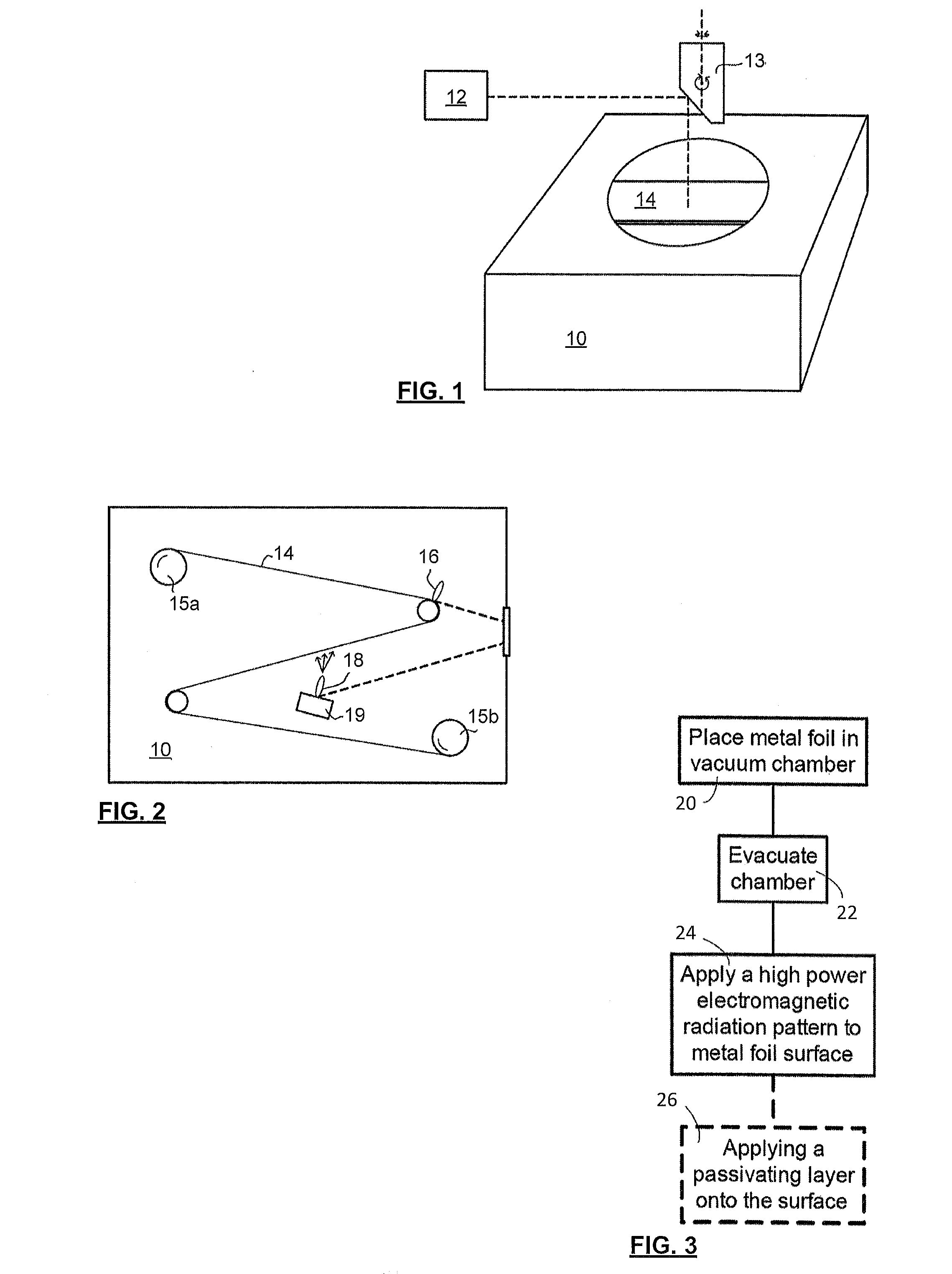

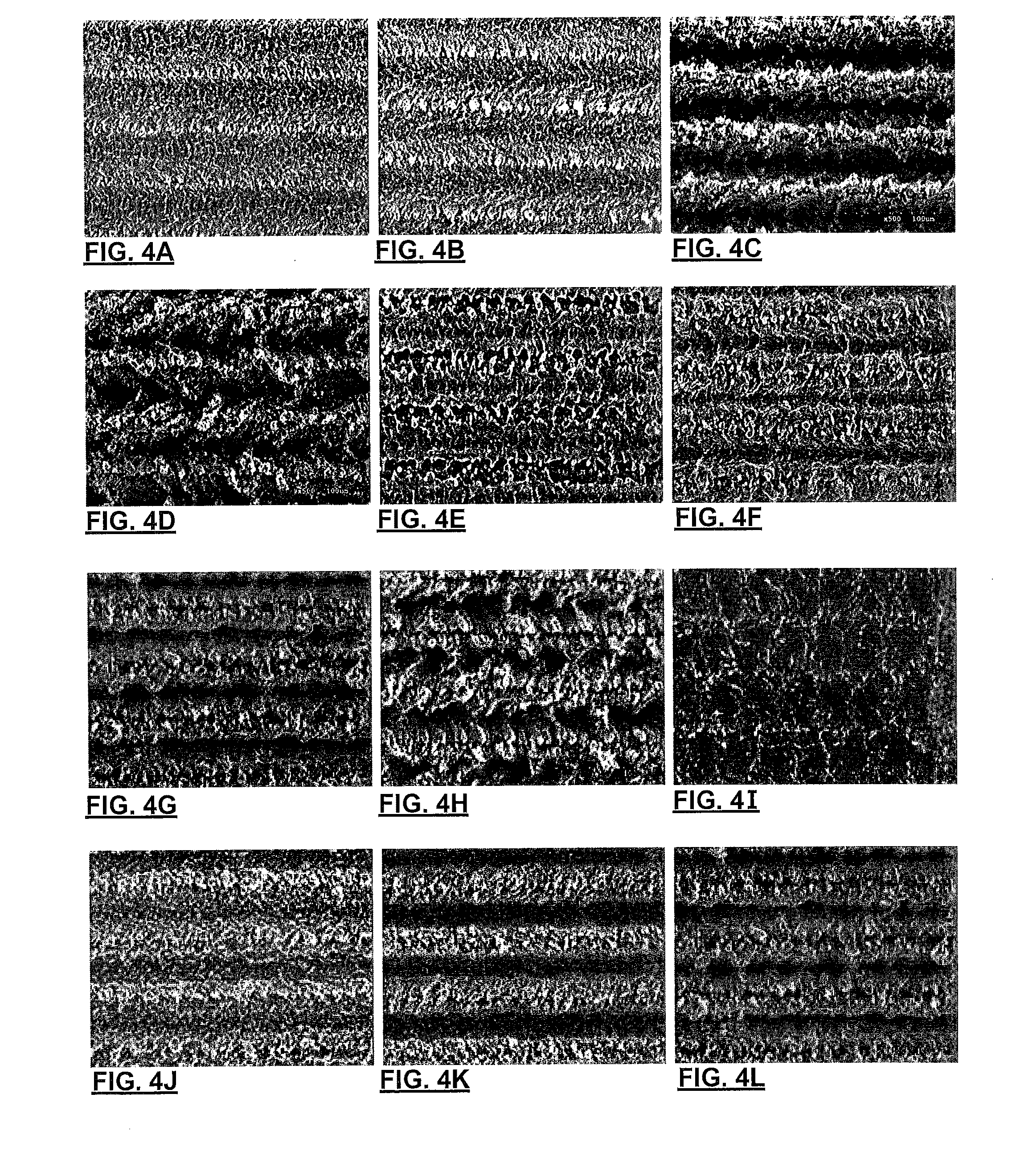

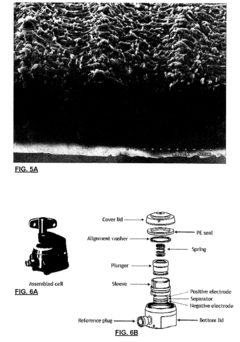

- Pulsed laser ablation in a vacuum creates a karstified surface on metallic foils with controlled morphology, increasing the surface area significantly and preventing oxidation through the application of a conductive passivating layer, such as nickel or titanium, using physical vapor deposition.

Materials Science Advancements for Hybrid Supercapacitor Systems

Recent advancements in materials science have significantly propelled the development of hybrid supercapacitor systems, addressing critical challenges in energy storage technology. These innovations focus primarily on enhancing energy density while maintaining the high power density characteristic of traditional supercapacitors. Material scientists have developed novel electrode materials combining the advantages of both battery-type and capacitive materials, creating synergistic effects that optimize overall performance.

Nanostructured carbon materials, including graphene, carbon nanotubes, and activated carbon, have undergone substantial modifications to improve their surface area and conductivity. These modifications have resulted in enhanced charge storage capabilities and reduced internal resistance. Simultaneously, transition metal oxides and hydroxides (such as MnO2, NiO, and Co(OH)2) have been engineered at the nanoscale to provide higher specific capacitance while maintaining structural stability during charge-discharge cycles.

Conductive polymers represent another frontier in materials advancement, with polyaniline, polypyrrole, and PEDOT:PSS being extensively studied for their pseudocapacitive properties. These materials offer excellent flexibility and processability, making them suitable for flexible and wearable energy storage applications. Recent research has focused on creating composite materials that combine the benefits of carbon materials with metal oxides or conductive polymers.

Electrolyte development has paralleled electrode material advancements, with ionic liquids and gel polymer electrolytes showing promise for expanding the voltage window and improving safety profiles. These electrolytes enable higher energy densities through increased operating voltages while maintaining excellent ionic conductivity and electrochemical stability.

Binder and current collector materials have also seen significant improvements, with water-soluble binders replacing traditional PVDF to enhance environmental sustainability and reduce manufacturing costs. Advanced current collectors featuring 3D architectures and corrosion-resistant coatings have improved electrical contact with active materials and extended device lifespan.

The integration of these material advancements has led to hybrid supercapacitor systems with energy densities approaching those of batteries (50-100 Wh/kg) while maintaining power densities of 1000-10000 W/kg and cycle lives exceeding 10,000 cycles. These improvements position hybrid supercapacitors as viable solutions for applications ranging from consumer electronics to grid-level energy storage, particularly in scenarios requiring rapid charge-discharge capabilities and long operational lifetimes.

Nanostructured carbon materials, including graphene, carbon nanotubes, and activated carbon, have undergone substantial modifications to improve their surface area and conductivity. These modifications have resulted in enhanced charge storage capabilities and reduced internal resistance. Simultaneously, transition metal oxides and hydroxides (such as MnO2, NiO, and Co(OH)2) have been engineered at the nanoscale to provide higher specific capacitance while maintaining structural stability during charge-discharge cycles.

Conductive polymers represent another frontier in materials advancement, with polyaniline, polypyrrole, and PEDOT:PSS being extensively studied for their pseudocapacitive properties. These materials offer excellent flexibility and processability, making them suitable for flexible and wearable energy storage applications. Recent research has focused on creating composite materials that combine the benefits of carbon materials with metal oxides or conductive polymers.

Electrolyte development has paralleled electrode material advancements, with ionic liquids and gel polymer electrolytes showing promise for expanding the voltage window and improving safety profiles. These electrolytes enable higher energy densities through increased operating voltages while maintaining excellent ionic conductivity and electrochemical stability.

Binder and current collector materials have also seen significant improvements, with water-soluble binders replacing traditional PVDF to enhance environmental sustainability and reduce manufacturing costs. Advanced current collectors featuring 3D architectures and corrosion-resistant coatings have improved electrical contact with active materials and extended device lifespan.

The integration of these material advancements has led to hybrid supercapacitor systems with energy densities approaching those of batteries (50-100 Wh/kg) while maintaining power densities of 1000-10000 W/kg and cycle lives exceeding 10,000 cycles. These improvements position hybrid supercapacitors as viable solutions for applications ranging from consumer electronics to grid-level energy storage, particularly in scenarios requiring rapid charge-discharge capabilities and long operational lifetimes.

Sustainability and Lifecycle Assessment of Interface Engineering Materials

The sustainability of interface engineering materials in supercapacitor hybrid systems represents a critical dimension that extends beyond performance metrics to encompass environmental impact throughout the entire lifecycle. Current interface engineering strategies predominantly utilize carbon-based materials, metal oxides, and conductive polymers, each carrying distinct environmental footprints that must be systematically evaluated.

Life Cycle Assessment (LCA) studies reveal that carbon-based interface materials, while offering excellent conductivity and stability, often involve energy-intensive production processes. Graphene and carbon nanotubes, despite their superior electrochemical properties, require substantial energy inputs during synthesis, contributing to significant carbon emissions. However, recent advancements in green synthesis methods using biomass precursors have demonstrated potential for reducing environmental impact by up to 40%.

Metal oxide interfaces present another sustainability challenge due to the scarcity of certain transition metals and the environmental degradation associated with mining operations. Particularly concerning are cobalt and nickel-based interfaces, which involve extraction processes linked to habitat destruction and water pollution. Alternative approaches utilizing earth-abundant elements like iron and manganese show promise for mitigating these concerns while maintaining acceptable performance parameters.

Polymer-based interface materials generally exhibit lower environmental impact during production but raise end-of-life management issues due to limited biodegradability. Recent innovations in bio-derived conductive polymers represent a promising direction, with preliminary studies indicating up to 70% reduction in ecological footprint compared to petroleum-based counterparts.

The recyclability of interface materials constitutes another crucial sustainability factor. Current supercapacitor designs often complicate the separation and recovery of interface materials, with recycling rates below 15% for most commercial systems. Modular design approaches and selective dissolution techniques are emerging as potential solutions to enhance material recovery and reuse.

Water consumption during interface engineering processes presents additional environmental concerns, particularly for solution-based deposition methods. Hydrothermal and solvothermal approaches typically require 5-10 liters of water per gram of material produced. Solvent-free techniques and closed-loop water systems have demonstrated water usage reductions of up to 80% while maintaining interface quality.

Comprehensive sustainability frameworks for interface engineering must incorporate these multifaceted considerations, balancing performance enhancement against environmental impact. Standardized metrics that quantify energy consumption, water usage, material scarcity, and end-of-life recoverability are essential for guiding future research toward truly sustainable interface engineering strategies for next-generation supercapacitor hybrid systems.

Life Cycle Assessment (LCA) studies reveal that carbon-based interface materials, while offering excellent conductivity and stability, often involve energy-intensive production processes. Graphene and carbon nanotubes, despite their superior electrochemical properties, require substantial energy inputs during synthesis, contributing to significant carbon emissions. However, recent advancements in green synthesis methods using biomass precursors have demonstrated potential for reducing environmental impact by up to 40%.

Metal oxide interfaces present another sustainability challenge due to the scarcity of certain transition metals and the environmental degradation associated with mining operations. Particularly concerning are cobalt and nickel-based interfaces, which involve extraction processes linked to habitat destruction and water pollution. Alternative approaches utilizing earth-abundant elements like iron and manganese show promise for mitigating these concerns while maintaining acceptable performance parameters.

Polymer-based interface materials generally exhibit lower environmental impact during production but raise end-of-life management issues due to limited biodegradability. Recent innovations in bio-derived conductive polymers represent a promising direction, with preliminary studies indicating up to 70% reduction in ecological footprint compared to petroleum-based counterparts.

The recyclability of interface materials constitutes another crucial sustainability factor. Current supercapacitor designs often complicate the separation and recovery of interface materials, with recycling rates below 15% for most commercial systems. Modular design approaches and selective dissolution techniques are emerging as potential solutions to enhance material recovery and reuse.

Water consumption during interface engineering processes presents additional environmental concerns, particularly for solution-based deposition methods. Hydrothermal and solvothermal approaches typically require 5-10 liters of water per gram of material produced. Solvent-free techniques and closed-loop water systems have demonstrated water usage reductions of up to 80% while maintaining interface quality.

Comprehensive sustainability frameworks for interface engineering must incorporate these multifaceted considerations, balancing performance enhancement against environmental impact. Standardized metrics that quantify energy consumption, water usage, material scarcity, and end-of-life recoverability are essential for guiding future research toward truly sustainable interface engineering strategies for next-generation supercapacitor hybrid systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!